EXHeat HEF 30 Manual

Installation, Operation & Maintenance

Instructions Manual

HEF Increased Safety

Anti-Condensation Heater

Page 2

Contents

1. Contact Details.....................................................................................................3

2. Description of Equipment....................................................................................4

3. Markings ...............................................................................................................5

4. Preservation and Storage Instructions ..............................................................6

5. Pre-installation Instructions................................................................................7

6. Installation Instructions.......................................................................................8

7. Special Conditions of Use.................................................................................11

8. Operating Instructions.......................................................................................12

9. Maintenance Instructions..................................................................................14

10. Fault Finding, Correction and Spares ............................................................16

11. COSHH Statement............................................................................................17

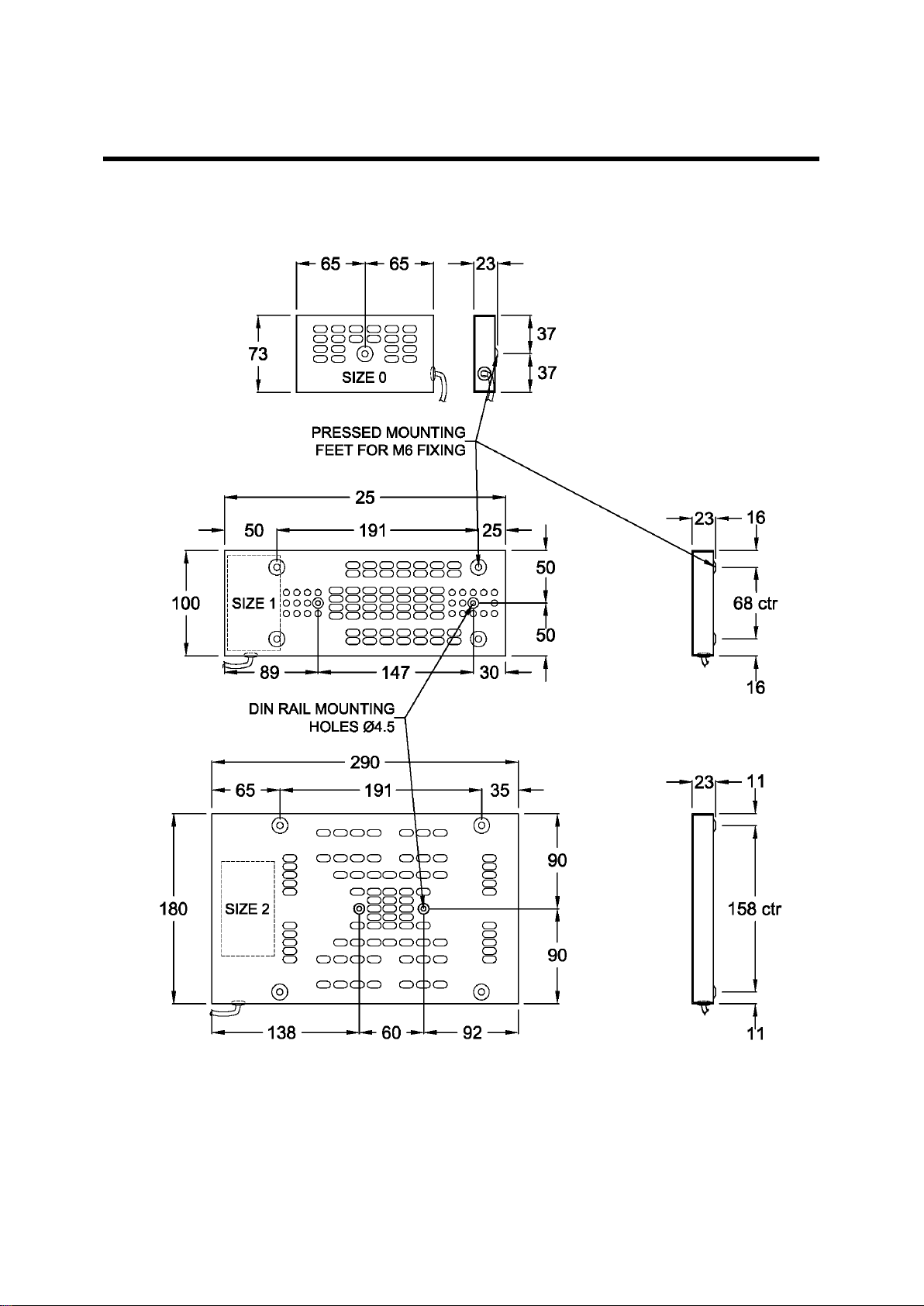

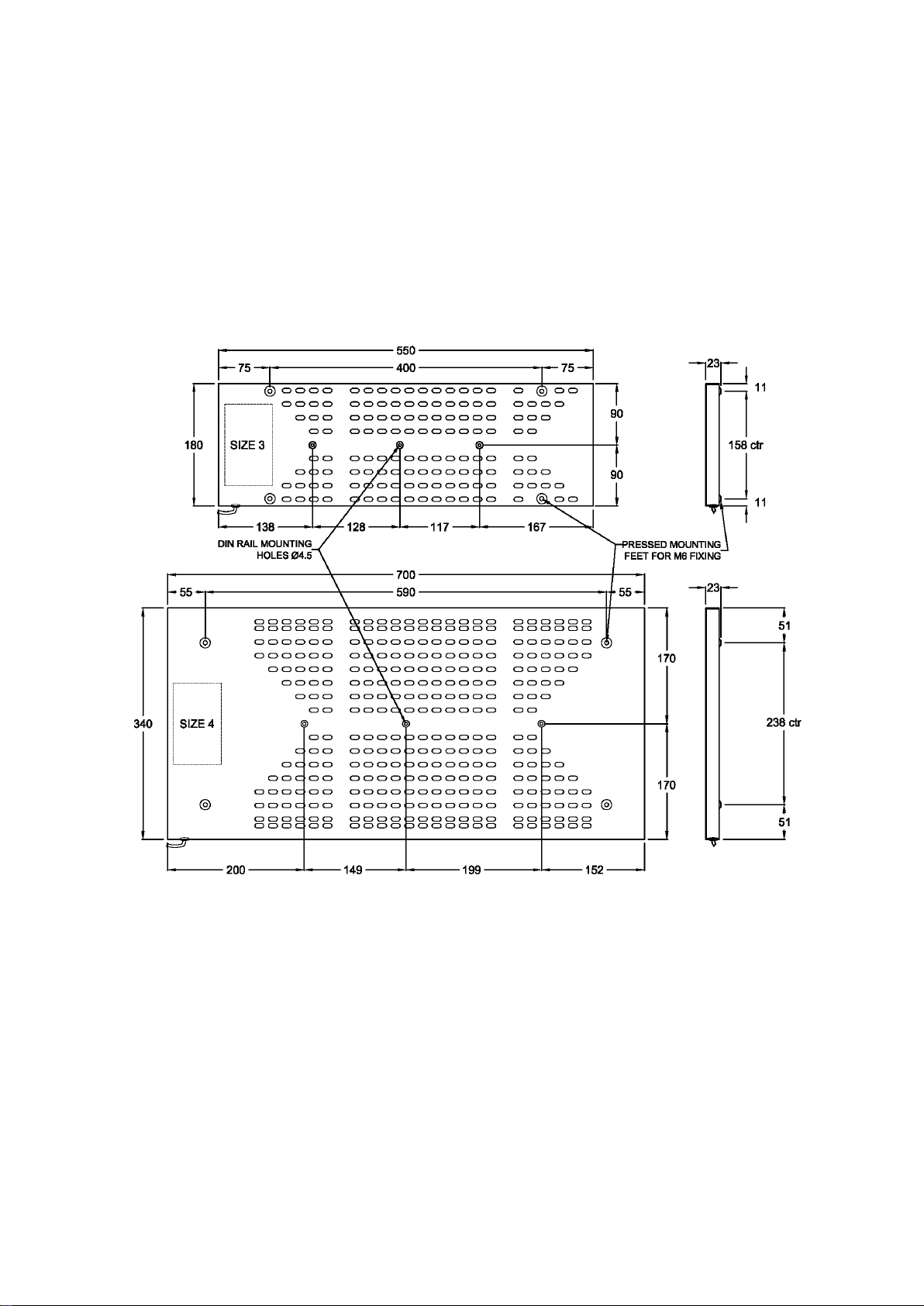

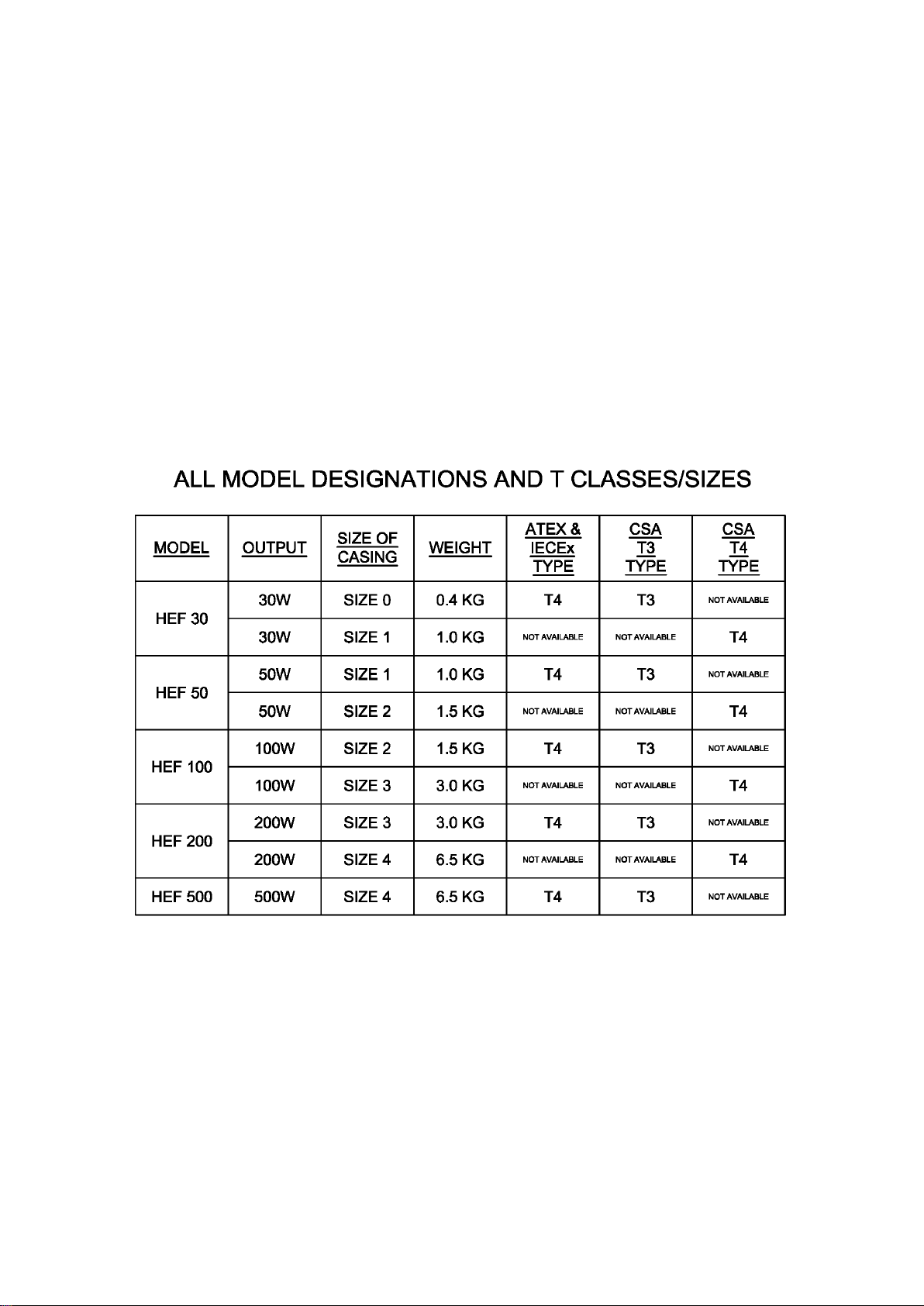

12. General Arrangement Drawings......................................................................18

