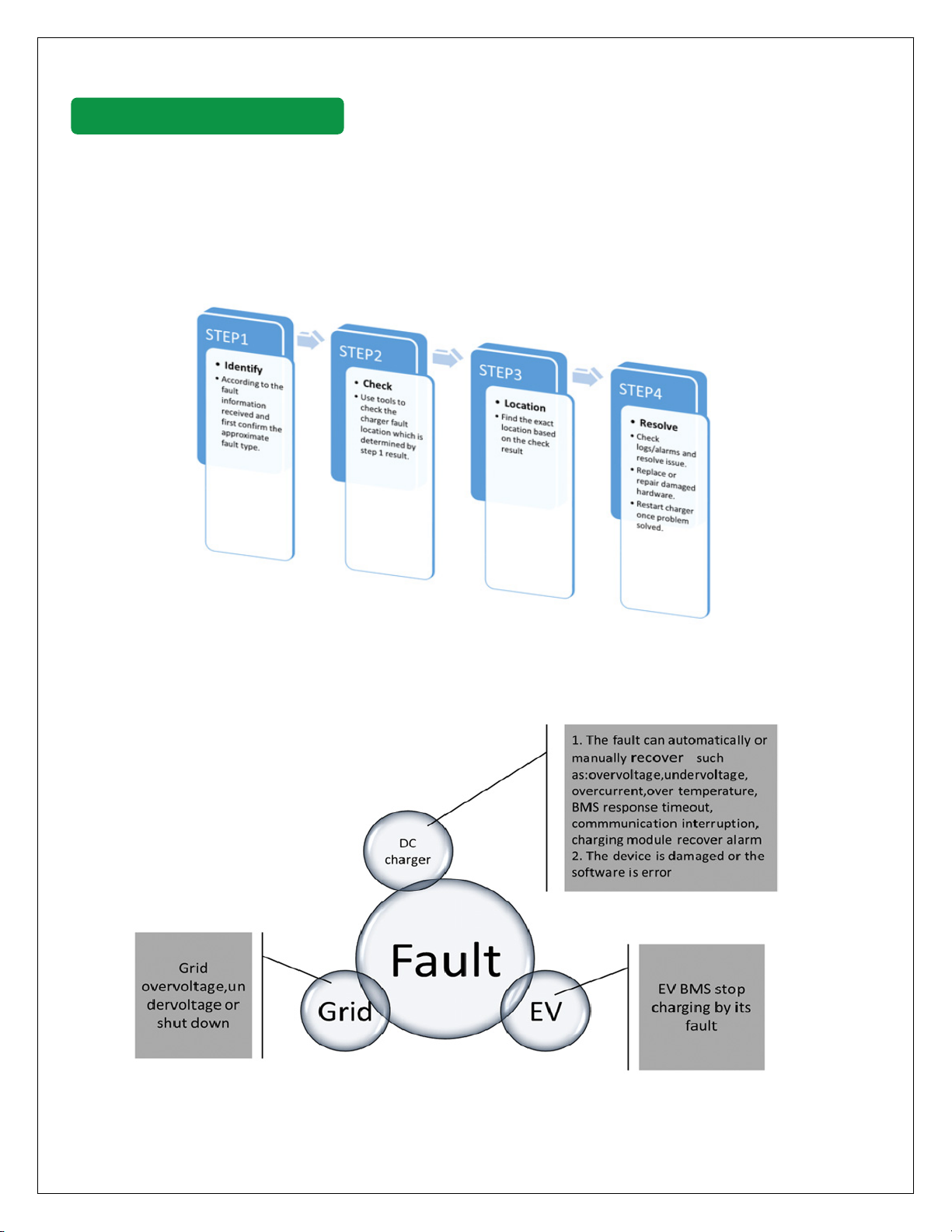

During charging, the vehicle requests for voltage & current and the charger delivers the same by

limiting the current as per requested current. However, charging may be stopped/interrupted by

various reasons. Charging can be stopped by the charger, the vehicle or by any other means. Charger

generates stop reason based on the nature of the cause of why the charging stops. The commonly

occurring stop reasons along with their explanations and resolutions are given below:

