Excelitas Technologies OmniCure AC5 Series User manual

035-00629R_Rev 3

OmniCure® AC5 Series User Guide

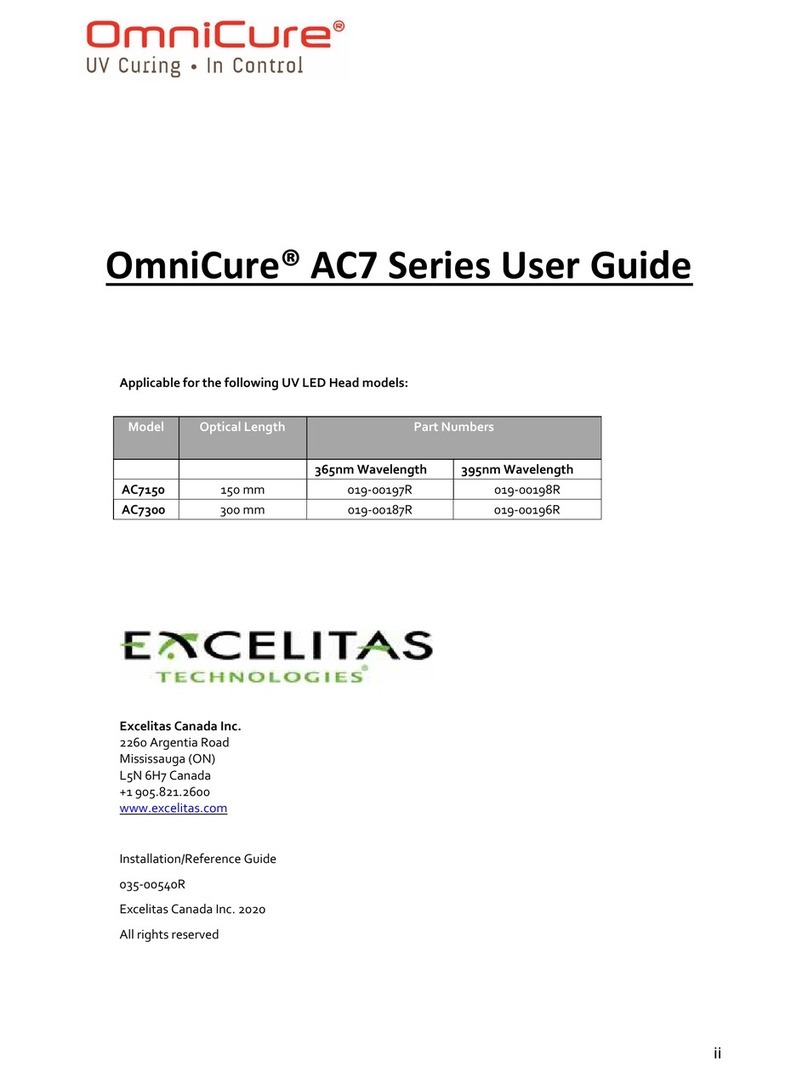

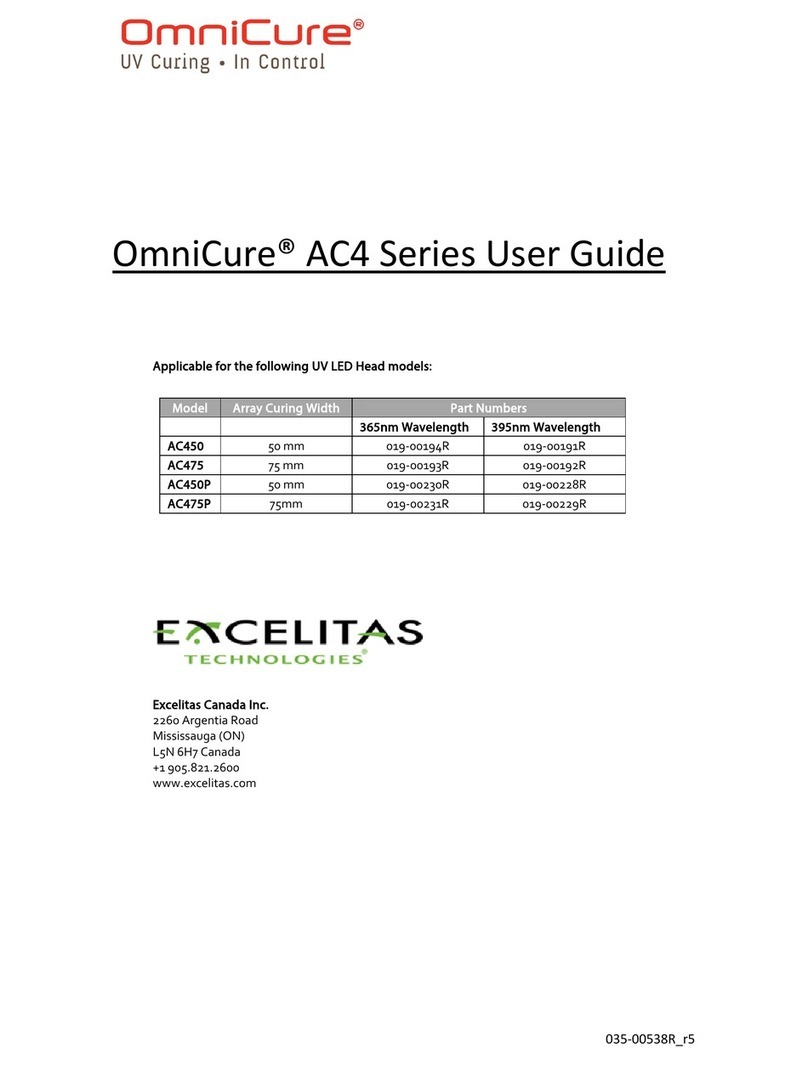

Applicable for the following UV LED Head models:

Excelitas Canada Inc.

2260 Argentia Road

Mississauga (ON)

L5N 6H7 Canada

+1 905.821.2600

www.excelitas.com

Model

Array Curing Width

Part Numbers

395nm Wavelength

405nm Wavelength

AC550

50

019-00279R-03

N/A

AC575

75

019-00280R-03

019-00421R-04

AC550P

50

019-00281R-03

N/A

AC575P

75

019-00282R-03

N/A

AC5 Series

UV Curing Solutions

ii

035-00629R-Rev 3

User Guide

035-00629R

Excelitas Canada Inc. 2023

All rights reserved

No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system or

translated into any language in and form by any means without the prior written consent of Excelitas Canada

Inc. Every effort has been made to ensure information in this manual is accurate; however, information in this

manual is subject to change without notice and does not represent a commitment on the part of the authors.

Trademarks:

OmniCure® is a trademark of Excelitas Canada Inc. All rights reserved. All other product names are

trademarks of their respective owners. All product or software photos shown are for reference only and are

subjected to change without notice.

Made in Canada. Doc. No. 035-00629R

AC5 Series

UV Curing Solutions

ii

035-00629R-Rev 3

Revision History

Revision #

Comments

Rev .0

Initial release

Rev. 1

Updates to regulatory section and webpage links

Rev. 2

Updates to regulatory section

Rev. 3

Addition of AC575-405

AC5 Series

UV Curing Solutions

iii

035-00629R-Rev 3

Table of Contents

1Introduction .........................................................................................................................1

2Safety Precautions/ User Warnings ........................................................................................2

Glossary of Symbols:........................................................................................................................................2

Safety Precautions: ..........................................................................................................................................2

3Optical Safety Data...............................................................................................................4

4Getting Started ....................................................................................................................5

Packaging Contents ......................................................................................................................................... 5

System Requirements ......................................................................................................................................5

Powering Up and Powering Down .................................................................................................................... 7

