109-3910 Rev. B

Page 2 of 4

Servicing the Battery

The machine is shipped with a filled lead acid

battery.

DANGER

POTENTIAL HAZARD

♦Charging the battery may produce explosive

gasses

WHAT CAN HAPPEN

♦Battery gasses can explode causing serious

injury.

HOW TO AVOID THE HAZARD

♦Keep sparks, flames, or cigarettes away from

battery.

♦Ventilate when charging or using battery in an

enclosed space.

♦Make sure venting path of battery is always

open once battery is filled with acid.

1. Tilt seat up to gain access to the battery.

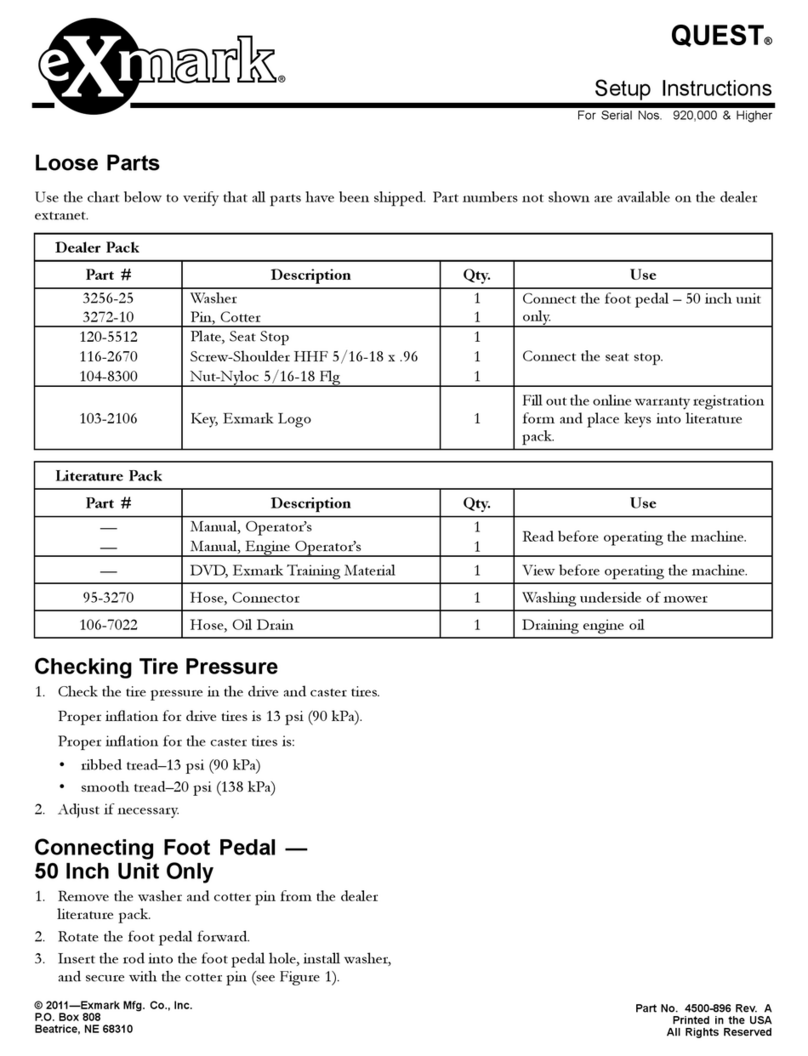

2. Check the voltage of the battery with a digital

voltmeter. Locate the voltage reading of the

battery in the table below and charge the battery

for the recommended time interval to bring the

charge up to a full charge of 12.6 volts or greater.

IMPORTANT: Make sure the negative battery

cables are disconnected and the battery charger

used for charging the battery has an output of 16

volts and 7 amps or less to avoid damaging the

battery (see chart below for recommended charger

settings).

Voltage

Reading Percent

Charge

Maximum

Charger

Settings

Charging

Interval

12.6 or greater 100% 16 volts /

7 amps No Charging

Required

12.4 – 12.6 75 – 100% 16 volts /

7 amps 30 Minutes

12.2 – 12.4 50 – 75% 16 volts /

7 amps 1 Hour

12.0 – 12.2 25 – 50% 14.4 volts /

4 amps 2 Hours

11.7 – 12.0 0 – 25% 14.4 volts /

4 amps 3 Hours

11.7 or less 0% 14.4 volts /

2 amps 6 Hours

or More

CAUTION

POTENTIAL HAZARD

♦If the ignition is in the “ON” position there is

potential for sparks and engagement of

components.

WHAT CAN HAPPEN

♦Sparks could cause an explosion or moving

parts could accidentally engage causing

personal injury.

HOW TO AVOID THE HAZARD

♦Be sure ignition switch is in the “OFF” position

before charging the battery.

3. Connect the negative battery cables.

NOTE: If the positive cable is also disconnected,

connect the positive (red) cable to the positive

battery terminal first, then the negative (black)

cable and green/white wire to the negative

battery terminal. Slip insulator boot over the

positive terminal.

NOTE: If time does not permit charging the

battery, or if charging equipment is not available,

connect the negative battery cables and run the

vehicle continuously for 20 to 30 minutes to

sufficiently charge the battery.

Installing the Motion Control

Levers

1. Remove the bottom 3/8” x 1” bolt and spring

disc washer from the motion control lever.

Loosen the upper 3/8” x 1” bolt and spring disc

washer that are screwed into the control arm

shafts (See Figure 3).

2. Position the lever so the bottom hole aligns with

hole in the control arm shaft. Install spring disc

washer and bolt.

3. Repeat on opposite side of unit.

NOTE: There are two lever height options

available. Place the levers in the top two holes

to increase height of the levers, or in the bottom

two holes to decrease the height of the levers.

WARNING: Battery posts, terminals, and related

accessories contain lead compounds, chemicals

known to the State of California to cause cancer and

reproductive harm. Wash hands after handling.