BSK-EN fire damper

INSTALLATION, MOUNTING AND OPERATING INSTRUCTIONS

Mounting information

Construction subject to change

No return possible Version: 2018-11-14 | Page 5

MOUNTING INFORMATION

INSTALLATION IN SOLID WALLS

• Installation in solid walls (shaft walls, shafts, ducts and fire

walls) made of, for example concrete, masonry according

to EN 1996 or DIN 1053; solid plaster board walls according

to EN 12859 or DIN 18163; apparent density ≥ 450 kg/m³

and wall thickness W ≥ 150 mm.

• Installation with horizontal damper leaf.

• Circumferential gaps "s" must be filled completely with

mortar of categories M2.5 to M15 according to EN 998-2,

NM II to III DIN V 18580 (previously: MG II to III according

to DIN 1053) or fire protection mortar of the correspon-

ding grade or with concrete suitable for the wall type. The

minimum gap size s

min

is 50 mm. If the fire damper is in-

stalled during the construction of the wall, the gaps "s" can

be omitted. The mortar bed depth has to be designed ac-

cording to the minimum wall thickness and may not be less

than this thickness.

• The distance between the fire dampers must be min. 200

mm.

• Distance to the bearing adjacent components (wall / solid

ceiling) is minimum 75 mm.

INSTALLATION IN SOLID CEILINGS

• Installation in solid ceilings, for example made of concrete,

foam mortar; apparent density ≥ 500 kg/m³ and ceiling

thickness D ≥ 150 mm.

• Installation with full mortar lining (circumferential gaps "s"

must be filled completely with mortar of category M15 ac-

cording to EN 998-2, NM II DIN V 18580 (previously: MG III

according to DIN 1053) or fire protection mortar of the cor-

responding grade. The minimum gap size smin is 50 mm. If

the fire damper is installed during the construction of the

ceiling, the gaps "s" can be omitted. The mortar bed depth

has to be designed according to the minimum ceiling thick-

ness and may not be less than this thickness.

• The distance between the fire dampers must be min. 200

mm.

• Distance to the bearing adjacent components (wall) is mi-

nimum 75 mm.

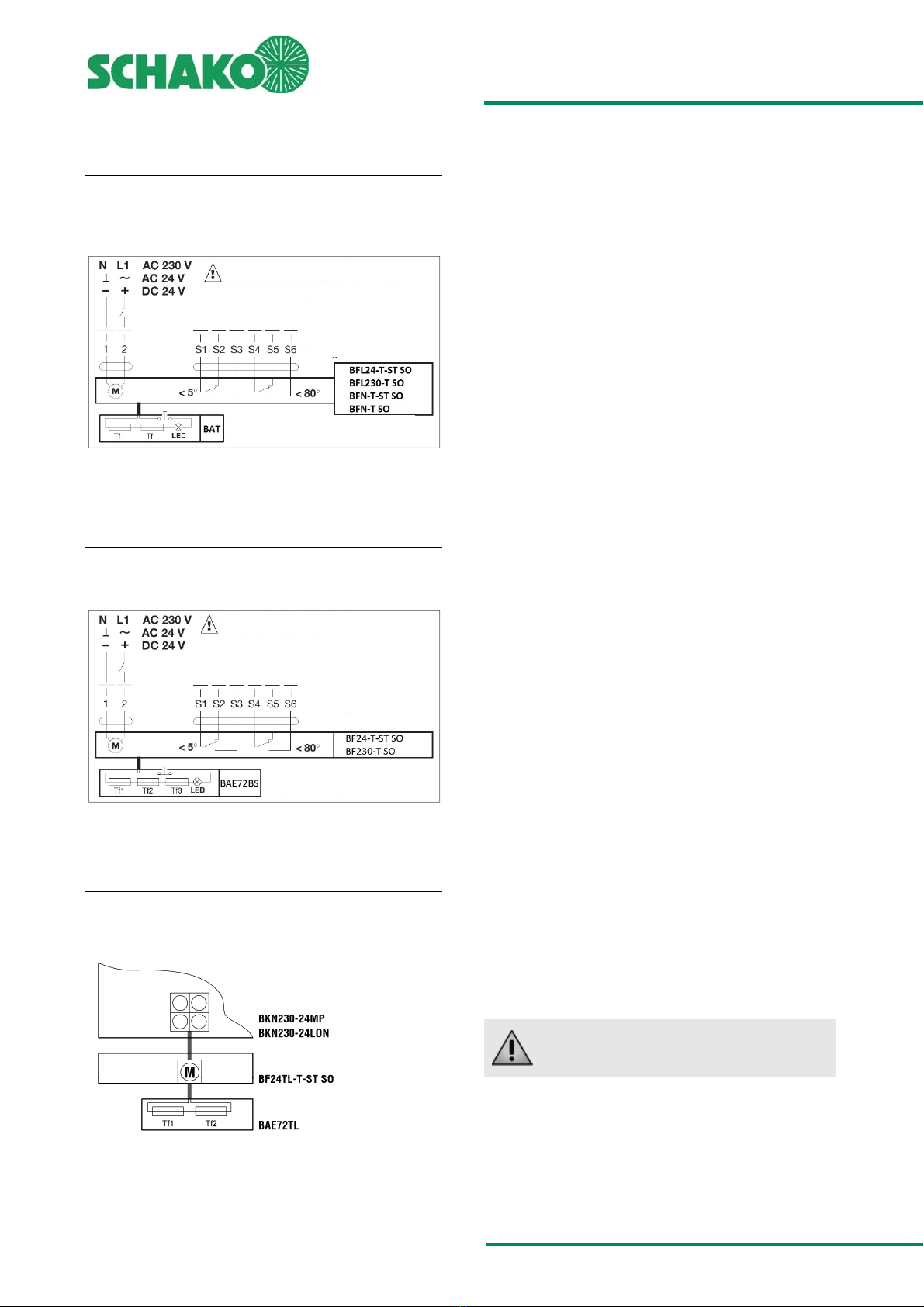

Installation in solid wall

Installation in solid ceilings

Figure 4: Installation in solid walls and ceilings

CONNECTION OF VENTILATION DUCTS

The fire dampers must be connected to the ventilation ducts

of the ventilation system either on one or on both sides. For

one-sided connections, finishing protective grating made of

non-combustible material (EN 13501-1) must be provided on

the respective opposite sides. The fire dampers can be

connected both to non-combustible and combustible

ventilation ducts.

The local regulations or national standards on ventilation

systems (in Germany e.g. LüAR) apply.

No inadmissible forces may affect the fire damper and space-

enclosing components especially in case of fire and impair

their fire resistance time. The required expansion joints

(flexible connecting pieces) must be designed as flammable,

elastic connecting pieces made of at least standard

inflammable materials (EN 13501-1) and installed between the

fire damper and ventilation duct. Flexible part of the

connecting piece (polyester fabric) must have the minimum

length of l

min

= 100 mm in the mounted state, this gives a

mounting dimension of approx. L = 160 mm. As an alternative,

instead of installing flexible connecting pieces, flexible

ventilation ducts made of aluminium can be connected.

Ventilation ducts must be suspended separately.