5Mounting the UV Head..........................................................................................................8

UV LED Head ...................................................................................................................................................8

Mounting the UV LED Head .............................................................................................................................9

UV LED Head Dimensions ................................................................................................................................9

6Connecting the UV LED Head .............................................................................................. 11

Interfacing with the System Controller (PLC).................................................................................................. 11

Integrating Monitoring with External Circuitry................................................................................................ 12

Interfacing with the Power Cable.................................................................................................................... 12

7Using the LED Head ............................................................................................................ 13

Understanding the LED Indicators.................................................................................................................. 13

Fault Status.................................................................................................................................................... 14

Symptoms and Possible Causes...................................................................................................................... 14

8Care and Maintenance......................................................................................................... 16

Cautions and Handling ................................................................................................................................... 16

Cleaning Materials ......................................................................................................................................... 16

Cleaning the LED Head .................................................................................................................................. 17

Cleaning the LED Head Air Intake................................................................................................................... 17

9Technical Specifications ......................................................................................................18

Environmental Conditions.............................................................................................................................. 18

UV LED Head Specifications........................................................................................................................... 18

Regulatory Compliance .................................................................................................................................. 19

WEEE Directive .............................................................................................................................................. 19

China RoHS....................................................................................................................................................20

10 Warranty............................................................................................................................ 21

Checking Your Lamp Hours ............................................................................................................................ 21

Replacement UV LED Module Warranty ......................................................................................................... 21

Returning your AC5- System to Excelitas Technologies for Service .................................................................22

11 Contact Information ........................................................................................................... 23

AC5 Series

UV Curing Solutions

iv

035-00629R-Rev 3

Figures

Figure 1 UV LED Head Connection Ports...................................................................................................................6

Figure 2 PLC Console ................................................................................................................................................6

Figure 3 UV LED Head ..............................................................................................................................................8

Figure 4 UV LED Head Dimensions............................................................................................................................9

Figure 5 Underside of AC550 ................................................................................................................................... 10

Figure 6 Underside of AC575 ................................................................................................................................... 10

Figure 7 PLC Connector (looking at UV Head).......................................................................................................... 11

Figure 8 PLC Digital Output Equivalent Circuit......................................................................................................... 12

Figure 9 Power Connector (looking at UV Head)...................................................................................................... 12

Tables

Table 1 PLC Connector Pin Out ............................................................................................................................... 12

Table 2 Power Connector Pin Out............................................................................................................................ 12

Table 3 LED Indicator Status (UV LED Head) ........................................................................................................... 13

Table 4 Environmental Conditions........................................................................................................................... 18

Table 5 UV LED Head Specifications........................................................................................................................ 18

Table 6 UV LED Warranty Status............................................................................................................................. 21

AC5 Series

UV Curing Solutions

1

035-00629R-Rev 3

1Introduction

The OmniCure® AC5 Series represents a new standard in UV LED curing systems. The series provides

unsurpassed levels of power, irradiance performance, control and monitoring in a compact form factor. The

OmniCure® AC5 Series systems are offered alongside a variety of power supply, controller and cabling

options, providing configuration flexibility to suit any application for end users and integrators alike.

Optical output is controlled via a PLC interface enabling a high degree of automation. At the heart of the

OmniCure® AC5 Series are the arrays of LEDs housed within the UV LED Head and located under the optical

lens providing excellent spectral and power stability. The UV LED Head has a typical lifetime in excess of

20,000 hours of accumulated 'on’ time, made possible by the integration of state-of-the-art electronics,

effective thermal management and high performance optics. Acoustic noise is minimised through an

innovative load-adaptive fan that keeps the LEDs operating efficiently and reliably while minimising the

resultant noise levels.

In the Excelitas Technologies family of UV LED light systems, all systems offer the same high level of

innovation, quality and reliability that our customers have come to expect. Since 1984, OmniCure® has

combined next generation optical engineering, state-of-the art electronics and fibre-optics to produce

sophisticated technologies that employ light. Today, OmniCure® is a leading developer of light-based systems

for sectors ranging from manufacturing to bio-medicine, and is unmatched in commitment to quality and

service.

