Excel Technology SYNRAD FH Series User manual

-~

ARTISAN

®

~I

TECHNOLOGY

GROUP

Your definitive source

for

quality

pre-owned

equipment.

Artisan Technology

Group

Full-service,

independent

repair

center

with

experienced

engineers

and

technicians

on staff.

We

buy

your

excess,

underutilized,

and

idle

equipment

along

with

credit

for

buybacks

and

trade-ins

.

Custom

engineering

so

your

equipment

works

exactly as

you

specify.

•

Critical

and

expedited

services

•

Leasing

/

Rentals/

Demos

• In

stock/

Ready-to-ship

•

!TAR-certified

secure

asset

solutions

Expert

team

ITrust

guarantee

I

100%

satisfaction

All

tr

ademarks,

br

a

nd

names, a

nd

br

a

nd

s a

pp

earing here

in

are

th

e property of

th

e

ir

r

es

pecti

ve

ow

ner

s.

Visit our website - Click HERE

operators

manual

6500 Harbour Heights Parkway

Mukilteo, WA 98275

1-800-SYNRAD1

Tel: (425) 349-3500

Fax: (425) 485-4882

E-mail: [email protected]

Web site: http://www.synrad.com

®

An Excel Technology Company

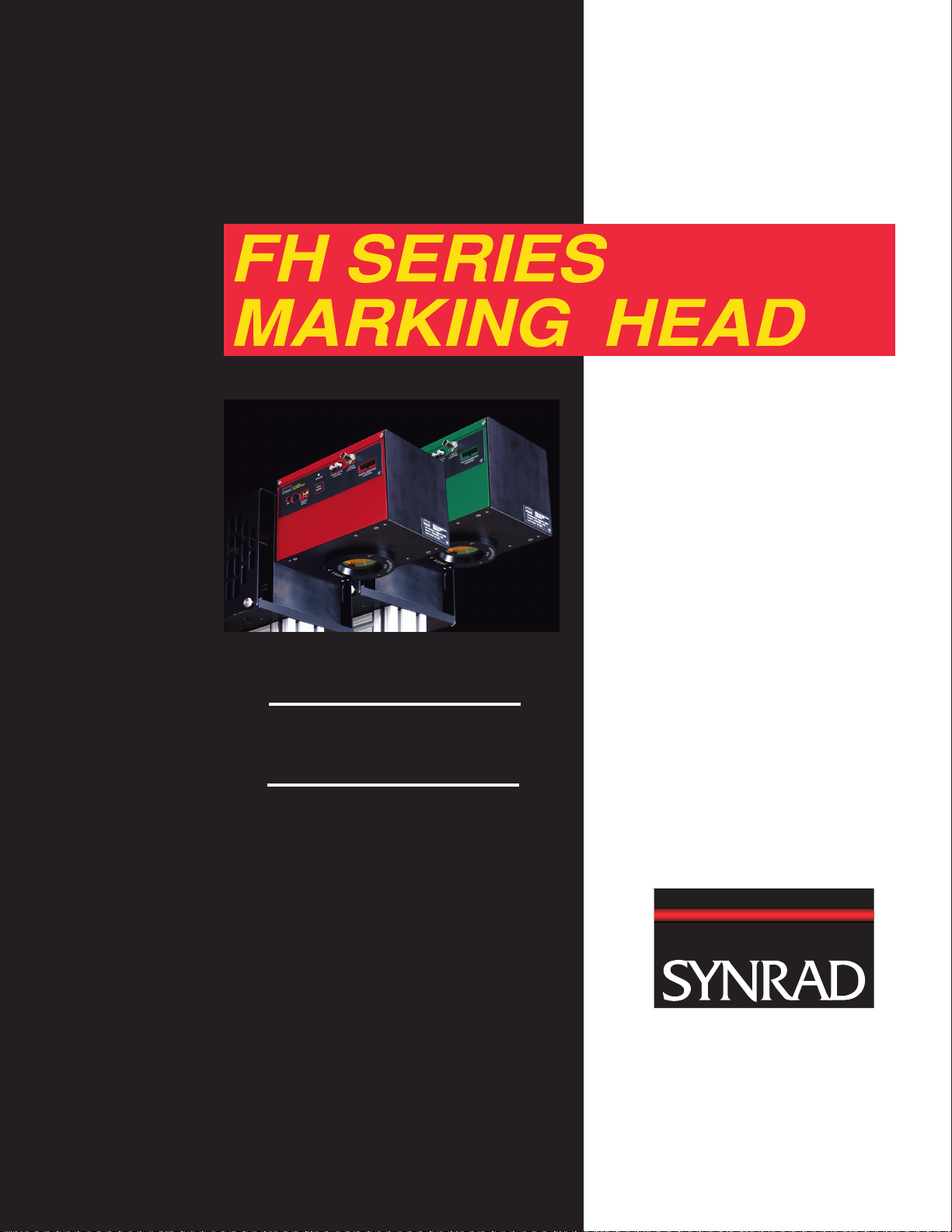

FH Series Marking Head

Operator’s Manual

for

Index and Tracker models

Version 2.0

Released June 2000

Part number 900-17922-01

6500 Harbour Heights Parkway

Mukilteo, WA 98275

1-800-SYNRAD1

Tel: (425) 349-3500

Fax: (425) 485-4882

E-mail: [email protected]

Web site: http://www.synrad.com

®

An Excel Technology Company

table of contents

iii

Synrad FH Series Marking HeadFH Series Marking Head

FH Series Marking HeadFH Series Marking Head

FH Series Marking Head operator’s manual

Getting Started 1

Laser Safety

Operation 2

Tracker 3

Hazard information................................................................................... 1

Terms ........................................................................................................................ 1

General hazards ........................................................................................................ 1

Label locations .......................................................................................... 3

Agency compliance .................................................................................. 4

Federal Communications Commission requirements ............................................. 4

Center for Devices and Radiological Health requirements .................................... 4

European Union requirements ................................................................................ 5

Declaration of Conformity ....................................................................... 7

Inventory .................................................................................................. 1-2

FH Series Marking Head ......................................................................................... 1-3

Mounting Rail .......................................................................................................... 1-4

Laser ......................................................................................................................... 1-4

Introduction.............................................................................................. 1-5

Marking system components ................................................................................... 1-5

Mounting .................................................................................................. 1-6

