MAX300-RTG Installation Manual

3

Introduction 5

INSTALLATION REQUIREMENTS.................................................................................................................................5

SHELTER REQUIREMENTS........................................................................................................................................5

AREA CLASSIFICATION OPTIONS..............................................................................................................................6

SPECIFICATIONS.......................................................................................................................................................6

.............................................................................................................................................................................8

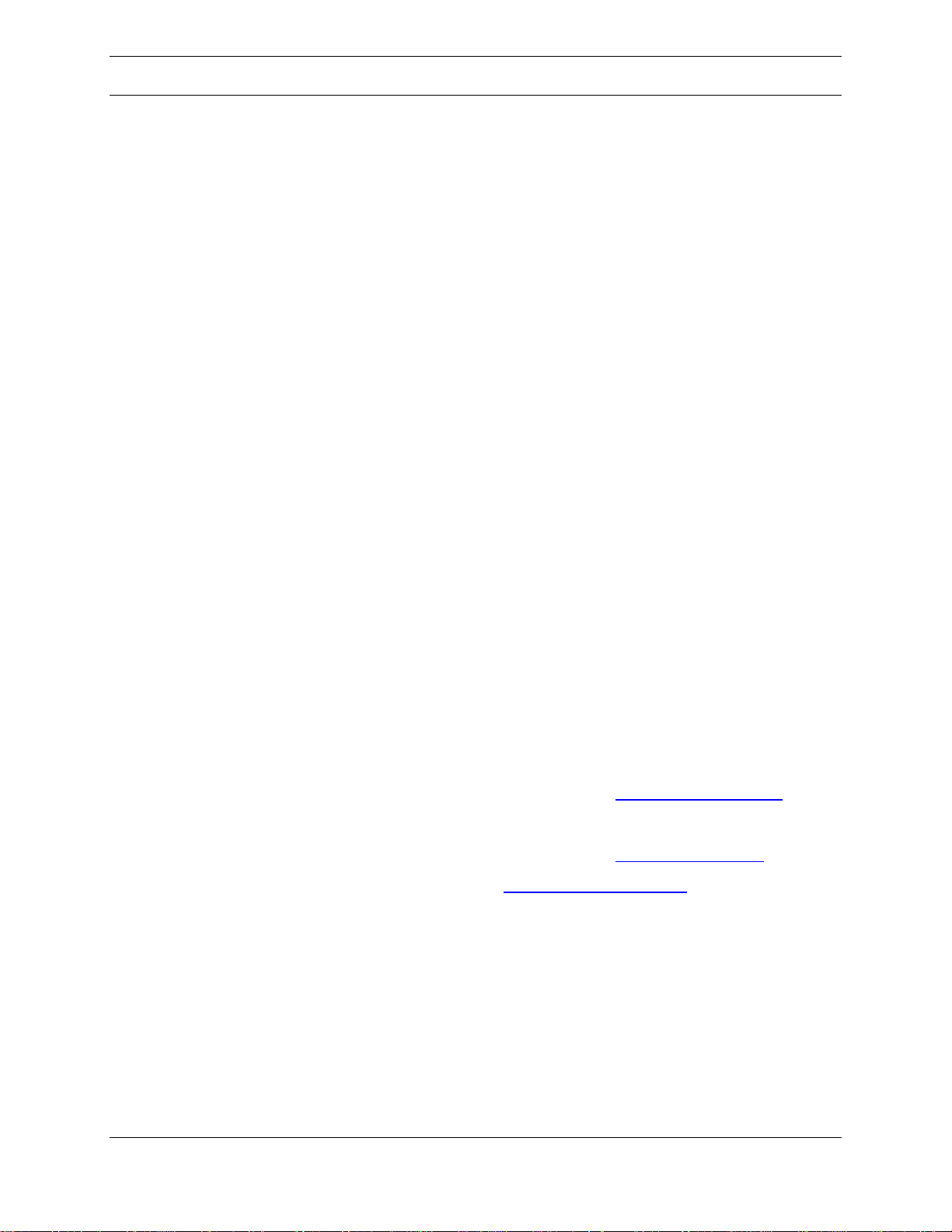

Figure 1: Layout of the ATEX/IECx Zone 1/Class I Div 1 unit (230V or 115V), with cart option ...........8