This manual covers the following models:

Model

Part Numbers

395nm Wavelength

405nm Wavelength

AC550

019-00279R

N/A

AC575

019-00280R

019-00421R-04

AC550P

019-00281R

N/A

AC575P

019-00282R

N/A

Excelitas Technologies recommends reading this guide to discover all features of the OmniCure® AC5 Series

Systems, and how to use them.

AC5 Series

UV Curing Solutions

2

035-00629R-Rev 3

2Safety Precautions/ User Warnings

Glossary of Symbols:

Caution risk of danger –consult accompanying documents.

Risk Group 3 (IEC62471)

WARNING: UV emitted from this product. Avoid eye and skin exposure to unshielded product.

CAUTION: Possibly hazardous optical radiation emitted from this product. Do not stare into operating lamp.

Input/ Output Signals

Input Signal

Caution, Hot Surface

Protective Conductor Terminal

Earth (Ground) Terminal

CAUTION, Risk of Electrical Shock

Safety Precautions:

This series of cautions and warnings relate to the installation, operation and maintenance of the OmniCure®

AC5 Series system. They are also presented throughout this User Guide as applicable.

WARNING

Do not stare directly at the light emitted from the LED array. This may be harmful, resulting in eye injury.

Always use UV protective eyewear as indicated below. Additionally, protect any exposed skin with appropriate

clothing or shielding as required.

Warning UV protective eyewear must meet the following recommended optical specifications:

•Spectral range; 350-440nm

•Optical Density ≥ 6

Warning Should the OmniCure® AC5 Series System be used in a manner not specified by Excelitas

Technologies, the protection provided by the equipment may be impaired.

The UV LED Head operation can be affected if handled incorrectly. Never touch the protective lens cover

assembly of the UV LED Head. The presence of skin oils may result in a decrease in system performance.

AC5 Series

UV Curing Solutions

3

035-00629R-Rev 3

Always ensure the power supply unit is turned off prior to disconnecting or re-connecting the UV LED Head.

Warning:

Monitoring the system during automated operation:

The level of UV energy supplied by the OmniCure® AC5 Series is sufficient to ignite flammable substances.

Therefore, when the unit is operated unattended in an automated environment, an alarm function must be

provided by the user to indicate a malfunction in the associated equipment used. During installation the

appropriate measures must be included to prevent any such occurrence.

AC5 Series

UV Curing Solutions

4

035-00629R-Rev 3

3Optical Safety Data

IEC 62471: Photobiological Safety of Lamps and Lamp Systems

Resulting Classification and Labelling

Hazard

AC550/P-395

AC575/P-395

AC575-405

Actinic UV

Risk Group 3

Near UV

Risk Group 3

Blue Light

Risk Group 1

Retinal Thermal

Risk Group 2

AC5 Series

UV Curing Solutions

5

035-00629R-Rev 3

4Getting Started

Packaging Contents

The package contains one of the following UV LED Heads, as well as a documentation quick start:

Model

Array Curing Width

Part Numbers

395nm Wavelength

405nm Wavelength

AC550

50

019-00279R

N/A

AC575

75

019-00280R

019-00421R-04

AC550P

50

019-00281R

N/A

AC575P

75

019-00282R

N/A

The package contains an alternative 100ppi filter for applications with more airborne particulates.

Replacement air filters (qty: 10) can be ordered from Excelitas Technologies under the part number 019-

00209R.

Carefully unpack the unit and store the packing material for future use.

System Requirements

In addition to the UV LED Head, the following components are required:

•Power supply

•Power cable

Note: You will also require a PLC controller unless you are using an existing controller. The PLC controller is

used to discover the extensive functionality of the UV LED Head, but integrators can access the full

feature set through integrating with the PLC interface directly. Refer to Section 6.