13. Wiring Diagrams...............................................................................................21

14. Routine Maintenance Inspection Records.....................................................22

15. Certification ......................................................................................................24

EXHEAT Industrial can provide versions of this manual in German, French, Italian,

Spanish, Portuguese, Polish, Chinese and Russian. These versions can be requested

at support@exheat-industrial.com

To maintain the equipment warranty and, if applicable, the Hazardous Area

Certification, the instructions contained within this manual must be complied with in

full.

Fitting any other device invalidates the hazardous area certification.

1. Contact Details

Page 3

1. Contact Details

Sales Enquiries

EXHEAT Industrial Ltd

Threxton House

Threxton Road Industrial Estate

Watton, Thetford

Norfolk, IP25 6NG

Tel: +44 (0) 1953 886 210

Fax: +44 (0) 1953 883 853

Email: sales@exheat-industrial.com

Website: exheat-industrial.com

Technical Support

EXHEAT Industrial Ltd

Threxton House

Threxton Road Industrial Estate

Watton, Thetford

Norfolk, IP25 6NG

Tel: +44 (0) 1953 886 269

Fax: +44 (0) 1953 883 853

Email: support@exheat-industrial.com

Website: exheat-industrial.com

2. Description of Equipment

Page 4

2. Description of Equipment

The EXHEAT Industrial Ltd HEF type increased safety anti-condensation heater is designed

for anti-condensation or frost protection within control panels, cabinets and small enclosures

in conjunction with a hazardous area thermostat or, on its own as a self-regulating heater.

