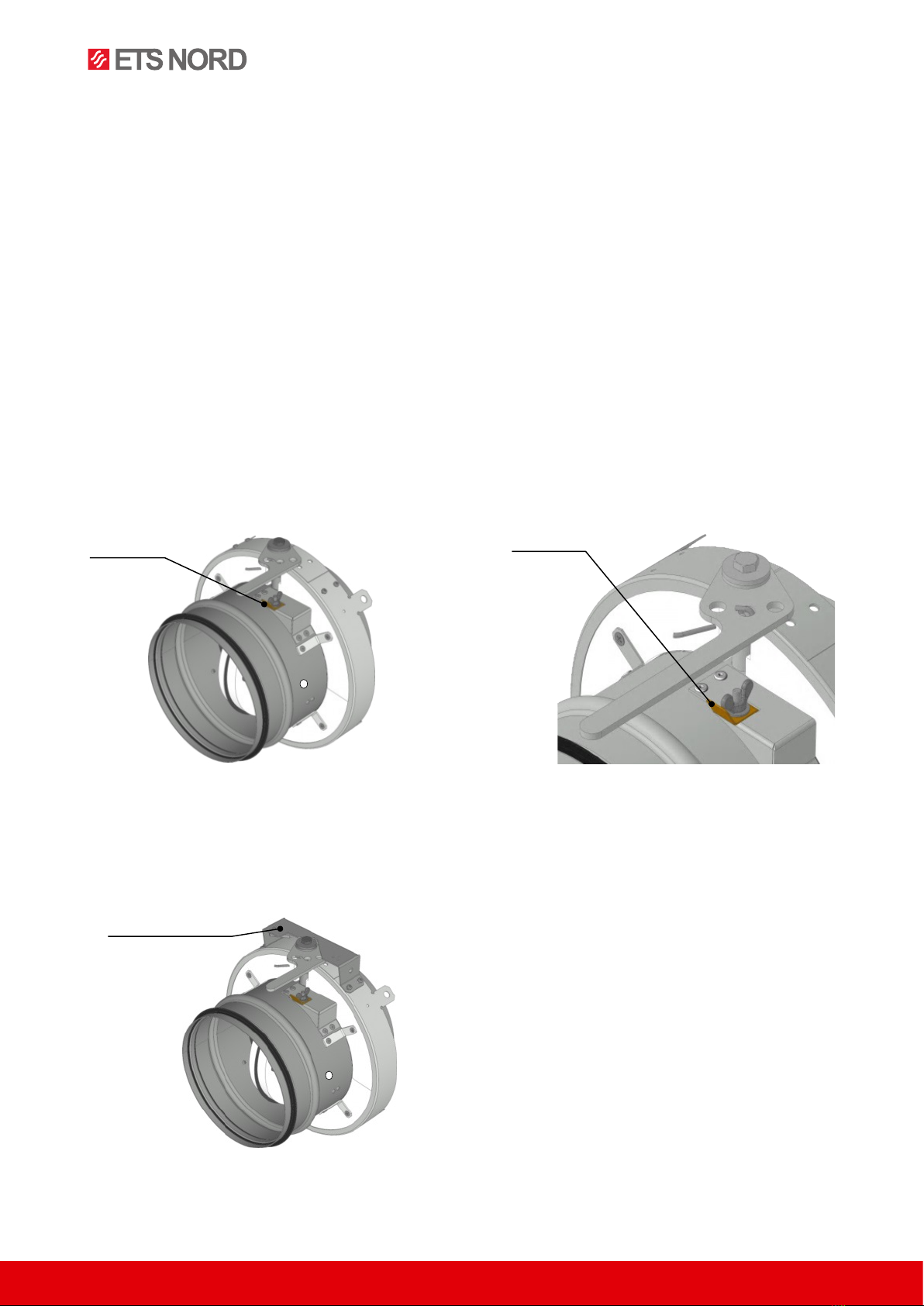

