M&R Cayenne Series User manual

V.121806 Part # MAN-CAYENNESERIES Cayenne Series Av1

$45.00 USD

Cayenne

™

Series

WWW.MRPRINT.COM

Toll-Free: 800-736-6431

USA Direct: 630-858-6101

USA Fax: 630-858-6134

Outside USA: +847-967-4461

Outside USA Fax: +847-967-0417

1N 372 Main St. Glen Ellyn, IL 60137 USA

Cayenne

™

Series V.121806

2M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

V. 121806 Cayenne

™

Series

Table of Contents

1. Safety and Operational Guidelines...........................................................................................................................5

1.1 Management Responsibilities...................................................................................................................................6

1.2 Operator Responsibilities..........................................................................................................................................7

2. General Information....................................................................................................................................................8

2.1 Service and Parts......................................................................................................................................................9

2.2 Defined Purpose .....................................................................................................................................................10

2.3 Warranty..................................................................................................................................................................10

3. Product Specifications.............................................................................................................................................11

4. Installation.................................................................................................................................................................12

4.1 Installation Instructions............................................................................................................................................12

4.2 Level Flash Cure.....................................................................................................................................................13

4.3 Install Quartz Heating Elements .............................................................................................................................14

4.4 Install Signal Cable .................................................................................................................................................15

4.4.1 Standard Series Press.....................................................................................................................................15

4.4.2 Z-Series Press.................................................................................................................................................16

4.5 Install Remote Sensor.............................................................................................................................................18

5. Operation...................................................................................................................................................................19

5.1 Control Panel ..........................................................................................................................................................19

5.2 Digital Control Unit..................................................................................................................................................20

6. Scheduled Maintenance...........................................................................................................................................24

7. Troubleshooting........................................................................................................................................................27

8. Replacement Parts ...................................................................................................................................................29

M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA 3

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

Cayenne

™

Series V.121806

This page intentionally left blank

4M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

V. 121806 Cayenne

™

Series

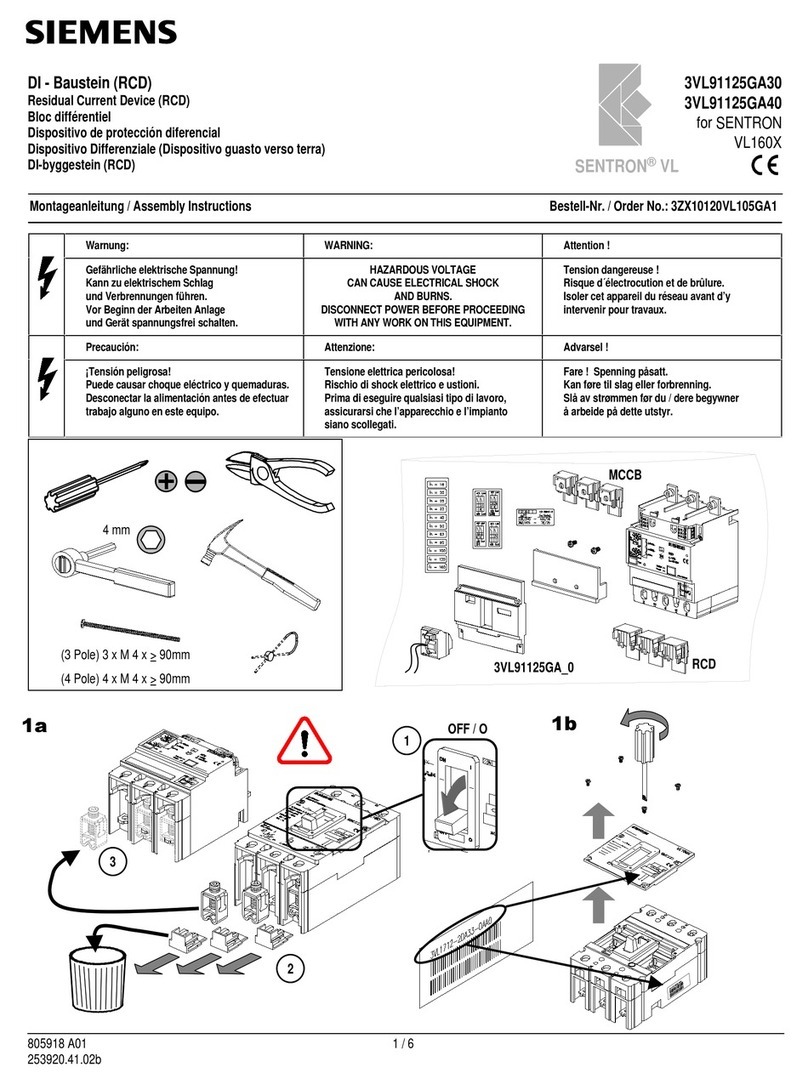

1. Safety and Operational Guidelines

DANGER

This symbol identifies situations that endanger people, property, and/or equipment. If such

conditions exist, the equipment must be shut down and all energy sources (electrical, gas, and

pneumatic) must be disconnected, purged, and locked out until the problem is resolved.

Never attempt to bypass or defeat any safety device. Do not attempt to operate the equipment if

any safety device is not functioning properly, or if any doubt exists about proper operation of safety

devices.

The product described in this publication may operate at high speed and contain numerous

moving parts. It may employ natural gas or propane, mechanical or pneumatic forces, and/or

hazardous voltages, and may create other conditions that could, through misuse, abuse,

unauthorized alteration or retrofitting, inattention, or lack of understanding, result in injury, death, or

damage to the product or to other equipment. In addition, improper operation may also depreciate

the value of the machine and other assets of the owner, and impair the working efficiency of the

machine.

Energy Sources M&R equipment may use one of more of the following energy sources:

•Compressed Air (Pneumatic Energy)

•Electricity

•Gas (Natural Gas or Propane)

Each form of energy presents its own unique hazards and requires appropriate precautions.

Danger From

Compressed Air

(Pneumatic

Energy)

Only qualified personnel should be allowed to work on pneumatic components or assemblies. Before

work is started on pneumatic components or assemblies, equipment should be disconnected from the

air supply and all pneumatic lines should be purged to prevent accidental operation of pneumatic

assemblies. All pneumatic pipes and hoses should be checked frequently for damage and wear.

