EWIKON HPS III-MHR100 User manual

Page 1/4

General assembly notes / Required tools

1. ATTENTION: Please remove the tip inserts from nozzle body before assembling

or disassembling the HPS III-MH nozzle in the mould!

2. The maximum nozzle temperature is 350 °C (662 °F)

3. Required tools:

HPS III-MHL nozzle, linear version:

• Allen key, wrench size 5 AF

• Torque wrench, adjustment range 16 Nm (11.8 ft·lb)

with insert for wrench size 5 AF

• Threaded screw or threaded rod M4

HPS III-MHR nozzle, radial version

• Allen key, wrench size 3 and 5 AF

• Torque wrench, adjustment range 2 and 11 Nm (1.5 and 8.1 ft·lb)

with insert for wrench size 3 and 5 AF

• Threaded screw or threaded rod M4

Assembly of the nozzle body

1. The nozzle is installed into the mould without tip inserts.

2. Please install the tip inserts according to the “Tip insert assembly” instructions on the

following pages

HPS III-MH hot runner nozzle for direct side gating

Assembly and exchange of tip inserts

Important

safety instruction

During assembly or dis-

assembly of the HPS III-MH

nozzle high temperatures arise.

Risk of burns!

Personal protective

equipment (gloves,

protective goggles)

must be worn during

all work steps.

Tip insert assembly for the HPS III-MHL nozzle, linear version

1. Install the tip inserts. Please ensure that they are positioned correctly and that the sealing

surfaces between tip insert and nozzle are clean. A screw M4 or a threaded rod can be

screwed into the tip insert as an assembly aid.

2. AttachclampingcoverandxitwiththesocketheadscrewsM6x12,withthe

socket head screws M6x12 being screwed from the centre outwards. Use half of the

denedtorque(pleaseseechart).

3. Heat up nozzle to processing temperature (maximum nozzle temperature 350 °C / 662 °F)

andwarmupthemoulduntilthemouldtemperatureisreached.KeeptheresultingΔT

(dierencebetweenprocessingandmouldtemperature)foratleast10minutesbefore

nallyretighteningthescrewswiththematchingtorque.Notadheringtothisprocedurecan

result in damaged sealing sleeves and leakage.

4. RetightensocketheadscrewsM6x12withthedenedtorque(pleaseseechart)fromthe

centre outwards.

5. Install heat protective cover.

Page 2/4

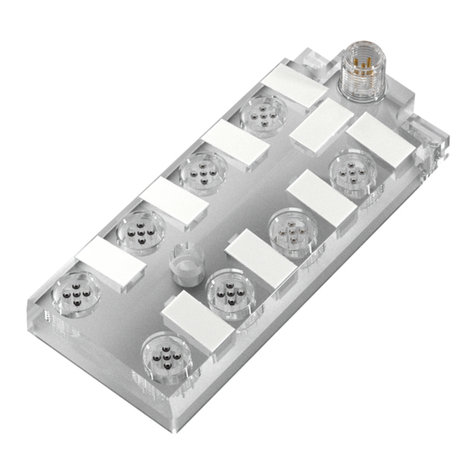

Tip insert

Assembly aid (socket head screw M4)

4x socket head screw

ISO 4762 M6x12-12.9

Clamping cover

B

1

2

4

5Versions of HPS III-MHL linear nozzle

Nozzle Width B [mm] No. of tips No. of screws Torque

(unlubricated)

MHL 93/95

MHL100

42 4 2 11 Nm (8.1 ft·lb)

62 8 4 11 Nm (8.1 ft·lb)

62 4 4 8 Nm (5.9 ft·lb)

62 4 2 11 Nm (8.1 ft·lb)

MHL200 62 4 2 16 Nm (11.8 ft·lb)

Tip insert assembly for the HPS III-MHR nozzle, radial version

1x socket head screw

ISO 4762 M6x10

1. Install the tip inserts. Please ensure that they are positioned correctly and that the sealing

surfaces between tip insert and nozzle are clean. A screw M4 or a threaded rod can be

screwed into the tip insert as an assembly aid.

2. AttachclampingcoverandxitwithcentralsocketheadscrewM6x10.

Usehalfofthedenedtorque(pleaseseechart).

