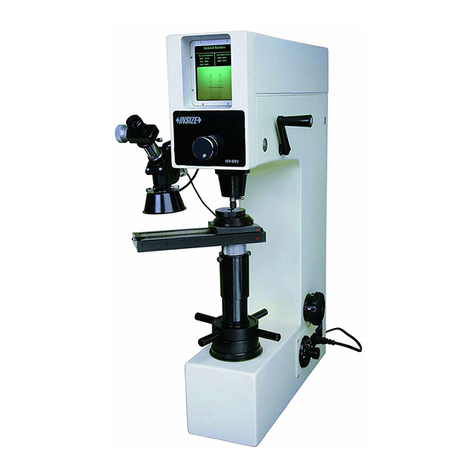

insize ISH-MR150 User manual

www.insize.com

OPERATION MANUAL

ISH-MR150

AUTOMATIC ROCKWELL HARDNESS TESTER

MN-ISH-MR150-E

1 2

The power socket for this apparatus shall be of a one-way 3-pin

type, the earth terminal shall meet the specified requirements of

grounding protection.

This instruction manual shall be read through prior to the use of

the apparatus, to understand the detailed operation steps and

special attentions, in order to prevent apparatus damage and/or

personal injury resulted from improper operation.

All bands and shake-reducing tapes shall be carefully removed

before apparatus installation and calibration.

It is strictly prohibited to tamper with the installation position of all

electric elements. Switches, sockets etc. It may cause damage

and/or injury.

It is not permitted to rotate the pressure selecting hand-wheel or

li f t ing screw during th e testing press u re c h arging or relievi n g

pe r i od (i. e . w h e n t he pre s s ur i z in g mo t or is o n ) o r d uri n g t he

pressure keeping pressure.

Attention

ISH-MR150 Rockwell Hardness Tester is an universalized

apparatus for Rockwell hardness determination. It can be used in

the test of Rockwell hardness of various materials. The applying

speed of test pressure can be adjusted by a buffering device, and

the change of pressure is obtained by rotating a pressure

selecting hand-wheel. Operation of the tester is quite easy, while

the performance is stable and thus the tester can be used in a

wide range.

Working principle of the Rockwell hardness tester. The test

procedure employs a conical diamond indenter or ball indenter of

a certain diameter to press into the specimen, an initial test

pressure P and a main test pressure P will be applied on the

0 1

indenter in sequence, and the total pressure (P + P ) will be kept

0 1

for a certain period, then the main pressure is to be removed, only

the initial pressure will be left. A difference e between the indent

depth h by this time and the indent depth h under the action of

1 0

initial pressure, is recorded as a permanent increment of indent

depth. Every 0.002 mm of this increment represents a unit of

Rockwell hardness. This is a quick test and only trivial indent will

be caused, so it is widely used to determine the hardness of

specimen.

Calculation formula of Rockwell hardness test:

HRA(C)= 100 - e/0.002

H R B = 1 3 0 - e / 0 . 0 0 2

e=h - h

1 0

Description

1

2

3

Working conditions of the tester:

Under ambient temperature, i.e. between 10-30 ºC;

The relative humidity in test room shall not be over 65%;

In an environment free from vibration;

Installation

1

No corrosive medium in surrounding.

16. Beam

17. Hoist Eye

18. Hanger

19. Resting Fork

20. Weight C

21. Weight B

22. Weight A

23. Nuts

16

17

18

19

20

21

22

23

Figure 3

3 4

Tester unpacking:

Open the packing box cover and take out all cushion

materials. Remove the accessory box.

Lift the bottom plate, unscrew the two (2) M 10 bolts under the

bottom plate with a spanner, to separate the hardness tester

from bottom plate, all steps shall be done in a safe manner.

After unpacking, the tester shall be placed on a stable bench

with levelness deviation less than 1 mm/m. A hole shall be

drilled at an appropriate location on the bench (see figure 1) to

enable the lifting screw to operate properly.