Danger From

Electrical

Energy

Only qualified personnel should have access to electrical enclosures or work on electrical systems,

and enclosures should be locked when not in use. Electrical equipment should be checked regularly.

WARNING

Failure to follow safety and maintenance procedures or to take appropriate corrected action when

required can result in severe or fatal personal injuries, property damage, and/or damage to the

equipment.

M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA 5

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

Cayenne

™

Series V.121806

1.1 Management Responsibilities

Management

Responsibilities 1. Ensure that this equipment is used only for the purposes set forth in the “Defined Purpose”

section of this manual.

2. Ensure that all employees involved with the operation of this equipment or working near it read,

understand, and act in accordance with the operational and safety standards set forth in this

manual, including the Operator Responsibilities listed below.

3. Ensure that all recommended preventive maintenance is carried out according to M&R

guidelines.

4. Should any problem arise which compromises the safe operation or normal functioning of this

equipment, ensure that the equipment is immediately shut down, sources of power to the

equipment is shut off and secured, and that personnel not trained to repair – and directly involved

in repairing – the equipment are removed from the immediate area and not allowed to return until

the equipment has been returned to a safe and fully-functional condition.

5. Provide, and compel use of, any personal protection devices that may be required for the safe

operation of this equipment.

6. Make no modification to equipment or equipment software without written approval from M&R.

7. Provide – and support with written documentation – necessary employee training to ensure safe

operation, including but not limited to instruction in:

a. the operation of this machine

b. the use of personal protection devices

c. preventive maintenance procedures

6M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

V. 121806 Cayenne

™

Series

1.2 Operator Responsibilities

Operator

Responsibilities Note: ‘Operator Responsibilities’ pertain to all employees who work on or near the equipment; this includes, but

is not limited to those who clean, maintain and repair the equipment as well as those who operate it. In

general, all those who work on or near the equipment have a duty to use reasonable and ordinary care

for their own safety when in the vicinity of the machine. Failure to use reasonable and ordinary care

subjects people and property to serious personal injury and/or death and to destruction of personal

and/or company property. M&R expressly disclaims any and all liability, whether in contract, tort or by

statute, for damages, whether in the nature of personal injury/death and/or property damage, and

whether direct, indirect, consequential or incidental, as a result of a failure to use reasonable and

ordinary care.

1. Ensure that this equipment is used only for the purposes set forth in the “Defined Purpose”

section of this manual.

2. Read, understand, and act in accordance with the safety and operational standards and

guidelines set forth in this manual.

3. Install and maintain the equipment and safety devices in accordance with this manual; this

includes checking the equipment and safety devices for external or visible damage at least once

per shift, and making sure all safety and danger notices are in place and in readable condition.

4. Make no modification to equipment or equipment software without written approval from M&R.

5. Ensure that all other employees working on or near this equipment are knowledgeable in its safe

operation, and closely supervise inexperienced employees; keep bystanders away from the

equipment.

6. Make sure the area around the equipment is clear and free of obstructions, clean up spills

immediately, and remove ink and other contaminants at the end of each shift.

7. Ensure that any and all safety guards (including but not limited to safety bar, foot switch, yellow

cycle interruption cords, infrared safety beam, yellow floor mats, or hand switches) provided with

this equipment for the purpose of protecting personnel by automatically stopping the equipment

are in place – and are not removed, disabled or rendered ineffective during operation.

8. Wear any personal protection devices required for the safe operation of this equipment.

9. Avoid wearing anything that could become entangled in moving parts; for example, but not by

way of limitation, tie back, pin up, or cover long hair.

10. Do not attempt to operate this equipment if you are sick, fatigued, or under the influence of

alcohol and/or drugs including, but not limited to, prescriptions and over-the-counter medications

that warn against the operation of equipment.

11. Avoid standing on any part of the equipment not intended for that purpose.

12. Immediately shut down the equipment, disconnect and lock out all sources of power (electrical,

gas, and/or pneumatic); and purge all lines under pressure if the equipment fails to be fully

operational or if any safety device fails to operate properly, and ensure that the equipment stays

offline until the safety device is again operational.

13. Perform – and document – preventive maintenance at intervals described in the Operator’s

Manual.

14. Keep this Operator’s Manual in clean, easily readable condition near the equipment at all times

so it can be quickly accessed by operators and maintenance personnel.

M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA 7

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

Cayenne

™

Series V.121806

2. General Information

This Document This document is based on information available at the time of its publication. While every effort has

been made to be accurate, the information contained herein does not purport to cover all details or

variations in hardware, software, features, or specifications, or to provide for every possible

contingency in connection with installation, operation and maintenance. Features may be described

herein which are not present in all models of this product. M&R Printing Equipment, Inc. and its

subsidiaries reserve the right to alter specifications in the manufacture of their products, and they

assume no obligation of notice to holders of this document with respect to changes subsequently

made.

M&R Printing Equipment, Inc. and its subsidiaries make no representation or warranty, expressed or

implied, whether pursuant to statute or case law with respect thereto, and assume no responsibility

for, the accuracy, completeness, sufficiency or usefulness of the information contained herein. No

warranties of merchantability or fitness for a particular purpose shall apply.

This is a publication of M&R Printing Equipment, Inc. and its subsidiaries. All information contained

herein is derived in part from proprietary and patent data of M&R Printing Equipment, Inc., and may

not be copied, electronically reproduced, or transmitted in any form without prior written permission,

in each case made and provided.

