CNC QB2 User manual

Page 1

QB2 CNC

User guide

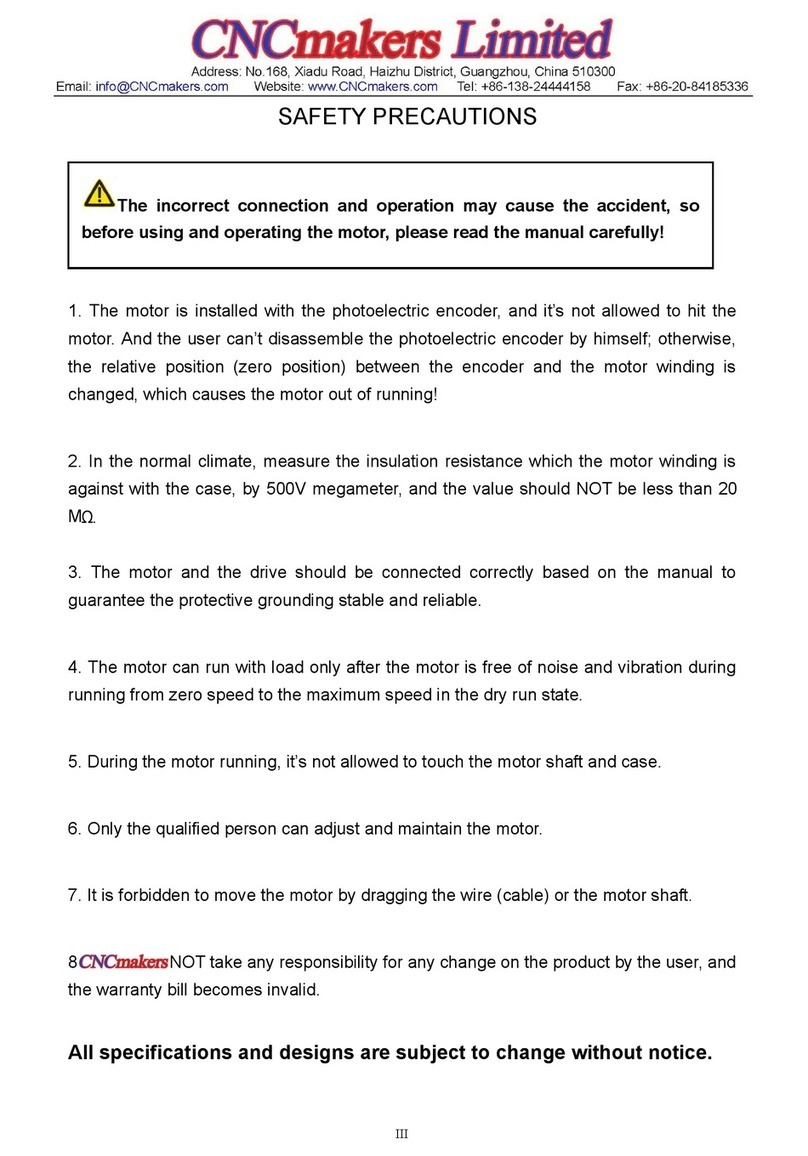

Safety precautions

Like any power tool, operating and using a CNC machine can be dangerous. Diligence must be applied when operating

any machine. It is recommended to wear appropriate PPE such as eye protection and ear muffs for your own safety.

NEVER leave a powered machine unattended at any time!

In the event of an issue or if something doesn’t seem right, it is recommended to immediately disconnect power to

the machine and unplug it from the wall power outlet. Contact our customer support team if you have any concerns

about your machine.

Always ensure your machine is free and clear of any swarf, dust or other obstructions that may impact the motion of

your machine. We highly recommend the use of a Dust shoe and vacuum system for keeping your machine clean and

clear of swarf and dust.

Always ensure to follow the maintenance guide at the bottom of this manual after initial assembly and setup and also

periodically to ensure your machine always performs to its optimal capacity.

Page 2

Unboxing your Machine and setup

1. Look for the screws on the crate that have purple paint on them. Use a Philips head

screw driver or impact driver bit to unscrew the main crate packaging. Once

unscrewed, get a friend to help you carefully lift the crate cover off. This will expose

the machine and components underneath. If you do not have a friend to help you can

unscrew the entire top cover and dismantle the packaging from top down.