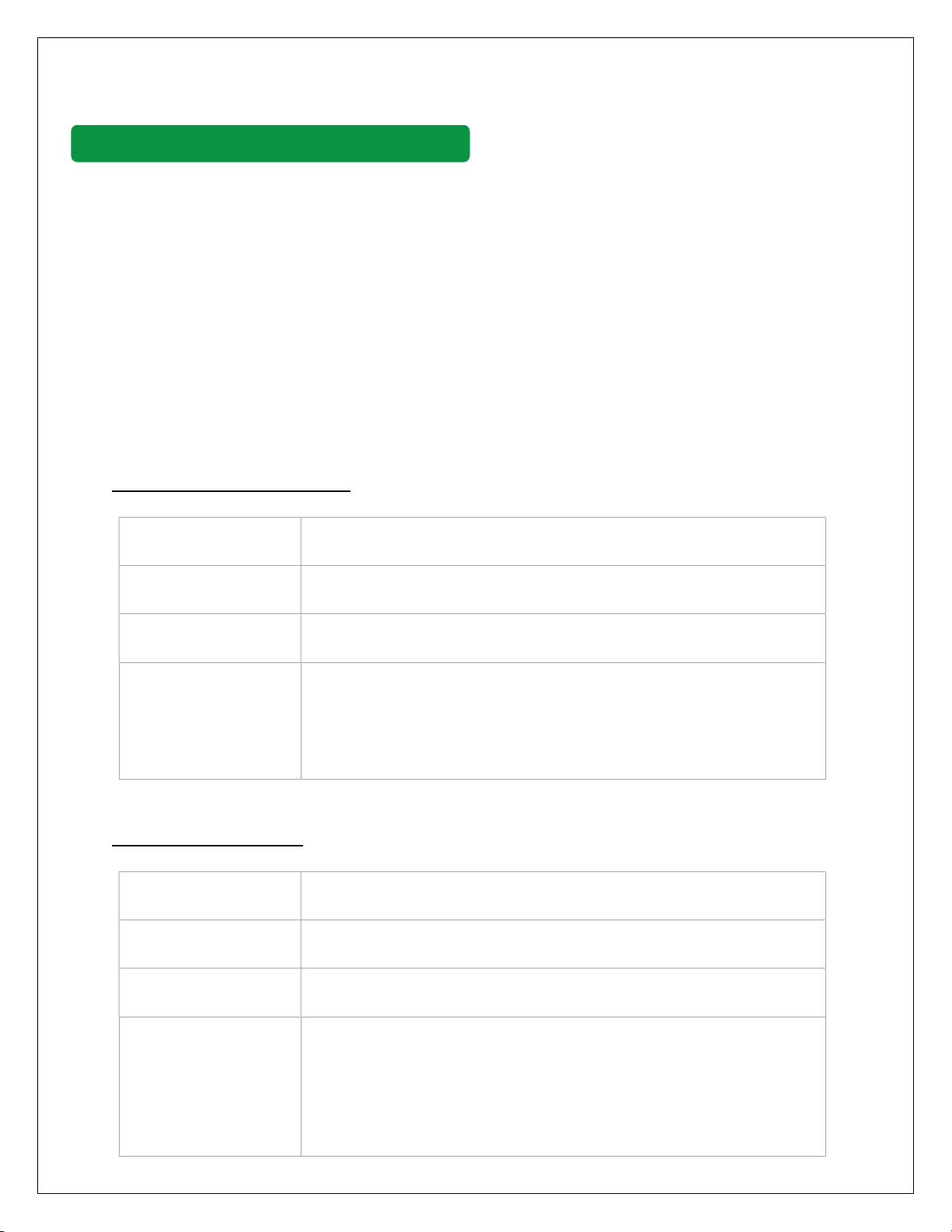

Charging Stopped/Interrupted by Charger

Parameter configuration failed

Error Code 201

Error Name Param config failed

Error Cause Related to charger PLC parameters configuration

Error Solution 1. Retry Charging.

2. If generated frequently take PLC serial and CAN log of the

respective gun and share for analysis.

Charging Enable timeout

Error Code 202

Error Name Charging enable timeout

Error Cause Start charging command is not received from the vehicle.

Error Solution 1. Retry Charging.

2. If generated frequently, please inform the vehicle

manufacturer regarding this.

3. If the issue persists, take PLC serial and CAN log of the

respective gun and share for analysis.

CHARGING STOP REASON TROUBLESHOOTING