EWC Controls PRD Service manual

Model PRD & PRD- RD

TB-224

P/N 090375A0224 REV. M

Leave this bulletin on the job site for future reference!

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected] 1

Copyright 2006-2008 EWC Controls All Rights Reserved©

Barometric By-Pass Damper

GENERAL DESCRIPTION

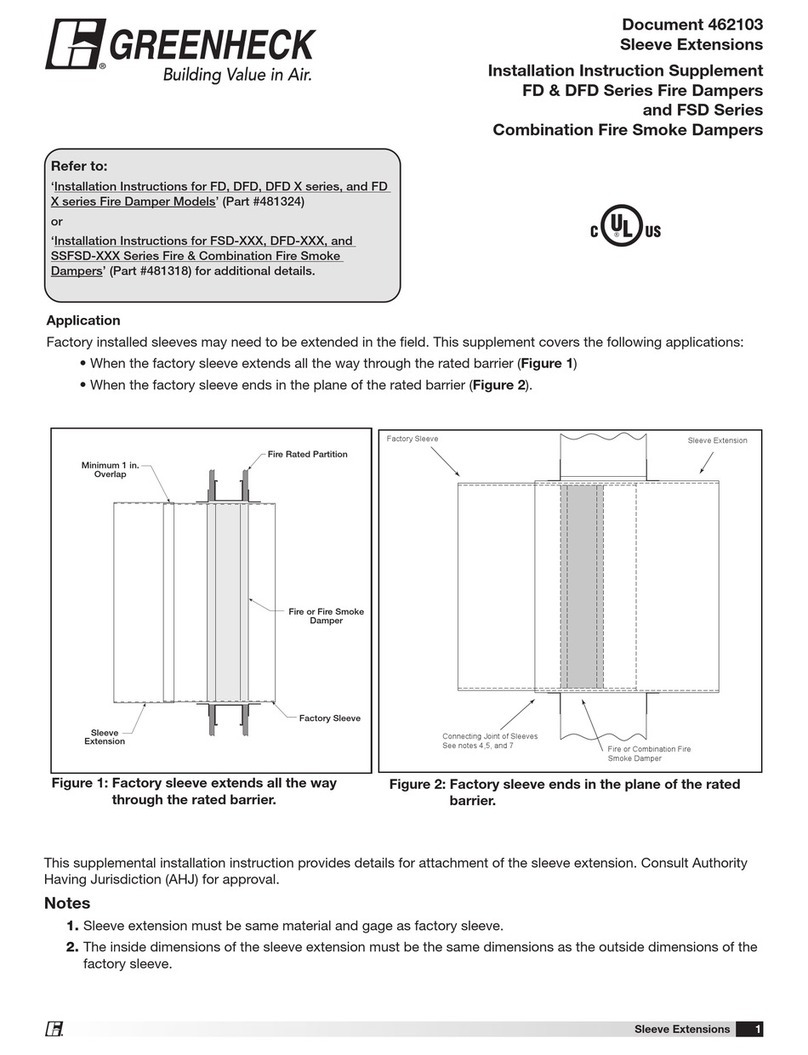

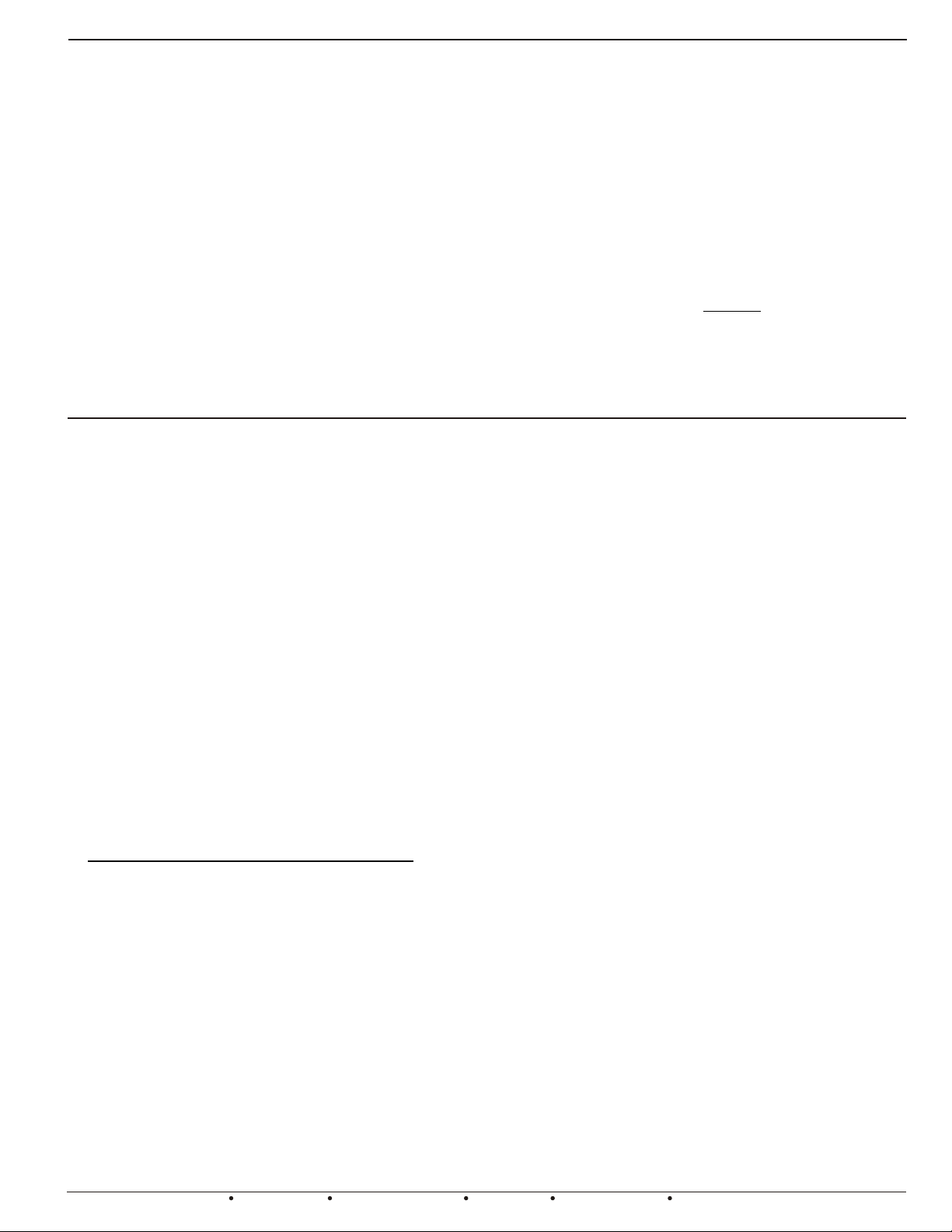

Note: This drawing of the Bypass damper, Hand Damper, Static Pressure control and Related duct work is intended to serve only as a guide.

Your actual duct work layout and components may differ. Use the graphic as a guide when planning or designing a Zone system regardless of

the Equipment type, Duct layout and Airflow configuration.

Supply Air

to

Zone Dampers

Pitot Tube

Ultra-Zone™PS4

Static Pressure Control

EBD

MotorActuatedorBarometric

PRD orPRD - RD

ByPassDamper

3/8” O.D.

Reference Tubing

Ultra-Zone™

Ultra-Zone™

HVAC