Mounting Rail .......................................................................................................... 1-6

L-bracket .................................................................................................................. 1-6

FH Head ................................................................................................................... 1-6

Laser ......................................................................................................................... 1-7

Connecting ............................................................................................... 1-8

DC Power cable ....................................................................................................... 1-8

Fiber Link Controller Card ..................................................................................... 1-9

Laser Control cable .................................................................................................. 1-11

WinMark Pro software ............................................................................. 1-12

System requirements ................................................................................................ 1-12

Installation ............................................................................................................... 1-12

Controls and indicators ............................................................................ 2-2

Control panel ........................................................................................................... 2-2

Initial start-up ........................................................................................... 2-3

Stand-alone operation ............................................................................................. 2-3

Computer-controlled operation .............................................................................. 2-5

Introduction.............................................................................................. 3-2

Tracker system components ..................................................................................... 3-2

Determining line speed ............................................................................ 3-3

WinMark Pro software ............................................................................. 3-5

Tracking tab ............................................................................................................. 3-5

Additional hardware................................................................................. 3-7

Rotary position encoder .......................................................................................... 3-7

Part sensor ................................................................................................................ 3-11

DC power supply ...................................................................................................... 3-14

Marking .................................................................................................... 3-15

Text .......................................................................................................................... 3-15

table of contents

iv Synrad FH Series Marking HeadFH Series Marking Head

FH Series Marking HeadFH Series Marking Head

FH Series Marking Head operator’s manual

Tracker (cont.)

