-----CONTE

NTS-----

1.

PRECAUTIONS

BEFORE

STARTING

OPERATION

.................................................................................. !

I)

Safety

precautions····..·····............................................................................................................................... 1

2)

Precaution

before

Start

ing

Ope

ration

....................:................................................................................... 1

3)

Precaution

for

Operating

Cond

itions......................................................................................................... !

2. S

PECIFICATIONS

·······..···................................................................................................................................... 1

3.

PREPARATION

BEFORE

STARTING

TO

OPERATE

................................................................................ 2

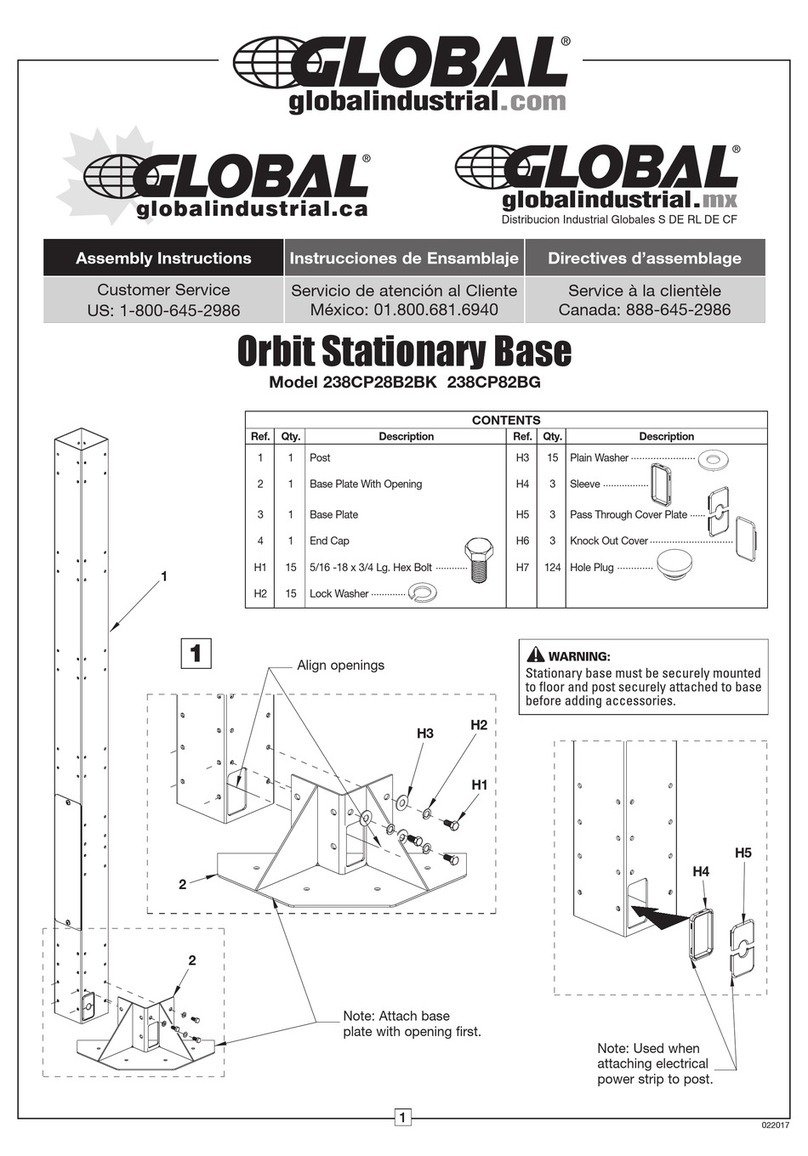

I)

Connection

of

control

box

............................................................................................................................ 2

2)

Oil

pan

............................................................................................................................................................. 3

.3)

Operation

panel

....................................................................................:........................................................ 3

4)

Adjusting

the

nee

.