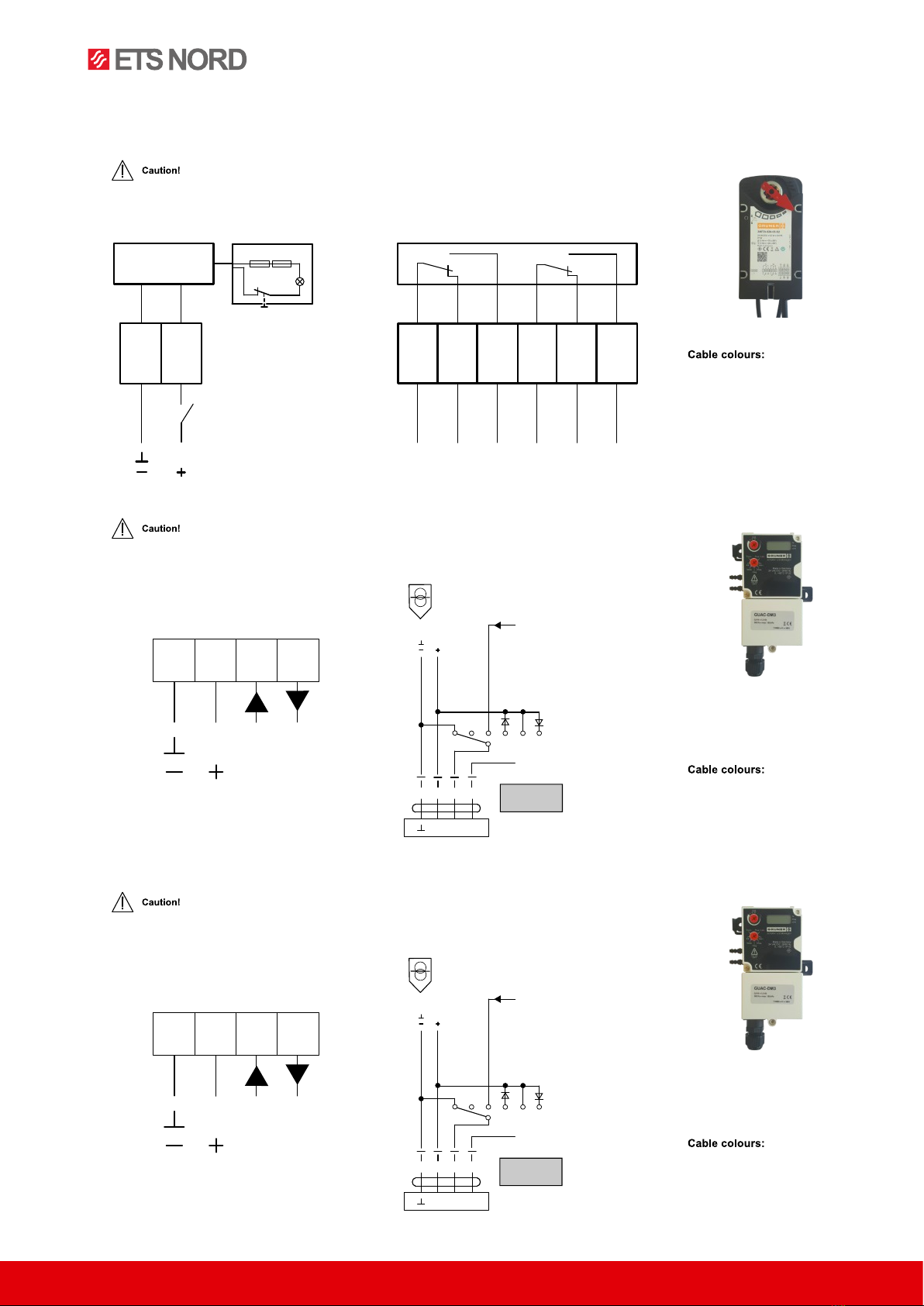

Images are for illustrative purposes.