8M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

V. 121806 Cayenne

™

Series

2.1 Service and Parts

Manufacturer’s

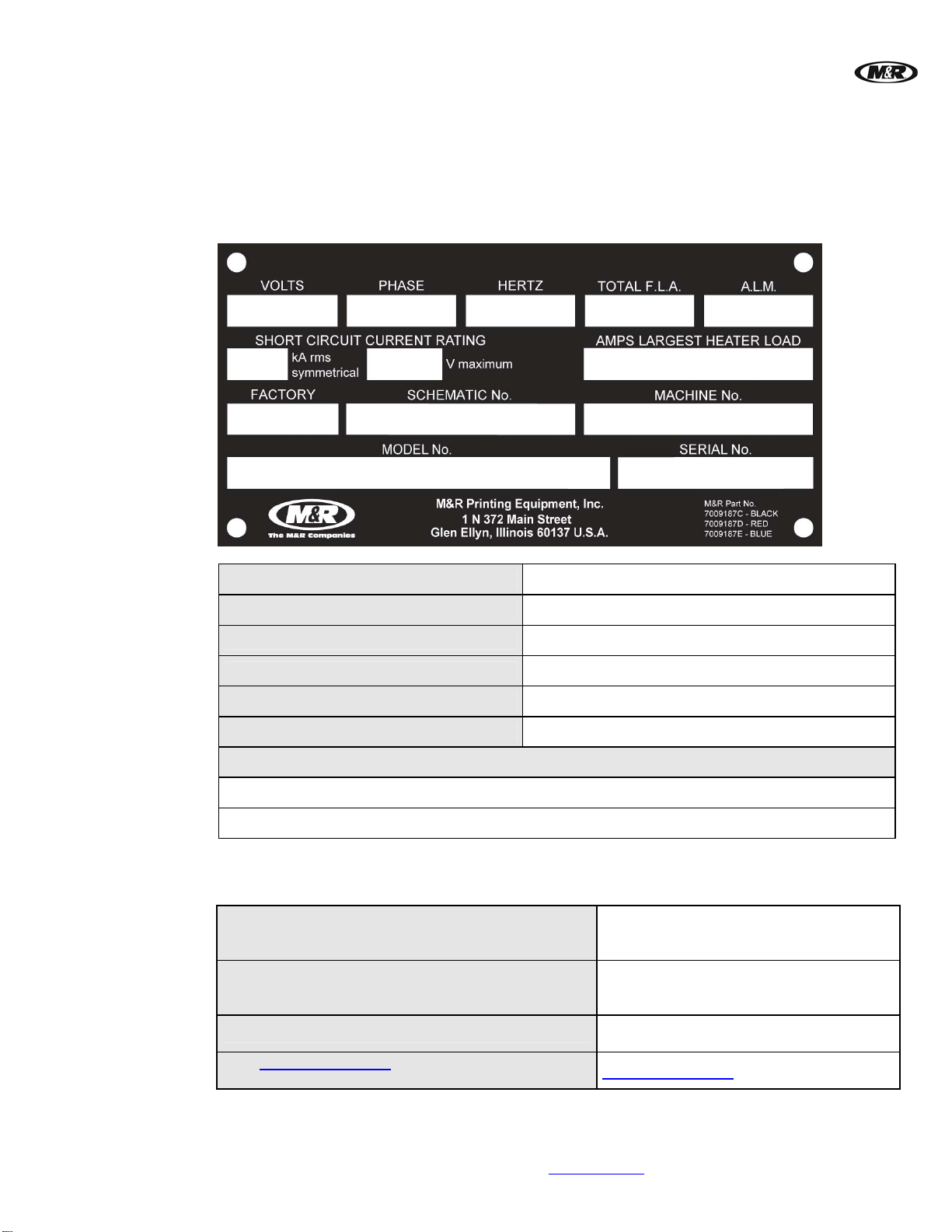

Rating Plate Most products manufactured by the M&R Companies carry a metal manufacturer’s rating plate similar

to the one shown below. Please use it to fill out the product information below, and be prepared to

provide the identification information when calling. This helps us respond to your needs more

quickly.

Model No.

Machine No.

Serial No.

Schematic No.

Date Installed

Installed by

Optional Features and Special Information

Contacting M&R If you need service or have questions about your equipment, call the appropriate number and ask for

Technical Support. If you need parts, ask for the Parts Department.

From the United States & Canada

Monday-Friday between 8:30 AM and 5:00 PM

Central Standard/Daylight Time

800-736-6431

Or

630-858-6101

From all other countries

Monday-Friday between 14:30 and 23:00 Greenwich

Mean Time (GMT) +847-967-4461

Outside Regular Hours Call our Global Hotline:

+630-462-4715

Visit www.mrprint.com for a list of global

contacts www.mrprint.com

M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA 9

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

Cayenne

™

Series V.121806

2.2 Defined Purpose

Textile Presses Textile Presses are designed to print textile inks on textile substrates, as more fully set forth in the

manual specific to that product. Any other use of this equipment is not permitted.

Textile Dryers Textile Dryers are designed to cure/dry textile inks on textile substrates, as more fully set forth in the

manual specific to that product. Any other use of this equipment is not permitted.

Graphic Presses Graphic Presses are designed to print graphic inks on rigid and semi-rigid flat substrates, as more

fully set forth in the manual specific to that product. Any other use of this equipment is not permitted.

Graphic Dryers Graphic Dryers are designed to cure/dry graphic inks on rigid and semi-rigid flat substrates, as more

fully set forth in the manual specific to that product. Any other use of this equipment is not permitted.

Exposure

Equipment Exposure Equipment is designed to produce photographic printing plates and printing screens, as

more fully set forth in the manual specific to that product. Any other use of this equipment is not

permitted.

Folding and

Packaging

Equipment

Folding and Packaging Equipment is designed to fold, transport, and package textile materials, as

more fully set forth in the manual specific to that product. Any other use of this equipment is not

permitted.

Ancillary

Equipment Ancillary Equipment is designed to perform specific operations related to processing and handling of

substrates, as more fully set forth in the manual specific to that product. Any other use of this

equipment is not permitted.

2.3 Warranty

Limited

Warranty Your Warranty does not apply to damages sustained due to equipment misuse, whether intentional or

negligent, and such misuse may void your warranty. Misuse includes – but is not limited to – the

items listed below. In addition, M&R Printing Equipment, Inc. accepts no responsibility for personal

injury or property damage caused by misuse.

