2 Intended use

2.1 Safeguard

– When working on the device voltage circuit elements are life-threatening. It is strictly

forbidden to break the sealing device and make measurements of the electrical parameters within the

device.

– Disconnect the power cord from the unit carried out only after disconnecting the power cord

from the mains.

– Check and replace the fuse only after disconnect the device from the network.

– To prevent the exploitation of persons having a third and higher group on electrical safety.

2.2 Operational pro edure

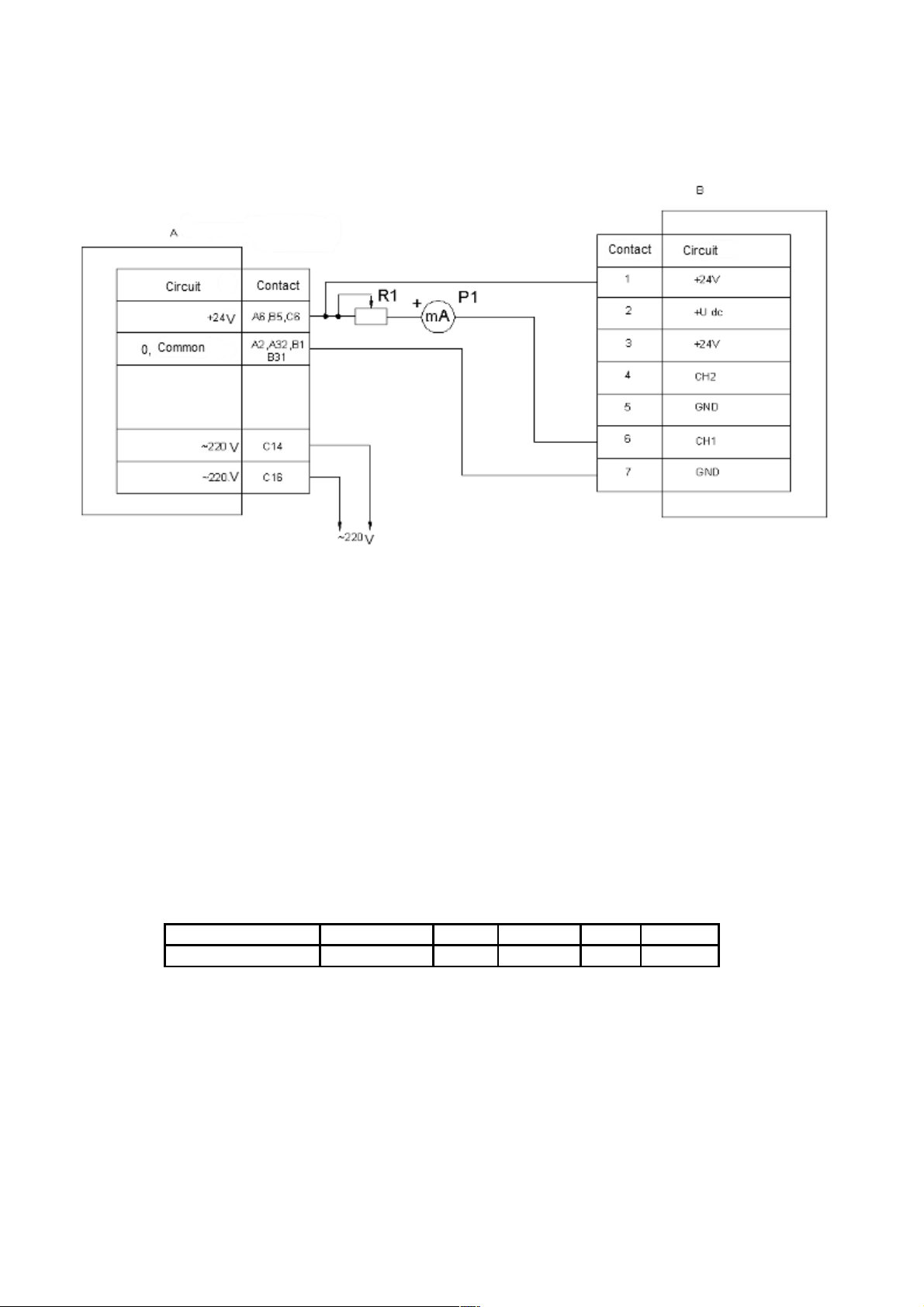

Connect the cable signal to block the fork «CURCUIT».

Attention! It is stri tly prohibited to short- ir uit onne tor "+ 24 V» on the plug «CH1» and

«CH2». This an lead to overload and failure of the urrent sensor.

Connect the unit under test, observing the name chains (shown on cable plug). When running on the

network to connect the power cord to the device itself shnur- to AC power. This indicator light "220 VAC

ON», LED «POWER ON», the decimal point in the third discharge, the indicator and the indicator light

«BATTAREY CHARGE», if the battery level is below normal. Intermittent flashing indicator light

«BATTAREY CHARGE» indicates the absence of batteries in the battery compartment or poor contact

with the slip slats.

When running on batteries the device is activated by pressing and holding the button «POWER ON»

before the decimal point in the third discharge indicator. If the battery discharges below normal on the

display appears: "-.-" after which the device automatically turns off.

Select with the keys select the measurement range and the desired channel number Mode. When

the output value of the measured value of range, the indicator displays the message: "--.--". After

measurement switch the appliance off by pressing and holding until the display message «OFF» button

«POWER OFF". After that, when running on batteries the device will turn off, while running on AC power

unit switches to low power consumption and will continue to charge the battery to the level of the nominal

charge, after which the charge will stop, the indicator light «BATTAREY CHARGE» goes off. After the

charge disconnect the power cord from the AC.