die

stop

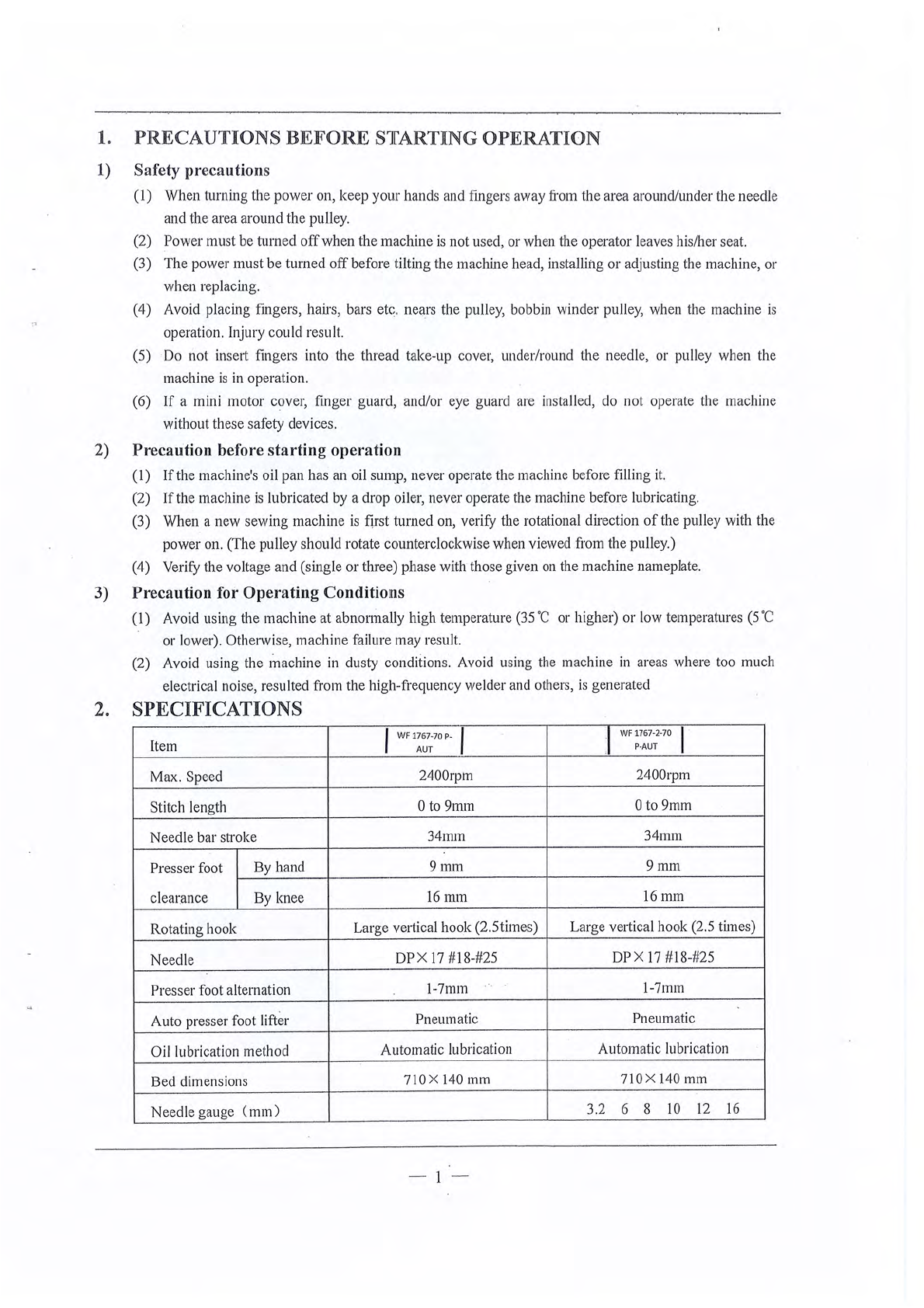

position .............................................................................................................. 3

5)