Enclosure

•Formed 316 perforated stainless steel.

Connections

•The connection of this heater is made via the supplied 3-core up to 1.5mm² supply

cable (16AWG). The standard cable is 1.0mtr long (longer available at request) and

it is the responsibility of the installer/end user to connect to suitable connectors/joint.

Refer to Section 7.

•The internal earth connection is made via the supply cable (internal earth strapped to

the enclosure within the heater) the heater internals are sealed and non-accessible.

The external earth derives from the fixing points either on a DIN rail or onto metallic

base.

Controls

•The nature of the self-regulating cable within the HEF affords it to be a stabilised

design type of heater, therefore there are no additional controls required.

•Should overall control of the temperature be required an EXHEAT Industrial Ltd

certified thermostat may be used, such as the AFT, HFT (standalone thermostats) or

the FXT range can be used for in-line variation.

Mounting

•Up to 4 off 6.2mm (Clearance) diameter mounting holes are provided with pressed

feet.This product may be mounted in any orientation, please refer to the general

arrangement drawing for dimensions of the fixing holes. Alternatively, there are

central holes for DIN rail mounting (4.5mm).

Voltage

•The HEF range can be either 120V nominal or 230V nominal with a range between

110V to 277V, 50 or 60 Hz. Subject to Sales Approval.

CAUTION – Check that the voltage and current of the heater is compatible with the

ratings of the supply or in line thermostat before energising.

