AC8-HD Series : Quick Start Guide

SIDE 1

Warning – Refer to Safety Precautions Booklet 035-00636R for all safety precautions prior to use.

User Guide 035-00677R download: http://www.excelitas.com/Pages/Product/OmniCure-AC8-HD.aspx

WARNING: Never look at operating LED! The light could severely damage the cornea and retina of the eye if the light is observed directly. Eye shielding

must be used at all times as well as clothing to protect exposed skin

Printed in Canada

efer to user guide for more details. 035-00682R Rev. 0

SETUP / Unpack

•Carefully unpack the unit and accessories from shipping carton.

•When removing the LED Head, ensure that the optical window is not placed directly on

a surface to avoid any damage.

1.1 System Requirements

In addition to the V LED Head, you will require the following components:

•Power supply

•Power cable

Note: You will also require a PLC controller or RS485 cable unless you are using an

existing controller. The PLC controller is used to discover the extensive functionality of

the V LED Head, but integrators can access the full feature set through integrating

with the PLC or RS485 interface directly. Refer to “Connecting the U LED Head”

documentation in the ser Guide

Connecting the Power Supply and PLC Controller

Note: All connectors are via screw style fastener -- do not over tighten the

connector screws.

Note: The following is a generic procedure, illustrated with the common

components described above. Refer to

“

Connecting the Power Supply and

PLC Controller” documentation in the User Guide

Tip: After securing the power cable to the power supply, it is recommended to

tie-off” the female connector cable on to the mounting brackets or process

rigging as a form of strain relief.

1. Make sure the power supply unit is turned off.

2. Connect the AC power cord

to the power supply.

3. Attach the male end of the

power cable to the power

supply unit, and connect the

female end of the power

cable to the UV LED Head

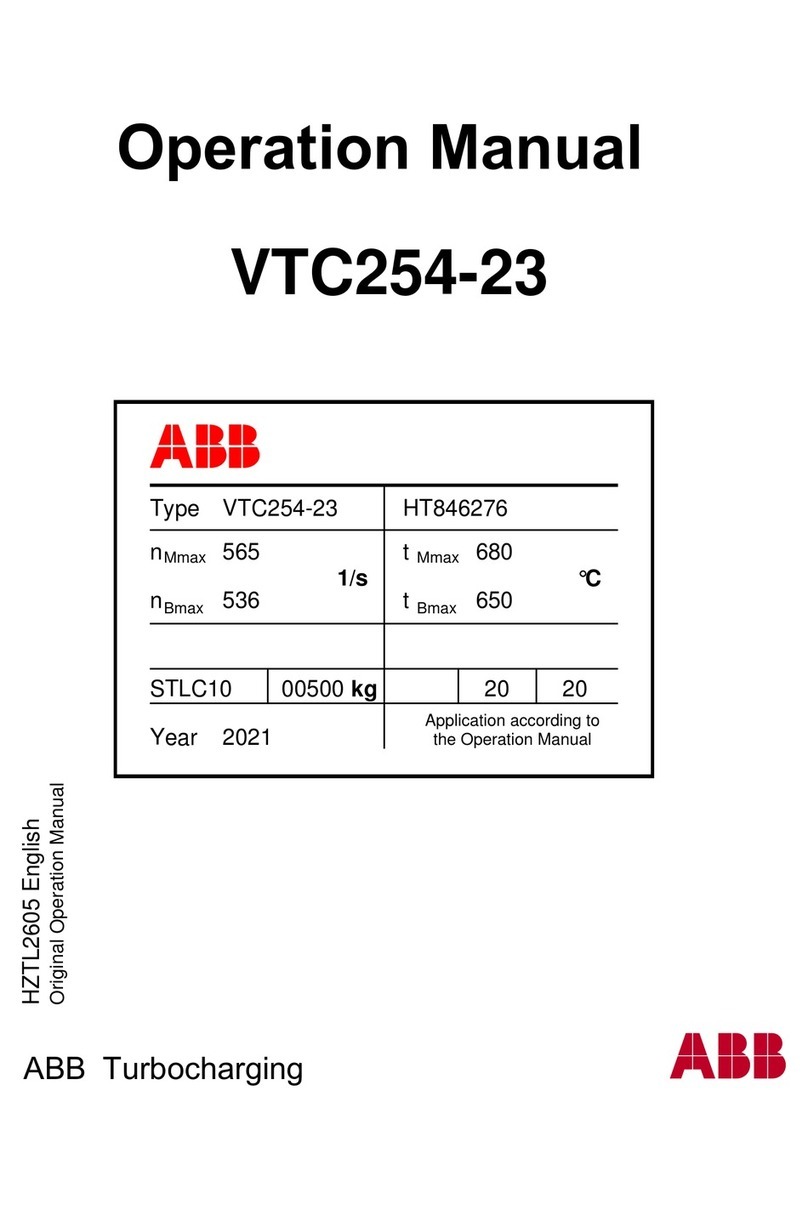

per Figure 1 – AC8300P-HD

shown.

Figure 1: UV LED ead Connection Ports

1.2 Powering Up and Powering Down

1. Ensure that the system has been properly installed and the V LED Head is securely

mounted with the optical lens in the desired orientation. Refer to “Mounting the U

Head” documentation in the ser Guide

2. Verify that the power supply unit’s AC supply cord is connected to a properly grounded

AC outlet.

3. If the power supply has a circuit breaker, switch it to the “ON” position.

4. Turn the main power switch of the power supply to the “ON” position and check the fan

for airflow.

5. The LED indicator on the V LED Head will flash green during “boot-up” and change to a

steady green indicating V LED Head is ready for use. It is recommended to wait for 15

seconds from initial power-up before attempting to control the V head. For more

information about the indicators. Refer to “Using the LED Head” in the ser Guide

1.3 Using the LED Head

The peak wavelength of the UV LED Head is 365nm, 385nm, 395nm, or 405nm +/-

5nm, depending on model.

For all models, adjusting the UV LED Head intensity can be actuated by an external

controller via the PLC interface. Refer to “Connecting UV LED ead”

documentation in the User Guide

Input voltage vs. desired intensity; 5V = 100% and 1V = 20%. A minimum voltage of

1V is required for light source operation.

Note: The light source will maintain a 20% intensity when the input voltage is in the

range of 0.5V. If the input voltage is below this, the light source will turn off.

Ensure the UV LED Head indicator is illuminated to a steady green before applying

UV power to the head. The UV LED Head indicator will illuminate to a steady amber

indicating UV is on. When UV is off, the indicator will revert back to a steady green

indicating UV is off.

The UV LED Head is capable of responding to PLC control signals in less than 0.2

seconds. Understanding the LED Indicators