Excel Tire Gauge PNEUTRONIC PNT-4 User manual

PNEUTRONIC PNT-4

DIGITAL AUTOMATIC TIRE GAUGE

INSTRUCTION MANUAL

When operating electrical equipment, basic precautions should always be followed,

including the following:

1. Read all instructions before installing and using this product.

2. Care must be taken as burns can occur from touching hot parts.

3. Do not operate equipment and place out of service if machine is damaged. Do not return to service

until equipment been examined by a qualied service person.

4. Users should follow the directions on the face of the machine.

5. This unit should not be operated by children.

6. This equipment is intended for motor vehicle use only.

7. To reduce the risk of re, do not operate equipment in the vicinity of open containers of ammable

liquids.

8. Keep hair, loose clothing, ngers and all parts of body away from moving parts.

9. Electrical circuit serving the equipment must be GFCI protected. Consult local and national codes

for installation and use.

10. Equipment should not be installed within 20 feet of fuel dispensing pumps. Consult local and

national codes for installation and use.

11. Unit contains a heater, so there may be hot surfaces in the unit.

12. Equipment must be securely fastened to a concrete pad prior to use.

13. Use only as described in this manual. Use only manufacture’s recommended attachments.

14. Always wear safety glasses and other appropriate personal protective equipment when servicing

the equipment.

15. While servicing the machine, with the exception of troubleshooting, the power should be

disconnected and properly locked out.

16. Ensure that tires are in suitable condition to be properly inated. Do not inate damaged tires.

Do not over inate tires.

17. If unit is equipped with the optional vacuum, do not pick up anything that is burning, such as

cigarettes, matches, or hot ashes. Do not use to pick up ammable or combustible liquids, such

as gasoline. Do not use without lters in place.

"SAVE THESE INSTRUCTIONS"