3. Markings

Page 5

3. Markings

ATEX Markings: IECEx Markings:

Cert No. ITS19ATEX104973X Cert No. IECEx ITS 19.0024X

II 2 G

Ex eb IIC T4…T3 Gb Ex eb IIC T4…T3 Gb

**’db eb’ when ‘d’ type in-line thermostat is used, ‘eb mb when ‘m’ type in-line thermostat is

used – See relevant thermostat IOM/Certs, markings and standards applied**

Certified to (Heater): Certified to (Heater):

EN 60079-0:2018 IEC 60079-0:2018 Ed 7

EN 60079-1:2014 IEC 60079-1:2014-06 Ed 7

Operating Ambient Temperature

-55°C ≤ Tamb ≤ +80°C when QTVR cable is used

-55°C ≤ Tamb ≤ +80°C when HTSX cable is used

-50°C ≤ Tamb ≤ +80°C when either cable is used with an in-line thermostat (d or m type).

CEC & NEC Markings:

Cert No. 70117806 for division label and CSA17.70117806U for zone label

(CAN-CEC / US-NEC)

Class I Division 2. Groups A, B, C & D. T4…T3

US (NEC): CAN (CEC):

Class I Zone 1 AEx e IIC T4…T3 Gb Ex e IIC T4…T3 Gb

Operating Ambient Temperature

-55°C ≤ Tamb ≤ +80°C

CSA Classes C2848-01, C2848-81

***Optional in-line thermostats may be connected with the HEF (Known as HEF-T), please

refer to the relevant thermostat IOM for the thermostat details***

4. Preservation and Storage Instructions

Page 6

4. Preservation and Storage Instructions

Storage

•Store the equipment in an inside location that is dry, clean and well ventilated.

CAUTION – The following preservation instructions must be adhered to, failure

to do so could result in the equipment warranty being invalidated:

•Store the equipment at between the temperatures as indicated on the

nameplates.

•Ensure that the equipment is not subjected to direct sunlight at ambient

temperatures above +30°C.

•Do not store the equipment for more than 3 months unless packed for long term

storage.

•Protect the equipment against external sources of vibration and/or impact.

•If practically possible, leave the equipment in its original sealed packaging until

required for installation.

5. Pre-installation Instructions

Page 7

5. Pre-installation Instructions

Pre-Installation Inspection

•Each heater (and heater with in-line thermostat) is manufactured to the highest

standard with great care and quality materials. All the goods are thoroughly

inspected and tested before leaving the manufacturing plant, and they must be

handled with care during storage and installation. Before the installation starts it is

advised that the heater is checked to ensure the insulation resistance reading is

above 2MΩ per element at no less than 500 volts dc.

•Should the Anti-Condensation heater fail this test contact the technical help on our

website: www.exheat-industrial.com/contact/support

•Inspect the heater for visible signs of damage, paying particular attention to the

supply cable, as this may get damaged during transport, also ensure that the heater

is not bent or squashed and that the fixing holes are free from obstruction.

Compliance with these instructions is a warranty requirement. Documented evidence must

be maintained in the form of a signed checklist. Copies of completed checklists and records

will be required in the event of any warranty claim.

Insulation Resistance

•The Insulation Resistance Test should be applied between the phase(s) and earth. A

reading of greater than 2MΩ at no less than 500 volts dc should be recorded.

•If the HEF heater has an in-line thermostat connected, the thermostat must be closed

for this test to be undertaken.