Figure 1

After the hardness tester is properly placed (see figure 2),

remove the top cover. Untie the fastening white gauze tape on the

extension rod ( figure 4), then promptly replace the top cover to

prevent dust from coming into the tester. Open the rear cover

and remove the white gauze tape on moveable parts.

2

3

Wipe off the anti-rust oil on the lifting screw and apply some thin

lubricating oil instead.

Figure 2

Installation of weights (figure 3):

During weights installation the tester shall be at a test pressure-

free state.

Take the weights out of the accessory box and rub them clean.

Rotate the pressure selecting hand-wheel to position 588, take

out the hanger from rear cover, and lead the hanger into the hole

on weight A, then tighten the two M10 nuts at the end of hanger,

hook the hanger onto the hoist eye at the rear of beam , and put

weight B and weight C on two resting forks respectively. Then

turn the pressure selecting hand-wheel a whole cycle and ensure

that the weights' pins shall fall into the groove on the resting

forks.

4

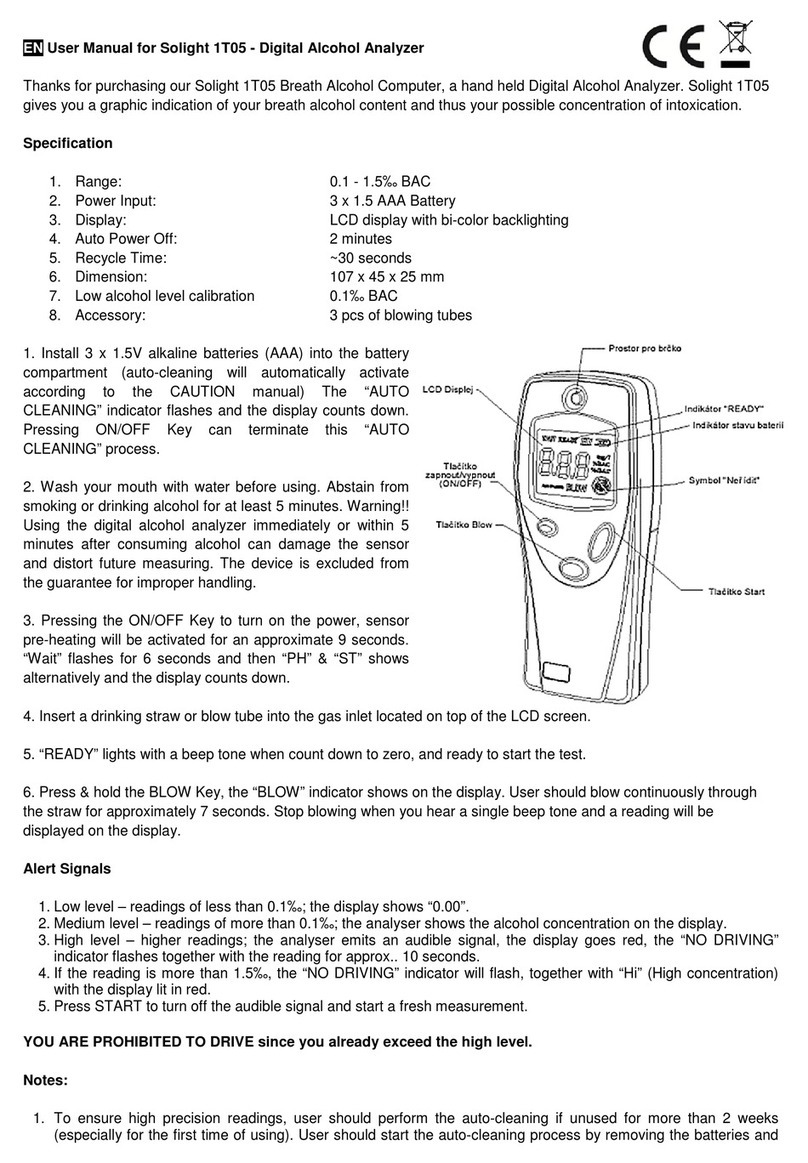

1. Indicator Light 2.Top Cover 3. Rear Cover 4. Panel

5. Indenter Locking Screw 6. Indenter 7. Test Stock

8. Lifting Screw Cover 9. Turn Wheel 10. Start Button

11. Power Source Plug 12. Potentiometer 13. Fuse

Plug 14. Switch 15. Pressure Selecting Hand-wheel

5 6

Relationship between selected test pressure and applied

weights is shown as follow:

