IMU-BPP-030-C-2017.08.17 - 1/6

CIAT Sp. z o.o. – ul. Langiewicza 62 – 95-050 Konstantynów Łódzki – POLAND

tel.: (48) 91 432 35 20 – fax: (48) 91

432 35 36 – e-mail:

[email protected] – www

.gryfit.

com

INSTALLATION AND USAGE MANUAL

Manufacturer: CIAT Sp. z o. o. – ul. Langiewicza 62 – 95-050 Konstantynów Łódzki, POLAND

EI 120 (vew – how – io) S1500C10000 AAmulti

CERTIFICATE OF CONSTANCY OF PERFORMANCE No.

1391-CPR-0104/2014-O1

1 – INSTALLATION

Installation should be done by a professional who has been trained in the installation of fire safety elements.

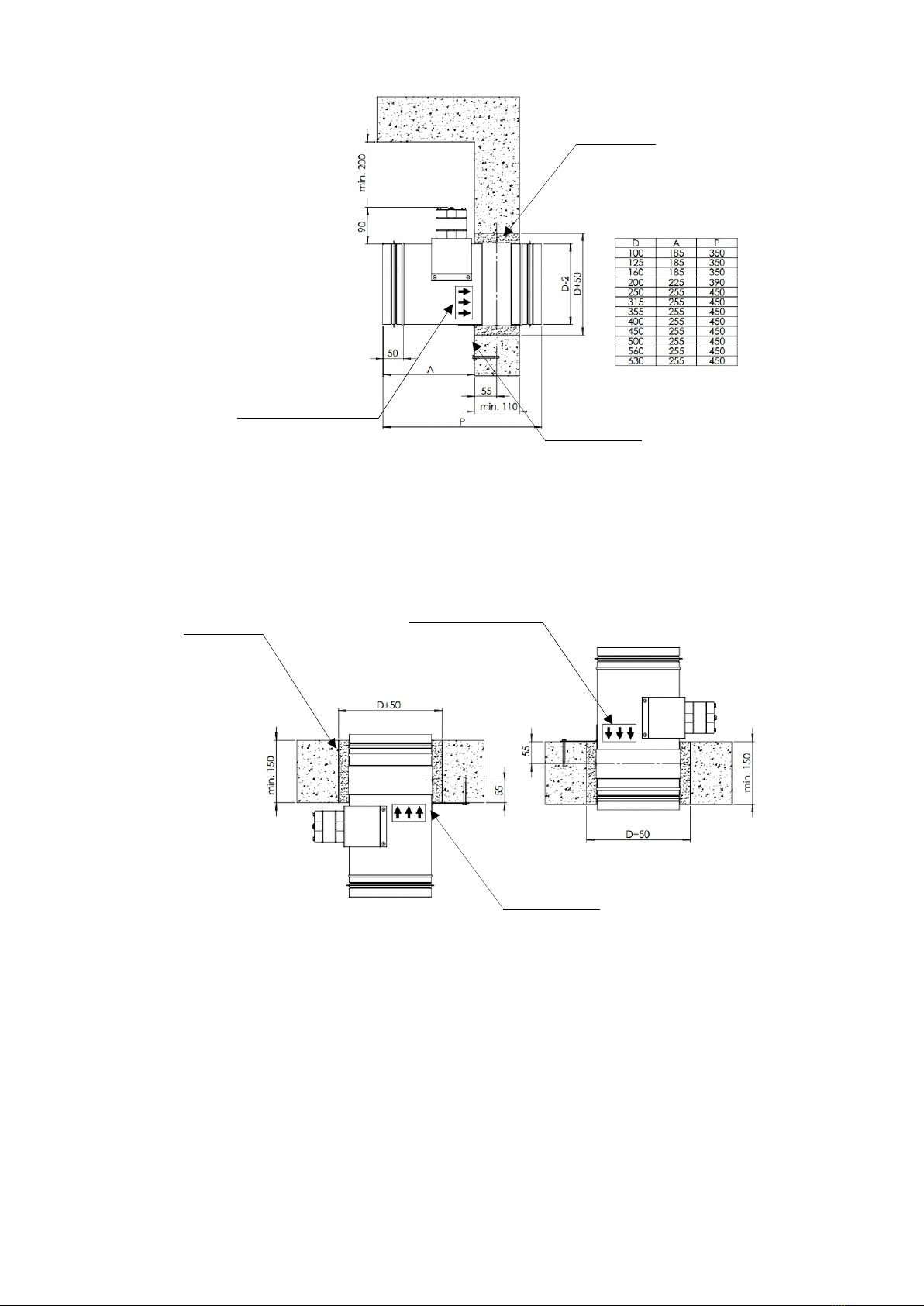

1.1 – OVERALL DIMENSION

To install the damper properly in vertical partition of brick or concrete the required overall dimension is D+50 mm.

1.2 – FIXING AND INSTALLATION

Place the damper axially in the opening. In order to provide partition with fire resistance, it is absolutely necessary

to respect damper installation border line which is clearly marked on the label to be found on the damper casing. In

case of installation in the brick or concrete walls, filling should be made of masonry mortar or non-shrink grout.

NOTE:

- While installing damper it is inadmissible to grime a control mechanism of the damper with mortar, glue or

paints. The control mechanism of the damper has to be absolutely protected until the masonry and painting

works are completed.

- The damper blade has to remain closed during installation and until mortar is hardened. The damper casing

cannot be burdened during installation in partition wall. It can result in deformation of the casing and damage of

the damper blade.

- Minimum clearance of 200 mm should be left for service between the nearest element of the building and the

mechanism.

1.3 – INSTALLATION METHOD

CX-5C can be installed in the following vertical and horizontal spaces:

- concrete walls thickness min. 110 mm,

- wall from full bricks thickness min. 110 mm,

- walls from aerated concrete thickness min. 110 mm,

- concrete ceilings thickness min. 150 mm.

1.3.1 – VERTICAL PARTITION

Minimum thickness of concrete, aerated concrete or brick vertical partition is 110 mm. It is recommended to use

optional UM installation brackets to facilitate installation. Installation brackets are delivered flat and have to be

bended before installation of the product.