Maintenance/Troubleshooting 5

Index

Appendix A

Technical Reference 4

Appendix B

Graphics ................................................................................................................... 3-17

Repositioning marks ................................................................................................ 3-17

Positioning for best quality ...................................................................................... 3-18

FH Head technical overview .................................................................... 4-2

Control circuitry ...................................................................................................... 4-2

Marking head ........................................................................................................... 4-2

Lens specifications ................................................................................................... 4-2

Custom test mark feature.......................................................................... 4-3

Overview .................................................................................................................. 4-3

Test Mark Control options ...................................................................................... 4-3

Creating a custom test mark .................................................................................... 4-4

Setting Test Mark Control options ......................................................................... 4-5

Downloading a custom test mark file ...................................................................... 4-5

Marking automation ................................................................................. 4-6

Connecting to parts handling equipment ............................................................... 4-6

Digital input circuitry .............................................................................................. 4-7

Digital output circuitry ............................................................................................ 4-9

Optional FLCC features ........................................................................... 4-11

Fast Acting Safety Interlock (FASI) ....................................................................... 4-11

DIP switch settings .................................................................................................. 4-12

General specifications .............................................................................. 4-13

FH package outline drawing ..................................................................... 4-14

FH Head / Model 48-1/48-2 package outline drawings ........................... 4-15

FH Head / Model 48-5/Evolution 100 package outline drawing ............. 4-17

FH Head / Evolution 125 package outline drawing ................................. 4-18

FH Head / Model 48-1/48-2 mounting .................................................... 4-19

FH Head / Model 48-5/Evolution 100/125 mounting ............................. 4-20

Maintenance ............................................................................................. 5-2

Daily inspections ...................................................................................................... 5-2

Cleaning the focusing lens ...................................................................................... 5-2

Troubleshooting ........................................................................................ 5-5

FH Series Marking Head ......................................................................................... 5-5

FH Series Tracker Marking Head ............................................................................ 5-5

Fiber Link Controller Card (FLCC) ....................................................................... 5-7

Mounting stand ........................................................................................ A-2

Parts list .................................................................................................... A-3

Tracker Motion Sensing Kit ..................................................................... B-2

Component suppliers ................................................................................ B-3

table of contents

v

Synrad FH Series Marking HeadFH Series Marking Head

FH Series Marking HeadFH Series Marking Head

FH Series Marking Head operator’s manual

Figure i FH Marking Head hazard label and CE label locations ....... 3

Figure ii European compliance mark .................................................. 6

Figure 1-1 Shipping box contents.......................................................... 1-2

Figure 1-2 Typical FH Series marking system ........................................ 1-5

Figure 1-3 Power Input connector polarity ........................................... 1-8

Figure 1-4 Fiber optic connectors .......................................................... 1-10

Figure 2-1 Control panel ....................................................................... 2-2

Figure 2-2 Test pattern ........................................................................... 2-4

Figure 3-1 Typical FH Series Tracker marking system ........................... 3-2

Figure 3-2a Part pitch greater than (lens field size - part length) ........... 3-3

Figure 3-2b Part pitch equal to (lens field size - part length) .................. 3-3

Figure 3-2c Part pitch less than (lens field size - part length) ................. 3-4

Figure 3-3 Tracking tab .......................................................................... 3-5

Figure 3-4 Part sensor output waveform ................................................ 3-5

Figure 3-5 Drawing Canvas coordinates relative to Tracker ................. 3-6

Figure 3-6 Wiring diagram for NPN or N-channel encoders ................ 3-8

Figure 3-7 Wiring diagram for PNP or P-channel encoders .................. 3-8

Figure 3-8 Linestack mark ..................................................................... 3-10

Figure 3-9 Wiring diagram for NPN or N-channel sensors ................... 3-12

Figure 3-10 Wiring diagram for PNP or P-channel sensors ..................... 3-12

Figure 3-11 Part sensor setup ................................................................... 3-13

Figure 3-12 Sample text mark.................................................................. 3-15

Figure 3-13 Beam/mark motion ............................................................... 3-16

Figure 3-14 Marking orientation ............................................................. 3-16

Figure 3-15 Configure Marking Order dialog box ................................... 3-17

Figure 3-16 Positioning mark across axis of motion ................................ 3-18