UNIT

Return Air

from

All Zones

Ultra-Zone™

Zone Control

Panel

24vac Power

Control Wiring

Supply

Air

Sensor

(required)

RD-HD

SID-HD

ND-HD

Hand

Damper

Return

Air

Sensor

(optional)

MP

Ultra-Zone™

6ft. if possible 6ft. if possible

-

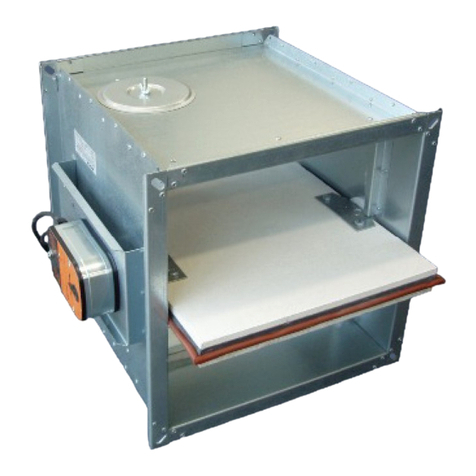

The model PRD & PRD-RD pressure regulating dampers are a single blade rectangular or round barometric damper

assemblies with a counter balanced weighted arm. The barometric by-pass damper is an economical way to manage

airflow when zone dampers close. Damper adjustment is achieved by off-setting the hex shaped arm, securing

weight #1 towards the bottom of that arm and moving the extra weight(s) (optional) up or down the arm, until the

correct bypass flow is achieved. See Page 2 for details. For field versatility, the hex shaped arm can be inserted into

either side of the damper. Additional weights can be added if necessary.