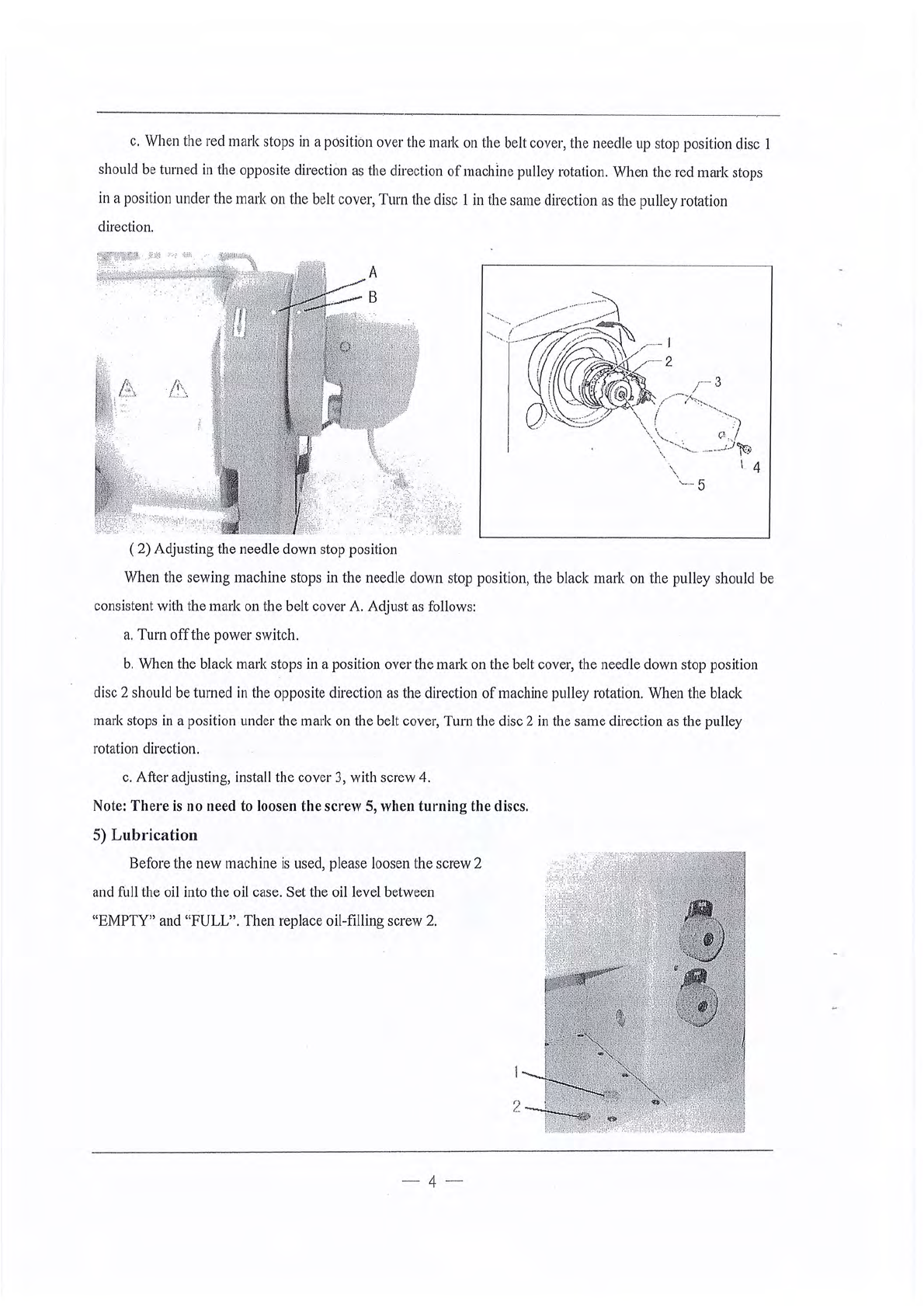

Lubrication

..................................................................................................................................................... 4

4.

HOW

TO

USE

THE MACHINE ........................................................................................................................ 5

I)

Threading················........................................................................................................................................ 5

2)

Adjust

ing

of

the

thread

regulator

.........................................................;.......

..

............................................ 5

3)

Adjusting

of

upper

thread

tension..........................,................................................................................. 5

4)

Winding

the

Io,ver

thread··

..····..................................................................................................................... 5

5)