6. Installation Instructions

Page 8

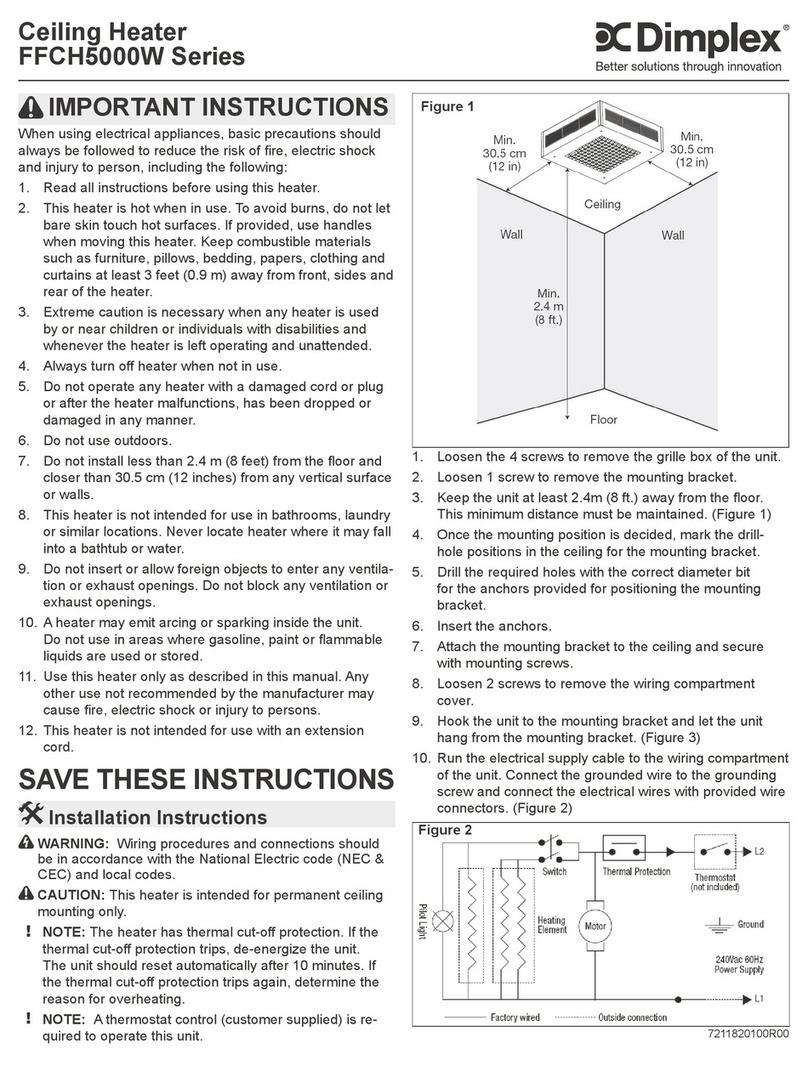

6. Installation Instructions

Should deviation from original design parameters occur, or change of

original design structure be required, please refer back to EXHEAT I

ndustrial

Ltd for consultation prior to installation.

•Refer to the relevant code of practice for the equipment:

•IEC/EN 60079-14 for selection and installation or the relevant global equivalent.

•IEC/EN 60079-17 for inspection and maintenance of electric apparatus for use in

potentially explosive atmospheres or the relevant global equivalent.

•Carefully remove the packaging from each product and check for damage.

Immediately report any damage to EXHEAT Industrial Ltd. (please keep this IOM and

the additional certification booklet for future reference).

•Ensure that the product is correctly installed in a suitable location by authorised and

competent persons.

•The HEF heater should be securely fixed in position using the pre-drilled fixing holes,

or the Din rail brackets, adhering to the correct orientation if applicable, and all client

made terminal connections checked for tightness before energising. (The HEF type

unit (including the in-line d or m version) is a sealed heater and must not be opened)

•Before operating the equipment, have the installation approved by the site authorised

person who is responsible to ensure that the installed system is safe for operation.

•Ensure compliance with any instructions and information provided in this manual and

on the drawings/certification supplied, also be aware of any additional warning that

may be present on the product on any warning labels.

•The installer and the end user shall ensure that the unit has free and unrestricted air

flow to allow natural convection to occur at all times. DO NOT COVER the Anti-

Condensation heater and do not allow anything to rest on or against it. Please allow

a minimum 50 – 100mm free air in front of the heater when installed.

•The product shall only be energised within its allowed ambient parameters, please

check the sales literature and certification for the product ambient temperature range.

•Before energising the product, ensure that the supply conforms to the specified

voltage on the products nameplate at a nominal variance of +/- 5% of the specified

voltage.

It is the client’s responsibility to ensure that safe systems of work are used

by all personnel operating and maintaining the equipment, including testing

when ‘live’.

If there is any uncertainty about these points, contact EXHEAT Industrial Ltd

for advice.

Failure to comply could result in the Hazardous Area Certificate being

invalidated.

6. Installation Instructions

Page 9

Electrical Supply Connection

•Refer to wiring diagrams in Section 13.

•There are no cable entries on the HEF Anti-Condensation heater. Connection is

to be made via the manufacturer installed 3 core supply cable.

•Connections to this heater are to be made via the 3-core flex. The flex is to be

installed into suitable rated terminals/joint box, crimped and terminated correctly.

•Refer to Section 7.

•Before connection ensure that the supply corresponds with that specified on the

nameplate label, and that the sizes and types of cables to be used are suitably rated

for the load and temperature of the product.

•Each heater circuit must be protected by a suitably rated over current device and

earth leakage circuit breaker device. See below for earth connection details.

•The HEF heater is not designed to be taken apart and inspected as all of the internal

connections are sealed.

•CAUTION – Check nameplate for correct voltage and classification.

Earth Connection

WARNING – These heaters MUST BE EARTHED.

•The internal earth connection on the HEF range is obtained by the connection of the

3-core supply cable. The external earth connection is to be made via one of the

heaters fixing methods. No additional earth connections are required.

•Should a thermostat be used, please refer to the thermostats IOM for earth

connection points.

Earth-fault Protection

For safety reasons, it is essential to limit the magnitude and duration of earth-fault currents.

It is impractical to cover all possible systems, however note that, regardless of which system

is used, the heater must be protected by a suitable device wired to shut down the heater in

the event that a heater element fails to earth. Suitable devices include a residual current

device (RCD) – this is the preferred method and should be used whenever possible – or an

insulation monitoring device.

•Maximum recommended setting for the RCD: 300mA/10mS. The duration time of

10mS (ten milliseconds) ensures that any fault is detected within a single cycle of a

thyristor system (where applicable).

•Maximum recommended setting for the insulation monitoring device: Insulation

resistance is not greater than 50 ohms per volt of rated voltage.

Ensure that the equipment is earthed in accordance with the plant earthing philosophy.

6. Installation Instructions

Page 10

If fitted, an anti-condensation heater must be protected by a 30mA earth leakage circuit

breaker. Recommended systems are available from EXHEAT Industrial Ltd upon request.

Before commissioning the equipment, the completed installation should be approved by an

authorised & competent person to ensure that it has been carried out correctly and that the

system is safe for commissioning.

Before switching the Anti-Condensation heater circuit on, ensure that all of the relevant

requirements, and any special conditions of use requirements have been adhered to. Refer

to Section 7.