The barometric by-pass damper is installed in the duct-work to regulate excess air pressure and volume. The damper

can be mounted to relieve pressure by returning the air back to the return air duct or by dumping it into a non-critical

conditioned area. A restricting hand damper can be installed downstream of the by-pass damper, which allows the

installer to set sufficient differential pressure across the bypass duct, controlling how fast the by-pass air mixes with

return air. See Application Note 090376A0169D.

The PRD & PRD-RD are effective By-Pass solutions for any Constant Speed or Variable Speed Zoned HVAC system

up to 4 ton capacity.

MODEL # SIZE

BYPASS Cfm*

560 Cfm

700 Cfm

825 Cfm

900 Cfm

1125 Cfm

1375 Cfm

12" x 8"

12" x 10"

12" x 12"

20" x 8"

20" x 10"

20" x 12"

PRD 12 x 8

PRD 12 x 10

PRD 12 x 12

PRD 20 x 8

PRD 20 x 10

PRD 20 x 12

# WEIGHTS

2

2

2

2

2

2

* CFM @ 900Fpm

(.15”wc friction loss)

BYPASS Cfm*

850 Cfm

1100 Cfm

1300 Cfm

1300 Cfm

1750 Cfm

2000 Cfm

* CFM @ 1400Fpm

(.3”wc friction loss)

MODEL #

BYPASS Cfm*

320 Cfm

500 Cfm

720 Cfm

950 Cfm

1250 Cfm

8"

10"

12"

14”

16"

PRD-RD 8

PRD-RD 10

PRD-RD 12

PRD-RD 14

PRD-RD 16

# WEIGHTS

1

1

1

2

2

BYPASS Cfm*

500 Cfm

750 Cfm

1100 Cfm

1400 Cfm

1900 Cfm

Use the Cfm tables provided below to size your by-pass damper using the guideline provided on the next page. Use

the 1400Fpm column to achieve smaller bypass runs at higher velocities. Use the 900Fpm column if you have the

space to accommodate a large bypass run at a nominal velocity.

SIZE

* CFM @ 1400Fpm

(.3”wc friction loss)

* CFM @ 900Fpm

(.15”wc friction loss)

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

2

BYPASS SIZING CALCULATIONSBYPASS SIZING CALCULATIONS

The bypass damper must be installed horizontal & level between the supply duct and the return duct.

Position the damper to open in the direction of airflow back to the return duct or into a conditioned area.

Place the duct connection on the return so that the bypass air has a minimum 6 feet of return duct. before it

enters the air handler, if space permits. If a Restricting Hand Damper is installed, it should have been setup

already. If not, refer to Application note 090376A0169D. Otherwise, close the hand damper ½ way.

Position the ARM in the “IDEAL ARM LOCATION” for the correct direction of air flow and tighten the

thumb screw. (Refer to page 4)

Position the Extra Weight (optional) high up on the ARM and tighten the thumb screw. Position Weight#1

towards the bottom of the arm and tighten the thumb screw. (Refer to page 3)

Energize ALL Zones to operate the unit with the Fan running on the Highest speed. (Usually a Cooling

demand, 2nd stage if applicable)

Return to the damper & confirm that the by-pass damper is closed. If necessary, reposition the Extra Weight

or Weight #1 lower on the ARM until the damper closes completely. (It should be closed to the point where

any additional force will start to open it) (Refer to page 3)

Turn off all Zones but the Smallest Zone & Wait about 45 seconds.

Monitor the airflow for the Smallest Zone. Is there to much Airflow or Noise? Proceed to Step 9.

Is there Insufficient Airflow? Proceed to Step 10.

Is the Airflow Acceptable? Proceed to Step 11.

Excess Velocity: Reposition the Extra Weight higher up on the ARM until the velocity in the smallest zone

has subsided to an acceptable level. If the velocity remains high, reposition Weight #1 higher up on the arm,

or if necessary, reposition the ARM closer towards “6 or 0” on the scale. (Depending on the model).

Insufficient Velocity: Reposition the Extra Weight lower on the ARM until the velocity is at an acceptable

level. If the velocity remains low, reposition the ARM closer towards the “3 or 9” on the scale ((Depends on

model. Refer to page 3&4) depending on direction of flow). If velocity still remains low for the smallest zone, to

much air is being forced through the barometric damper. You can order additional weights or you should

consider installing an Electronic By-Pass Damper (Model EBD).