Hanger + Weight A + Weight B + Weight C

Hanger + Weight A + Weight B

Hanger + Weight A

Applied Weights

Test Pressure

Graduation, N

588

980

1470

Scale

HRA

HRB

HRC

5

Preparation prior to the use:

Surface of the specimen to be tested must be smooth and

clean, free from dirt, scaling, indentation or significant marks

resulted from machining. Scale, Indenter, Testing Pressure

and Applicable Range for Rockwell Hardness Test .

Operation

1

Minimum thickness of the specimen shall be larger than 10

times the depth of indenture. No obvious deformation shall be

seen on back of the specimen after hardness test.

The specimen to be tested shall be placed in stable state on

top of the test stock. It shall be fixed during the test process.

Ensure that the test pressure is perpendicularly exerted on

the specimen.

In case of a cylindrical shape specimen to be tested, the V

type test stock shall be used and offset needs to be made to

the values. Offset for cylindrical shape specimen shall be a

positive value.

Scale

A

D

C

F

B

G

H

E

K

Indenter

Diamond indenter

conical angle:

120 spherical

radius at vertex:

0.2 mm

°

Ball indenter

diameter:

1.5875mm (1/16in)

Ball indenter

diameter:

3.175mm (1/8in)

Initial

Pressure

(N)

98.07

Combined

Pressure

(N)

588.4

980.7

1471.0

588.4

980.7

1471.0

588.4

980.7

1471.0

Applications

hard alloy, carbide for

surface quenched steel,

hard steel sheet

thin steel sheet, surface

quenched steel

quenched steel, tempered

steel, hard cast iron

cast iron,a luminum,m agnesium

alloy, bearing alloy, annealed

copper alloy, mild steel sheet

mild steel, aluminum alloy,

copper alloy, malleable cast

iron, annealed steel

phosphorus iron, beryllium

bronze, malleable cast iron

aluminum, zinc, lead etc.

bearing alloy, tin, hard plastics,

and other soft materials

The most commonly used scales for Rockwell hardness test are A, B and C.

Hardness tester operation procedure:

2

Plug the power cord and turn on the boat-shape switch. The

illuminating light is on.

Choose a scale according to table based on the rough

hardness of the material to be tested. Rotate the pressure

selecting hand-wheel clockwise to set the total pressure.

When use the diamond indenter, press the head of diamond

with middle finger and gently push it into the hole on indenter

rod till it rests neatly on the supporting surface, then slightly

tighten the indenter locking screw, and place the specimen on

test stock.

Rotate the turn wheel clockwise to let the lifting screw move

upward, ensuring that the specimen to be tested slowly

contact with the indenter with no impact, till the short pointer

on the centigrade panel turn from the first step black point to

7 8

the red one, and by this time the long pointer shall have

passed three circles and point to position “C” (or position “B”in

case of HRB determination), which indicates that the initial

test pressure of 98.07N is achieved. The deviation of long

pointer shall not exceed 5 grades, otherwise the pointer shall

not be allowed to turn back, instead that the test spot shall be

changed to restart the operation.

Rotate the graduation dial to set the pointer on position “C”.

The value pointed by the long pointer on centigrade panel at

this time shall be taken as the determined hardness value of

the specimen (in case of HRB determination, value shall be

read from the inner circle).

Rotate the lifting wheel counterclockwise to lower the test

stock. Repeat above procedure at various spots.