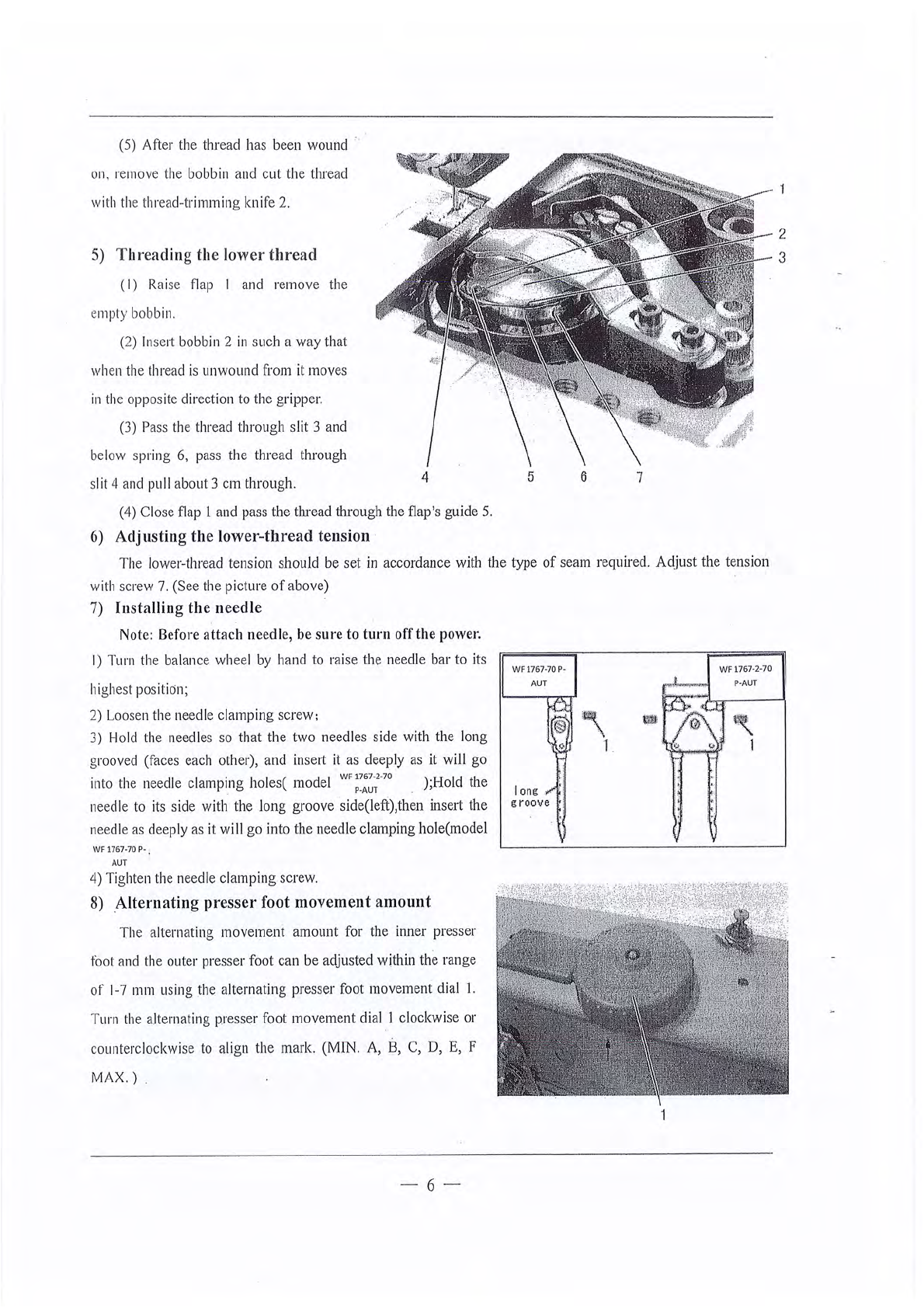

Threading

the

lower

thrend

..........._.............................................................................................................. 6

6)

Adjusting

the

lower

-

thrend

tension·............................................................................................................ 6

7) l

nstnlling

the

needle.............:......................................................................................................................... 6

8)

Alternati

ng

presser

foot

1nove1nent

amount

.............................................................................................. 6

9)

Adjusting

the

presser

foot

pre

ssure..

........................................................................................................ 7

I

0)

Adjusting

the

stitch

l

ength

........................................................................................................................... 7

II)

Using

the

111nnual

switches........................................................................................................................... 7

12) Clenning······..·····.............................................................................................................................................. 8

13)

Lubrication

....................................

_.

......................................;...............................:......................................... 8

14)

Adjusting

the

tra

iling length

nfter

thread

trimming

................................................................................ 9

15)

Back

ta

cki

ng

................................................................................................................................................... 9

16) Adjus

ting

the

feed

dog

.................................................................................................................................. 9

17)

Adjusting

the

needl

e

bnr

height

.......................,........................................................................................... 9

.i

18)

Adjusting

th

e

gap

between

the

needle

nnd

the

rotary

hook

tip.........:.................................................. 10

1

9)

Adjusting

of

the

nee

dle

and

the

hook

timin

g........................................................................................... 10

20)

Hook

protection·

..·····..···................................................................................................................................

11

21)

Adjusting

the

needle a

nd

feed

mechani

sm timing...................................................................................

11

22)

Adjusting

the

opener

position.....................................................................................................................

11

23)

Adj

u

sting

the

presser

foot

heig

ht

.............................................................................................................. 12

24)

Adjus

ting

the

alternating

presser

foot

movement

amount

................................................................... 13

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com