2. Once your machine is exposed you can unscrew the electronics board from the front

of the crate and slide it onto the machines spoil board for easy transport to its home

location bench or table. At this point you can also carefully remove the small parts

accessories box that is hanging onto the Gantry. This usually contains your endmills,

laser goggles, Dust shoe and other accessories you may have purchased with your

machine.

Page 3

3. Now that we have everything loose it is a good idea to get a friend or 3 to help move

your machine on to your table/bench. Be very careful to avoid skewing the machine

while transporting it and under no circumstances should you ever grab the ballscrews.

Always ensure the ballscrews are protected to avoid bending them. They control your

machines movement so keeping them nice and straight and under the right tension is

very important.

Some users may choose to move the entire pallet and bottom packaging onto the bench

and run the machine from there. This is OK to do also. If doing this, keep the machine

fastened to the pallet itself.

If you have removed the pallet and crate baseboard from the machine it is

recommended to use the 6 angle brackets; 3 on front, 3 on back (that secured your

machine to the pallet originally) to secure the machine down to the new bench. Start

with the 3 on the rear of the machine and check squareness of your machine. If the

machine is square then secure the front down.

4. Once your machine is in position it is time to find a spot for your electronics. To make

it easy, you can mount the existing MDF board that has the electronics fixed to it to

the front of your machines table. This will provide easy access to the VFD and E-stop.

You can also choose to unmount the electronics from the MDF board and position

them where you like as long as cables will reach of course. It is not recommended to

power up just yet but we will shortly!

Mounting suggestion using the existing MDF electronics mounting board:

Page 4

Things to check before powering on!

We’re almost there! It’s important to do some quick checks to ensure your machine is ready

to go. Sometimes in transport, things can wiggle loose. Here are some things to check.

❖Check all nuts and bolts on the machine.

❖Check the green connectors that connect all the wires. They should be firm and

secure. Try giving each wire a slight tug in each screw terminal to make sure

they are definitely secure!

PRO TIP: You can familiarize yourself and follow the maintenance guide at the

bottom of these instructions to check that everything is nice and secure after the

machine has been moved into its home location.

❖Download and install our CNC3D Commander software if you have a Windows

computer. It can be found here:

https://www.cnc3d.com.au/commander

Let’s plug it in!

Take the single power plug lead and plug it directly into a wall socket. It is NOT

recommended to run the machine from a power board. Once powered on, your Nighthawk

controller fan will come on and so will the display on your VFD.

You can now either choose to connect to your machine via USB on your PC or wifi via by

directly accessing the Nighthawk controllers web interface.

We highly recommend visiting the user manual for the Nighthawk controller found here:

https://www.cnc3d.com.au/nhc

Page 5

PLEASE NOTE

Some key things with the QB2

Machine settings

Our trained team preconfigure every aspect of your machine prior to it being sent to you.

You do not need to change any settings in your controller and definitely DO NOT load any

profiles onto your machine within the Profiles tab of our Commander software.

By default, we set soft limits to the maximum travel limits of your X and Y axis. Whenever

you first power on your machine you MUST home your machine. If your controller is ever in

an Alarm state, you can reset it by clicking the “Unlock” button in Commander. If this fails to

clear, hit the E-stop button in Commander then the unlock button.