These components may be sourced separately or may be purchased from Excelitas Technologies. Check with

Excelitas Technologies to determine the appropriate components for your requirements. The following table

provides the part numbers of recommended component parts, as well as a part number to order all

components as a package:

Component Parts

AC550-395nm

AC550P-395nm

AC575-395nm

AC575P-395nm

AC575-405nm

UV Head

019-00279R

019-00281R

019-00280R

019-00282R

019-00421R-04

System Controller

019-00186R

019-00186R

019-00186R

019-00186R

019-00186R

DC Power Cable

018-00559R

018-00559R

018-00559R

018-00559R

018-00559R

PLC controller

019-00214R

019-00214R

019-00214R

019-00214R

019-00214R

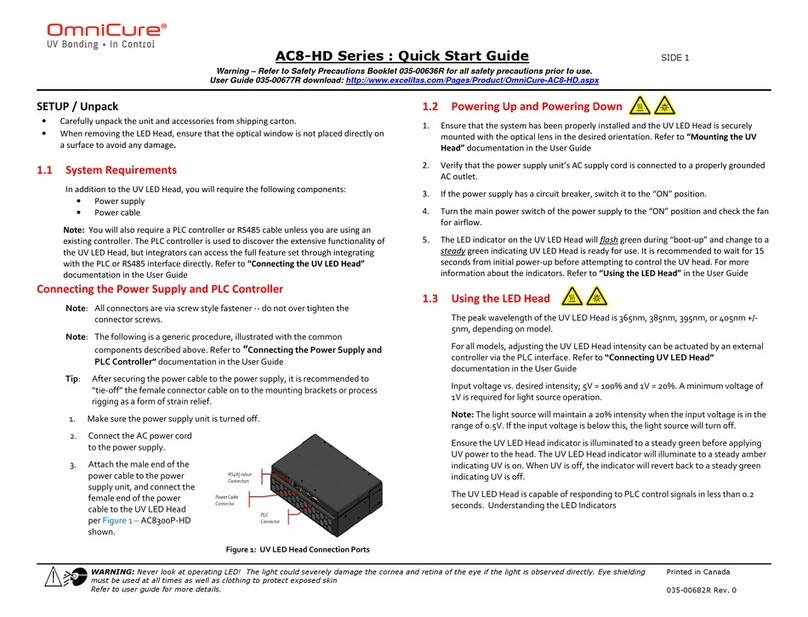

Connecting the Power Supply and PLC Controller

Note: All connectors are via screw style fastener -- do not over tighten the connector screws.

Note: The following is a generic procedure, illustrated with the common components described above;

please refer to specific documentation related to your power supply and controller.

Tip: After securing the power cable to the power supply, it is recommended to “tie-off” the female

connector cable on to the mounting brackets or process rigging as a form of strain relief.

AC5 Series

UV Curing Solutions

6

035-00629R-Rev 3

1. Make sure the power supply unit is turned off.

2. Connect the AC power cord to the power supply.

3. Attach the male end of the power cable to the power supply unit, and connect the female end of the

power cable to the UV LED Head per Figure 1.

Figure 1 UV LED Head Connection Ports

4. Connect the PLC loop-back connector to the PLC pass-through port (see Figure 2).

5. Power up the UV LED Head per Section 4.4, and then push the LED Enable button on the controller to

turn power on to the LED Head.

6. Adjust intensity using the up or down buttons to the right of the display (see Figure 2). to increase and

decrease the intensity respectively. Refer to Section 6, “Using the LED Head”

7. UV LED & Temperature faults will be indicated by an illuminated LED on the control console. To clear,

press the Clear Fault button (see Figure 2).

Figure 2 PLC Console

Power Cable

Connector

PLC

Connector

AC5 Series

UV Curing Solutions

7

035-00629R-Rev 3

Powering Up and Powering Down

1. Ensure that the AC5 Series system has been properly installed and the UV LED Head is securely mounted

with the optical lens in the desired orientation. Refer to Section 5, “Mounting the UV Head”.