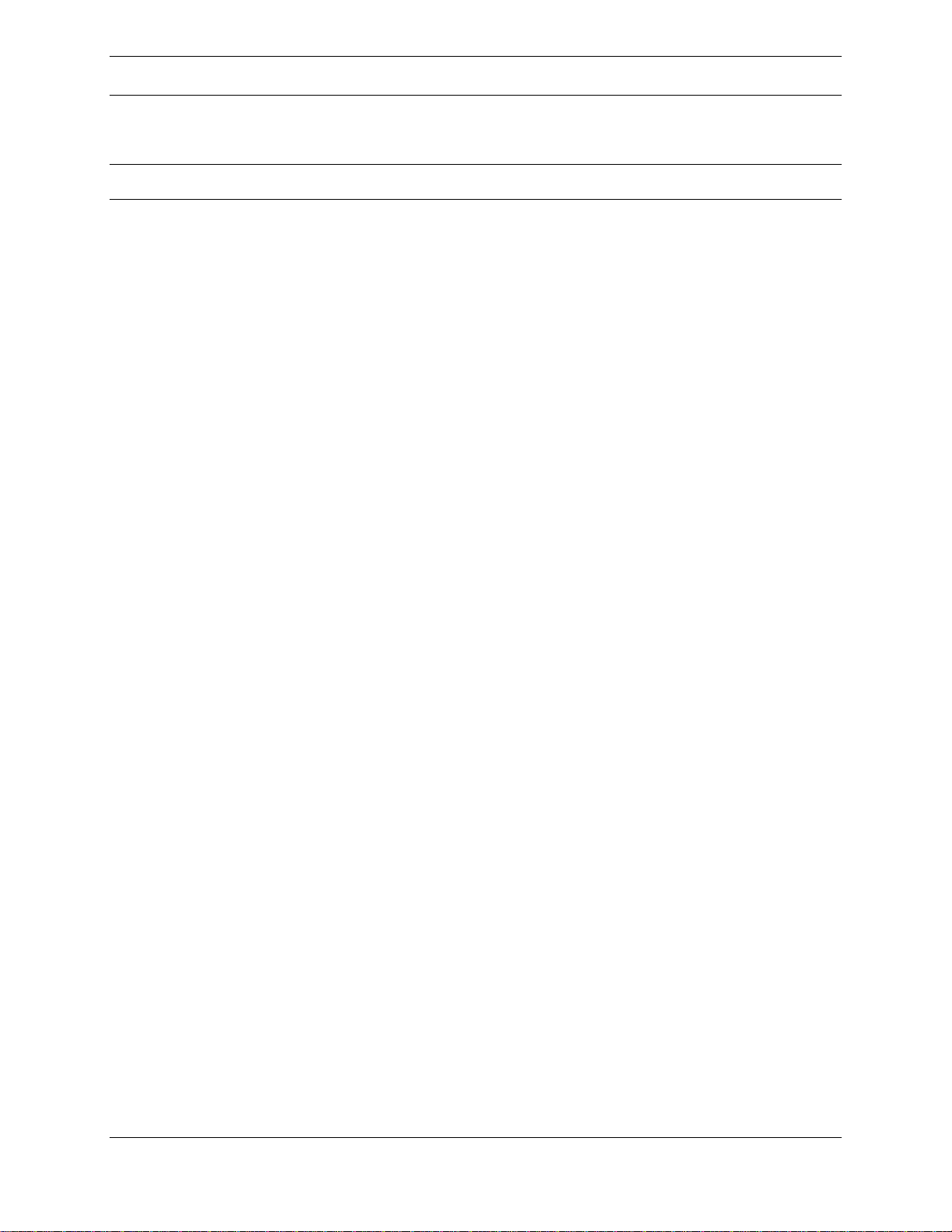

Figure 2: Layout of the ATEX/IECEx Zone 2 /Class I Div 2 unit (230V or 115V), with cart option ...................9