Page 6

Initial setup steps once powered on

Surfacing your spoil board

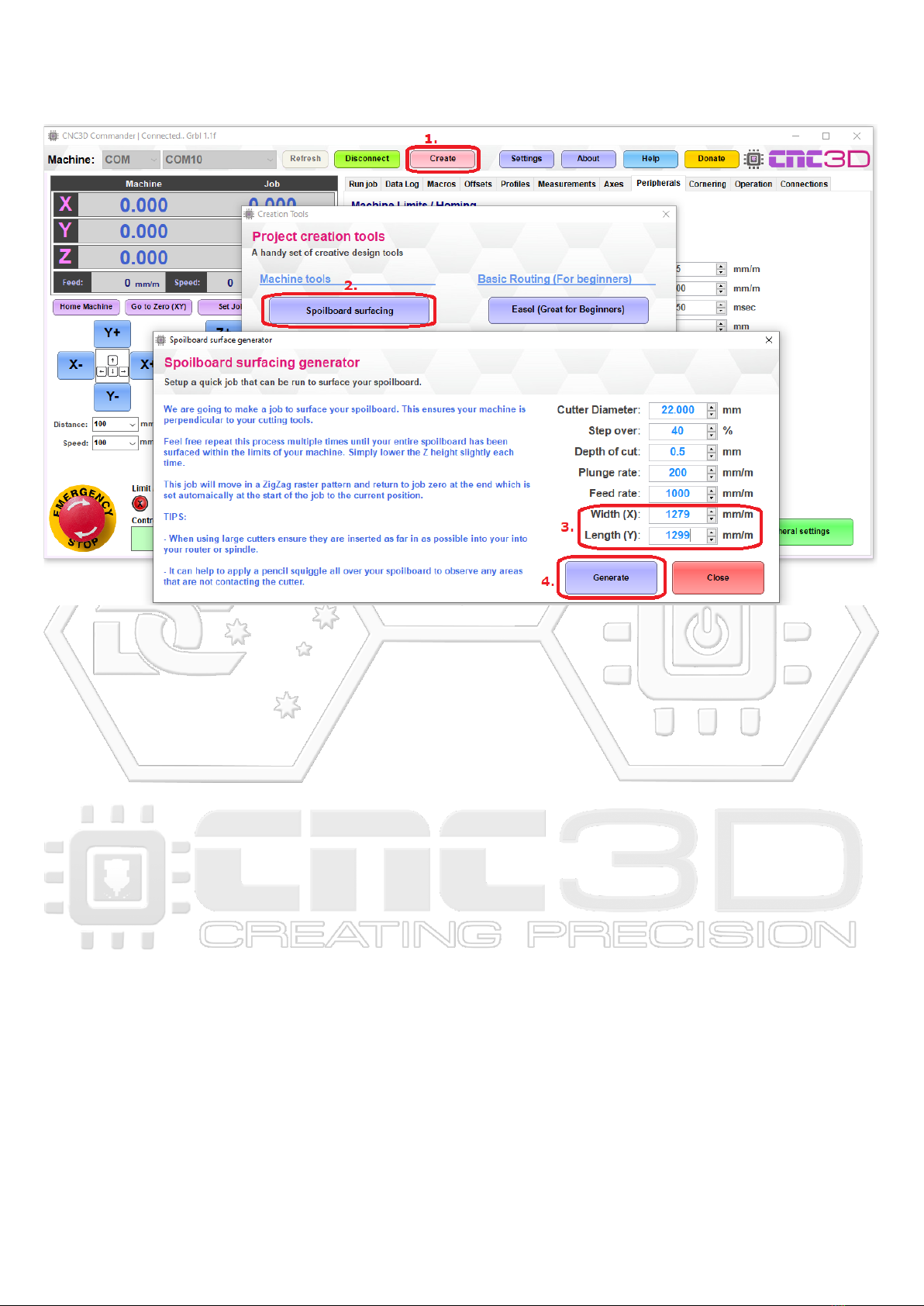

It is highly recommended to surface the top of your spoil board. Surfacing the entire

working area means that your tool will always be perpendicular to your cutting tool.

To do this, follow the steps above for making a rectangle but make one the size of your

actual working area. This information is stored in the Peripherals tab of commander, do not

use a measuring tape to get these measurements as the physical size and the working size

will be different. See example below for where to find these measurements:

In this case we can see our X and Y maximum travel limits in Red and the homing pull off

value in Orange. To work out our machine’s maximum travel we need to deduct the homing

pull off from the maximum travel. In this case:

X will be [1282 - 3 = 1279mm]

Y will be [1302 –3 = 1299mm]

When using the spoil board surfacing wizard in Commander, we have preconfigured some

values that suit the QB2 CNC design. It is recommended to keep most of the settings but to

change the “Width (X)” and “Length (Y)” values to match your machine. Once you have

entered these values, you can save this job by clicking the “Generate” button. This will

prompt you to save the file. Choose a location you can easily find it.