2. Verify that the power supply unit’s AC supply cord is connected to a properly grounded AC outlet.

3. If the power supply has a circuit breaker, switch it to the “ON” position.

4. Turn the main power switch of the power supply to the “ON” position and check the fan for airflow.

5. The LED indicator on the UV LED Head will flash green during “boot-up” and change to a steady green

indicating UV LED Head is ready for use. It is recommended to wait for 15 seconds from initial power-up

before attempting to control the UV head. For more information about the indicators, see Section 7,

“Understanding the LED Indicators”.

After turning on UV power, the system will reach a fully stable operating temperature in 2-3 minutes. Caution

–the UV LED Head can become very hot, avoid handling until the UV LED Head has cooled down (approx. 5

min) or use protective gloves.

Before disconnecting any cables, power down the UV LED Head using the PLC

controller and turn off the power supply. (Note: the cooling fan may take up to 10

seconds to stop).

AC5 Series

UV Curing Solutions

8

035-00629R-Rev 3

5Mounting the UV Head

UV LED Head

Figure 3 UV LED Head

M

ou

nt

in

g

H

ol

es

M

ou

nt

in

g

H

ol

es

Fan Exhaust

All Models Front

AC550

Underside

Mounting

Holes

Power Cable Connector

PLC Connector

Status Indicator

Air Intake Filter

Mounting Holes

All Models Back

AC575

Underside

M

o

u

n

t

i

n

g

H

o

l

e

s

Optical lens

AC5 Series

UV Curing Solutions

9

035-00629R-Rev 3

Mounting the UV LED Head

**WARNING**

Do not block the air intake or the exhaust fans for the UV LED module's cooling

system. Ensure that both intake and exhaust vents located on the LED heads have

at least 2 inches (5cm) of clearance to allow sufficient air flow.

The UV LED Head includes twelve threaded mounting holes (four on the front, four on the back, and two on

each side panel) M4 X 7mm deep. Mounting holes are identical in all AC5- models

(019-00279R, 019-00280R, 019-00281R, 019-00282R) Refer to Figure 3 above.

**CAUTION**

The threaded mounting holes in the AC5- incorporate a blind configuration; ensure

that the appropriate length of mounting hardware is used. Attempting to install

over-length mounting screws could damage the threaded mounting holes and

internal components.

UV LED Head Dimensions

The UV LED Head (all models) weighs ~1.1kg (2.4lbs).

The dimensions are the same for all models of the AC5- series, except for the underside as shown in Figure 5

and Figure 6 below.

Figure 4 UV LED Head Dimensions

AC5 Series

UV Curing Solutions

10

035-00629R-Rev 3

Figure 5 Underside of AC550

Figure 6 Underside of AC575

AC5 Series

UV Curing Solutions

11

035-00629R-Rev 3

6Connecting the UV LED Head

Interfacing with the System Controller (PLC)

PLC Input Signal Requirements

Signal Type

Digital

Analog

Input

•Voltage: 0 –24V

•Current: 1 –40mA

•Voltage: 0 –5V

•Current: 500uA

Output

•Voltage: 0 –5V

•Current: 4mA (max.)

•Voltage: 0 –5V

•Current: 100uA

PLC Connector Pin-Out

Figure 7 PLC Connector (looking at UV Head)

PIN

Name

Description

1

Intensity Input

Input voltage is converted to required current to achieve desired intensity;

intensity will vary linearly between 20% and 100% for voltages between 1V

and 5V respectively.

A minimum voltage of 0.4V is required for proper light source operation. If

the user inputs a voltage below the minimum required, the light source will

not turn on.

2

Enable High

0.0V to +0.6V = Turns LEDs off (Open input will default to OFF).

+2.4V to +24.0V = ON.

3

Enable Low

0.0V to +0.6V = Turns LEDs on.