No less than 5 spots shall be tested for each specimen (first

spot will not be accounted). Number of test spots may be

reasonably reduced in case of lot inspection.

Press the start button, motor starts to exert main test pressure

automatically. Indicative light turns off automatically.

The buzzer will sound during the total testing pressure

holding time. The total pressure holding time period is 10

seconds and can be adjusted by potentiometer.

When the total pressure is held for the predetermined period,

motor will restarts to remove the main pressure and the

indicator light will turn on.

Adjustment of the hardness value display. The accuracy of the

tester is calibrated at factory. If any error is caused by improper

handling during transportation, operator can make adequate

adjustment but in prior to do that he shall thoroughly understand

the structure and working principle of the tester apparatus. The

procedure is as following: Remove the top cover. If displayed

value is lower than the actual hardness of standard block, loosen

M4 nut and slightly turn in screw clockwise, then tighten the nut

and make the test again until the displayed value falls in the

specified tolerance. If displayed value is higher, turn the screw

counterclockwise.

3

24 Extension Rod

25 Nut

26 Screw

Figure 4

Repeatability & Tolerance of Rockwell Hardness Display Value:

Scale Hardness of

Standard Blocks

Display

Tolerance

Allowable Display

a)

Repeatablity

20HRA - ≤75HRA ±2HRA ≤0.02(100-H) or

b)

0.8 Rockwell Unit

>75HRA - ≤88HRA ±1.5HRA

20HRB - ≤45HRB ±4HRB

>45HRB - ≤80HRB ±3HRB

20 HRC - ≤70HRC ±1.5HRC

≤0.02(100-H) or

b)

0.8 Rockwell Unit

≤0.04(130-H) or

b)

1.2 Rockwell Unit

a) Where H is the mean hardness value.

b) Take the larger one of these two values as basis.

20 HRC - ≤70HRC ±1.5HRC

A

B

C

9 10

The operator shall operate the tester by following the instructions

contained in this manual. Frequent calibration against standard

blocks is necessary before and after actual tests. For tester not

frequently used, several pre-tests shall be done on the standard

blocks after the tester is turned on.

During a hardness test, it is strictly prohibited to turn the pressure

selecting hand-wheel when applying, keeping or removing the

testing pressure.

Use of the standard blocks can only be done on their working

surface. A minimum distance of 3 mm between two successive

test spots or between the center of indent and edge of the

specimen is necessary. Life period of a standard block is limited

to 2 years.

When handling the hardness tester, the extension rod shall be

fixed, and the weights and hanger shall be removed.

The hardness tester shall be kept in clean state. After completion

of testing procedure, the tester shall be covered with a dust cover.

Hardness block and indenter shall be coated with antirust oil after

use to prevent rust and corrosion.

Periodical verification shall be done, at least once a year, on the

tester so as to ensure its accuracy.

Common trouble shooting. It is recommended that the user

contact the manufacturer if problems occur with the tester.

However, the following table may help the user to detect and

solve some common problems.

Maintenance

1

2

3

4

5

6

7

Problem Possible cause Suggested remedy

The long pointer

deviates from its

zero point.

Adjustment of

displayed value may

cause deviation of the

long pointer.

Refer to figure 4.

Slightly loosen nut and

turn M4 screw in small

increment to align the

pointer onto its zero

point, then fix the screw

and fasten the nut.

Extraordinary error

occurs on display

1.Damaged indenter.

2.Wrong order of weights

placement.

3.Friction between

weights and inner wall

of the tester body caused

by unleveled installation

of the tester.

4.The dust-proof cover is

higher than the

supporting surface of

the lifting screw.

5.Wrong selection of

total test pressure or

indenter.

Replace diamond

indenter or ball indenter.

Place weights according

to figure 3.

Calibrate the tester with

a leveling instrument

Lower the dust-proof

cover to below the

upper surface of the

lifting screw and fasten

the screw.

Select appropriate test

pressure according to

table 2.