Congratulations, your PRD By-Pass damper is now properly adjusted.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

BAROMETRIC BYPASS SET-UP PROCEDUREBAROMETRIC BYPASS SET-UP PROCEDURE

Start with the system’s Total Cfm (2000Cfm) 3 zone system (Zone 1 = 750Cfm, Zone 2 = 750Cfm, Zone 3 = 500Cfm plus 4 open runs @ 50Cfm)

Calculate the Cfm for the smallest zone that can run by itself (500Cfm)

Calculate the Cfm for any non-dampered (open) duct runs (4 x 50Cfm = 200 Cfm)

Calculate Damper stop leakage (20%) on both inactive zones (750cfm x .20 = 150 x 2 = 300Cfm)

Subtract all values from total Cfm (2000 - 500 - 300 - 200 = 1000 Cfm bypass flow)

The left over amount is the bypass Cfm. Refer the bypass Cfm to the chart on Page 1, match to the closest size. If you don’t have enough room for

that size, then go down one size. By-pass velocity will increase on smaller bypass ducts. Regardless of the bypass size, consider installing a

Restricting Hand Damper after the Bypass damper, in order to set sufficient differential pressure and control how fast the bypass air mixes with

the return air. (See graphic on page 1)

EXAMPLE: 5 ton system @ 400 Cfm Per ton = 2000 Cfm 2000 Cfm

Subtract Smallest Zone = 500 Cfm -500 Cfm

Subtract Damper Stop Leakage = 300 Cfm -300 Cfm

Subtract Open Runs = 200 Cfm -200 Cfm

1000 Cfm

1000 Cfm @1400Fpm = 12x10 PRD

or

1000 Cfm @ 900 Fpm = 20x10 PRD

1.

2.

3.

4.

5.

6.