3. ScrewinsocketheadscrewsM4x12crosswise.Usehalfofthedenedtorque

(please see chart).

4. Heat up nozzle to processing temperature (maximum nozzle temperature 350 °C / 662 °F)

andwarmupthemoulduntilthemouldtemperatureisreached.KeeptheresultingΔT

(dierencebetweenprocessingandmouldtemperature)foratleast10minutesbefore

nallyretighteningthescrewswiththematchingtorque.Notadheringtothisprocedurecan

result in damaged sealing sleeves and leakage.

5. RetightencentralsocketheadscrewM6x10withdenedtorque(seetable).

6. RetightensocketheadscrewsM4x12crosswisewithdenedtorque(seetable).

7. Install heat protective cover.

Page 3/4

Tip insert

Assembly aid (socket head screw M4)

4x socket head screw

ISO 4762 M4x12-12.9

1x socket head screw

ISO 4762 M6x10-12.9

Clamping cover

The number of

the M4x12 socket

head screws varies

depending on

the number of

tip inserts.

1

5 6

7

2 3

Versions of HPS III-MHR radial nozzle

Nozzle

Torque (unlubricated)

M4x12 - 12.9 M6x10 - 12.9

MHR 93/95 /

MHR100 / MHR111 4 Nm (3.0 ft·lb) 11 Nm (8.1 ft·lb)

MHR112 / MHR122 2.5 Nm (1.8 ft·lb) Central socket head screw not

available for this version

MHR200 4 Nm (3.0 ft·lb) 2 tips: 6 (4.4 ft·lb)

4 tips: 11 (8.1 ft·lb)

Page 4/4

Technical information subject to alteration • EWIKON 06/2019 • Item no. 13826

EWIKON Heißkanalsysteme GmbH

Siegener Straße 35 • 35066 Frankenberg Tel: (+49) 64 51 / 50 10

Disassembly of nozzles or replacement of tip inserts

Unscrew and remove

clamping cover

Tilt tip insert out of the mould insert and remove it

For most resins the plastic cap can be removed from the tip insert directly after the tip insert has been disassembled and

when it is still hot.

Should this not be possible please use a hot air blower to heat up the resin around the tip insert until the plastic cap can be removed.

Important: To prevent the tip inserts from damaging while cleaning them never heat up the tip

inserts to more than 350 °C. Therefore, it is not allowed to burn the resin around the tip inserts

or to use gas ames.

Cleaning of tip inserts

Attention: In order to avoid damage to the tips the nozzle

must be heated up to processing temperature before deinstalling the tip inserts.

1. Heat up nozzle to processing temperature (maximum nozzle temperature 350 °C / 662 °F) and warm up the mould until the mould

temperatureisreached.KeeptheresultingΔT(dierencebetweenprocessingandmouldtemperature)foratleast10minutesto

heat the gate area through. To avoid a leaking out of melted plastic from the nozzle body the temperature can be minimally

decreased if necessary. At any time the plastic must be elastic enough to deinstall the tip insert without damage and increased

eort.Thismustbecheckedforeachindividualcasebeforedeinstallation.

2. Deinstall heat protective cover (if installed).

3. Deinstall clamping cover according to the following procedure to avoid tilting:

HPSIII-MHL nozzles: Unscrew the socket head screws in the following order: 1 - 3 - 4 - 2.

HPSIII-MHR nozzles: Unscrew the socket head screws M4 crosswise, unscrew the central socket head screw M6 last.

4. Deinstall tip inserts according to the shown scheme. A threaded rod can be screwed into the tip insert as a deinstallation tool.

Tilt tip inserts carefully to the outside and remove them.

5. Cool down nozzle to room temperature.

6. The nozzle can be disassembled when all tip inserts have been removed.

This manual suits for next models

11

Other EWIKON Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Festo

Festo HGDS Series operating instructions

Erskine Attachments

Erskine Attachments 200001 Operator's manual

SCHUNK

SCHUNK PLG 20 Translation of original operating manual

TMG

TMG STS35 product manual

ABB

ABB HT606930 Operation manual

Jerguson

Jerguson LUMASTAR EPL-100 Installation, operation & maintenance instructions