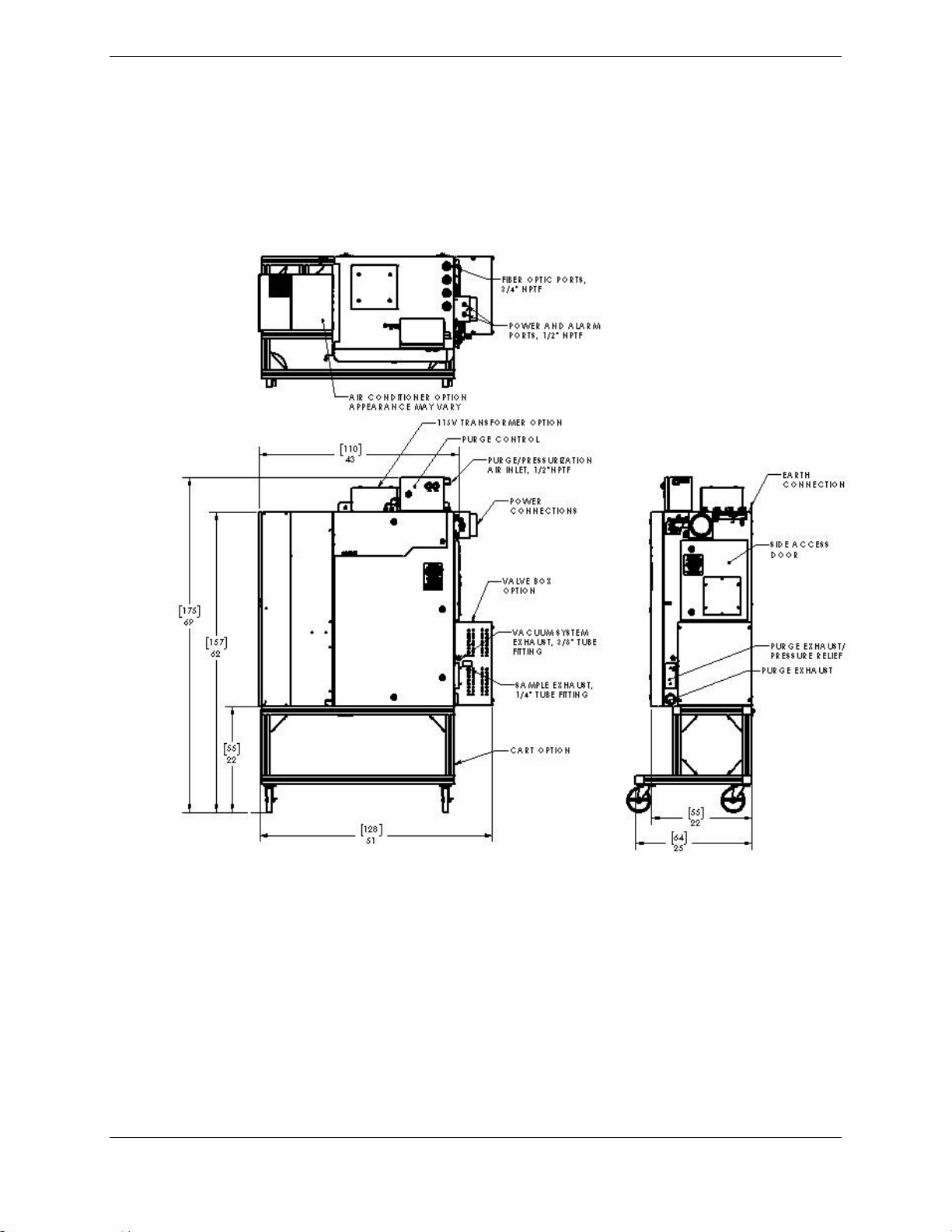

Figure 3: Layout of the ATEX/IECEx Zone 1/Class I Div 1 unit (230V or 115V), without cart option.............10