Figure 3-17 Positioning mark for best quality.......................................... 3-18

Figure 4-1 Test Mark Control dialog box .............................................. 4-3

Figure 4-2 Physical layout of Parts Handling Control connector ......... 4-6

Figure 4-3 Input circuit .......................................................................... 4-7

Figure 4-4 5 V logic IC input ................................................................. 4-8

Figure 4-5 Relay or foot switch input .................................................... 4-8

Figure 4-6 Output circuit ....................................................................... 4-9

Figure 4-7 Output to isolated I/O module ............................................. 4-10

Figure 4-8 Output to relay driver ........................................................... 4-10

Figure 4-9 Output to TTL or CMOS logic interface ............................ 4-10

Figure 4-10 DIP switch settings ............................................................... 4-12

Figure 4-11 FH Marking Head package outline and

mounting dimensions ........................................................... 4-14

Figure 4-12 FH Head / Model 48-1/48-2 package outline and

mounting dimensions ........................................................... 4-15

List of Figures

table of contents

vi Synrad FH Series Marking HeadFH Series Marking Head

FH Series Marking HeadFH Series Marking Head

FH Series Marking Head operator’s manual

List of Figures (cont.)

Figure 4-13 FH Head / Model 48-1/48-2 package outline and

mounting dimensions ........................................................... 4-16

Figure 4-14 FH Head / Model 48-5/Evo 100 package outline and

mounting dimensions ........................................................... 4-17

Figure 4-15 FH Head / Evolution 125 package outline and

mounting dimensions ........................................................... 4-18

Figure 4-16 FH Head / Model 48-1/48-2 mounting drawing .................. 4-19

Figure 4-17 FH Head / Model 48-5/Evolution 100/125 mounting

drawing ................................................................................. 4-20

Figure A-1 Mounting stand .................................................................... A-2

List of Tables

Table i European Union Directives .................................................. 6

Table 1-1 Shipping box contents.......................................................... 1-3

Table 1-2 Shipping box contents.......................................................... 1-4

Table 1-3 Shipping box contents.......................................................... 1-4

Table 2-1 Test pattern dimensions........................................................ 2-4

Table 3-1 Rotary position encoder specifications ................................. 3-7

Table 3-2 Part sensor specifications ...................................................... 3-11

Table 3-3 Power supply specifications .................................................. 3-14

Table 4-1 FH lens specifications ........................................................... 4-2

Table 4-2 Parts Handling Control connector pin assignments ............ 4-7

Table 4-3 Input signal parameters......................................................... 4-8

Table 4-4 Output signal parameters ...................................................... 4-9

Table 4-5 DIP switch / signal relationships .......................................... 4-11

Table 4-6 Factory DIP switch settings .................................................. 4-12

Table 4-7 FH Series Marking Head general specifications ................... 4-13

Table 5-1 Required cleaning materials ................................................. 5-2

Table 5-2 Cleaning solvent selection ................................................... 5-4

Table A-1 Parts list for short mounting stand ....................................... A-3

Table A-2 Parts list for medium mounting stand .................................. A-4

Table A-3 Parts list for tall mounting stand .......................................... A-5

Table B-1 SYNRAD Tracker Motion Sensing Kit part numbers ......... B-2

Table B-2 SYNRAD Tracker Motion Sensing Kit contents................. B-2

vii

Synrad FH Series Marking HeadFH Series Marking Head

FH Series Marking HeadFH Series Marking Head

FH Series Marking Head operator’s manual

Trademark/copyright information

WinMark Pro is a registered trademark of SYNRAD, Inc.

ActiveMark, Evolution, and Fenix are trademarks of SYNRAD, Inc.

All other trademarks or registered trademarks are the property of their respective owners.

© 1999, 2000 by SYNRAD, Inc.

All rights reserved.

viii Synrad FH Series Marking HeadFH Series Marking Head

FH Series Marking HeadFH Series Marking Head

FH Series Marking Head operator’s manual

Warranty information

This is to certify that the FH Series Marking Head is warranted by SYNRAD, Inc. to be free of all defects

in materials and workmanship for a period of one year from the date of purchase. This warranty does not

apply to any defect caused by negligence, misuse (including environmental factors), accident, alteration,

or improper maintenance.