+2.4V to +24.0V = Turns LEDs off (Open input will default to OFF).

4

Thermal Fault

0.0V to +0.4V (ground) = Fault

+2.4V to +5.0V (open) = No Fault

5

IsoDGND

Ground Reference for digital IOs

6

IsoVCC

+5.0V Output.

7

Reserved

Do not connect

8

Door Lock *

0.0V to +0.6V = UV Emission Allowed.

+2.4V to +24V = UV Emission Stopped.

9

IsoGND

Ground Reference for analog IOs.

10

LED ON

0.0V to +0.4V (ground) = LED off

+2.4V to +5.0V (open) = LED on.

11

Reserved

Do not connect

12

UV LED Fault

0.0V to +0.4V (ground) = Fault

+2.4V to +5.0V (open) = No Fault

AC5 Series

UV Curing Solutions

12

035-00629R-Rev 3

PIN

Name

Description

13

Reserved

Do not connect

14

Clear Fault/

LED Hours

High-to-low transition clears faults; low-to-high transition initiates visual

indicator sequence of accumulated LED hours

15

Temperature

Monitor

Output is a voltage proportional to the maximum UV LED heat sink

temperature.

Conversion Factor: 0.05V/°C.

Table 1 PLC Connector Pin Out

* The integrated door lock function provides the integrator with a means of shielding operators

from accidental UV exposure by utilising a dry contact switch on the door of the UV shield and connecting

between pins 5 and 8 on the PLC interface.

Integrating Monitoring with External Circuitry

All inputs and outputs from the PLC interface are opto-isolated. The digital outputs are implemented using

NPN logic. The equivalent circuit is shown in Figure 8 below

Figure 8 PLC Digital Output Equivalent Circuit

Interfacing with the Power Cable

Figure 9 Power Connector (looking at UV Head)

PIN

Name

Description

A1,A2

+ve

48V DC power feed. A1 and A2 shorted together internally

A3,A4

-ve

48V DC power return. A3 and A4 shorted together internally

A5

Chassis

Chassis ground connection

Table 2 Power Connector Pin Out

48V Input Requirements:

•Voltage: 46-50V DC

•Current: AC550/P=8A; AC575/P=12A

Note: For safety, the AC5 Series is internally fused at 15A. This fuse is not replaceable. If it is suspected that

the internal fuse has blown, please contact Excelitas Technologies Service Centre for further assistance

and refer to Sections 0 and 11 of this manual.

AC5 Series

UV Curing Solutions

13

035-00629R-Rev 3

7Using the LED Head

The peak wavelength of the UV LED Head is 395nm +/- 5nm or 405nm +/- 5nm, depending on model.

For all models, adjusting the UV LED Head intensity can be actuated by an external controller via the PLC

interface. Refer to Section 6 for Pin-Outs.

Input voltage vs. desired intensity; 5V = 100% and 1V = 20%. A minimum voltage of 1V is required for light

source operation.

Note: The light source will maintain 20% intensity when the input voltage is in the range of 0.5V. If the input

voltage is below this, the light source will turn off.

Ensure the UV LED Head indicator is illuminated to a steady green before applying UV power to the head. The

UV LED Head indicator will illuminate to a steady amber indicating UV is on. When UV is off, the indicator will

revert back to a steady green indicating UV is off.

The UV LED Head is capable of responding to PLC control signals in less than 0.2 seconds.

Understanding the LED Indicators

LED Indicator

Condition

Steady green

System Ready; no critical faults

Steady amber

UV LED turned ON

Steady red

Critical fault

•Temperature Fault

•LED Fault

•System Error

Slow flashing green

(~1x/second)

POST and Initialization

Input voltage is less than 46V or greater than 50V. Unit is still

functional.

