1 09/15

•The casing is made of galvanised steel, and joined by

welding.

•The housing is made from galvanized steel. It has a

symmetrical design that allows wall mounting regardless

of air flow.

•The blade is made of ceramic material resistant to high

temperaturesand abrasion.

•These dampers meet the conditions required for the

symbol (S) to cold smoke seal. In case of fire, smoke

poisoning is the leading cause of death.

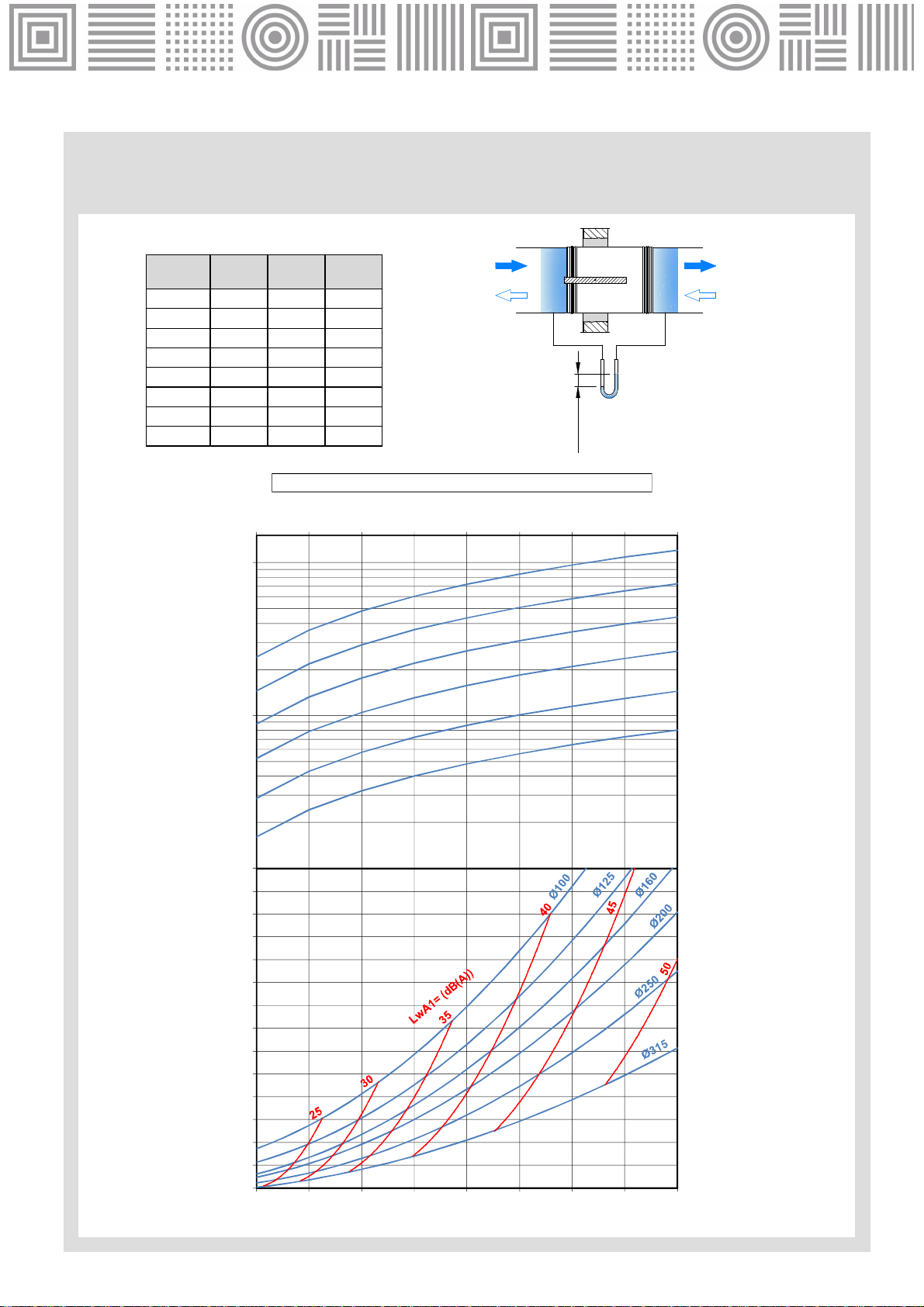

•The airtightness to the passage of cold smoke is

achieved through a joint between the perimeter of the

housing and the blade. This design, together with the low

thickness of the blade, allow to minimize the pressure

loss..

•For high temperatures,the damper is equipped with an

expanding intumescent seal, forming a paste that prevents

the passage of hot air and smoke from one side of the

damper to another.

•A rubber sealing ring at both ends of the casing ensures

an airtightness between the damper and the ducts.

