8

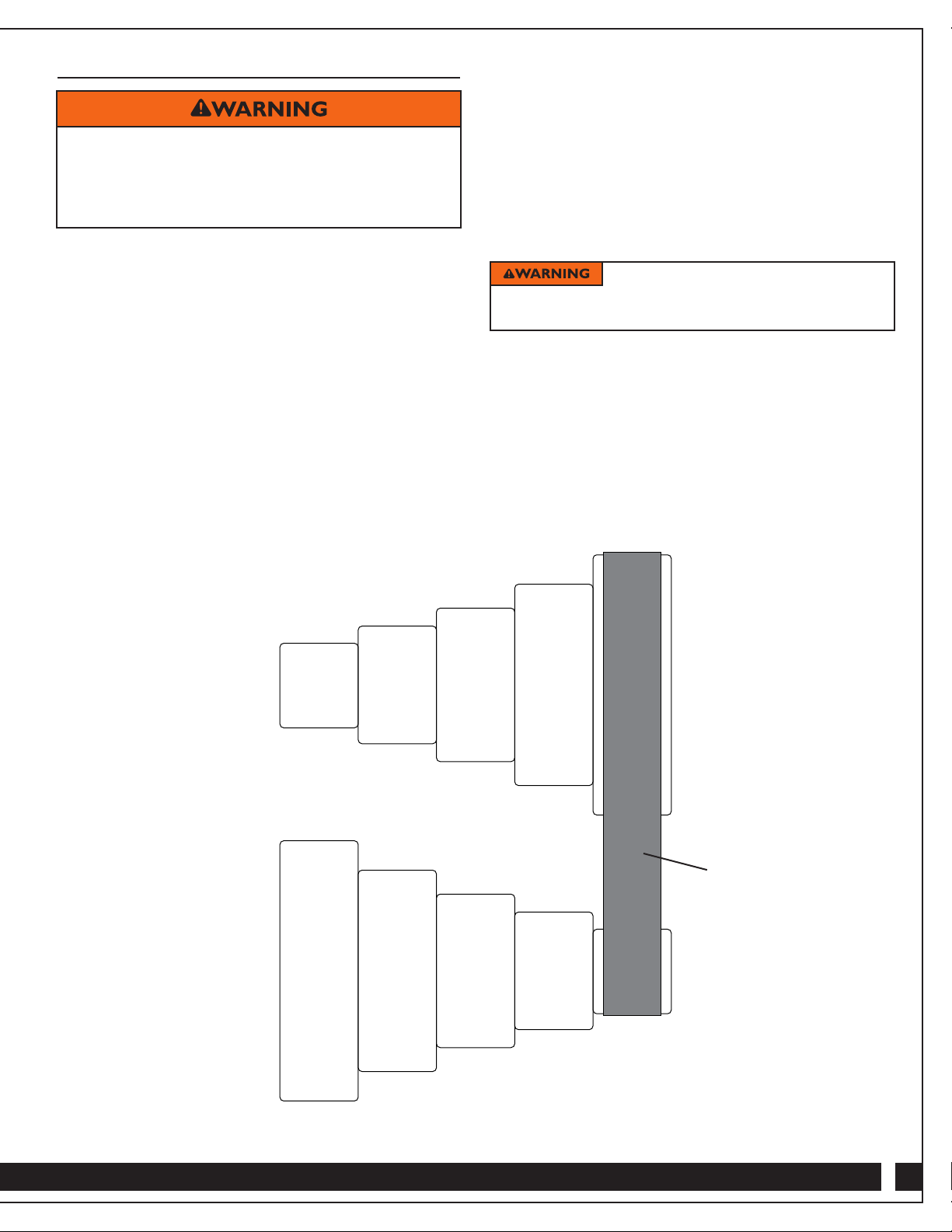

Mounting a Workpiece Between

Centers (Spindle Turning)

When turning a workpiece with the grain running parallel to

the lathe bed (furniture legs are a good example) the workpiece

(often called a blank) typically is mounted between the lathe’s

Spur Center and Live Center. To mount a blank between centers:

1. Draw diagonal, corner-to-corner lines on both ends of the

blank to locate the center points.

