GELFREE 8100 Fractionation System (10 of 30)

Operating Procedures

Installation and Power Up

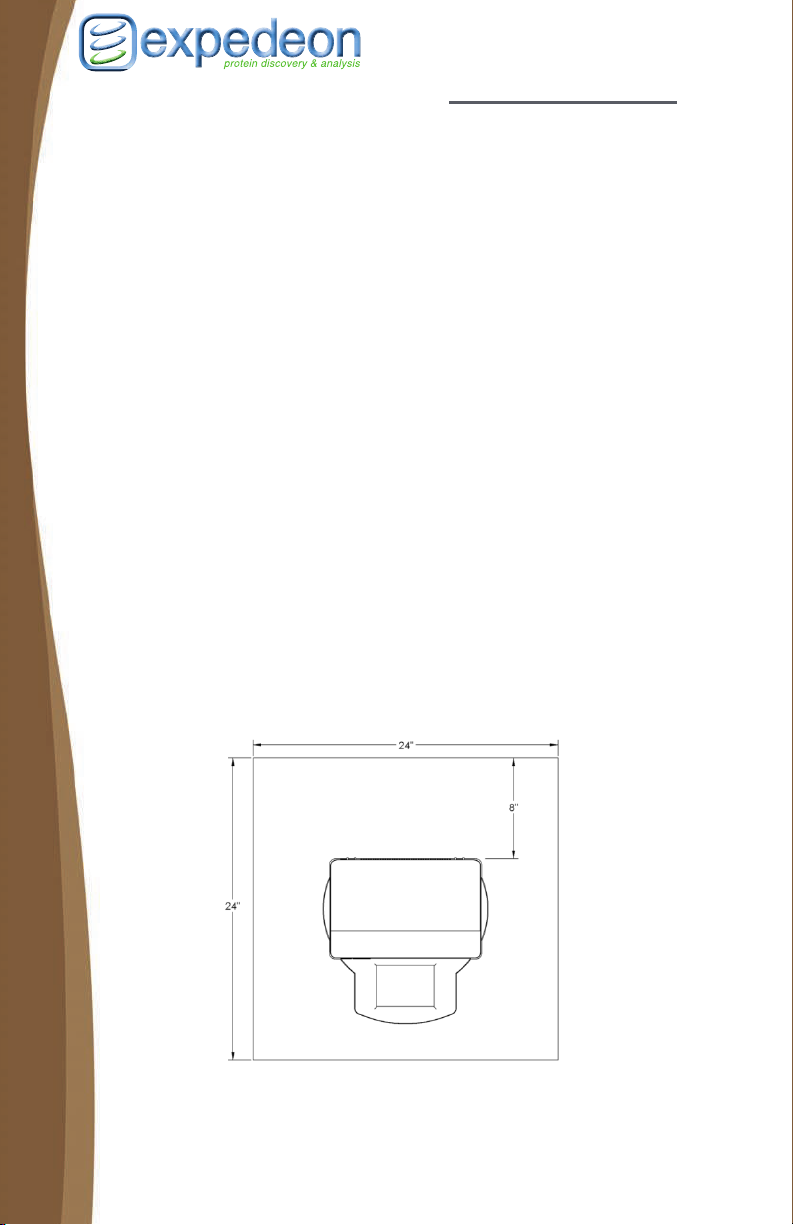

To power on the instrument, insert the provided power cord into the

socket on the back of the instrument, move the instrument to its

final position, and plug the cord into a suitable power supply (100-

240 VAC, 50-60 Hz). Power on the unit using the switch located on

the back of the instrument above the power cord.