1. Use of the equipment for any non-defined purpose

2. Improper installation or use of the equipment

3. Operation of the equipment with defective safety devices

4. Operation of the equipment with safety devices removed, disabled, not working in whole or in

part or in any manner rendered ineffective for the purpose for which they were designed

5. Failure to comply with instructions for transportation, storage, installation, operation,

maintenance, setup, and take-down of the equipment as described in the Operator’s Manual

6. Unauthorized modification of the equipment or equipment software

7. Failure to replace worn or defective parts

8. Failure to use M&R supplied replacement and repair parts

9. Defective repairs made to the equipment

10. Dangerous conditions which result from improper use of the equipment

10 M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

V. 121806 Cayenne

™

Series

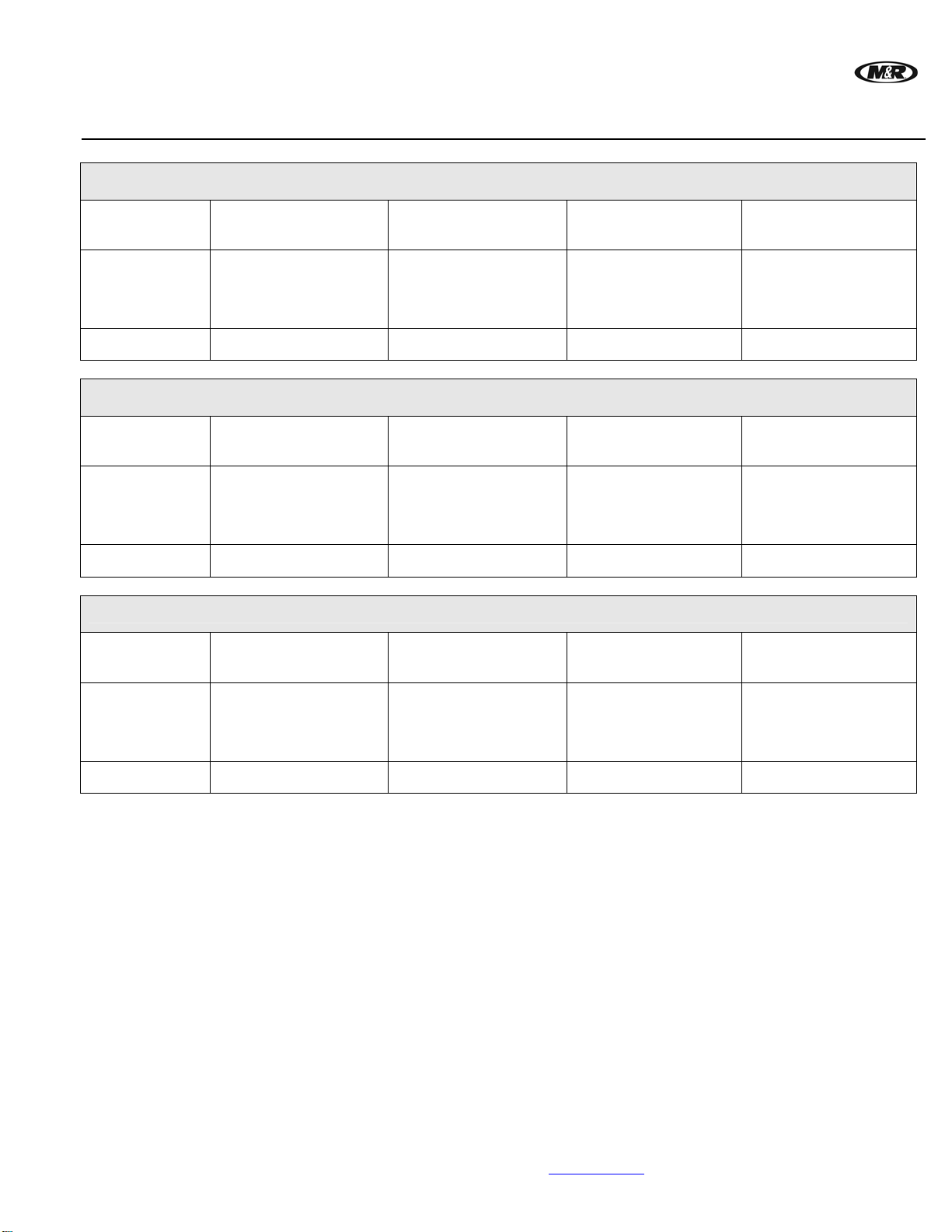

3. Product Specifications

Cayenne™Series Specifications

Cayenne D&Z

1818 Cayenne D&Z

1822 Cayenne D

2224 Cayenne D&Z

2230

Electrical

Requirements1

208/230 V, 3 ph, 31/34 A,

50/60 Hz, 12.2 kW

400 V, 3 ph, 19 A, 50/60

Hz, 12.2 kW

208/230 V, 3 ph, 31/34 A,

50/60 Hz, 13.7 kW

400 V, 3 ph, 20 A, 50/60

Hz, 13.7 kW

208/230 V, 3 ph, 34/37 A,

50/60 Hz, 15.3 kW

400 V, 3 ph, 22 A, 50/60

Hz, 15.3 kW

208/230 V, 3 ph, 39/43 A,

50/60 Hz, 18.3 kW

400 V, 3 ph, 27 A, 50/60

Hz, 18.3 kW

Size 46 x 46 cm (18 x 18”) 46 x 56 cm (18 x 22”) 56 x 61 cm (22 x 24”) 56 x 76 cm (22 x 30”)

Cayenne™Series Specifications

Cayenne D

2236 Cayenne D

2430 Cayenne D

2436 Cayenne D

3042

Electrical

Requirements1

208/230 V, 3 ph, 50/56 A,

50/60 Hz, 22.8 kW

400 V, 3 ph, 35 A, 50/60

Hz, 22.8 kW

208/230 V, 3 ph, 42/43 A,

50/60 Hz, 18.3 kW

400 V, 3 ph, 27 A, 50/60

Hz, 18.3 kW

208/230 V, 3 ph, 50/53 A,

50/60 Hz, 20.4 kW

400 V, 3 ph, 30 A, 50/60

Hz, 20.4 kW

208/230 V, 3 ph, 76/90 A,

50/60 Hz, 35.5 kW

400 V, 3 ph, 55 A, 50/60

Hz, 36.5 kW

Size 56 x 91 cm (22 x 36”) 61 x 76 cm (24 x 30”) 61 x 91 cm (24 x 36”) 76 x 107 cm (30 x 42”)

Cayenne™Series Specifications

Cayenne D

3236 Cayenne D

4032 Cayenne D

4036 Cayenne D

4838

Electrical

Requirements1

208/230 V, 3 ph, 71/79 A,

50/60 Hz, 33.5 kW

400 V, 3 ph, 48 A, 50/60

Hz, 33.5 kW

208/230 V, 3 ph, 86/94 A,

50/60 Hz, 39.9 kW

400 V, 3 ph, 58 A, 50/60

Hz, 39.9 kW

208/230 V, 3 ph, 74/82 A,

50/60 Hz, 30.8 kW

400 V, 3 ph, 32 A, 50/60

Hz, 30.8 kW

208/230 V, 3 ph, 85/94 A,

50/60 Hz, 36.5 kW

400 V, 3 ph, 60 A, 50/60

Hz, 37 kW

Size281 x 91 cm (32 x 36”) 102 x 81 cm (40 x 32”) 102 x 91 cm (40 x 36”)2122 x 96 cm (48 x 38”)2

1If incoming voltage differs from the voltage(s) listed, calculate amperage accordingly. Other

electrical configurations are available: Contact M&R for details.

