8/67

Table of Contents

Features & Benefits..........................................................................................................9

1.1. Principle of Intended Use ................................................................................................10

1.2. Organisational Measures................................................................................................12

1.3. Staff Selection and Qualification, General Obligations...................................................13

1.4. Safety Notes on Specific Operating Phases....................................................................13

1.5. Reference to Special Types of Danger ............................................................................15

1.6. Transport.........................................................................................................................16

1.7. Packaging and Storage....................................................................................................16

1.8. Environmental Protection ................................................................................................16

1.9. Disposal ..........................................................................................................................16

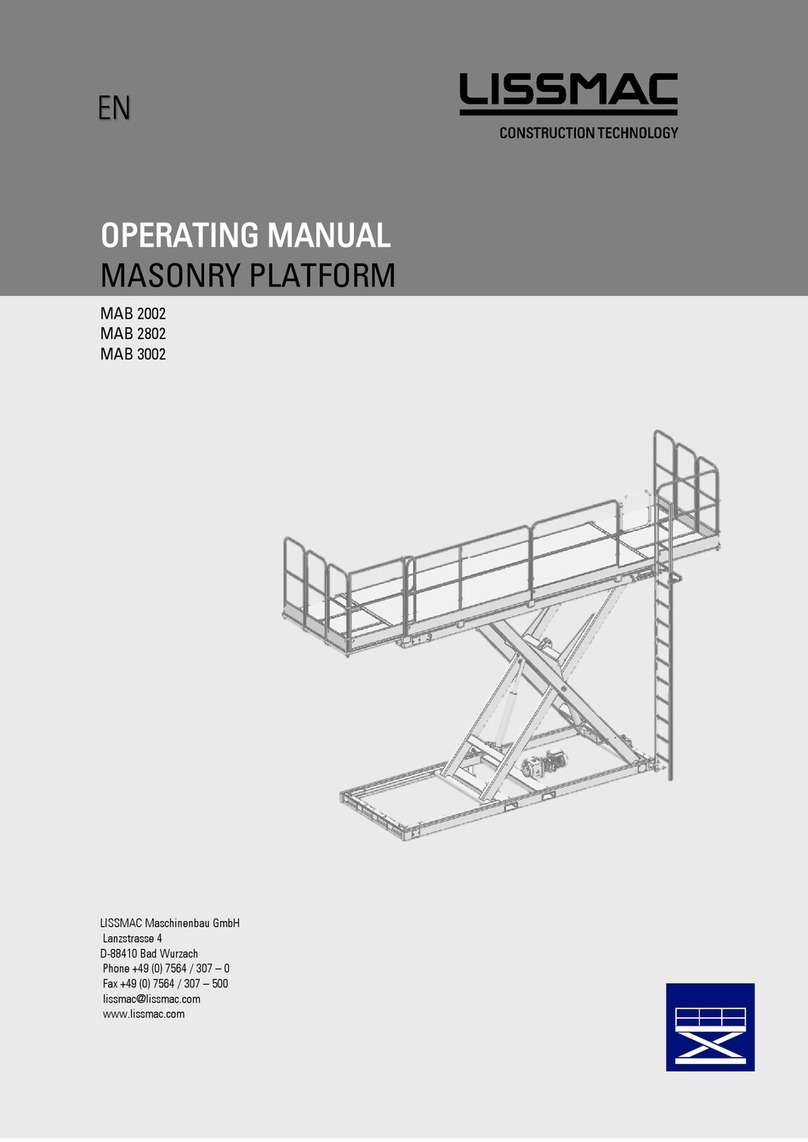

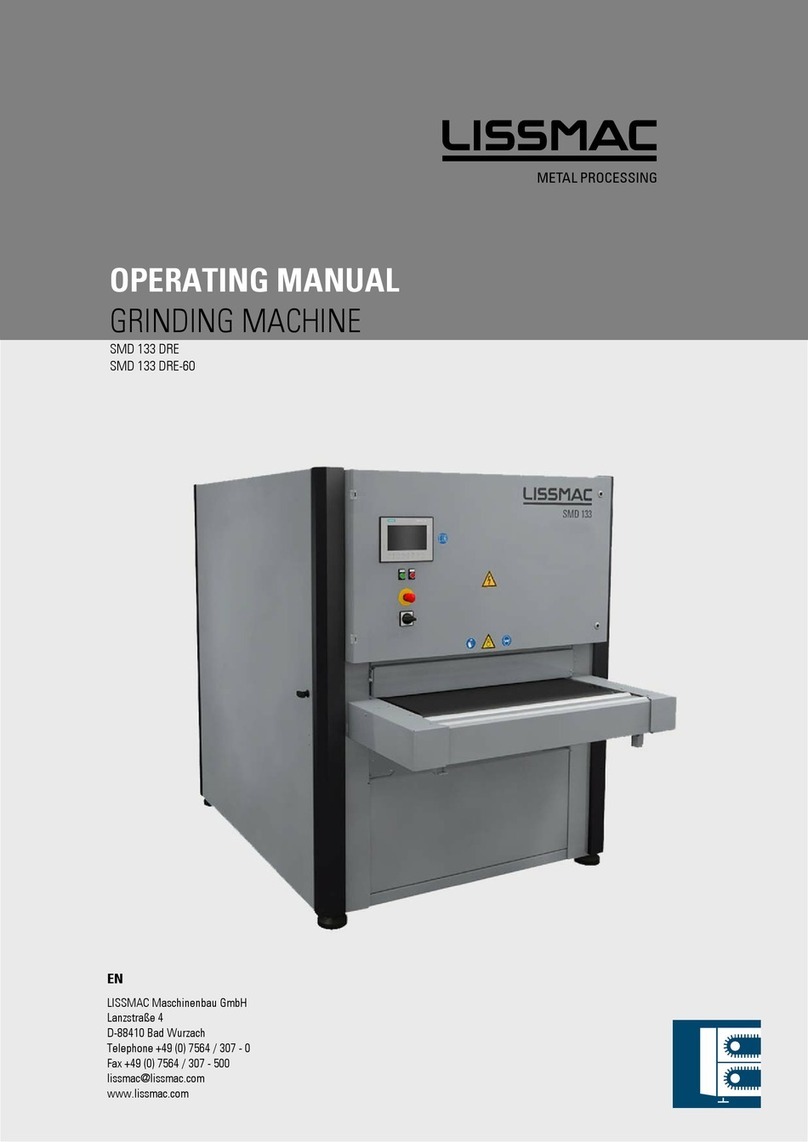

Machine Description......................................................................................................17

2.1. Component Overview ......................................................................................................17

2.2. Accessories.....................................................................................................................17

2.3. Protective Devices...........................................................................................................17

2.4. Technical Data ................................................................................................................19

2.5. Sound Power Level..........................................................................................................20

2.6. Load capacity of the Platform..........................................................................................20

Commissioning................................................................................................................21

3.1. Connections ....................................................................................................................21

3.2. Controls...........................................................................................................................21

3.3. Putting Down the Masonry Work Platform .....................................................................22

3.4. Setup of the Masonry Work Platform..............................................................................23

3.5. Installation of Railings ....................................................................................................24

3.6. Installation of emergency escape ladder ........................................................................25

Transport.........................................................................................................................26

4.1. Transport on Truck ..........................................................................................................26