We reserve the right to make changes. RDT-048-0423 7

®NORDfire |FDMS

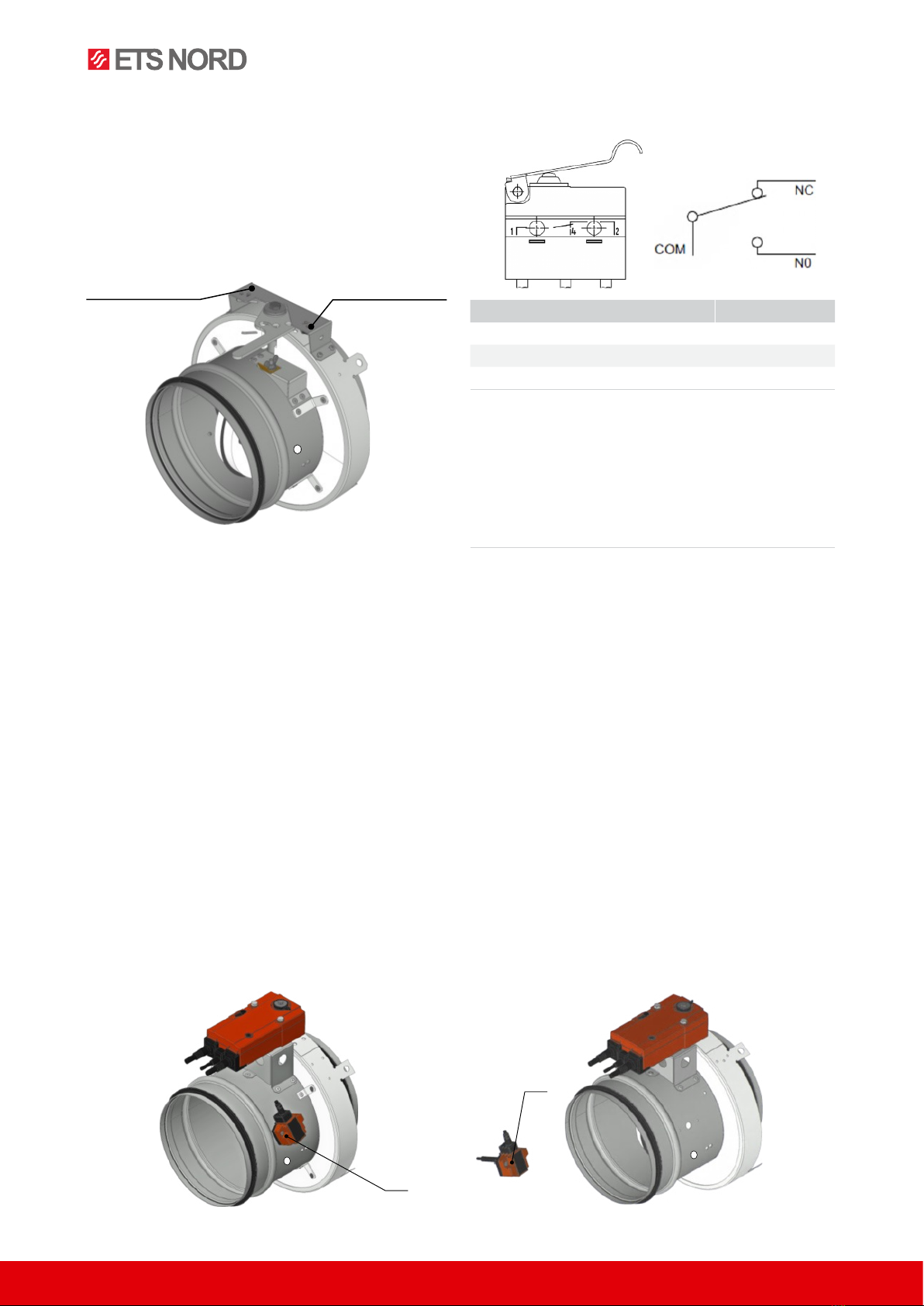

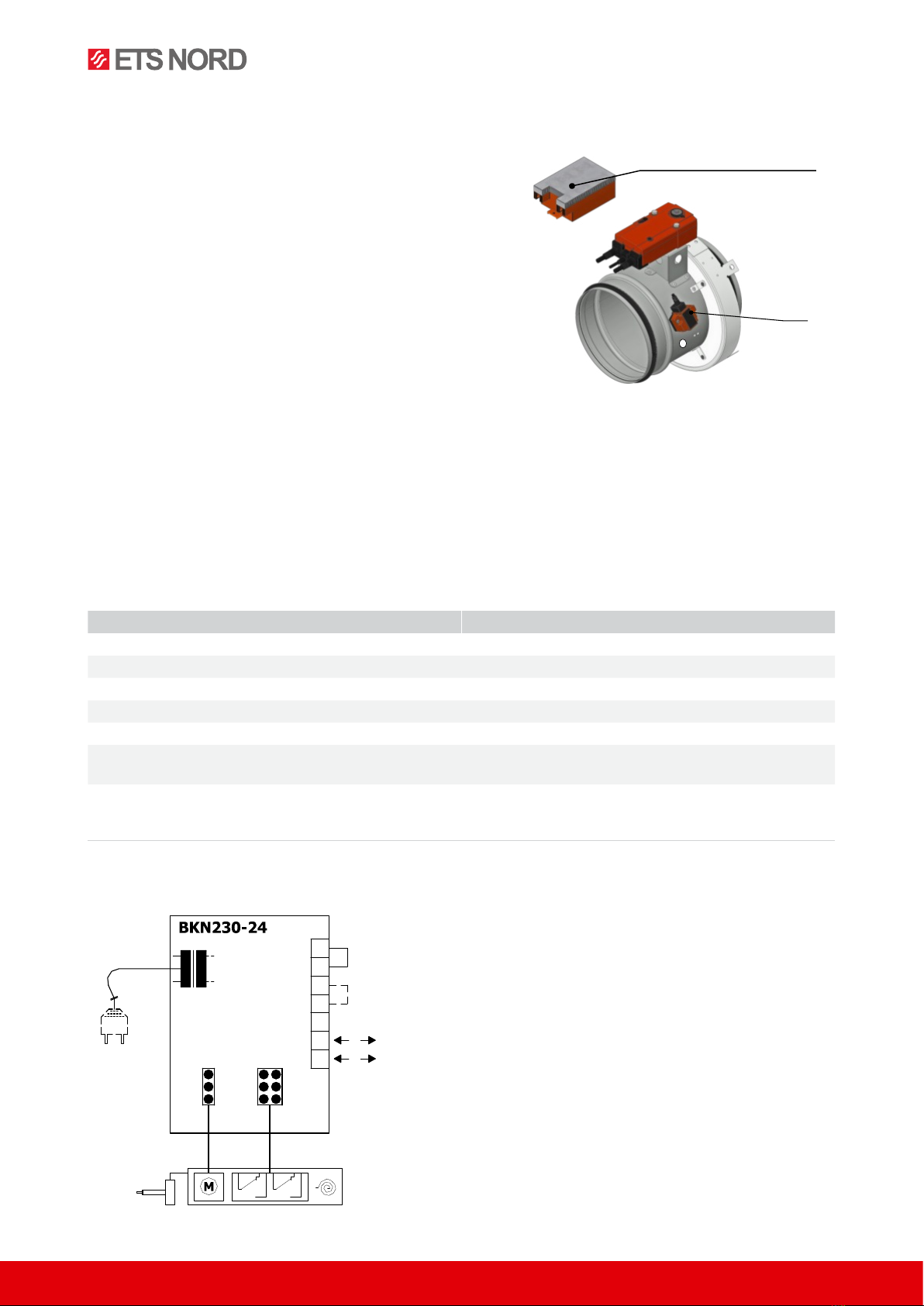

2.5 Design .60 - Damper with Electrical Actuator and Communication and Supply Device

This is design with the communication and supply device

BKN230-24 and the actuator BFL (BFN) 24-T-ST. It simplifies

electrical wiring and interconnection of fire damper. This design

facilitates checking of the damper on site and enables central

control and check of fire damper during by a simple “2-wire”

wiring with superordinate control unit. BKN230-24 is working

as a decentralized network device for supplying of the actua-

tor BFL (BFN) 24-T-ST on one hand and on the other hand it

transmits the signal information about the fire damper position

and failure. Control command SWITCH-ON and SWITCH-OFF

from superordinate system controls via the same wiring to the

actuating mechanism. To allow more simple connection, the

actuator BFL (BFN) 24-T-ST is equipped with two connecting

plugs (one with three jacks and one plug with six jacks). They

are inserted directly to BKN230-24. BKN230-24 is supplied with

a conductor and EURO-plug for connecting to the 230V mains. Two wire cable from superordinate system is

connected to BKN230-24 by means of clamps 6 and 7 in BKN. If the drive is supposed to be controlled without

any signal from the superordinate, it can be switch-on by means of a bridge between clamps 3 and 4 in BKN.

A green LED diode on BKN230-24 is lighting in case the voltage 24V is present in the drive. If the TEST button

on BAT is switched-on or if the power supply (e.g. by a signal from ELECTRICAL FIRE SIGNALISATION) is

disconnected, the fire damper position will be “FAILURE”. It means damper blade goes in position “CLOSED”.

Communication and supply device BKN230-24 has to be placed near the damper (BKN isn´t mounted on damper

body). It is necessary for easy connection of actuator equipped by BKN230-24 device.

