Turntable control SmartTurn

Table of contents

Dok-ID:EXPERT-0003-EN-2011 3

1General Information...............................................................5

1.1 Information about this manual .......................................5

1.2 Explanation of symbols..................................................6

1.3 Disclaimer......................................................................7

1.4 Copyright........................................................................7

1.5 Replacement parts.........................................................8

1.6 Guarantee terms............................................................8

1.7 Customer service...........................................................8

2Safety ......................................................................................9

2.1 Responsibility of the customer.......................................9

2.2 Personnel requirements...............................................10

2.2.1 Qualifications................................................10

2.3 Intended use................................................................11

2.4 Environmental protection.............................................12

3Technical data - turntable controller..................................13

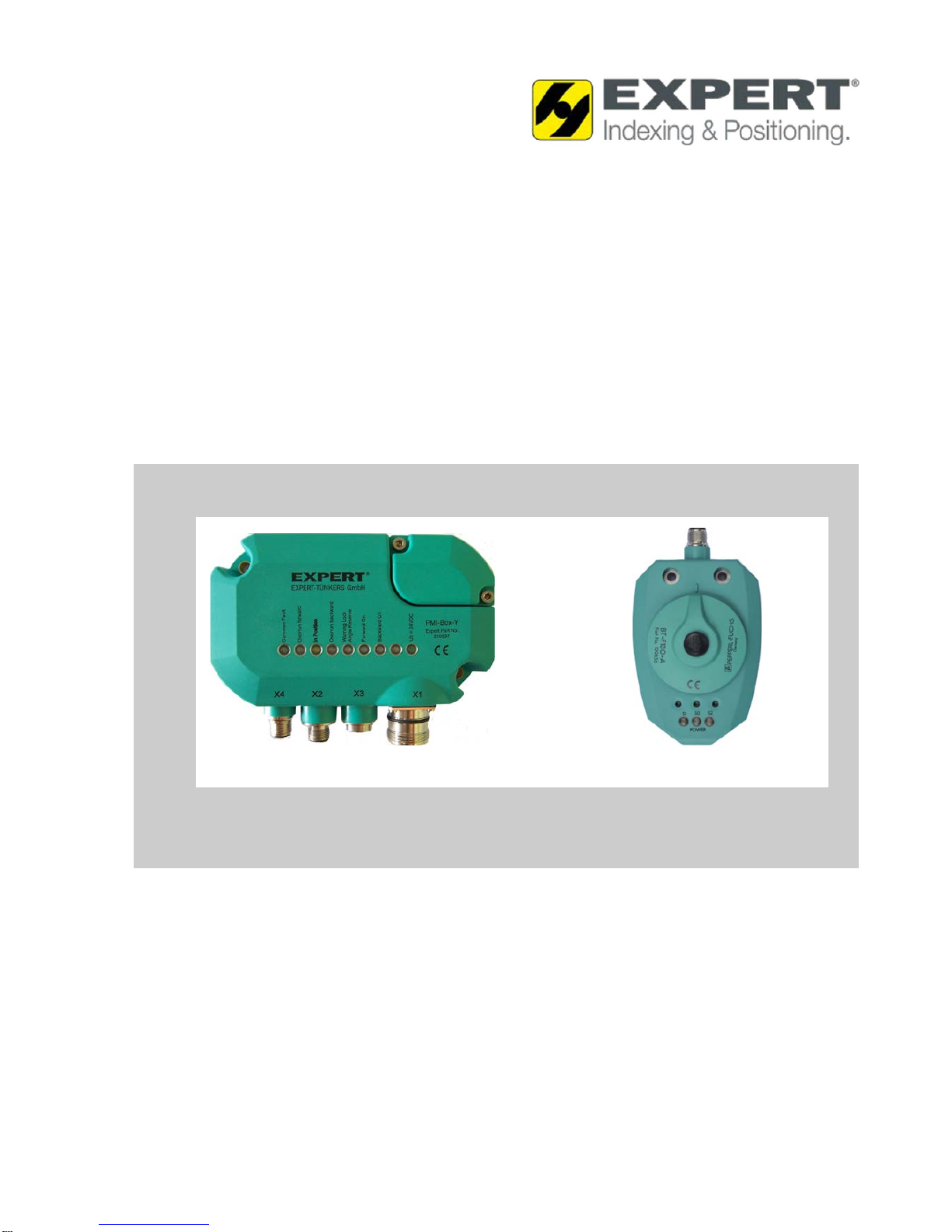

4Structure and function ........................................................14

4.1 Overview......................................................................14

4.1.1 Device description........................................15

4.2 Functional description..................................................16

4.2.1 Standard mode.............................................17

4.2.2 Special mode................................................18

4.2.3 0-position optimization..................................20

4.2.4 Brake wear monitor ......................................22

4.2.5 Overrun monitor ...........................................23

4.2.6 System monitoring........................................23

4.2.7 Device settings - control unit........................24

4.3 Connections.................................................................27

4.3.1 Control unit, see Fig. ....................................27

4.3.1.1 Pin assignment control unit...........28

4.3.2 Sensor, see Fig. 1 ........................................30

4.3.2.1 Pin assignment sensor..................30

4.4 Optional components and accessories........................31

5Installation and commissioning.........................................32

5.1 Safety...........................................................................32

5.2 Mounting instructions...................................................33

5.2.1 Connecting to the power supply...................33

5.3 Electrical installation ....................................................34