7. Special Conditions of Use

Page 11

7. Special Conditions of Use

Please adhere to the warnings within this IOM and on the heater/thermostat nameplates,

when using the equipment. Please also note the special conditions of use as listed below:

•The HEF type heater (with or without an additional in-line thermostat) must be

installed within an enclosure with the minimum of IP54 protection.

•The Flying lead on the HEF type heater (with or without an additional in-line

thermostat) must be connected to suitably rated terminals, either within a safe area

or within Ex e type terminal box – as a minimum.

•The equipment is not field serviceable by the user and shall not be opened.

•The equipment shall be installed so that pulling, flexing or mechanical damage of the

cable is prevented.

•The equipment has non-conductive surfaces which are a potential electrostatic charging

hazard – see the instructions for guidance.

•The equipment shall be supplied via a fuse that is mounted externally in a safe area and

rated at 277 V ac, 6 A maximum. The fuse shall have a breaking capacity which exceeds

the prospective short circuit current of the supply

8. Operating Instructions

Page 12

8. Operating Instructions

General

Electrical equipment must be designed, tested and installed such that, when it is used

correctly, health and safety risks are kept to a minimum. The client must be provided with

information about any necessary safety conditions, warned of any possible hazards that may

arise during normal operation and told how to avoid them.

•The HEF heater is to be designed to self-regulate the temperature within the cabinet

or enclosure by means of the internal self-limiting cable installed within it. Should

overall temperature regulation be required it can be wired in series with an EXHEAT

Industrial Ltd thermostat, such as the AFT, HFT or the FXT range.

•There is no temperature adjustment required for this heater, it will self-regulate.

Should a thermostat be installed, refer to the relevant thermostat IOM for

temperature setting instructions.

•The HEF range is designed to operate in ambient temperatures of up to +80°C and

the user must ensure that this maximum ambient temperature is not exceeded at any

time. Refer to section 3.

CAUTION – If a thermostat is used, check that the voltage and current of the

HEF to be controlled by the thermostat is compatible with the ratings of the

thermostat before energising.

The user must ensure that the following is adhered to:

•Any employees working on the equipment are authorised & competent in the proper

working procedures in order to ensure their and others safety. The plant must be

maintained in a safe condition.

•Carefully remove all protective packaging and visually inspect product for any transit

damage.

•The heaters must be handled with care and stored in clean and dry conditions, as per

Section 4.

•All prevailing rules, regulations and bylaws in force at the time and place of

installation must be observed.

•The heater should be securely fixed in position (adhering to the correct orientation if

applicable) and all the client made terminal connections checked for tightness before

energising.

•Refer to the relevant code of practice for the equipment:

•IEC/EN 60079-14 for selection and installation or the relevant global equivalent.

•IEC/EN 60079-17 for inspection and maintenance of electric apparatus for use in

potentially explosive atmospheres or the relevant global equivalent.

•Ensure that any special conditions for use detailed on the Hazardous Area

Certification are complied with (see additional certification booklet supplied with this

product).

8. Operating Instructions

Page 13

Any modification not carried out by EXHEAT Industrial Ltd could invalidate certification and

warranty.

Provided the above conditions are adhered to, the equipment should be safe for use under

normal operating conditions.

It is virtually impossible to achieve conditions which are completely hazard-free when

working on energised circuits. Responsibility for safe conduct of the authorised & competent

person or persons operating on the equipment rests with those under whose authority they

act.

9. Maintenance Instructions

Page 14

9. Maintenance Instructions

General Safety Precautions

The end user must ensure that maintenance, installations, commissioning and testing of the

equipment is only carried out by authorised and competent persons.

The following rules must be adhered to:

•All prevailing site safety regulations shall be adhered to at all times.

•Check for hazardous gases before and during any maintenance activity.

•Fully isolate the equipment from the electrical supply before and whilst any work is

being carried out.

•Before removing the terminal enclosure lid/doors, allow sufficient time for the internal

HEF range heater to cool down after electrical isolation.

•Comply with safe working conditions.

•Do not work alone on the equipment when it is energised.

•Familiarise all persons working on the equipment with the instructions and

information provided within this manual.

•Be aware of hazards which may arise when working on energised equipment and

take all necessary precautions.

The following preventative maintenance should be carried out at the intervals shown below,

for any replacement parts, please contact EXHEAT Industrial Ltd.

Compliance with these maintenance instructions is a mandatory requirement. Documented

evidence must be maintained in the form of a signed checklist. Copies of completed

checklists and records will be required in the event of a warranty claim. Refer to Section 14.

If the HEF heaters are not used for more than three months they must be

tested for insulation resistance.

Three-monthly Maintenance Inspections

•Generally, inspect the equipment for external damage.

•Ensure that the product is clear of obstruction and that the airflow remains

unrestricted.

Six-monthly Maintenance Inspections

The following should be undertaken every six months with the addition to the three-monthly

maintenance inspections above:

9. Maintenance Instructions

Page 15

•Isolate the electrical supply as per Section 6.

•The HEF heater and thermostats should be clean, dry and free from debris.

•Ensure that electrical terminations and cable glands are undamaged and secure.

•Measure the overall insulation resistance of the heater. Use a 500V dc

megohmmeter to take a reading between the earth and the phase terminals. The

reading should be greater than 2 megohm. If it is not, refer to Section 5.