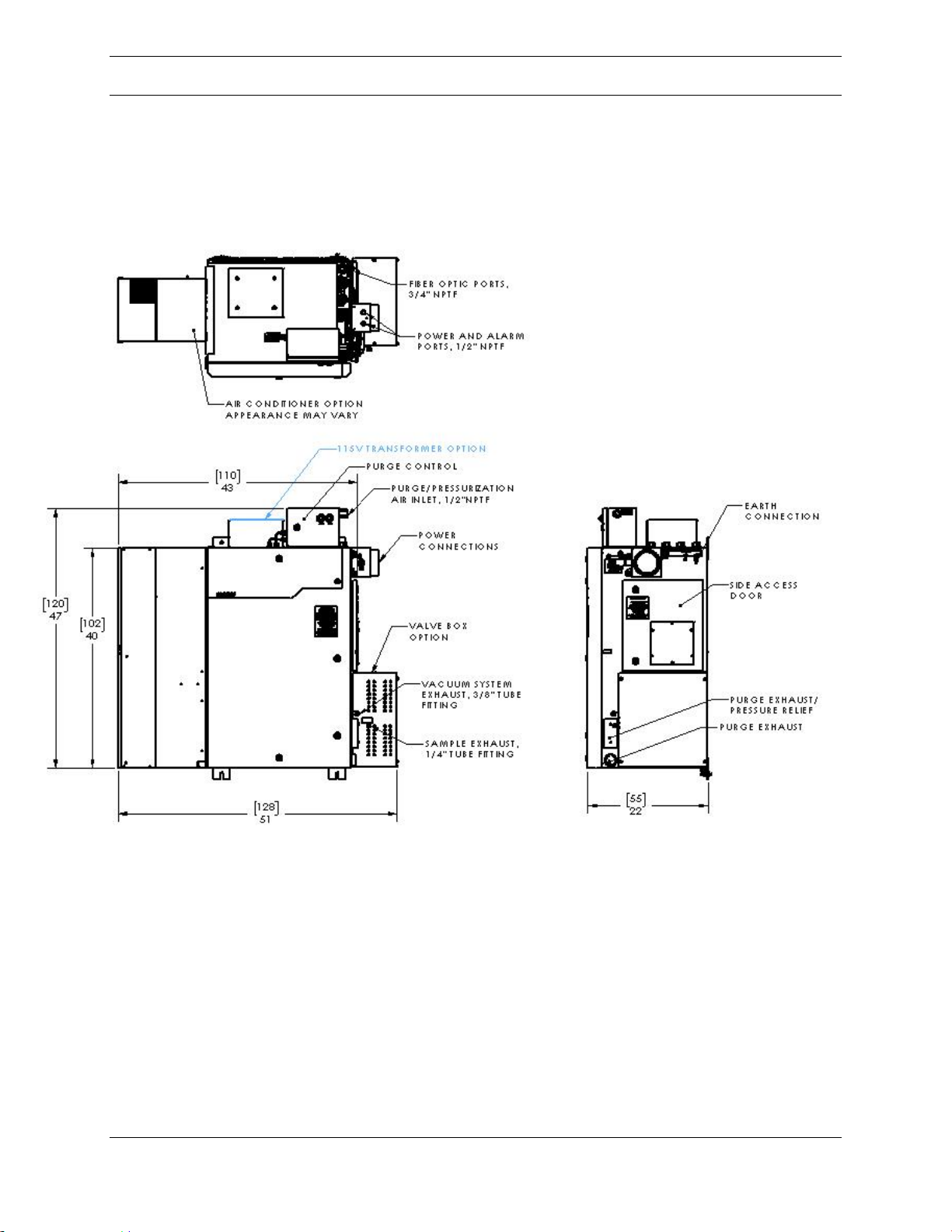

Figure 4: Layout of the ATEX/IECEx Zone 2/Class I Div 2 unit (230V or 115V), without cart option.............11

................................................................................................................................................................................12

Figure 5: Layout of the ATEX/IECEx Zone 1/Class I Div 1 unit (230V or 115V) with water cooled heat

exchanger and cart option .................................................................................................................................12

................................................................................................................................................................................13

Figure 6: Layout of the ATEX/IECEx Zone 2/Class I Div 2 unit (230V or 115V), with water cooled heat

exchanger and cart option .................................................................................................................................13

Figure 7: Installation Clearances......................................................................................................................14

................................................................................................................................................................................14

SAFETY ...................................................................................................................................................................15

Model Definitions and Marking......................................................................................................................15

WARNINGS ..............................................................................................................................................................18

APPLICATION SUITABILITY......................................................................................................................................24

INSTALLATION.........................................................................................................................................................24

PRESSURIZATION GAS SUPPLY .................................................................................................................................24

SAMPLE GAS SUPPLY.............................................................................................................................................25

AC POWER REQUIREMENTS ....................................................................................................................................26

MAX300-RTG ELECTRICAL CONNECTION DIAGRAMS.........................................................................................27

Figure 8: Power connection diagram, Zone 1/Div 1 units, 230VAC ........................................................27

...........................................................................................................................................................................28

Figure 9: Power connection diagram, Zone 1/Div 1 units, 115VAC ........................................................28

Figure 10: Power connection diagram, Zone 2/Div 2 units, 230VAC ......................................................29

Figure 11: Power connection diagram, Zone 2/Div 2 units, 115VAC ......................................................29

...........................................................................................................................................................................30

Figure 12: Earth connection diagram ...........................................................................................................30

Earthing.............................................................................................................................................................30

Plumbing Connections....................................................................................................................................31

Rotary Valve Inlets..........................................................................................................................................31

Figure 13: Diagram of 16 port rotary valve inlet..........................................................................................33

Figure 14: Diagram of 31 port rotary valve inlet..........................................................................................34

...........................................................................................................................................................................34

Figure 15: Diagram of 46 port rotary valve inlet..........................................................................................35

Figure 16: 16 port rotary valve details..........................................................................................................36

Figure 17: FastValve (40/80/120/160 port valve option) –for use with non-explosive sample ...........37

Calibration Gases............................................................................................................................................37

Figure 18: Calibration Gas Connection........................................................................................................38

Figure 19: External communications disconnect box option.....................................................................41

Status Connections.........................................................................................................................................44

4-20mA Analog Inputs and Outputs .............................................................................................................46

4-20mA Analog Inputs: KL3012 and KL3022..............................................................................................47

4-20mA Output: KL4021 and KL4022 Modules..........................................................................................47

Digital I/O..........................................................................................................................................................48