2. Carefully remove the Spur Center from the Headstock

Spindle, taking care not to injure your hand on the sharp

point and wings. If the Spur Center won’t come out when

you pull on it, use the Knockout Bar and, if necessary, a

dead-blow mallet to dislodge it. Don’t strike the end of the

Knockout Bar too hard, though, and be sure to catch

the Spur Center.

3. If the Faceplate is installed on the Headstock Spindle,

remove it by rotating counterclockwise.

4. Stand the blank on end and hold it securely or clamp it in

a vise. Position the Spur Center so that its center point is

at the intersection of the “X” you drew on the end of the

blank. Hold it straight and hit the end a couple of times with

a dead-blow mallet to seat the Spur Center at least 1/4" into

the blank. The Spur Center might come free from the blank,

but the impressions in the wood will make it easier to mount

the blank securely on the lathe. (If you are using an

especially hard wood, you might need to drill a 1/8"-diameter

by 3/16"-deep hole in the end of the blank after setting

the Spur Center.)

5. Reinstall the Spur Center in the Spindle and bring the blank

up to it, making sure to line up the impressions with the

wings on the Spur Center. Hold the blank parallel

to the Lathe Bed.

6. Release the Tailstock Lock Lever and slide the Tailstock until

the tip of the Live Center almost touches the blank. Press the

Tailstock Lock Lever to lock down the Tailstock.

7. Continuing to hold the blank, loosen the Quill Lock Handle.

Carefully turn the Quill Handwheel to advance the Live

Center, making sure to line up the tip with the center of

the “X” on the end of the blank. Once the tip of the Live

Center makes contact, continue tightening the Quill

Handwheel to make sure the blank is fully and securely

captured by both the Spur Center and Live Center. Tighten

the Quill Lock Handle to lock the quill in position.

8. Loosen the Banjo Lock Lever and the Tool Rest Lock

Handle. Slide the Tool Rest Banjo up to the workpiece,

leaving about 1/8" between the Tool Rest and the workpiece.

Spin the workpiece by hand to make sure no part of it will

contact the Tool Rest once the lathe is turned on. Lock the

Banjo Lock Lever.

9. Adjust the Tool Rest up or down to your preferred height

for the task and engage the Tool Rest Lock Handle. Typically,

the top edge of the rest will be just above the horizontal

centerline of the workpiece. Again, spin the workpiece by

hand to make sure no part of it will contact the Tool Rest.

Mounting a Workpiece using the Faceplate

When turning a workpiece with the grain running perpendicular

to the lathe bed (bowls and platters are good examples) the

workpiece (often called a blank) typically is mounted with screws

to the Faceplate or with a worm screw in a four-jaw chuck. To

mount a blank using the faceplate:

1. Prepare your blank for turning by making sure it is sized

to allow it to spin on the lathe without contacting the Lathe

Bed and does not exceed the recommended size limitations

of the lathe. Remove any corner edges with a band saw

or handsaw. Also make sure that the area where you will be

mounting the Faceplate is reasonably flat. If it’s not, you’ll

need to chisel out an area large enough to accommodate

the Faceplate.

2. Use a center finder or some other means to locate and mark

the center of your blank.

3. Center the Faceplate over the center mark on your blank and

mark the locations of ALL of the Faceplate’s screw holes

on the blank.

>Make sure your workpiece is fully secured on the lathe

between centers, with a faceplate and screws of sufficient

length, or in four-jaw chuck with appropriate jaws. An

inadequately secured workpiece could come off the

lathe at high velocity, potentially causing serious injury.

>Check your workpiece for any splits, cracks or other

defects that could compromise the integrity of the

wood and possibly lead to the workpiece coming

apart or coming off the lathe. Do NOT turn

blanks that have defects.

>Make sure your workpiece is fully secured on the lathe

between centers, with a faceplate and screws of sufficient

length, or in four-jaw chuck with appropriate jaws. An

inadequately secured workpiece could come off the

lathe at high velocity, potentially causing serious injury.

>Check your workpiece for any splits, cracks or other

defects that could compromise the integrity of the

wood and possibly lead to the workpiece coming

apart or coming off the lathe. Do NOT turn

blanks that have defects.

If the Tailstock Lock Lever won’t

release because it’s too tight or won’t secure the Tailstock

because it’s too loose, adjust the mounting nut on the

underside of the tailstock slightly to achieve the proper

clamping pressure.