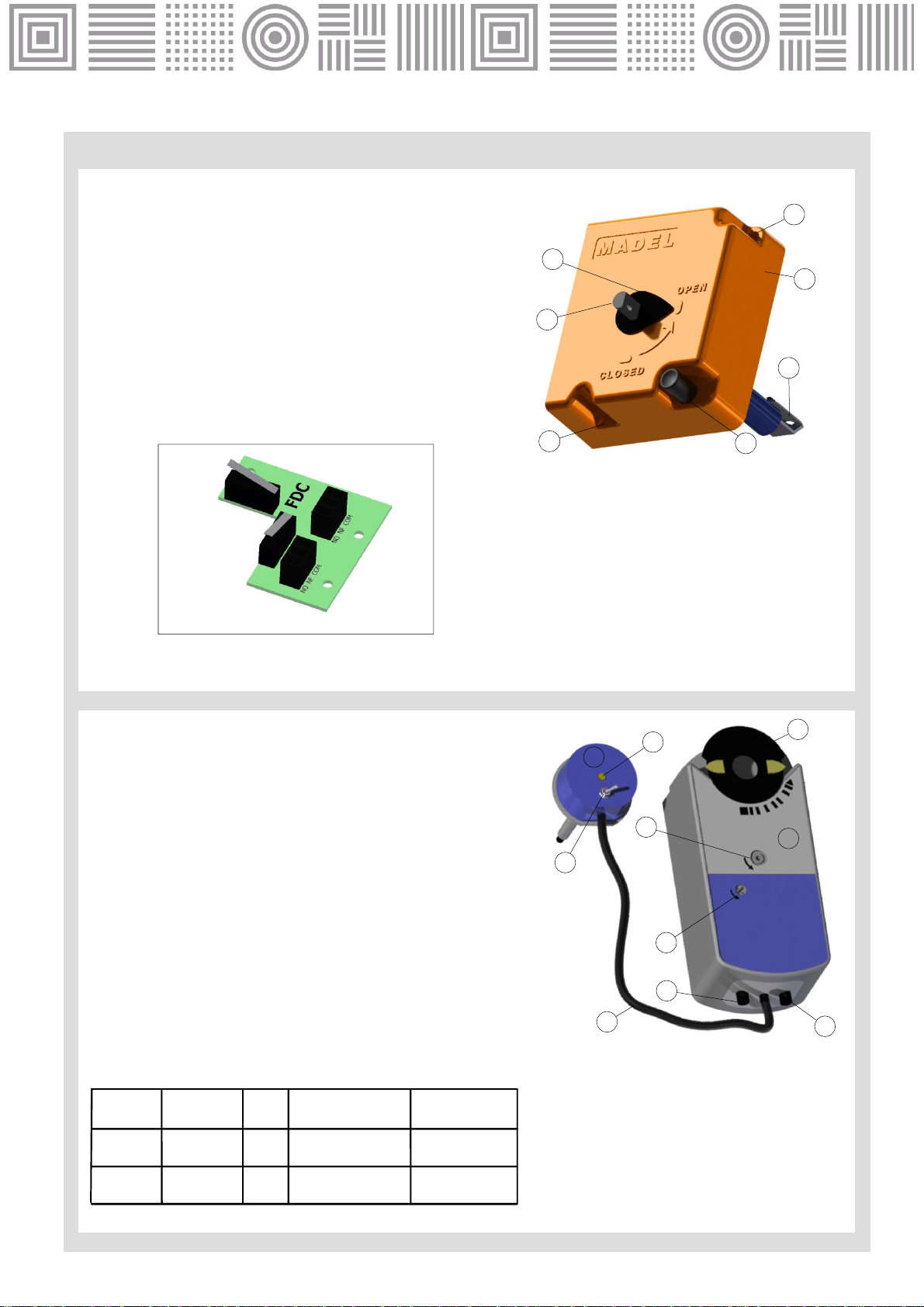

•The operating devices of the dampers is automatic

shooting by means of a thermal fuse calibrated at 72 °C to

activate the closure when reaches that temperature. Reset

is manual except for motorized dampers.

•The fire dampers FMC-EIS-120 work as a separator

between two sectors of fire and ensure the same fire

resistance that the structural elements of

compartmentalisation,which limits the risk of spreading

of fire by interior of the building.

•FMC-EIS-120 fire dampers are according with the

following standards:

FMC-EIS-120 fire dampers EIS-120

EN 15650:2010

European Test Standard, EN 1366-2

(Fire resistance tests for service installations –

Part 2: Fire dampers)

European Classification Standard, EN 13501-3

(Fire classification of construction products and building

elements –

Part 3: Classification using data from fire resistance tests on

products and elements used in building service installations:

fire resisting ducts and fire dampers)

European Standard for CE Marking, EN 15650

(Ventilation for buildings. Fire dampers)

European Test Standard, EN 60529:1991

(Degrees of protection provided by enclosures (IP Code))

European Test Standard EN 1751

(Ventilation for buildings –

Air terminal devices –

Aerodynamic testing of dampers and valves)

International Test Standard ISO 10294-4

(Fire resistance tests –Fire dampers for air distribution systems

Part 4: Test of thermal release mechanism)