4.2. Relocation with the Forklift.............................................................................................26

4.3. Movement with Construction Crane ...............................................................................27

4.4. Movement with the Wheel Set.......................................................................................28

Operation ........................................................................................................................29

5.1. Operation ........................................................................................................................29

5.2. Switch Off .......................................................................................................................30

5.3. Work Interruption............................................................................................................30

Disassembly....................................................................................................................31

Servicing .........................................................................................................................32

7.1. Maintenance Work .........................................................................................................32

7.2. Maintenance Braces .......................................................................................................33

7.3. Oil Level Inspection.........................................................................................................34

7.4. Hydraulic Oil....................................................................................................................34

7.5. Torque values of Screw Connections ..............................................................................34

7.6. Recurring Inspections......................................................................................................35

7.7. Maintenance Plan ...........................................................................................................36

Troubleshooting..............................................................................................................37

Accessories....................................................................................................................38

9.1. Subframes.......................................................................................................................38

9.2. Wheel Set .......................................................................................................................38

9.3. Masonry Work Platforms, Double ...................................................................................39

Decommissioning .........................................................................................................42

Special connection conditions ....................................................................................42

Warranty .......................................................................................................................43

Spare parts....................................................................................................................46

Hydraulic diagram ........................................................................................................56

Circuit diagram..............................................................................................................60