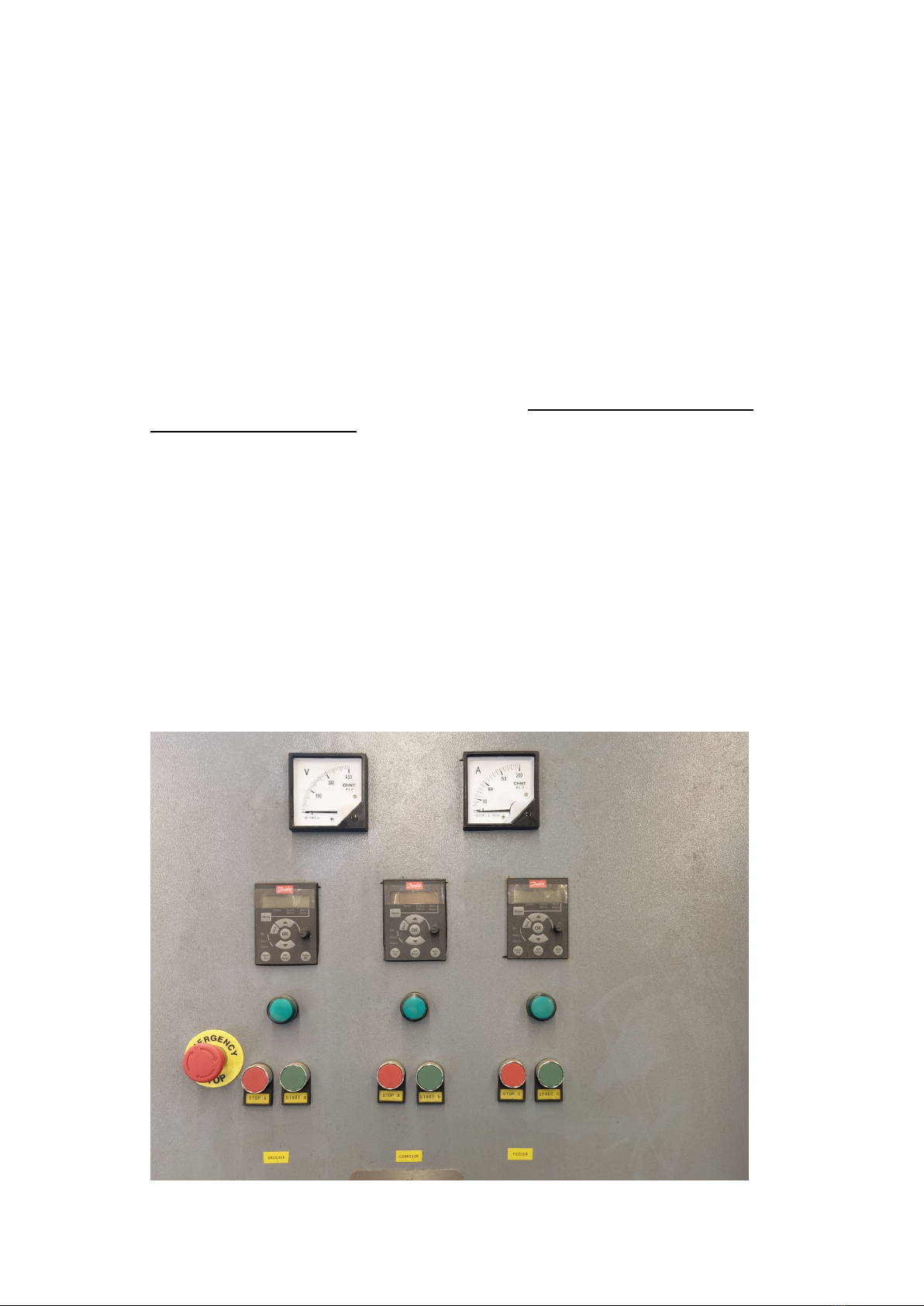

8. Turn crusher on using the Green Crusher start button. Fig 4. Then turn on the

Main conveyer followed by Feed Conveyor using the relevant Green Conveyor

start buttons. The operator MUST remain on the platform to observe and

remove any non-bottle waste.

9. The conveyors can be stopped and started using the Conveyor Red and Green

buttons. ALWAYS stop Feed conveyor first. All plastic bottles, Aluminium cans,

bottle openers, and any metal or rock or dense non bottle product MUST be

removed from the conveyor. Failure to do so can cause severe damage to the

machine.

10.To shut down the machine turn Feed conveyor Off and then Main Conveyor Off

using the red conveyor stop buttons and then allow crusher to continue

running for 20 seconds and then turn crusher off using red Crusher button.

11.Some machines may have an optional foot switch installed to stop and start

both conveyors simultaneously.

12.EMERGENCY STOP – Only use the emergency stop for an emergency.

If the emergency stop is used to shut the machine down in normal operation it

will turn off the crusher and conveyer together and the crusher will shut down

while there is glass in the crushing process. This will probably require clearing

before the machine can restart.

The Waste Tray located at base of conveyor, must be continually monitored and

emptied as required. Failure to do so will damage cleats on the conveyor. The

waste can be tipped onto the conveyor and crushed as needed.

fig 4