2Two Cayenne models are available with quartz lamps arrayed in a T-shape: Contact M&R for

details.

M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA 11

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

Cayenne

™

Series V.121806

4. Installation

4.1 Installation Instructions

Inspection Carefully inspect for signs of damage in transit. If equipment has been damaged in transit, notify the

Freight Forwarder immediately. M&R is not responsible for damage that occurs during transportation.

Components -Flash cure

-Quartz heating elements

-Signal cable

-Assembly hardware

-Optional sensor assembly (for presses not pre-wired for PLC integration)

Step 1 Install the two rear leveling legs with adjustment handles (1)

and leveling pads (2) as shown. The threaded studs with

adjustment handle (1) are screwed into the threaded hole

on the lower leveling angle brackets on the chassis, and

then into the metal leveling pad (2) which rests on the floor.

Step 2 Unlock the front frame holder assembly on the print head

and move it into the locked upright position.

Step 3 Standard Series Press

Move the print carriage and front proximity bracket back

towards the center of the press. Position the flash cure over

the pallet as shown.

Z-Series Press

Move the print carriage back towards the center of the

press. Position the flash cure over the pallet as shown.

12 M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

V. 121806 Cayenne

™

Series

4.2 Level Flash Cure

Step 1 The flash cure must be parallel to the pallet surface.

Dimensions (1) between the surface of the heating

elements and the pallet surface should be 2-1/4” at all four

corners.

Level the flash cure using the two rear leveling legs and the

front to rear pivoting adjustment. When the flash cure is

parallel to the pallet, adjust height or distance from the

pallet using the hand wheel (2). Tighten the side handles to

lock in position.

Place a level on the unit’s surface to check for level front to

back and side to side.

Step 3 To adjust the front to rear angle of the heating element,

loosen bolts (1) located on both sides of the chassis.

Step 4 Adjust the front to rear angle by turning the bolt (1) located

at the bottom center of the chassis. Make additional leveling

adjustments using the two rear leveling pads. When leveling

adjustments are completed, re-tighten the bolts loosened in

previous step.

M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA 13

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

Cayenne

™

Series V.121806

4.3 Install Quartz Heating Elements

Avoid Heating

Element

Damage

Oily or foreign substances will damage the heating element. In case of contact, wipe the surface with

Isopropyl Alcohol. Always wear lint-free gloves when handling the heating element.

WARNING: Never operate the flash cure when placed on

its side. In this position, the quartz heating element

filaments (1) compress and arcing results in premature

failure of the element filament. Always operate the flash

cure with the quartz heating elements in the horizontal

(normal operating) position.

Step 1 The quartz heating element has a female electrical

connector (1) at both ends.

Step 2 Hold the quartz heating element near both ends and push

the female electrical connector onto the spring loaded male

contact (1).

Step 3 Place the opposite end of the quartz heating element on the

male pin contact (1) on the other side of the reflector

assembly; allow the spring loaded pressure to hold it in

position.

Step 4 Install the remaining quartz heating elements as described in the previous steps.

14 M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

V. 121806 Cayenne

™

Series

4.4 Install Signal Cable

4.4.1 Standard Series Press

The flash cure is designed to receive operational signals either from the M&R press PLC or

from an independent remote sensor located under the index table assembly.

WARNING: Ensure none of the pallets are positioned under the flash cure for an excessive

time while the flash cure is on. Extreme heat can damage pallets, garments and/or cause a

fire.

Step 1

Install the signal cable from the socket (1) marked

PLC/SENSOR SIGNAL on the flash cure to the

plug socket (2) located on the lower electrical

enclosure of the press. The remaining plugs are

provided for installation of additional flash cure

systems.

Step 2 Press the F4 key twice to select the mode of

operation for the flash cure, PLC mode or

Proximity mode. The control displays MODE on

the upper line, and either PRX or PLC on the

lower line indicating which mode is currently

selected. Press the arrow keys to change the

mode.

Note: In PLC mode, the flash cure receives its start

signal from the PLC on the press. In PRX mode,

the flash cure receives its start signal from the

floor stand mounted proximity switch.

M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA 15

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

Cayenne

™

Series V.121806

4.4.2 Z-Series Press

Ensure the digital controller on the quartz flash is set for PLC control and the

communications protocol is set to YES.

Step 1 Connect the male plug (1) from the first flash cure

to the female receptacle (2) on the press.

Step 2 To connect multiple flash cure systems together,

connect the male plug (3) on the second flash cure

to the female receptacle (4) from the first flash

cure.

Step 3 For additional flash cures connect the male plug

(5) on the third flash cure to the female receptacle

(6) on the second flash cure.

Connect additional flash cures in the same

manner.

Step 4 Press F4 key three times to select the

communications protocol. The control displays

MDBUS on the upper line, and either YES or NO

on the lower line indicating if the protocol is

currently selected. Press the arrow keys to

change the protocol.

Note: When YES is selected, the flash cure is

controlled from the main control panel.

16 M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

V. 121806 Cayenne

™

Series

Step 5 Install the signal cable from the socket (1) marked

PLC/SENSOR SIGNAL on the flash cure to the

plug socket (2) located on the lower electrical

enclosure of the press. The remaining plugs are

provided for installation of additional flash cure

systems.

Step 6 Press the F4 key twice to select the mode of

operation for the flash cure, PLC mode or

Proximity mode. The control displays MODE on

the upper line, and either PRX or PLC on the

lower line indicating which mode is currently

selected. Press the arrow keys to change the

mode.

Note: In PLC mode, the flash cure receives its start

signal from the PLC on the press. In PRX mode,

the flash cure receives its start signal from the

floor stand mounted proximity switch.