•Earth continuity must be maintained between all earth points and the main structure,

ensure that any earth conductors are correctly and securely fitted between all earth

points and main structure.

•Ensure all trip devices are working properly.

Annual Inspections and Long-Term Storage Inspections

Ensure that the following inspections are carried out if equipment is in storage or in use for a

year or more:

•Undertake the recommended three-monthly and six-monthly inspections as

above.

•Inspect for low insulation resistance, as Section 5.

•Only EXHEAT Industrial Ltd can undertake any replacements in hazardous area

equipment, any unauthorised modifications will invalidate the hazardous area

certification and any warranty.

•If equipment is being left unused for a period greater than three months, undertake

the 6-monthly maintenance before energizing.

Only EXHEAT Industrial Ltd or approved Services Representative are

authorised to replace HEF related components. The hazardous area

certification and warranty will be invalidated if this requirement is not strictly

observed.

10. Fault Finding, Correction and Spares

Page 16

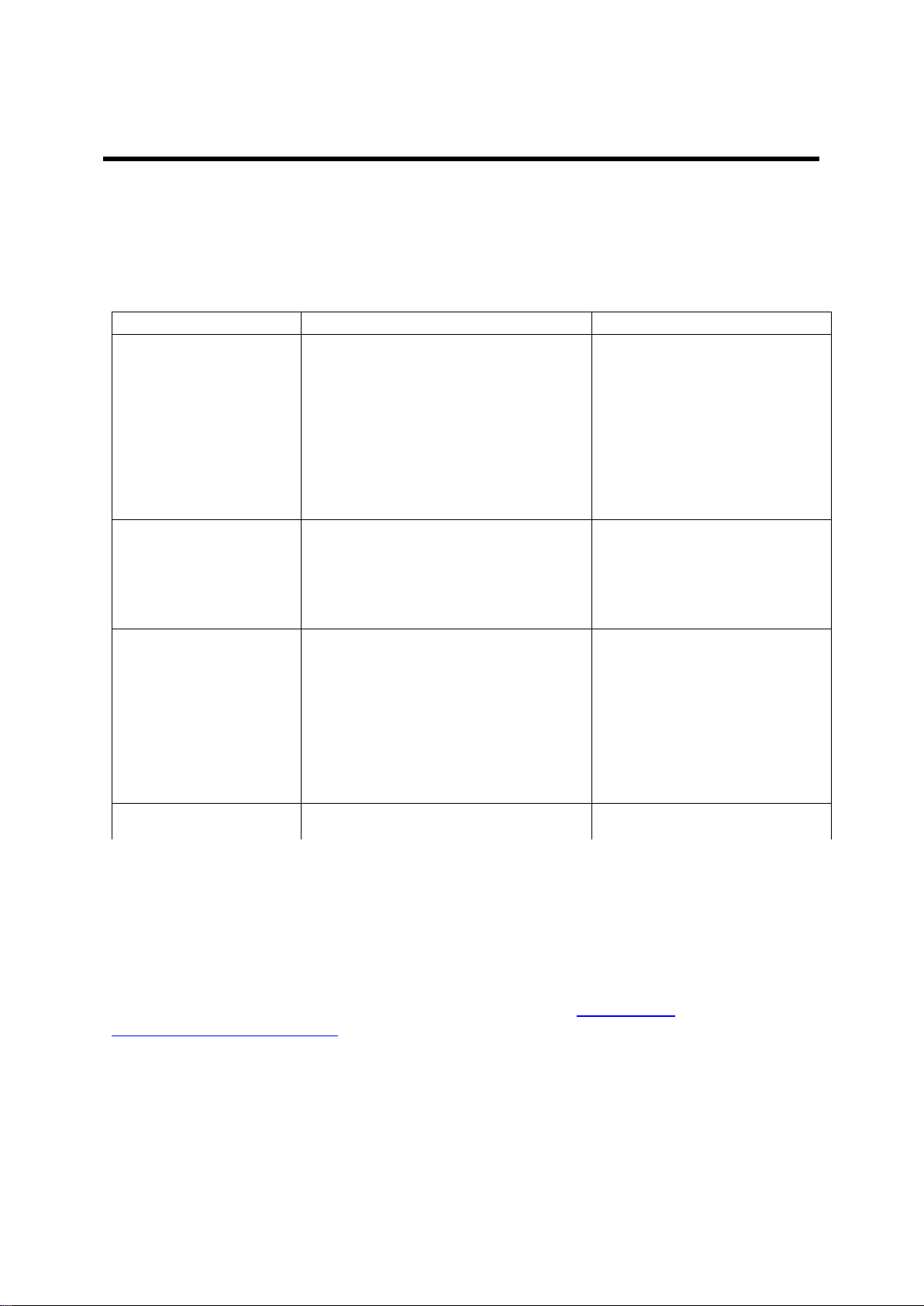

10. Fault Finding, Correction and Spares

All HEF Type Heaters

See Maintenance instructions for procedures relating to these faults.

Fault

Check

Resolution

Heater fails to achieve

required design air

temperature

•Isolated power supply.

•Supply fuses.

•Is the ambient temperature greater

than that required (thermostat has

turned off). (if thermostat installed)

•The designed heating output is less

than the required amount, or is

there greater heat loss due to a

change in location.