IMPORTANT SAFETY INSTRUCTIONS

1

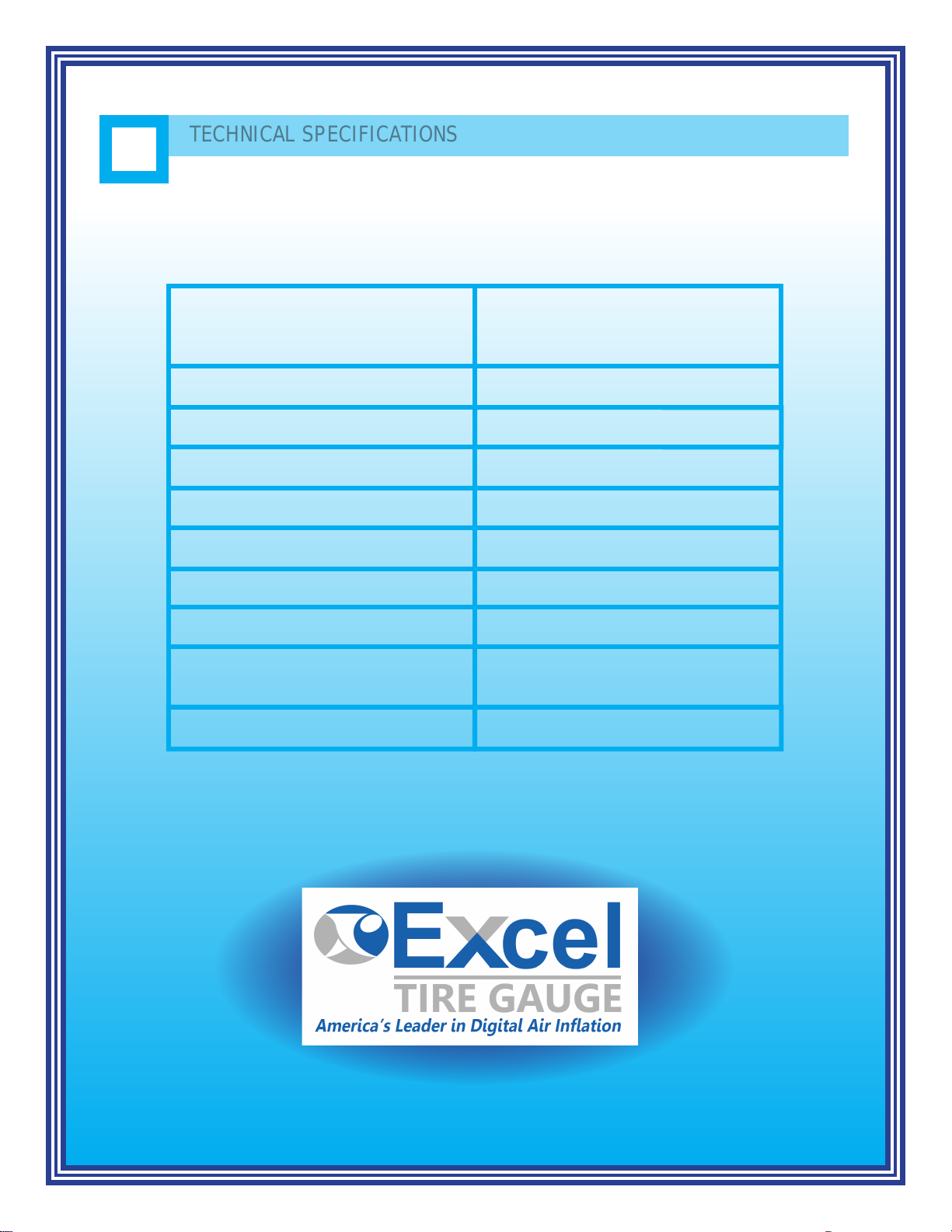

ELECTRICAL REQUIREMENT

ELECTRICAL CONSUMPTION

ELECTRICAL FREQUENCY

MAXIMUM PRE-SET PRESSURE

MAXIMUM SUPPLY PRESSURE

AVERAGE AIR FLOW

ACCURACY

OPERATING TEMPERATURE

AIR RELATIVE HUMIDITY

( WITHOUT CONDENSATION )

WEIGHT

127 VAC +/- 10%

230 VAC +/- 10%

12 VDC +/- 10%

10 W

50 / 60 Hz

145 psi. - 10 Bar

175 psi. - 12 Bar

0.5 m3/min - 17.7 ft3/min

< 1% F.S.

14o- 122o F ( -10o- 50o C )

0 - 95%

1.7 Kg / 3.8 Lbs

TECHNICAL SPECIFICATIONS

INSTALLATION

2

2.1 Before installing the inlet air supply hose, ensure that the airline is free of any

contaminantsbysucientlyblowingoutthelinepriortoconnection.

Alteredairsupplyisrecommended.Thesupplypressureshouldnotexceed

175 psi.

2.2 Securetheinletandoutlethosestotheconnectorswithhoseclamps.

2.3 Fastenthegaugeviatheprovidedmountingholestoasuitablesurfacewith

appropiate anchors.