M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA 17

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

Cayenne

™

Series V.121806

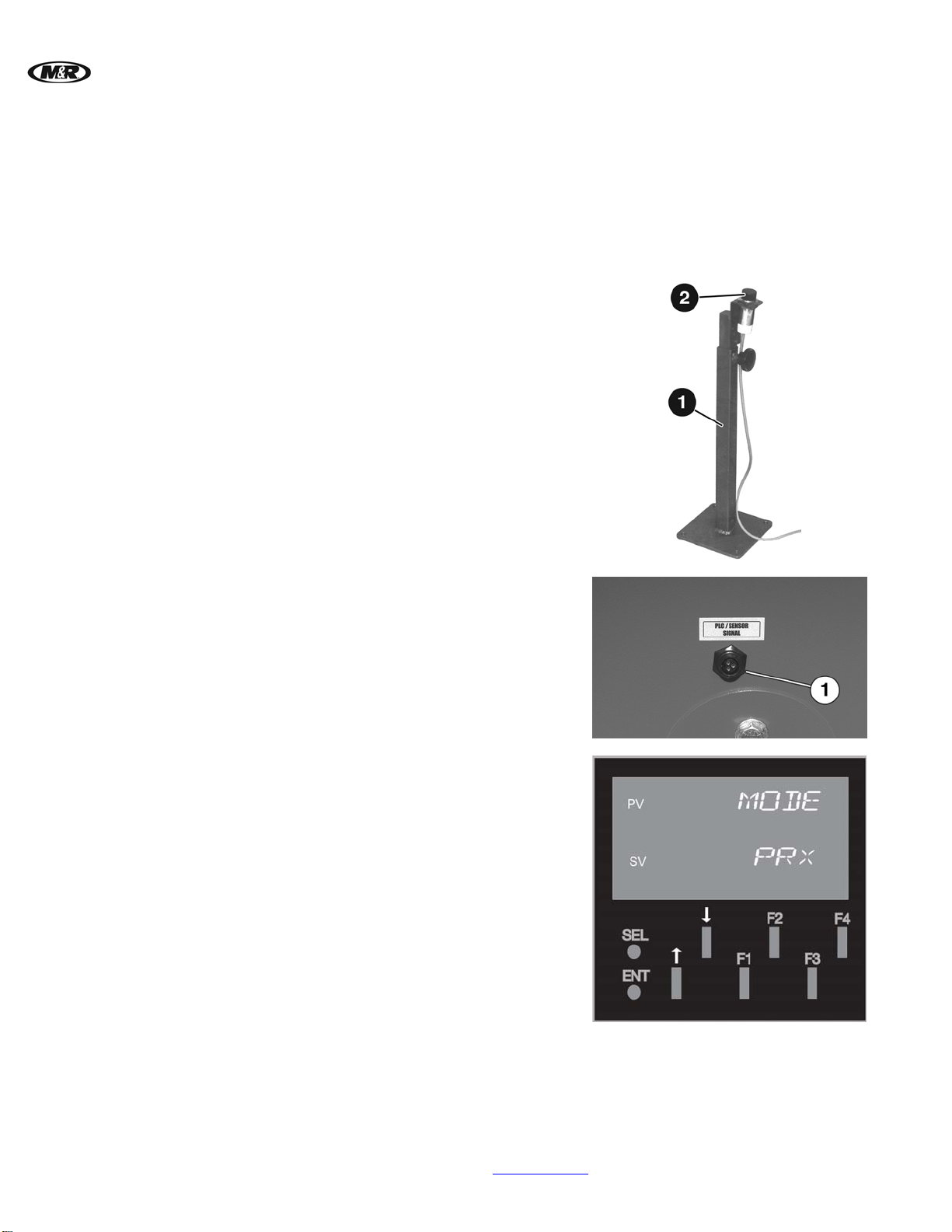

4.5 Install Remote Sensor

Using Remote

Sensor

For M&R presses which do not include pre-wired plug sockets on the electrical enclosure, the flash

cure is operated and controlled through the use of a remote sensor assembly.

The remote sensor supplies the signal to the flash cure in this type of installation. Ensure the digital

controller is set for Proximity or PRX.

Step 1 Position the floor stand (1) and sensor (2) underneath the

index table pallet at the print station just before the print

station where the flash cure is located. Position the sensor

to read the lower pallet support arm just as it starts the

index cycle.

Step 2 Install the signal cable from the sensor floor stand to the

socket (1) marked PLC/SENSOR SIGNAL on the flash

cure.

Step 3 Press the F4 key twice to select the mode of operation for

the flash cure, PLC mode or Proximity mode. The control

displays MODE on the upper line, and either PRX or PLC

on the lower line indicating which mode is currently

selected. Press the arrow keys to change the mode.

Note: In PLC mode, the flash cure receives its start signal from

the PLC on the press. In PRX mode, the flash cure

receives its start signal from the floor stand mounted

proximity switch.