If, within one year from the date of purchase, any part of the FH Series Marking Head should fail to

operate, contact the SYNRAD Customer Service department at 1-800-SYNRAD1 (outside the U.S. call

425-349-3500) and report the problem. When calling for support, please be prepared to provide the date

of purchase, model number and serial number of the unit, and a brief description of the problem. When

returning a unit for service, a Return Authorization (RA) number is required; this number must be

clearly marked on the outside of the shipping container in order for the unit to be properly processed. If

replacement parts are sent to you, then you are required to send the failed parts back to SYNRAD for

evaluation.

If the FH Series Marking Head fails within the first 45 days after purchase, SYNRAD, Inc. will pay all

shipping charges to and from SYNRAD when shipped as specified by SYNRAD Customer Service. After

the first 45 days, SYNRAD will continue to pay for the costs of shipping the repaired unit or replacement

parts back to the customer from SYNRAD. The customer, however, will be responsible for shipping

charges incurred when sending the failed unit or parts back to SYNRAD or a SYNRAD Authorized

Distributor. In order to maintain your product warranty and to ensure the safe and efficient operation of

your FH Series Marking Head, only authorized SYNRAD replacement parts can be used. This warranty is

void if any parts other than those provided by SYNRAD, Inc. are used.

SYNRAD, Inc. and SYNRAD Authorized Distributors have the sole authority to make warranty state-

ments regarding SYNRAD products. SYNRAD, Inc. and its Authorized Distributors neither assumes nor

authorizes any representative or other person to assume for us any other warranties in connection with

the sale, service, or shipment of our products. SYNRAD, Inc. reserves the right to make changes and

improvements in the design of our products at any time without incurring any obligation to make

equivalent changes in products previously manufactured or shipped. Buyer agrees to hold SYNRAD

harmless from any and all damages, costs, and expenses relating to any claim arising from the design,

manufacture, or use of the product, or arising from a claim that such product furnished Buyer by

SYNRAD, or the use thereof, infringes upon any Patent, foreign or domestic.

laser safety

1

Synrad FH Series Marking HeadFH Series Marking Head

FH Series Marking HeadFH Series Marking Head

FH Series Marking Head operator’s manual

Hazard information

Hazard information includes terms and symbols used in this manual or on the equipment to alert both

operating and service personnel to the recommended precautions in the care, use, and handling of laser

equipment.

Terms

Certain terms are used throughout this manual or on the equipment labels. Please familiarize yourself

with their definitions and significance.

Hazards that will result in serious personal injury or death.

Hazards or unsafe practices that could result in serious personal injury or death.

Hazards or unsafe practices that could result in minor personal injury or product

damage.

Points of particular interest for more efficient or convenient equipment operation;

additional information or explanation concerning the subject under discussion.

General hazards

Following are descriptions of general hazards and unsafe practices that could result in death, severe

injury, or product damage. Specific warning and cautions not appearing in this section are found

throughout the manual.

Danger:

Warning:

Caution:

Note:

Warning

possible

personal

injury

Direct or diffuse laser radiation can inflict severe corneal injuries.

Always wear eye protection when in the same area as an exposed

laser beam. Eyewear protects against scattered energy and is not

intended to protect against direct viewing of the beam or reflections

from metallic surfaces. Protective eyewear that blocks 10.6 µm CO2

laser radiation is available from SYNRAD, Inc.

Enclose the beam path whenever possible. Direct or diffuse laser

radiation can seriously burn human or animal tissue.

U.S. customers should refer to and follow the laser safety precautions

in ANSI Z136.1-1993, American National Standard for Safe Use of

Lasers. Procedures listed under the Standard include the appoint-

ment of a Laser Safety Officer, operation of the product in an area of

limited access by trained personnel, servicing of equipment only by

trained and authorized personnel, and posting of signs warning of the

potential hazards.