Contact EXHEAT Industrial Ltd

for advice.

Air temperature too high

•Temperature control device set

points correct?

•Does the compartment have a

thermostat switch? If so is it

switching the heater correctly?

Check with the installer.

Earth leakage trip

Limiting earth-fault currents (magnitude

and/or duration) is essential for safety.

The earth-fault protection device is

intended to provide critical safety

protection if there is current leakage to

earth. Fully investigate and rectify any

trip condition before resetting the

system and operating the unit again.

Where an earth leakage trip has

occurred, isolate the unit and:

•Check insulation resistance

is according to Section 4.

•Check settings of earth

leakage protection device

are according to Section 5.

In-line thermostat not

switching

Ambient temperature against the

temperature set point of the thermostat

Refer to the thermostat IOM for

further diagnosis assistance.

Spares

There are no spares available for the HEF range (including the in-line thermostat options).

Should any item be damaged or not working correctly, it will need to be sent back to

EXHEAT Industrial Ltd for any remedial work. Contact us via www.exheat-

industrial.com/contact/support

11. COSHH Statement

Page 17

11. COSHH Statement

Health and Safety Information

There are no hazardous or toxic substances applied with this order as defined in COSHH

(control of substances hazardous to health) regulations (2002).

12. General Arrangement Drawings

Page 18

12. General Arrangement Drawings

HEF_iom_dwg_1

12. General Arrangement Drawings

Page 19

HEF_iom_dwg_2

12. General Arrangement Drawings

Page 20

This manual suits for next models

4

Table of contents

Other EXHeat Heater manuals

Popular Heater manuals by other brands

TGM

TGM HT Series user manual

Heatstore

Heatstore HSFAH30 Installation and operating instructions

Goldair

Goldair GFE255 operating instructions

Kruger

Kruger HEIMDAL45 instruction manual

Intertec Data Systems

Intertec Data Systems SL VARITHERM DPA operating instructions

2VV

2VV VENESSE Comfort VCV Series manual

MVP

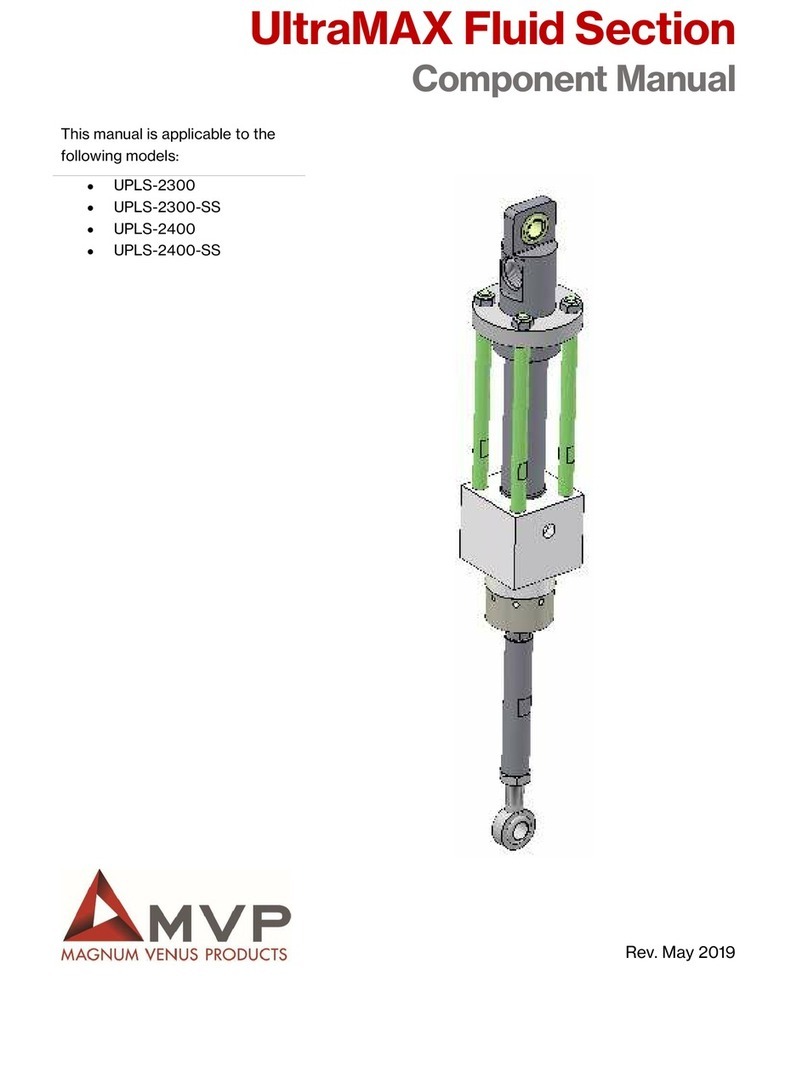

MVP ULTRAMAX UPLS-2300 Component manual

Goldair

Goldair GCW220 operating instructions

Orbegozo

Orbegozo FH 6065 instruction manual

DORCHESTER

DORCHESTER DR-TC 60 Installation, commissioning and maintenance instructions

Martec

Martec Phoenix Mini installation instructions

Schniewindt

Schniewindt 93/F53-63 instruction manual