18 M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

V. 121806 Cayenne

™

Series

5. Operation

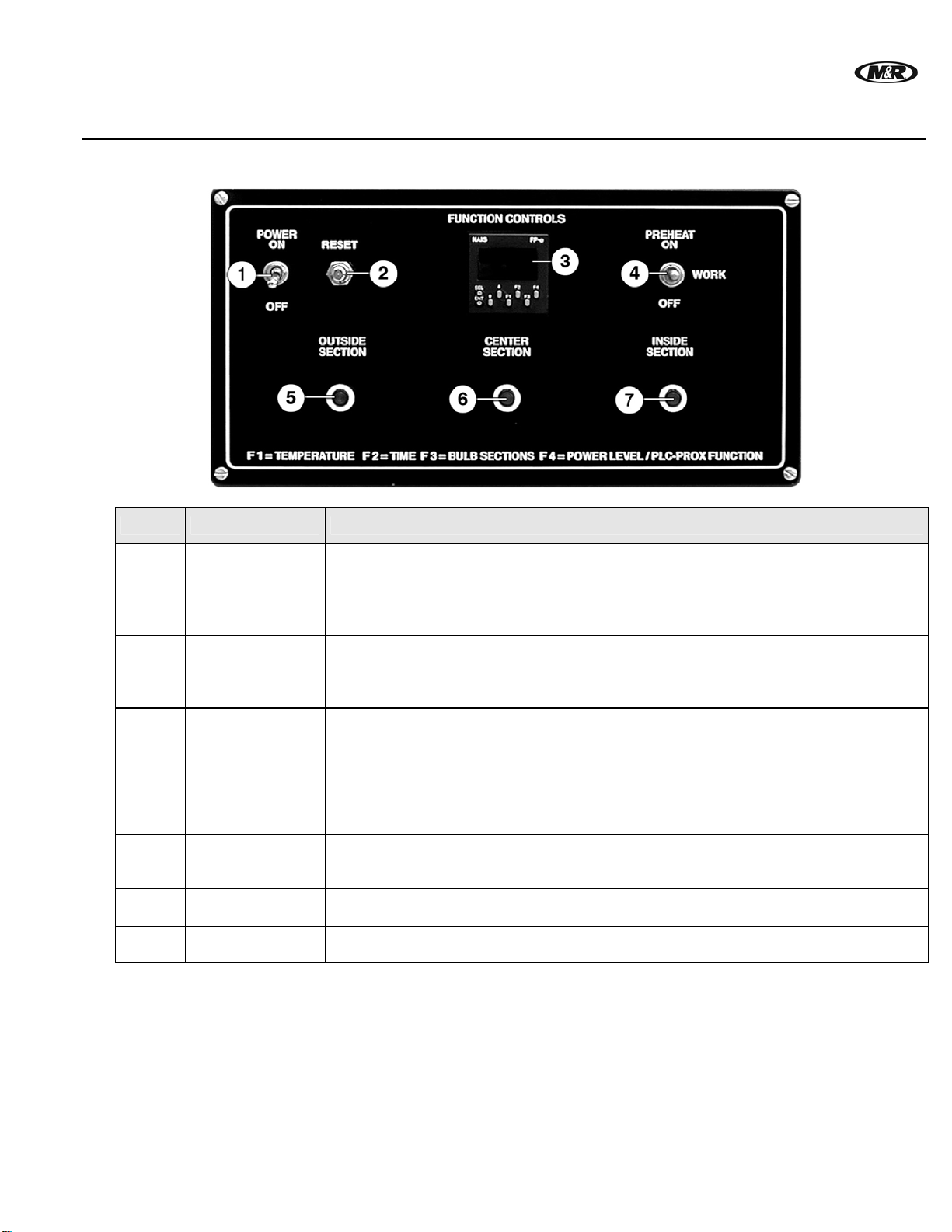

5.1 Control Panel

Number Name Function

1 POWER ON /

OFF Switch The POWER ON/OFF switch supplies electrical power to the flash cure.

Place the switch in the ON position to turn on.

Place the switch in the OFF position to turn off.

2 RESET Button The RESET button resets the control system, allowing operation of the flash cure.

3 Digital Controller The Digital Controller selects temperature, output power, exposure time, lamp

section selection and mode of operation; proximity or PLC. The controller also selects

flash cure unit number, either Fahrenheit or Celsius temperature display and 50 or 60

Hz. electrical supply frequency.

4 PREHEAT ON /

WORK / OFF

Switch

The PREHEAT ON/WORK/OFF switch is used to preheat the quartz heater elements

when the flash cure is turned on. PREHEAT ON (momentary position) activates the

quartz bulbs for the time set. During the preheat time, the switch may be placed in

the OFF position to disconnect power to the bulbs. WORK position shows the flash

cure is ready to work in either the PLC or PROX mode. In the OFF position, the bulbs

cannot receive power or energize regardless of which mode, PLC or PROX, is

selected.

5 OUTSIDE

SECTION This light illuminates when the outside section of quartz heater elements are

operating. When not illuminated, the outside section of quartz heater elements is not

operating.

6 CENTER

SECTION This light illuminates when the center section of quartz heater elements are operating.

When not illuminated, the center section of quartz heater elements is not operating.

7 INSIDE SECTION This light illuminates when the inside section of quartz heater elements are operating.

When not illuminated, the inside section of quartz heater elements is not operating.

M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA 19

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

Cayenne

™

Series V.121806

5.2 Digital Control Unit

The M&R flash cure uses an alpha/numeric digital controller to control flash time, quartz heating

element section use and power output.

Note: On a Z-Series press, communication protocol allows users to control flash operation from the main control

panel. After entering or changing a value on the flash cure, press the ENT key to communicate the value

to the PLC.

Power Ensure power is supplied to the equipment. The control

displays the flash cure model on the top line and FLASH on

the lower line.

Reset and

PV/SV Place the POWER switch to ON. The control displays

PRESS on the top line and RESET on the lower line. Press

RESET on the control panel; the current Process

Temperature Value (PV) and Set Temperature Value (SV)

now display.