European customers should refer to and follow the laser safety

precautions in EN 60825-1, Radiation Safety of Laser Products,

Equipment Classification, Requirements, and User 92s Guide.

laser safety

2Synrad FH Series Marking HeadFH Series Marking Head

FH Series Marking HeadFH Series Marking Head

FH Series Marking Head operator’s manual

Hazard information

Warning

possible

personal

injury

Materials processing can generate air contaminants such as vapors,

fumes, and/or particles that may be noxious, toxic, or even fatal.

Material Safety Data Sheets (MSDS) for materials being processed

should be thoroughly evaluated and the adequacy of provisions for

fume extraction, filtering, and venting should be carefully consid-

ered. Review the following references for further information on

exposure criteria:

ANSI Z136.1-1993, American National Standard for Safe Use of

Lasers, section 7.3.

U.S. Government’s Code of Federal Regulations: 29 CFR 1910,

Subpart Z.

Threshold Limit Values (TLV’s) published by the American Confer-

ence of Governmental Industrial Hygienists (ACGIH).

It may be necessary to consult with local governmental agencies

regarding restrictions on the venting of processing vapors.

Other hazards

The following hazards would be typical for this product family when incorporated for intended use: (A)

normal hazards associated with high potential DC supply voltages; (B) risk of injury when lifting or

moving the unit; (C) risk of exposure to hazardous laser energy through unauthorized removal of access

panels, doors, or protective barriers; (D) risk of exposure to hazardous laser energy and injury due to

failure of personnel to use proper eye protection and/or failure to adhere to applicable laser safety

procedures; (E) generation of hazardous air contaminants that may be noxious, toxic, or even fatal.

Additional laser safety information

The SYNRAD web site contains an online laser safety handbook (http://www.synrad.com/LaserFacts/

lasersafety.html) that provides information on (1) Laser Safety Standards for OEM’s/System Integrators

including Product Classification, Product Housing, Product features, and Other CDRH Requirements;

(2) Laser Safety Standards for End Users including Class I Installations, Class IV Installations, Laser

Hazards, ANSI Standard, U.S. State Requirements, and OSHA; (3) References and Sources including

CDRH, ANSI/OSHA; and (4) Assistance with Requirements.

Caution

possible

personal

injury

Use of controls or adjustments or performance of procedures other

than those specified herein may result in hazardous radiation

exposure.

laser safety

Synrad FH Series Marking HeadFH Series Marking Head

FH Series Marking HeadFH Series Marking Head

FH Series Marking Head operator’s manual

Label locations

Figure i FH Marking Head hazard label and CE label locations

TEST

MARK

FIBER OPTIC

CONTROL

POWER

INPUT

ON

LASER

CONTROL

PARTS HANDLING

CONTROL

STATUS

FHSERIES

MARKINGHEAD

50%POWER

+30VDC, 3A

F

U

S

E

F

U

S

E

5A, FB

DANGER

Invisible laser radiation

when open. Avoid eye or

skin exposure to direct or

scattered radiation.

AVOID EXPOSURE

Invisible laser radiation

is emitted from

this aperture.

DANGER

Invisiblelaserradiation

whenopen.Avoideyeor

skinexposuretodirector

scatteredradiation.

AVOID EXPOSURE

Invisible laser radiation

is emitted from

this aperture.

AVOID EXPOSURE

Invisible laser radiation

is emitted from

this aperture.

laser safety

4Synrad FH Series Marking HeadFH Series Marking Head

FH Series Marking HeadFH Series Marking Head

FH Series Marking Head operator’s manual

Agency compliance

The FH Series Marking Head with its associated Fiber Link Controller Card has been tested and certified

to comply with certain United States and European Union (EU) directives. These directives impose

product performance requirements related to electromagnetic compatibility (EMC) and product safety

characteristics for laser products. The associated directives and specific provisions to which the FH Series

Marking Head must comply are identified and described in the following paragraphs.