Slow flashing red

Major and critical fault

Slow flashing amber

UV LED ON with 48V input voltage out of requirement

Fast flashing green

(~3x/second)

Warranty status - operating hours is < 9,000

Fast flashing amber

Warranty status - operating hours = between 9,000 and 10,0000

Fast flashing red

Warranty status - operating hours is >10,000

Table 3 LED Indicator Status (UV LED Head)

A transition from high-to-low is required to clear the alarm signals. Use the PLC function:

Pin #

Description

I/O

Behaviour

14

Clear fault/

LED hours

In

0V to 0.6V (Open) Logic Low

2.4V to 24V Logic High

High-to-low transition = clear faults

Low-to-high transition = LED hours

Caution: Routine maintenance should only be completed by a user qualified personnel to avoid risk of injury

to the end user. No user serviceable components are located within the power supply

or UV LED Head enclosures.

AC5 Series

UV Curing Solutions

14

035-00629R-Rev 3

Fault Status

PLC Output

•LED Fault: At least one module fails to turn on.

•Thermal Fault that includes:

•At least one module’s temperature is over the maximum limit.

•At least one module’s temperature is lower than the minimum limit or open circuit.

•Internal Fault.

Troubleshooting

Symptoms and Possible Causes

Service to be completed by qualified Excelitas Technologies personnel only!

Always wear optical safety glasses while troubleshooting. Never put hands or

fingers in front of the lens. Serious personal injury may result.

Do not place any potentially combustible materials (e.g. paper, card, etc.) in front of

the LED Head. Risk of fire and damage to the UV LED Head may result.

If the system fails to power up:

•Make sure the AC power cord is securely plugged into a functional AC outlet and into the AC inlet on

the power supply unit.

•Make sure that the circuit breaker on the power supply unit is not tripped. If so, reset breaker.

•Make sure all cable connections (power supply to UV LED Head) are secure.

•Ensure that the power supply is switched on and the green LED indicator on the front panel is lit.

•Make sure the door lock electrical loopback on the PLC is installed properly.

If the system powers up but experiences a thermal fault during operation:

•Ensure UV Head is installed with adequate clearance around intake and exhaust ports.

•Ensure intake air filter is not clogged or obstructed.

•If filter is clogged, either clean with compressed air or replace with a new filter insert.

If the system powers up but does not emit UV:

•Check that the door lock loop is intact.

•Ensure that the voltage levels on pins 2 and 3 of the PLC interface match the logic required to enable

the LEDs.

•Check the visual indicator for signs of a fault.

If a fault condition has been detected:

•Attempt to clear the fault by toggling the voltage high on pin 14 of the PLC interface or by pressing the

“Clear Fault” button on the PLC controller.

If the system exhibits a fault condition with a slow-flashing red:

•Power-cycle the UV Head to clear.

AC5 Series

UV Curing Solutions

15

035-00629R-Rev 3

If the light intensity is too low:

•Make sure the input voltage is at least 46V (input voltage to the Head for the purposes of powering the

head is typically 48V (46-50V DC)).

•Out-of-range input voltage will be indicated on the visible indicator on the UV LED Head with a slow

flashing green.

•Clean the optical window of the UV LED Head as described in Section 8, “Cleaning the LED Head”.

•Verify that the intensity level of the UV LED Head is set to the correct level, using the PLC Controller.

If problems persist beyond these troubleshooting points, please contact Excelitas Technologies Service

Department (refer to Section 11, “Contact Information”).

This manual suits for next models

4

Table of contents

Other Excelitas Technologies Industrial Equipment manuals

Excelitas Technologies

Excelitas Technologies OmniCure S1500 PRO User manual

Excelitas Technologies

Excelitas Technologies FlashPac LS-1130 User manual

Excelitas Technologies

Excelitas Technologies OmniCure AC7 Series User manual

Excelitas Technologies

Excelitas Technologies OmniCure AC4 Series User manual

Excelitas Technologies

Excelitas Technologies OmniCure AC8-HD Series User manual

Excelitas Technologies

Excelitas Technologies OmniCure S2000 Elite User manual