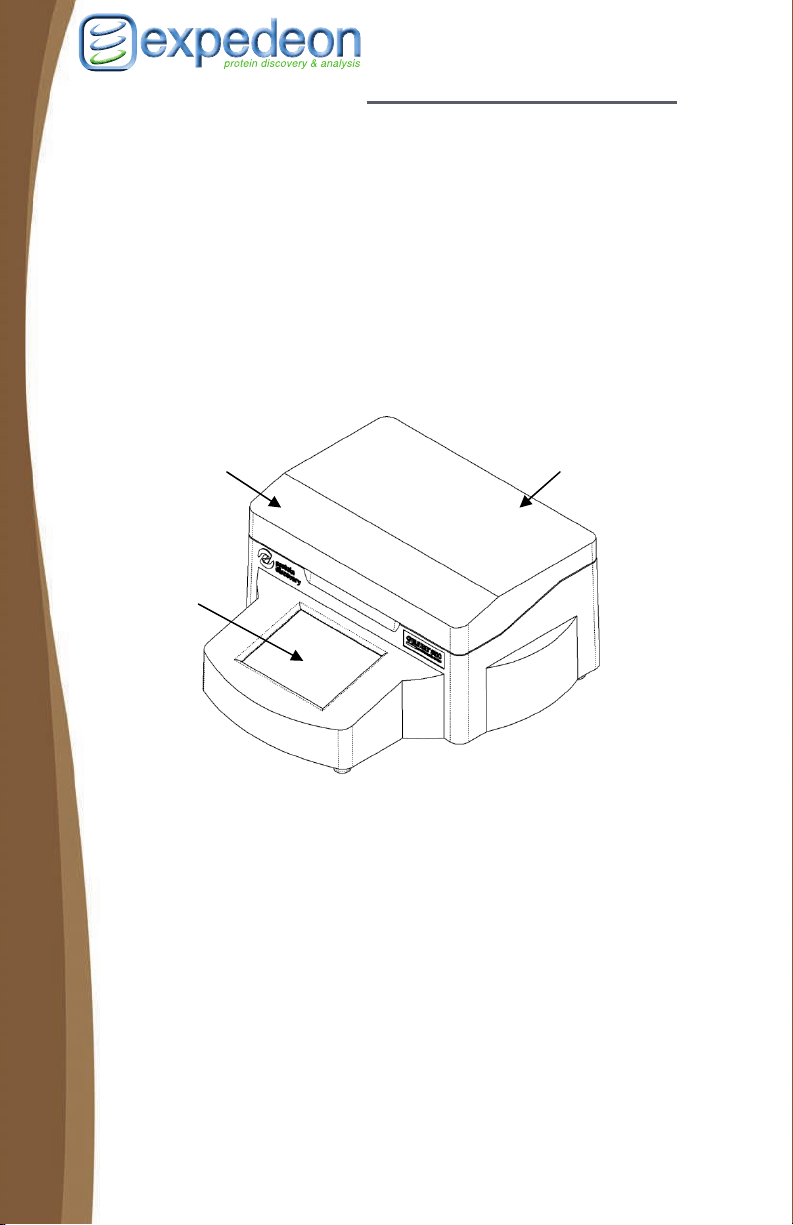

During the power up procedure, the Protein Discovery logo will be

isplayed on the touch screen. Once powered up, the main control

screen fo ill be displ peration

of the high vo r interlock by o osing the lid of

the instrument. In the lower right corner of the main screen, the ‘Lid

State’ indicator will switch from green (closed) to red (open) to

indicate engagement of the interlock.

Loading the Cartridge and Electrode Placement

Opening the access to the c partment for

loading and unloading the cartridg cting fractions

during the experiment. The cartridge is loaded such that the well

numbers imprinted on the cartridge can be read by the operator and

the arrows imprinted on the cartridge point to the right. The

cartridge positioning key (Figure 3) prevents the user from loading

the cartridge in ntatio rtridge shou d

rest fully on the bottom of the cartridge compartment. With th

cartridg by the

user. Th n of the

et when raising

and lowering the electrodes into position.

d

r the instrument w

ltage powe

ayed. Verify proper o

pening and cl

lid allows artridge com

e and for colle

the wrong orie n. The loaded ca l

e

e in place, the electrode arrays are lowered in place

e arrows in Figures 5 and 6 indicate the directio

applied force when raising and lowering the electrodes. Do not

force the electrodes into position – this can permanently damage

the mechanism. Very little resistance should be m

© 2013 Expedeon, Inc. All Rights Reserved.