Federal Communications Commission

requirements

The United States Communication Act of 1934 vested the Federal Communications Commission (FCC)

with the authority to regulate equipment that emits electromagnetic radiation in the radio frequency

spectrum. The purpose of the Communication Act was to prevent harmful electromagnetic interference

(EMI) from affecting authorized radio communication services in the frequency range above 9 kHz.

SYNRAD’s FH Series Marking Head has been tested and found to comply by demonstrating performance

characteristics that have met or exceeded the requirements of CFR 47, Chapter 1, Part 2, Subpart J.

With respect to instances of electromagnetic interference by other devices, SYNRAD defines marking

variations to be an “acceptable loss of performance” as long as the following criteria are met: (1) there is

no damage to the marking equipment or machinery into which it is integrated, (2) the marking variation

does not cause a hazardous or unsafe condition, (3) the marking variation is apparent to the operator, and

(4) normal operation is recovered after removal of the interfering signal.

FCC information to the user

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Center for Devices and Radiological

Health requirements

Under the Radiation Control for Health and Safety Act of 1968, the U.S. Food and Drug Administration

(FDA) issued a performance standard in the Code of Federal Regulations (CFR) for laser products. This

performance standard (21 CFR, Part 1040.10) was developed to protect public health and safety by

imposing requirements upon manufacturers of laser products to provide an indication of the presence of

laser radiation, to provide the user with certain means to control radiation, and to assure that all person-

nel are adequately warned of potential hazards through the use of product labels and instructions.

SYNRAD’s FH Series Marking Head is an OEM product intended for incorporation as a component of a

laser marking system and as such does not comply with 21 CFR, Subchapter J without additional safe-

guards. Additional safeguards required to meet the standard depend on the system in which the FH Series

Marking Head is to be incorporated. For instance, if the system is intended to be a Class 1 laser system,

the OEM integrator will have to provide guarding to prevent laser emission in excess of the Accessible

Emission Limits (AEL) for Class 1 devices. For incorporation in a Class IV laser system, the integrated

system must include a beam attenuator, a keyswitch, a remote interlock, and other safety features as

required under the standard.

laser safety

5

Synrad FH Series Marking HeadFH Series Marking Head

FH Series Marking HeadFH Series Marking Head

FH Series Marking Head operator’s manual

Agency compliance

European Union requirements

The European Union’s Electromagnetic Compatibility (EMC) Directive 89/336/EEC is the sole Directive

developed to address electromagnetic interference (EMI) issues in electronic equipment. In particular,

the Directive calls out documents that define the emission and immunity standards for specific product

categories. For the FH Series Marking Head, the standard EN55011 defines the radiated RF emissions

limit. The generic standard EN50082-1 defines immunity requirements published by the International

Electromechanical Commission (IEC). FH Series Marking Heads have demonstrated performance

characteristics that have met or exceeded the requirements of EMC directive 89/336/EEC.

Operational requirements of the FH Series Marking Head are 30 VDC @ 3 amps (max). In accordance

with Low Voltage Directive 73/23/EEC Article 1, the Low Voltage Directive would not apply to this

family of devices. However, due to the considerable risks and hazards associated with the installation and

operational use of this apparatus when incorporated with associated laser equipment, the manufacturer

has provided appropriate product warning labels and instructions to the user regarding laser safety. Laser

safety instructions and warnings are included in this manual.

The FH Series Marking Head is intended for incorporation as a component of a laser marking system.

When incorporated as a part of a laser marking system, and dependent upon the user application and

installation, additional warning labels and safety barriers may be required to protect the operator of the

system. The final system and installation should be evaluated to meet the requirements of EN60825-1

under Low Voltage Directive 73/23/EEC.

SYNRAD, Inc. assumes no responsibility for the compliance of the system into which the FH Series

Marking Head is integrated, other than to supply and/or recommend components and apparatus that are

CE marked for compliance with applicable European Directives. FH Series Marking Head systems are

intended for installation and use in laboratory or manufacturing facilities by trained personnel only.