1.

3.

4.

5.

2.

Indicator lamp do

not light up when

tester is turned on

1.No power

2.Fuse blows out

3.Damaged lamp

Check if the power

cord is properly

connected.

Replace the fuse

with the new one in

accessory box.

Replace the lamp

with the new one in

accessory box.

1.

2.

3.

Minimum thickness of the sample shall be larger than 10 times the

depth of indenture. No obvious deformation shall be seen on

back of the sample after hardness test. The relationship between

minimum thickness of the sample and its hardness are shown in

the following table .

Appendix

1

Minimum thickness of the specimen (mm)

Hardness (HR)

11 12

Offsets for Rockwell hardness test when diameter of the

specimen is less than 38 (25) mm.

2

Hardness

Value

(HRC)

(HRA)

Diameter of Cylindrical Specimen (mm)

6 10 13 16 19 22 25 32 38

Offsets (HR) to Rockwell Scale C & A

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

3.0

2.5

2.0

1.5

1.5

1.0

1.0

0.5

0.5

0.5

3.0

2.5

2.0

2.0

1.5

1.0

1.0

1.0

0.5

0.5

0.5

0

3.0

2.5

2.0

2.0

1.5

1.5

1.0

1.0

1.0

0.5

0.5

0.5

0.5

0

2.5

2.5

2.0

1.5

1.5

1.0

1.0

1.0

0.5

0.5

0.5

0.5

0.5

0

0

2.0

2.0

1.5

1.5

1.0

1.0

1.0

0.5

0.5

0.5

0.5

0.5

0.5

0

0

1.5

1.5

1.5

1.0

1.0

1.0

0.5

0.5

0.5

0.5

0.5

0.5

0

0

0

1.5

1.0

1.0

1.0

1.0

0.5

0.5

0.5

0.5

0.5

0.5

0

0

0

0

1.0

1.0

1.0

0.5

0.5

0.5

0.5

0.5

0

0

0

0

0

0

0

1.0

1.0

0.5

0.5

0.5

0.5

0.5

0

0

0

0

0

0

0

0

Hardness

Value

(HRB)

Diameter of Cylindrical Specimen (mm)

6 10 13 16 19 22 25

Offsets (HR) to Rockwell Scale B

20

30

40

50

60

70

80

90

100

5.0

4.0

3.5

5.0

4.0

3.5

3.0

2.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

4.5

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.5

4.0

3.5

3.0

3.0

2.5

2.0

1.5

1.5

1.0

3.5

3.0

2.5

2.5

2.0

2.0

1.5

1.5

1.0

3.0

2.5

2.5

2.0

2.0

1.5

1.5

1.0

0.5

Specification

SPECIFICATION

Hardness scale

Test force

Display

Stage elevation

Load control

Min. reading

Max. workpiece height

Max. workpiece depth

Dimension

Weight

Preliminary test force

HRA, HRB, HRC

98N

588N, 980N, 1471N

analogue

manual

automatical (load/dwell/unload)

0.5HR

170mm

165mm (from the center of indenter)

520×160×700mm

60kg

, HRD, HRF, HRG

13

Standard Delivery

1pc

1pc

1pc

1pc

1pc

Main unit

Ø60mm flat anvil

Ø150mm flat anvil

V-type anvil

Diamond indenter

1pc

1pc

1pc

1pc

carbide indenter

Hardness test block HRB85-95

Hardness test block HRC60-70

Hardness test block HRC20-30

Ø1.5875mm ball

Table of contents

Other insize Test Equipment manuals

insize

insize ISH-BRV User manual

insize

insize IST-TT Series User manual

insize

insize ISH-RD200 User manual

insize

insize ISHR-D121 User manual

insize

insize ISHW User manual

insize

insize ISF-MT1K User manual

insize

insize IST-TT Series User manual

insize

insize ISR-S300 User manual

insize

insize ISHR-P151 User manual

insize

insize ISH-MRD200 User manual