Page 7

Once done, close out of the Surfacing wizard and the Creation tools. This should take you

back to the main Commander window.

The next step is to prepare to run the job! To do this we need to home your machine first.

Once homed, loosen off your collet nut on your spindle and insert a 6mm collet and the

22mm surfacing bit provided with your QB2 CNC. Please ensure the surfacing bit is inserted

quite high into the collet but not all the way in. Once in, tighten the collet nut up.

Note: Extreme force is not required to tighten your collet nut. Just make sure it is secure.

If you ordered one, attach your dust shoe and vacuum hose at this time as well.

Get a marker and squiggle some lines all over your spoil board. This will allow us to tell if

surface has been machined or not. See photo below of areas that were missed on our first

pass trying to surface the spoil board.

Page 8

Using the jogging buttons in Commander, put a piece of scrap paper under the surfacing bit

and lower the Z down until it is just touching the paper. Ensure to reduce your downward

travel distance as you get closer to the surface to ensure the machine does not crash into

the spoil board.

Once you feel resistance when moving the paper around you can remove the paper and

discard it.

Page 9

Back in our Commander software, Click the “Zero job” button. Then click on Load Job and

select the file you saved out of the surfacing wizard. Once loaded, hit the green run button

on your VFD and wait until the spindle is up to speed. Once at speed, turn on your vacuum

extraction (if attached) and hit the ‘Run Job’ button. See sequence here:

Page 10

This will start the process of surfacing your spoil board. It may take a long time to complete

this process. If something doesn’t seem right then immediately hit the E-stop button on your

control box or via our Commander software.

Note: Using the E-stop on your Nighthawk controller or via our Commander software will

only stop your machine moving but will not stop your spindle. If you want to stop both the

spindle and machine quickly, we recommend using the mechanical E-stop on your control

box.

Once the job is complete check to see if we removed all of the markings on the bed. If we

didn’t, repeat the process again 1mm lower than last time until the entire area is surfaced.

SOME GREAT NEWS!

The process we have just followed here is basically how every job will be run if streaming

the job. You will be running all future jobs like this. Also keep in mind you can upload jobs to

your Nighthawk controller and run them off your SD card. Saving this handy spoil board job

will make it easy next time you want to freshen up your surface OR after you replace your

spoil board.

Page 11

Tramming your spindle

You may notice after surfacing you have some ridges in your spoil board. This is due to the

spindle needing some minor adjustments to be truly “flat” with your spoil board.

During assembly of your machine our team align your spindle and bracket using engineering

squares. This is fine for general tramming but extra tramming steps can be performed to

ensure you have smooth bottom results with larger cutting tools. The best way to test your

tramming is to create a small rectangle job in Easel or Carbide Create or use the new Spoil

board surfacing wizard in Commander’s Creation Tool section. If using the Commander spoil

board wizard make a 100x100mm rectangle and insert your supplied 22mm surfacing bit and

6mm collet.

Page 12

Tramming Side to side

Your Z axis plate has 4 bolts that hold it to your X axis plate. These bolts can be loosened off

to allow you to tilt the angle of your spindle for tramming. There is a centre locating pin

between these plates to make this process easy. It is recommended to loosen off 3 of the

bolts quite loosely while keeping one bolt slightly loose to allow some control when

tramming. The 4 bolts are located here:

Page 13

Tramming Front to back

As time goes on, we here at CNC3D like to innovate and improve on our machine designs to

make things like tramming your spindle an easier and user-friendly process. One of these

improvements is the addition of a “shoulder bolt”on the big Y-axis plates. There will be

some machines that have these bolts and some that do not so ensure you are following the

correct tramming procedure for your machine.

If your gantry has a shoulder bolt

Shoulder bolts have a washer on the bolt as seen below in BLUE. If you have no washer then you need to follow

the below guide for “NO shoulder bolt”.

If you need to adjust your tramming front to back then we need to look at adjusting the

gantry angle.

To do this, we first need to loosen off *slightly* the shoulder bolt highlighted below in BLUE.

Once these are loose, loosen all of the bolts highlighted in YELLOW below.

