Fire damper - FDMRPage 2 Version 2023-06-15

TPM 140/19

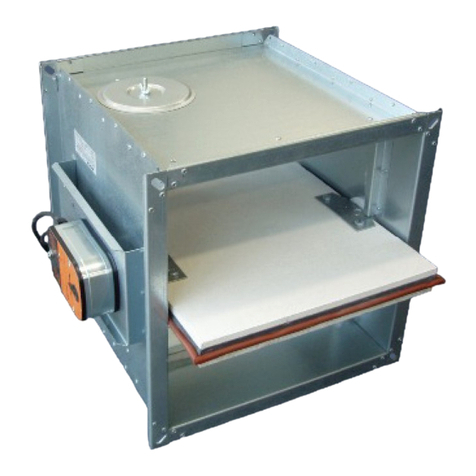

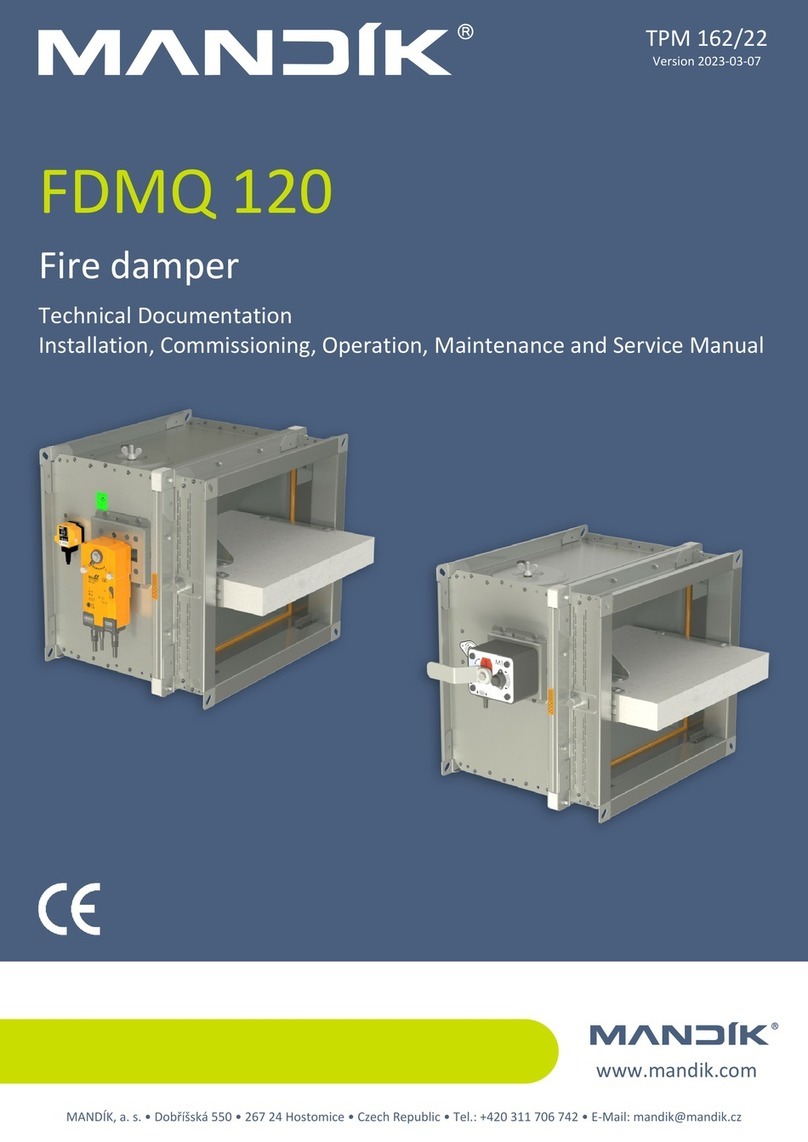

These technical specifications state a row of manufactured sizes and models of fire dampers FDMR

It is valid for production, designing, ordering, delivery, maintenance and operation.