20 M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

This manual suits for next models

12

Table of contents

Other M&R Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

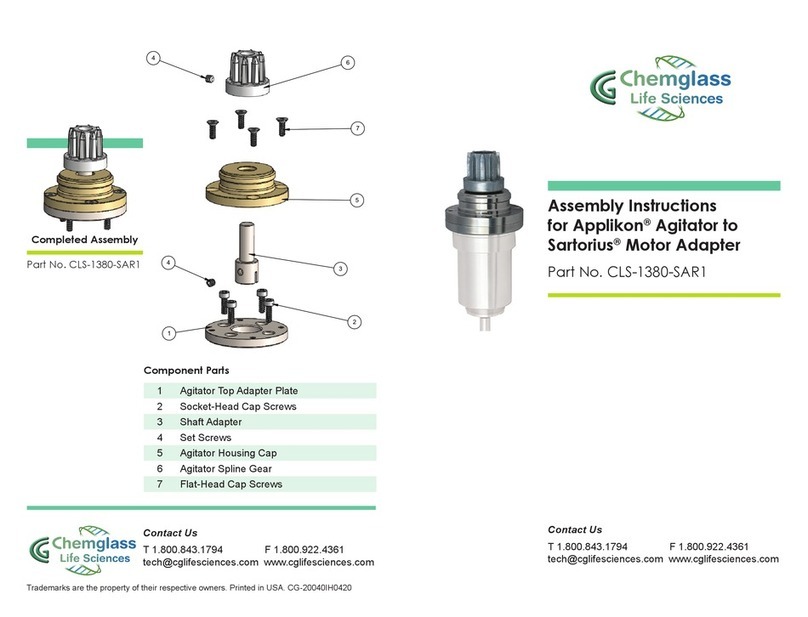

Chemglass

Chemglass CLS-1380-SAR1 Assembly instructions

Maxcess

Maxcess Fife-200 Installation and service manual

Mid-West Instrument

Mid-West Instrument 109 Series Installation and operating instructions

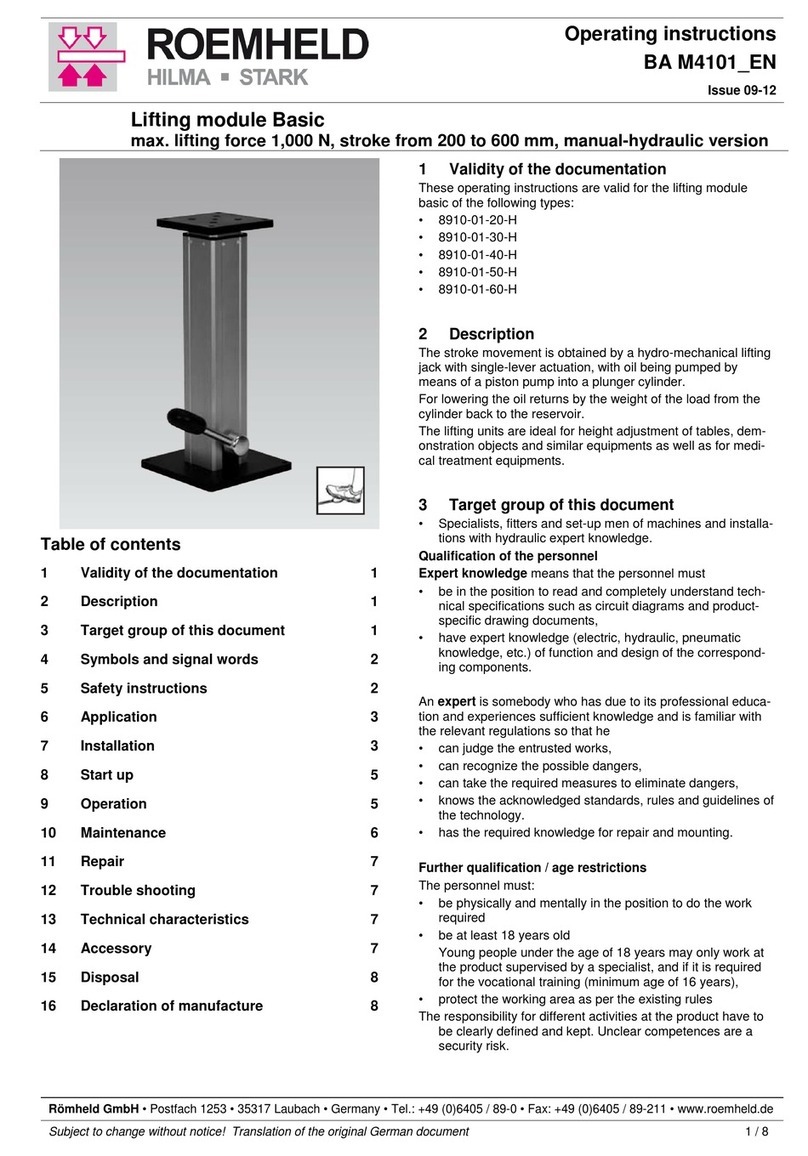

Roemheld

Roemheld 8910-01-20-H operating instructions

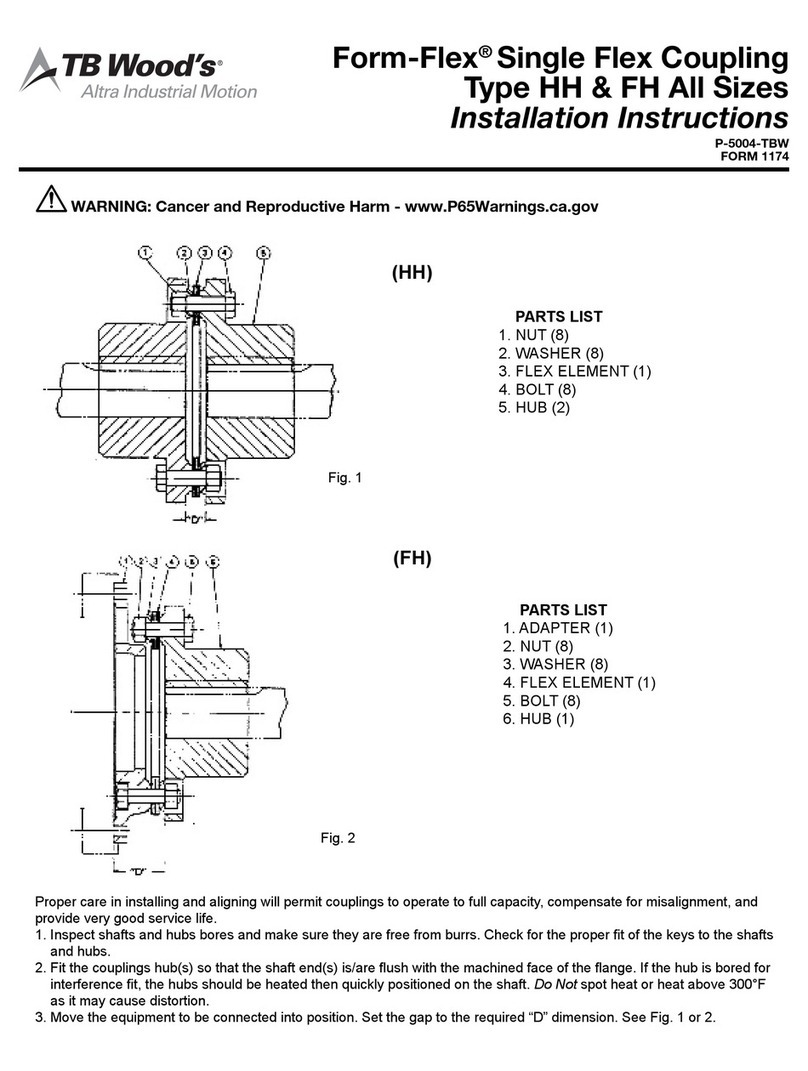

TB Wood's

TB Wood's Form-Flex HH Series installation instructions

Emerson

Emerson ANDERSON GREENWOOD Installation and maintenance instructions