2.3 Connectthepowercordtoasuitableelectricalreceptacle.

INLETOUTLET

3

4

TECHNICAL SPECIFICATIONS

MAINTENANCE

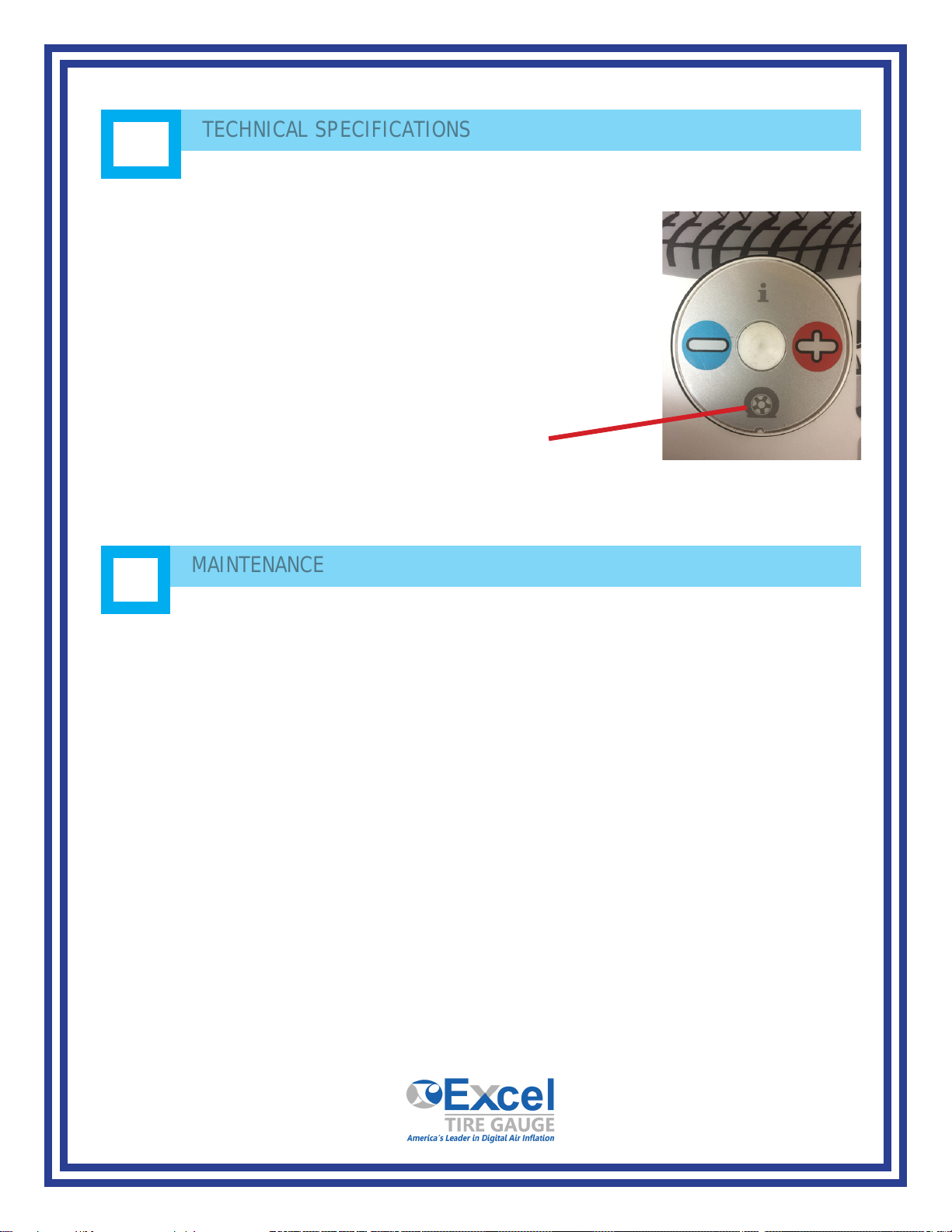

3.1 Set pressure using the +and

-

buttons.

3.2 Connect chuck to tire valve stem.

3.3 Waitforthetiregaugeto“beep”indicatingthat

setpressurehasbeenreached.

3.4 Intheeventthatthetireisat,presstheattire

button to begin the infation process

4.1 Neverallowinletpressuretoexceed175psi.

4.2 Use only an “OPEN END” chuck.

4.3 Ensure that the air supply is free of contaminants.

4.4 ThePNT4canbewipeddownwithsoapandwater.

5

TROUBLESHOOTING

5.1 DisplayreadsEr1,Er2,Er4,orEr8-Removechuckfromtire,resetthepower.

If the problem continues, contact service.

5.2 Blankdisplay-checkthepowersupply.

5.3 Ifaconstantairleakisnoticedduringtheinitialstartupoftheunit,checkto

ensurethattheinletandoutlethoseswerenotreversedwhenconnectedtothe

gauge.

5.4 DisplayreadsEr3-Checkthesupplyairforadequatepressure.Ifproblem

persists,cleantheinletlterlocatedundertheinlethoseconnector.

5.5 DisplayreadsEr5-Verifythatthepowersupplyisthesameasrequiredbythe

equipment.

5.6 DisplayreadsEr7-Verifythatthechuckisnotcloggedandthatitisan

“openend”chuck.Er7willalsoappearifchuckstaysconnectedtothetirefor

longerthan15secondsafteritisinated.

5.7 Ifthegaugedoesnotreachthedesiredpressure,anddisplaysahigherorlower

value, look for air leaks from the hose or connections.

5.8 Ifcalibrationtimeseemsexcessive,cleanairlterandcheckairlinefor

obstructions.

5.9 Ifthegaugedoesnotperformcalibration,pushthe“attire”buttonifthetireis

deated,orreplacechuck.

5.10 Ifgauge“beeps”whenchuckisnotconnectedtoatire,verifythatthechuckis

notcloggedandthatitisa“openend”chuck.

5.11 If it appears that the gauge is functioning by itself continuously, verify that the

chuckisnotcloggedandthatitisa“openend”chuck.

WARRANTY

All parts, excluding hose and hose chucks, have one year limited warran- ty from date of purchase

(Outside labor is not covered).

Excel requires that the customer calls into our Technical Support Dept. to troubleshoot the problem

rst before shipping any parts back to us under warranty.

Contact Info: Phone: 401-732-8420

Toll Free: 1-866-455-8768

Oce hours:

Monday - Friday 8:00AM – 4:30 PM (EST)

Aer troubleshooting the problem and warranty is validated, our Tech- nical Support Rep. will

issue a RMA # (Return Merchandise Authorization) for the defected part(s) to be returned.

Defective parts should be sent to Excel along with serial number of the machine, installation date,

and problem. With a black marker, make sure to write the RMA # on the outside of the box.

Once the defected part has been received, a new or repaired part will be sent back free of charge

via ground freight. Expedited freight is at an addi- tional cost.

Note: Freight cost is not included when shipping the defected part back. .

Important: Use of this product in any way not stated in this manual can compromise safety

features of this product.

6

WARRANTY

Excel Tire Gauge, LLC.

215 Jeerson Blvd, Warwick, RI 02888

Tel: 401 732 8420 Fax: 401 384 6157

WWW.EXCELTIREGAUGE.COM

Table of contents