CONTENT

I. GENERAL...........................................................................3

Description....................................................................3

II. DESIGN.............................................................................4

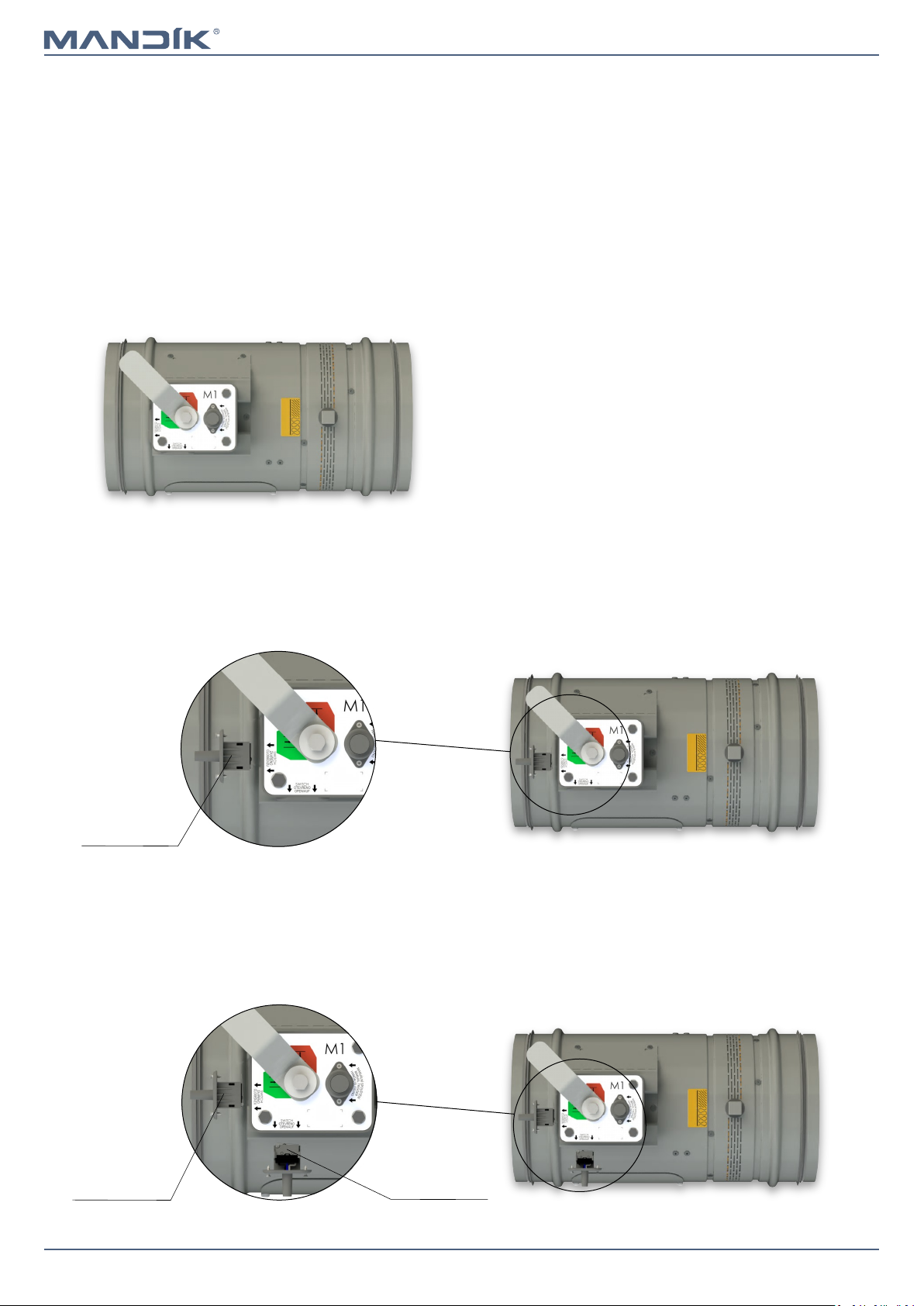

Design with manual control..........................................4

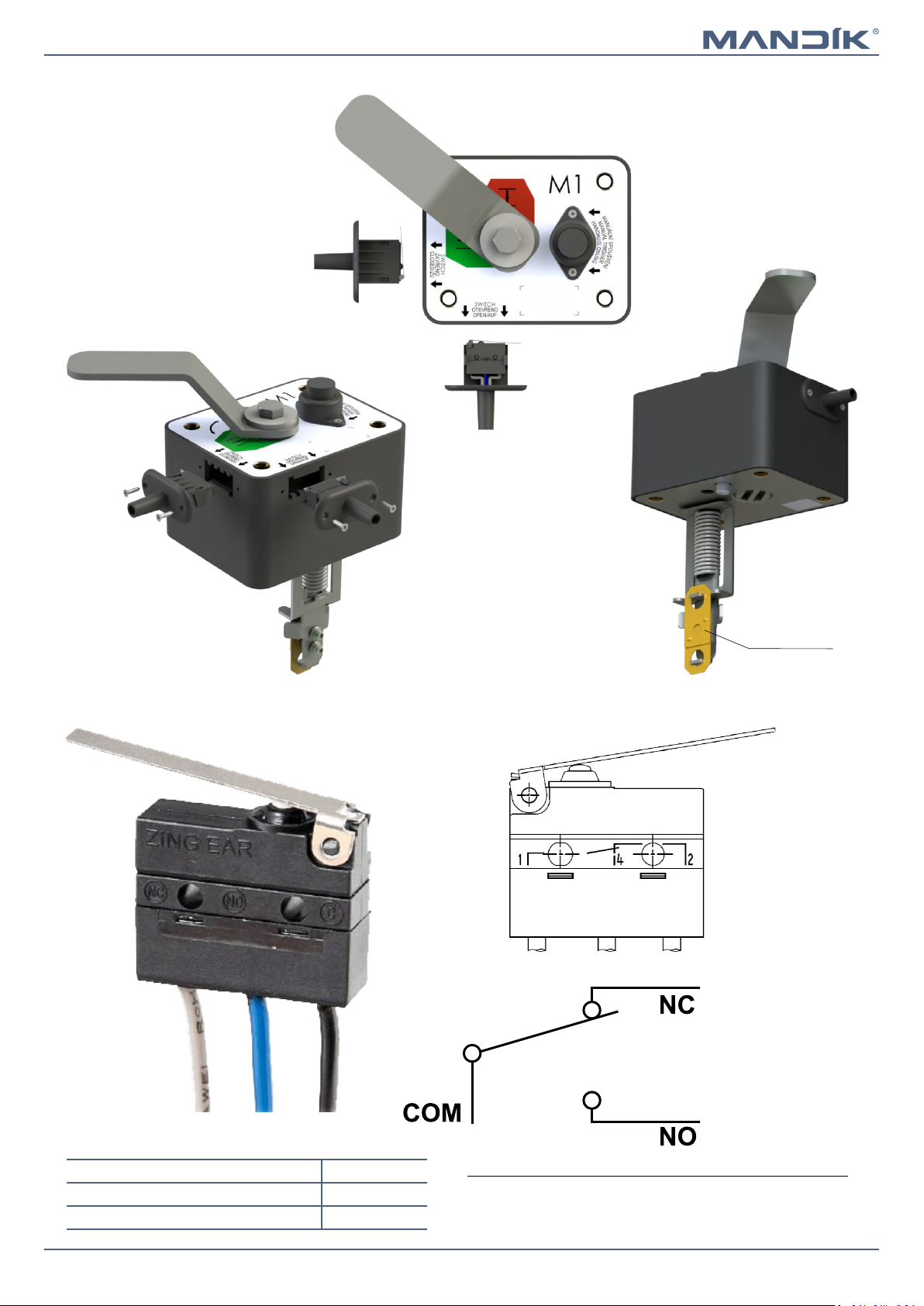

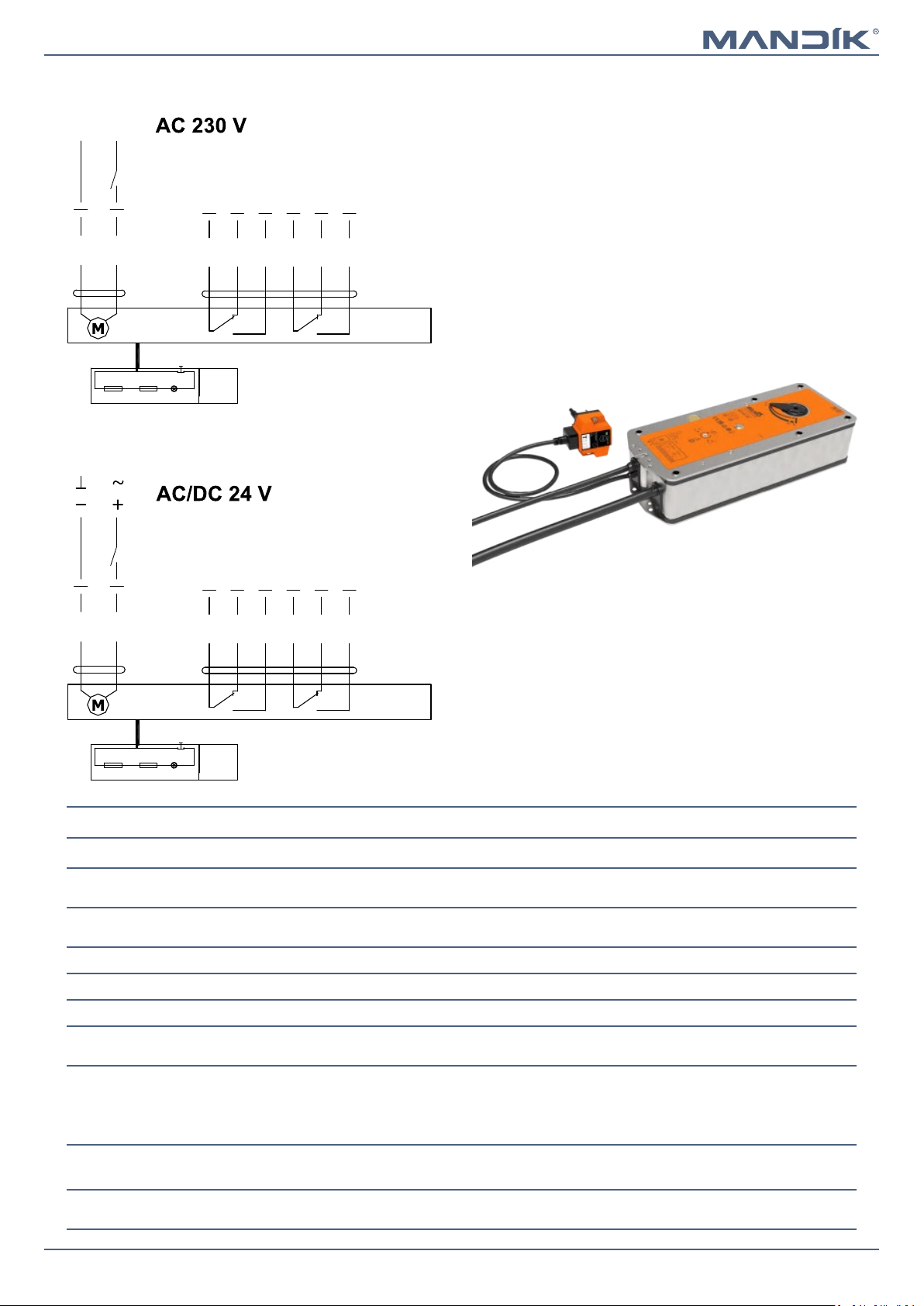

Design with spring return actuator...............................6