BAROMETRIC BY-PASS SET-UP PROCEDUREBAROMETRIC BY-PASS SET-UP PROCEDURE

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected] 3

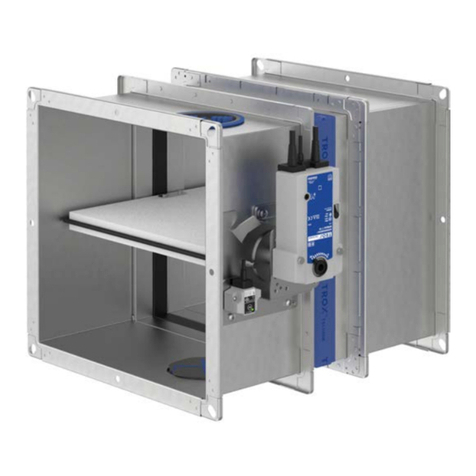

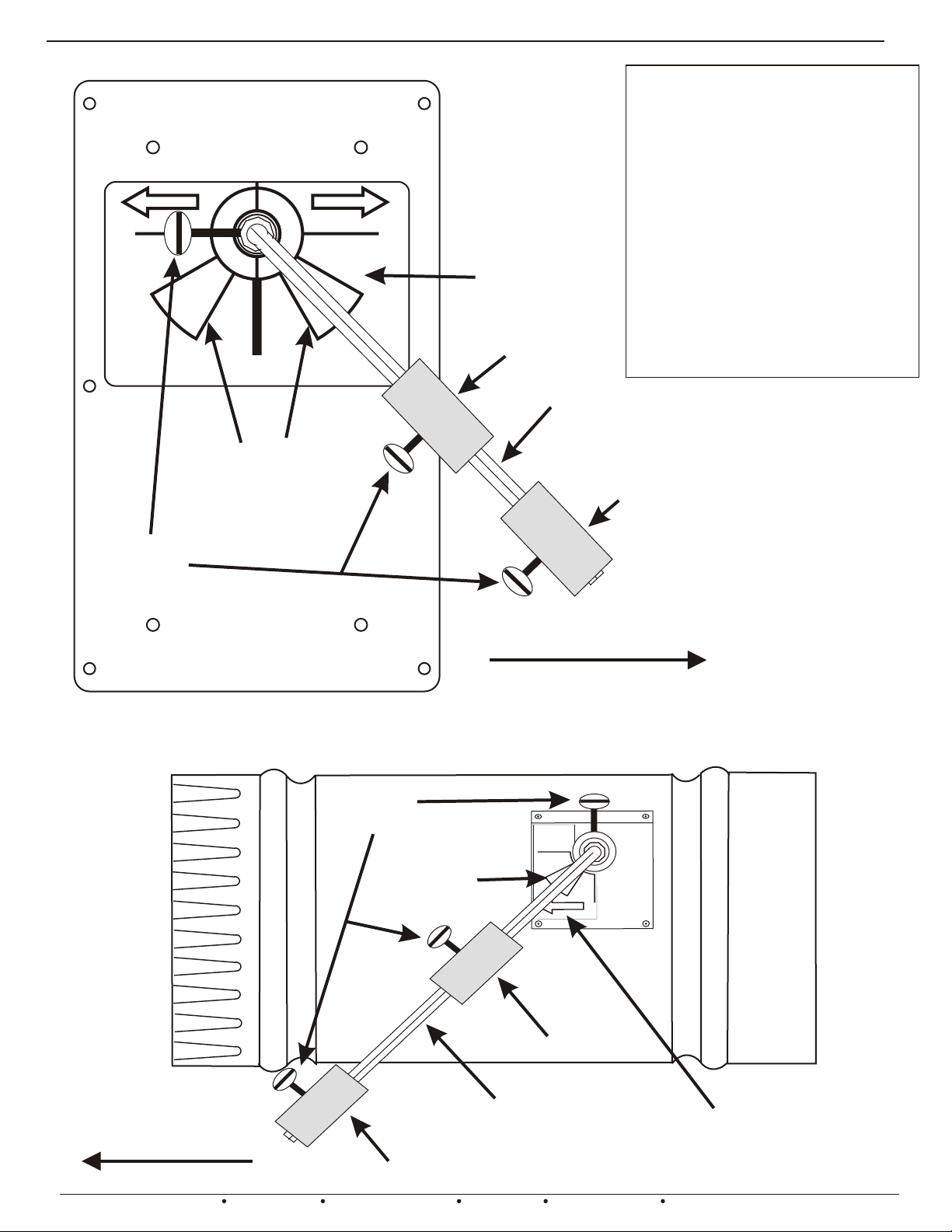

The direction of airflow can

be reversed on the PRD if

Contact EWC Controls Inc.,

Technical support if

necessary for further details.

necessary, by pushing the

Door over the stop on the

bottom of the damper frame.

Then, adjust the arm to the

proper position based on the

new airflow direction.

3

4

5

6

7

8

9

POSITION ARM IN IDEAL LOCATION IF

AIR FLOW IS IN DIRECTION INDICATED

BY THE ARROW ABOVE

IDEAL ARM

LOCATION

IDEAL ARM

LOCATION

AIRFLOW AIRFLOW

POSITION ARM IN IDEAL LOCATION IF

AIR FLOW IS IN DIRECTION INDICATED

BY THE ARROW ABOVE

ARM

GRADUATED

ADJUSTMENT

SCALE

THUMB

SCREWS

IDEAL

ARM

LOCATION WEIGHT #1

EXTRA WEIGHT

IDEALARM

LOCATION

AIRFLOW

POSITION ARM

INIDEAL

LOCATION

0

1

ModelPRD- RDRoundBypassDamper

IDEAL

ARM

LOCATION

WEIGHT#1

THUMB

SCREWS

ARMGRADUATED

ADJUSTMENT

SCALE

EXTRAWEIGHT

Model PRD-RectangularBypassDamper

This arm position reflects

Air-flow from Left to Right!

This arm position

reflects Air-flow from

Right to Left!

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

4

BAROMETRIC BY-PASS DAMPERBAROMETRIC BY-PASS DAMPER

ASSEMBLY OF PRD & PRD-RD BY-PASS DAMPER

1 - INSTALL BY-PASS DAMPER PER INSTRUCTIONS ON PAGE 2.

2 - SLIDE LOCKING-COLLAR OVER DAMPER SHAFT.

3 - INSERT HEX ARM INTO DAMPER SHAFT.

4 - ALIGN LOCKING-COLLAR THUMB SCREW WITH ONE OF THE 4 HOLES ON THE DAMPER

SHAFT WHILE HOLDING ARM AT THE DESIRED ANGLE.

5 - TIGHTEN THUMB SCREW TO SECURE HEX ARM IN PLACE.

6 - POSITION WEIGHT ON HEX ARM AND TIGHTEN THUMB SCREW TO SECURE IN PLACE.

7 - REFER TO PAGE 2 FOR SET-UP PROCEDURE.

THUMB SCREW

LOCKING-COLLAR

DAMPER SHAFT

HEX-ARM

FIGURE 3 -- CUT AWAY VIEW OF ASSEMBLY

FIGURE 4 -- CLOSE-UP VIEWS OF ASSEMBLY

This manual suits for next models

1

Popular Fire And Smoke Damper manuals by other brands

Greenheck

Greenheck EHH-401 Installation, operation and maintenance manual

Krantz

Krantz RK-F10 manual

Trox Technik

Trox Technik FKA2-EU Installation and operating manual

Gryfit

Gryfit LX-5 Installation and usage manual

Tamco

Tamco AIR-IQ Installation guidelines

Schako

Schako BSK-EN Installation, mounting and operating instructions