Technical data of the device BKN230-24

Communication and Supply Device BKN230-24

Nominal voltage AC 230V 50/60Hz

Power consumption 3,5 W (operating position)

Dimensioning 11 VA (including actuating mechanism)

Protection class II

Degree of protection IP 42

Ambient temperature

Storage temperature

- 30 °C … + 50 °C

- 40 °C … + 50 °C

Connection - mains

- drive

- terminal board

Cable 0,9 m with EURO plug of 26 type

6 pole plug, 3 pole plug

screw terminals for conductor 2×1,5 mm²

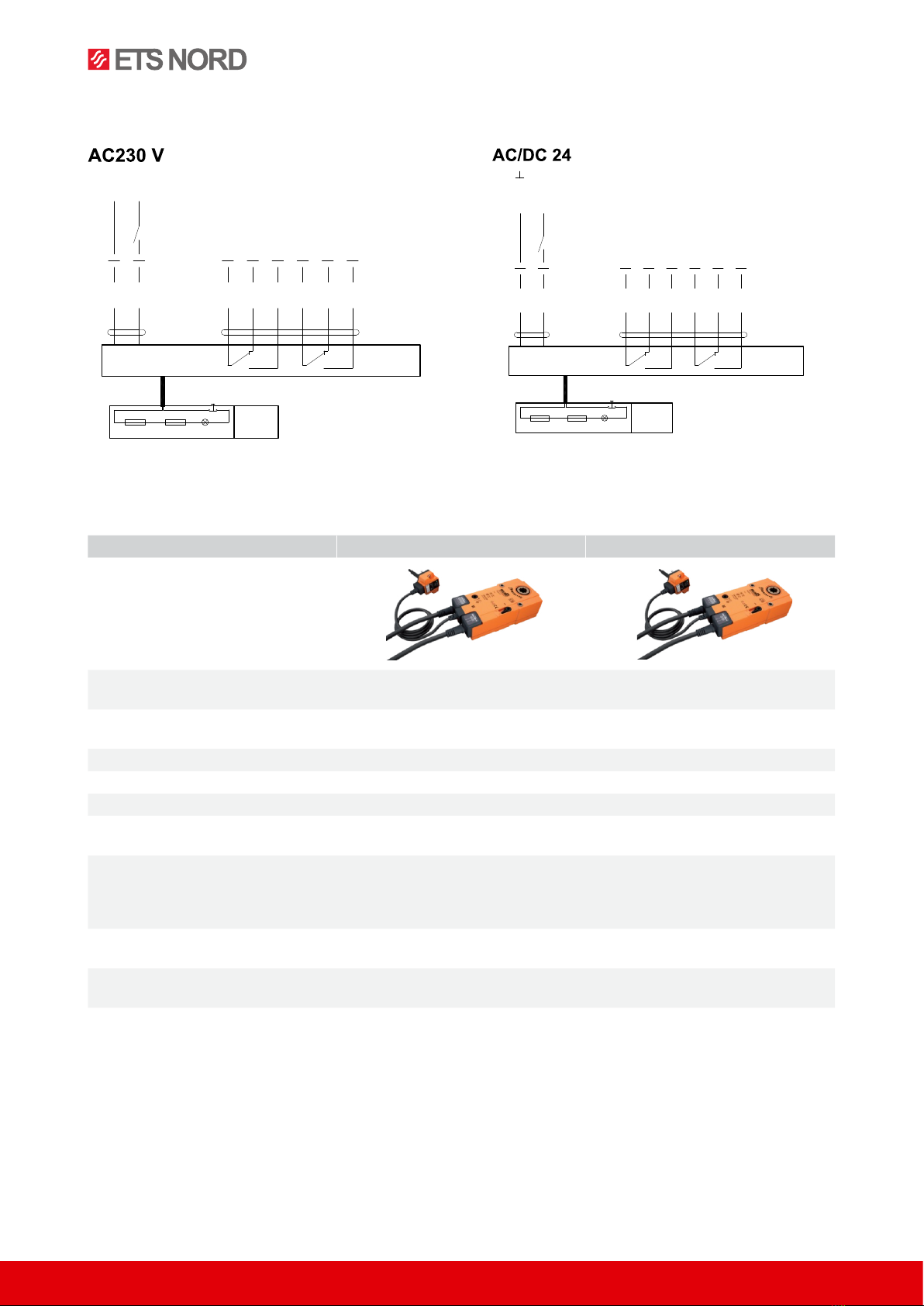

Wiring diagram of the BKN device with actuator, with act. mechanism BFL 24-T-ST, BFN 24-T-ST

1

2

3

4

5

6

7b

a

1)1)

2)

BAT

1) Bridge has been installed by the manufacturer. If needed, it can be removed ad

replaced with a thermoelectric starting mechanism. If terminals 1 and 2 are not

interconnected, safety function is initiated.

2) Bridge can be used only for starting and without BKS24… !

Two conductor wiring to BKS24

Communication unit BKN230-24

BAT