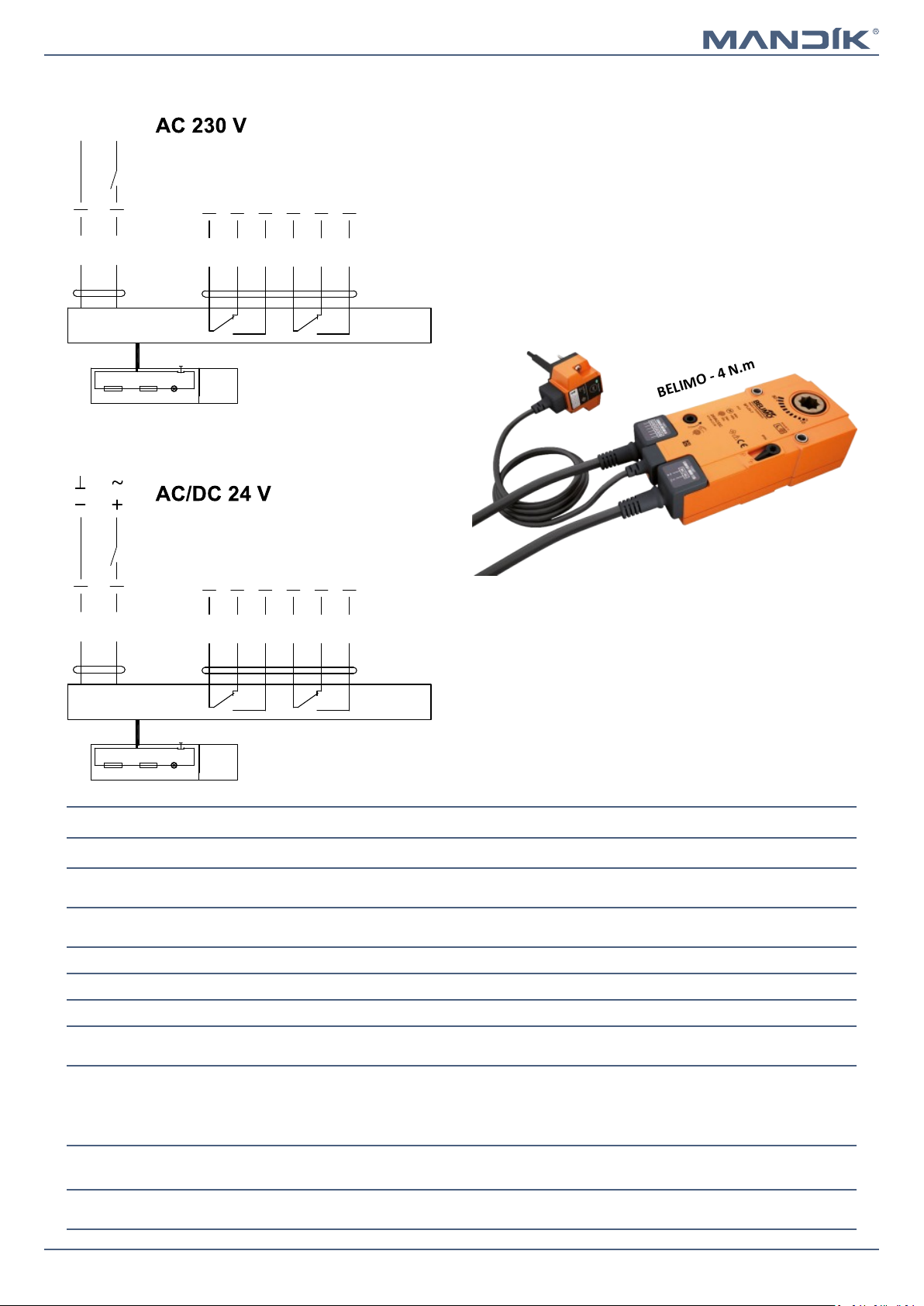

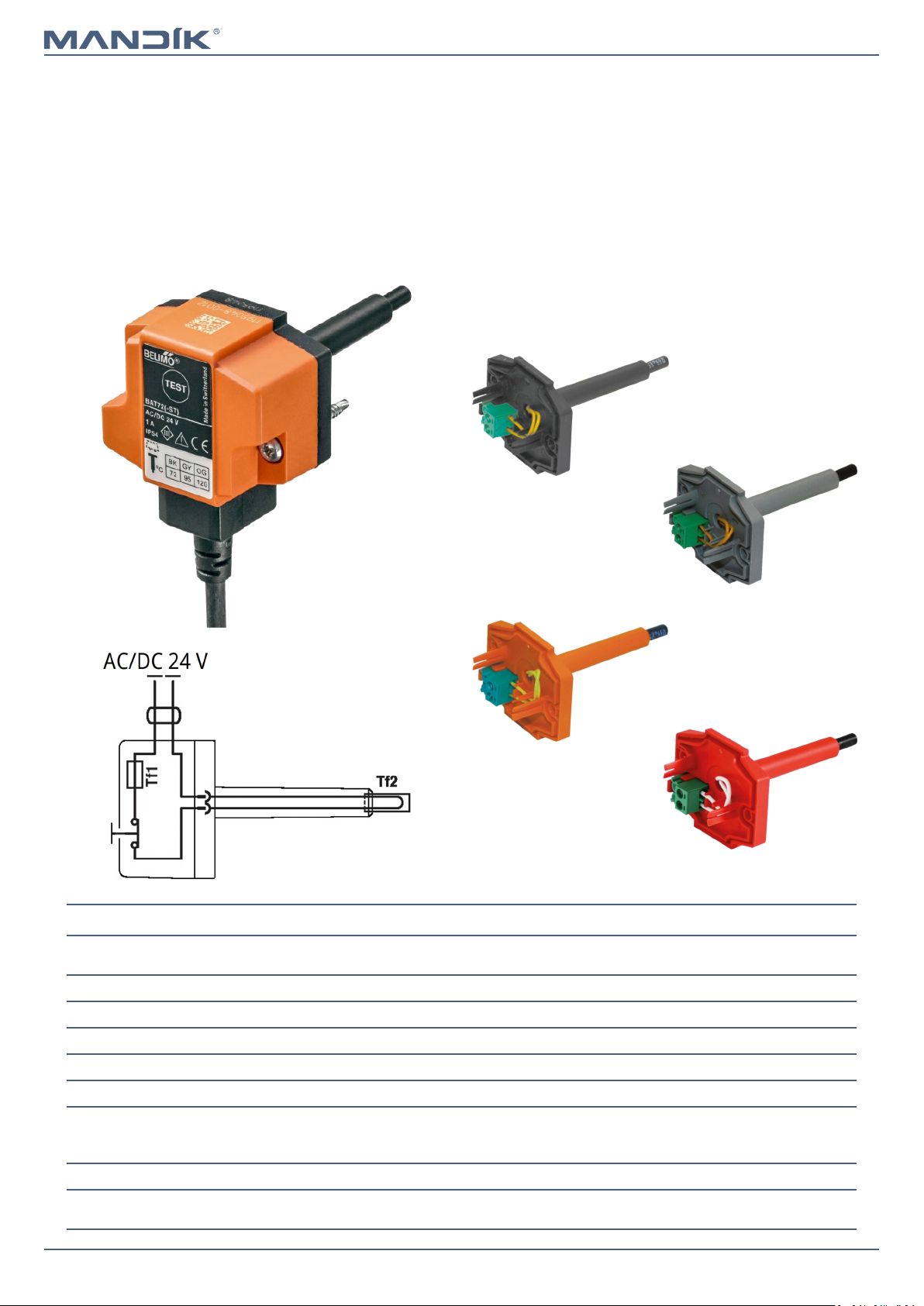

Design with the communication and supply device12

Communication and control device BKS 24-1B and

BKS 24-9A................................................................17

III. DIMENSIONS.................................................................19

Technical parameters.................................................24

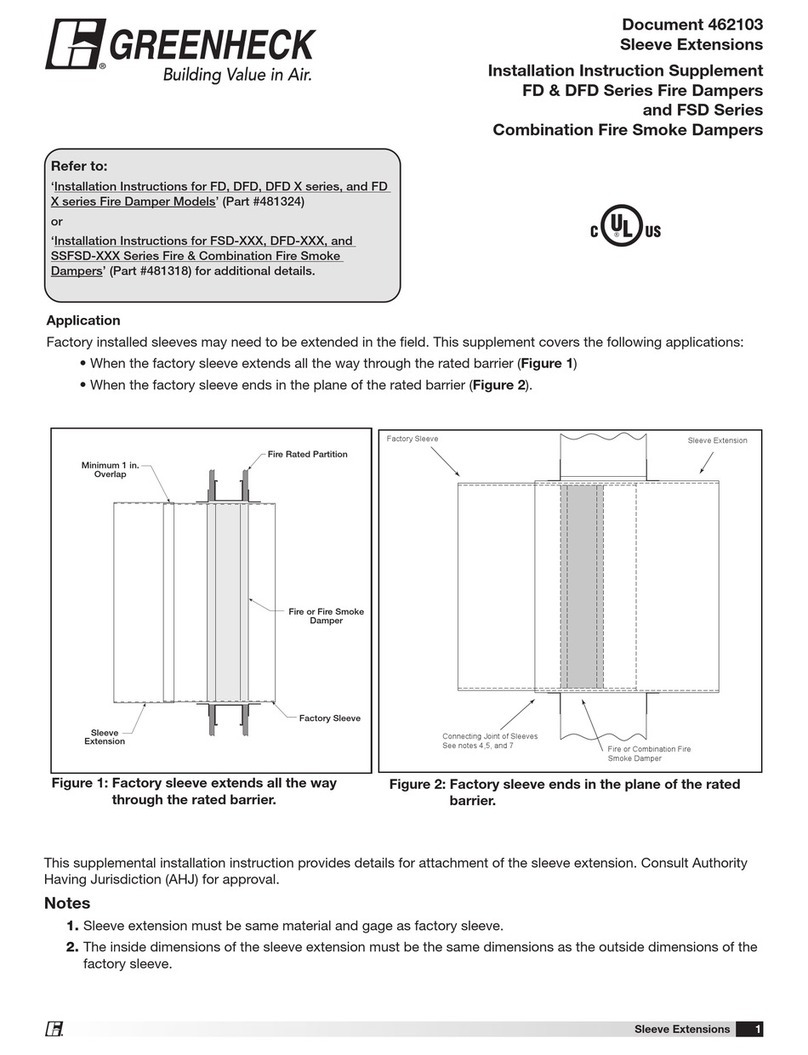

IV. INSTALLATION..............................................................25

Placement and installation.........................................25

Statement of installations...........................................27

In solid wall construction.........................................28

Installation outside solid wall constrution..............35

In gypsum wall construction....................................38

Installation outside gypsum wall constrution.........46

Installation in sandwich wall construction..............49

Shaft walls...............................................................50

In solid ceiling construction.....................................53

Installation outside solid ceiling constrution...........57

Installation frames......................................................61

Installation frame R1, R2.........................................62

Installation frame R3, R4.........................................71

Installation frame R5...............................................74

Installation frame R6...............................................81

Installation frame R7...............................................84

V. SUSPENSION SYSTEMS..................................................87

Example of duct connection.......................................90

VI. TECHNICAL DATA..........................................................91

Pressure loss...............................................................91

Noise data...................................................................92

VII. MATERIAL, FINISHING.................................................93

VIII. TRANSPORTATION, STORAGE AND WARRANTY.........94

Logistic terms..............................................................94

Warranty.....................................................................94

IX. ASSEMBLY, ATTENDANCE AND MAINTENANCE...........95

Entry into service and revisions..................................97

X. ORDERING INFORMATIONS...........................................99

Ordering key...............................................................99

Data label..................................................................100