4. Commissioning

•Once the MIU has been installed, the cable glands, conduit, earth connections and any other

connections (e.g. pneumatic) shall be inspected for correct installation before the unit is put

into service.

•Apply a thin, even layer of the grease (provided) onto the threads of the lid.

•The lid shall be correctly fitted, and the lid locking device secured.

•If the commissioning is being carried out in the Hazardous Location, appropriate precautions

must be taken to prevent an incident. A relevant “Hot Work Permit” or similar must be obtained

from the appropriate authority and regulations followed.

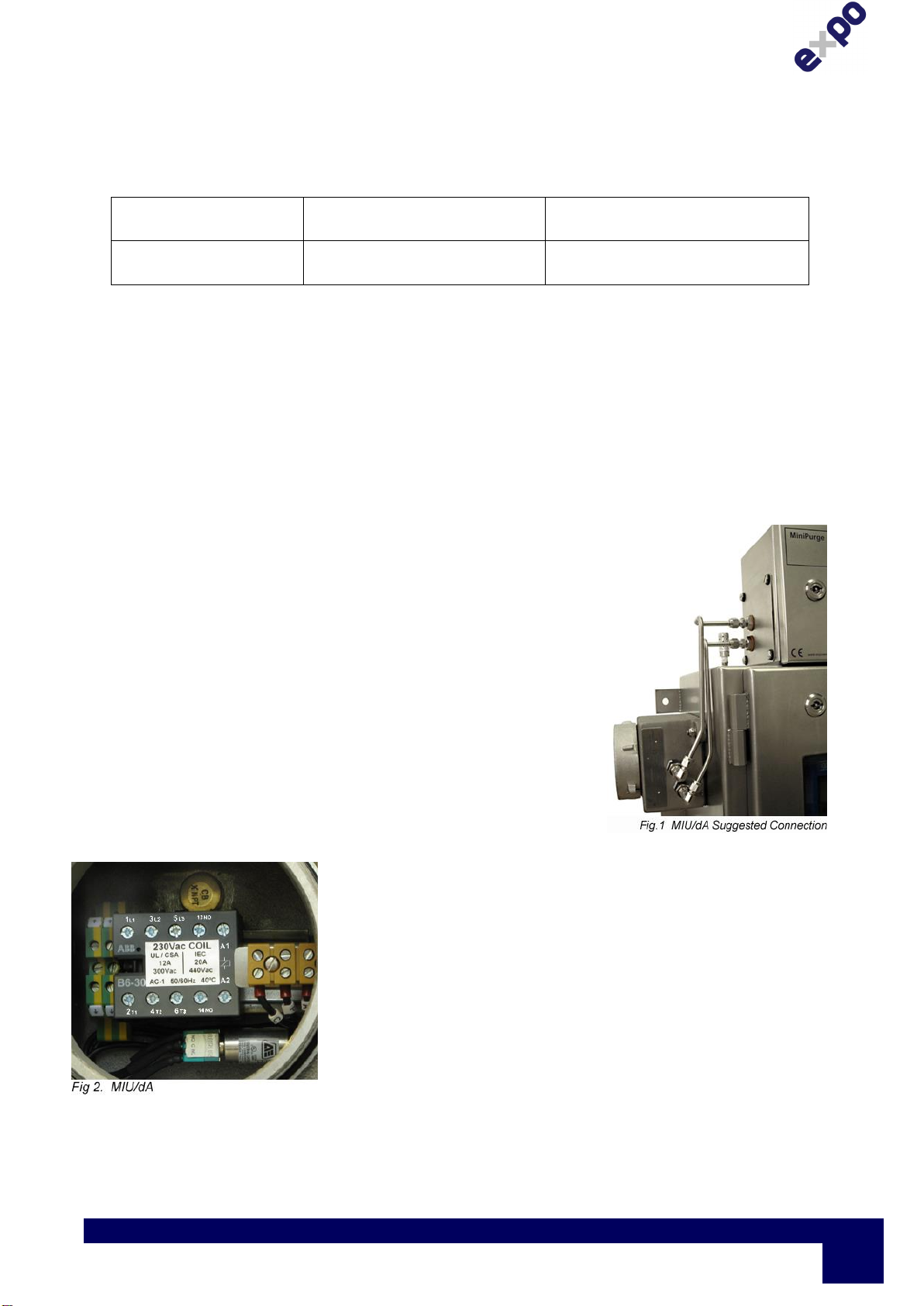

Commissioning the MIU when installed with a MiniPurge Control System

•Commissioning the MIU requires a working pressurized enclosure and MiniPurge system. For

operation and commissioning instructions for the MiniPurge system, refer to the appropriate

manual supplied with the MiniPurge. The description below assumes a standard Leakage

Compensation MiniPurge is in use.

•Operation of the Alarm / Pressurized contact can be tested as follows:

•With the air supply turned off, there should be continuity between the A and C terminals, and

no continuity between the C and P terminals.

•Close the enclosure door and turn the air supply on. The purge should begin, and the

Pressurized indicator on the MiniPurge should change from “Red” to “Green”. There should

now be continuity between the C and P terminals, and no continuity between the C and A

terminals of the MIU.

•Operation of the power switching contacts can be tested as follows:

•With the air supply off, the power switching contacts should be open circuit. Remember to turn

on the power supply, for units that require a power supply to control the switching (MIU/dX and

MIU/dT units).

•Close the enclosure door. Turn on the air supply. The purge cycle should begin.

•Once the purge cycle has been completed the power switching contacts will close. Both

pneumatic connections between the MiniPurge and MIU are now pressurized,

•Ensure the pneumatic connections do not leak.

•The final check is the most important and must not be ignored. The enclosure should be

pressurized, a purge cycle completed, and the power contacts closed. Turn the air supply to

the MiniPurge off. After a few seconds the enclosure will lose pressure and the following

should happen

oThe Pressurized indicator on the MiniPurge should change from “Green” to “Red”.

oThe power contacts should open disconnecting power to the enclosure.

oThere should be continuity between the A and C terminals, and no continuity between

the C and P terminals.

oThe above assumes the MiniPurge system is set to “Alarm & Trip” (i.e. Disconnect) not

to “Alarm Only”

•If the final check has been completed successfully, turn on the air supply to the MiniPurge.