In accordance with Machinery Directive, 89/392/EEC. Article 1, paragraph 4 and 5, the Machinery

Directive does not apply to this device. In consideration of the incorporation of the FH Series Marking

Head into devices that may fall under the definition of a “machine”, SYNRAD, Inc. considers the

application of the EMC Directive as sufficient evidence that the FH Series Marking Head product family

will not compromise the compliance of the “machine” into which it is incorporated.

laser safety

6Synrad FH Series Marking HeadFH Series Marking Head

FH Series Marking HeadFH Series Marking Head

FH Series Marking Head operator’s manual

Agency compliance

Table i contains a summary of EU performance requirements pertaining to the FH Series Marking Head.

Table i European Union Directives

Applicable Standards/Norms

89/336/EEC Electromagnetic Compatibility

EN 55011:1991 Radiated and Conducted Emissions

EN 50082-2: 1995 Immunity

ENV 50140 RF Electromagnetic Fields

ENV 50204:1995 RF Electromagnetic Fields, Pulse Modulation

ENV 50141 RF Common Mode

EN 60950 Equipment Safety

EN 61000-4-2:1995 Electrostatic Discharge Immunity

EN 61000-4-4:1995 Electrical Fast Transient/Burst Immunity

After a product has met the requirements of all applicable EU directives, the product can bear the official

compliance mark of the European Union as shown in Figure ii.

Figure ii European compliance mark

laser safety

7

Synrad FH Series Marking HeadFH Series Marking Head

FH Series Marking HeadFH Series Marking Head

FH Series Marking Head operator’s manual

Declaration of Conformity

Declaration of Conformity

Applicable EU Directive(s): 89/336/EEC Electromagnetic Compatibility

Applicable Standards/Norms: EN 55011:1991 Radiated and Conducted Emissions,

Class A, Group II

EN 50082-2: 1995 Immunity

ENV 50140 RF Electromagnetic Fields

ENV 50204:1995 RF Electromagnetic Fields,

Pulse Modulation

ENV 50141 RF Common Mode

EN 60950 Equipment Safety

EN 61000-4-2:1995 Electrostatic Discharge Immunity

EN 61000-4-4:1995 Electrical Fast Transient/Burst Immunity

Manufacturer: SYNRAD, Inc.

6500 Harbour Heights Parkway

Mukilteo, WA 98275

Model Number Serial Number Date of Compliance

(Compliant Unit)

FH Marking Head Beta 001 20 December 1999

FH Tracker Marking Head Beta 001 20 December 1999

We, SYNRAD, Inc., hereby declare under our sole responsibility that the equipment specified above

conforms to the above Directive(s) and Standard(s).

Corporate Officer: European Contact:

Dr. Joerg Thieme

Excel Technology Europe GmbH

_______________________________ Maisacher Str. 129

Dave Clarke, President of SYNRAD 82256 Fürstenfeldbruck

Germany

_______________________________

Date

20 December 1999

_______________________________

Dr. Joerg Thieme

Excel Technology Europe GmbH

laser safety

8Synrad FH Series Marking HeadFH Series Marking Head

FH Series Marking HeadFH Series Marking Head

FH Series Marking Head operator’s manual

This page intentionally left blank.

1

getting started

11

Synrad FH Series Marking HeadFH Series Marking Head

FH Series Marking HeadFH Series Marking Head

FH Series Marking Head operator’s manual

Use information in this section to prepare your FH Series Marking Head for operation.

The order of information presented in this section is the same as the order of tasks that

you will need to perform. The best way to get the marking head ready for operation is to

start at Inventory and work your way through WinMark Pro Software.

This section contains the following information:

■Inventory –describes all components shipped with your FH Series Marking Head.

■Introduction –describes the history of the FH Head.

■Mounting –explains marking head mounting requirements.

■Connecting –explains how to connect cables and install the Fiber Link Controller

Card.

■WinMark Pro software –describes WinMark Pro software, which is used to create

and mark laser graphics.

Note: If you are installing an FH Tracker Marking Head, please perform the tasks

described in the “Getting Started”and “Operation”sections before proceeding

to the “Tracker”section.

Table of contents

Other Excel Technology Test Equipment manuals