Page 14

Repeat this process on the other side of the machine in the exact same pattern as the first

side. This will allow us to “twist” the gantry front to back. Make slight adjustments at a time

to both sides and re-secure the BLUE bolt first, then the YELLOW bolts. Check if it is

trammed correctly by cutting into your test piece. Repeat these adjustments until the test

piece seems to surface quite flat with no ridges showing up as it skims the surface.

Page 15

If your gantry has NO shoulder bolt

If you need to adjust your tramming front to back then we need to look at adjusting the

gantry angle.

To do this, we first need to loosen off the 2 bolts that secure your ball screw. These are

highlighted below in BLUE. Once these are loose, loosen all bearing block bolts highlighted

in YELLOW below. With the RED bolt, ever so slightly loosen it. It needs to keep the gantry

plate in a fixed position.

Page 16

Repeat this process on the other side of the machine in the exact same pattern as the

original side. This will allow us to “swing” the gantry front to back. Make slight adjustments

at a time to both sides and re-secure the RED bolt first, then the YELLOW, then finally the

BLUE bolts. Check if it is trammed correctly by cutting into your test piece. Repeat these

adjustments until the test piece seems to surface quite flat with no ridges showing up as it

skims the surface.

To look up more advanced methods of spindle tramming a quick YouTube search for

“spindle tramming” should return a variety of results.

Repeat the process of surfacing your spoil board again until you are happy with the bottom

finish of your spoil board.

Your machine should now be correctly setup and ready to go!

😊

Page 17

Getting started with your laser

LASER SAFETY WARNING!

Always ensure you are wearing laser safety goggles and other

appropriate PPE when using any high-powered lasers. Please

ensure the laser is pointing away from people and sensitive

materials.

Remember when plugging in or unplugging any wiring

INCLUDING the laser connector, it is vital to ensure the machine

is NOT powered up. So called “hot-swapping”can cause

irreparable damage to the laser or the Nighthawk Controller!

Page 18

1. Raise your spindle high enough so that you can fit the laser to the side of the Right-

hand side of your spindle bracket. Use the 2 bolts provided to secure it to the

bracket. We always recommend fitting it to the right-hand side so you can still

safely home when the laser is attached. POWER OFF YOUR MACHINE then connect

to white laser plug to the top of the laser.

2. Once firmly attached you can power up the machine and connect to it in

Commander remembering that you will need to re-home it before being able to jog

any axis. Use the alloy spacer provided with your laser to set the correct focal point

of the laser. To do this, position the spacer under the laser head and carefully

lower your Z axis until the brass laser head is just clearing the alloy spacer. Take

care not to damage the laser by crashing into the spacer!

We recommend following our video guide here for using your laser:

https://www.youtube.com/watch?v=8Syf86xmeZs&t

Some key laser points!

Always remove your laser when using your spindle and never leave

your machine unattended when using it. Also ensure you have

adequate extraction to your work area as laser jobs can produce

harmful fumes when operating.

Page 19

QB2 CNC Maintenance guide

It is recommended to visit this guide immediately after positioning your machine

and setting it up. It is also recommended to periodically visit this guide to ensure

smooth operation and a long service life of your machine or if something isn’t

quite right such as cuts not coming out right or Z axis depth inconsistent.

1. Check ALL of the nuts and bolts on your machine.

Visit all of the nuts and bolts on your machine. You will need a 2mm, 2.5mm, 3mm

and 4mm allen keys and a small flat blade screwdriver to check every connection. Test

each bolt and tighten them if they are loose. This includes the green connectors that

join the wires together on your limit switches and stepper motors.

IMPORTANT: When tightening any allen key bolts it is recommended to use a solid

allen key end NOT any ball end side of an allen key or you run the risk of stripping the

bolt heads.

2. Check to make sure your gantry is square.

It is important to ensure your machine frame stays square. Use a tape measure or

ruler to make sure both sides of the machine are equal distance from the front. To do

this, measure from the gantry side plate to the front plate. Repeat the same process

on the other side of the machine and record the results. If one side is more than 1mm

out from the other side you need to manual turn the lead screw on one side of the

machine until it is within 1mm of the other side. You can look at repeating this simple

process daily or every 1-2 weeks. The more frequently it is performed, the better your

machine will operate.

Page 20

Table of contents

Other CNC Industrial Equipment manuals