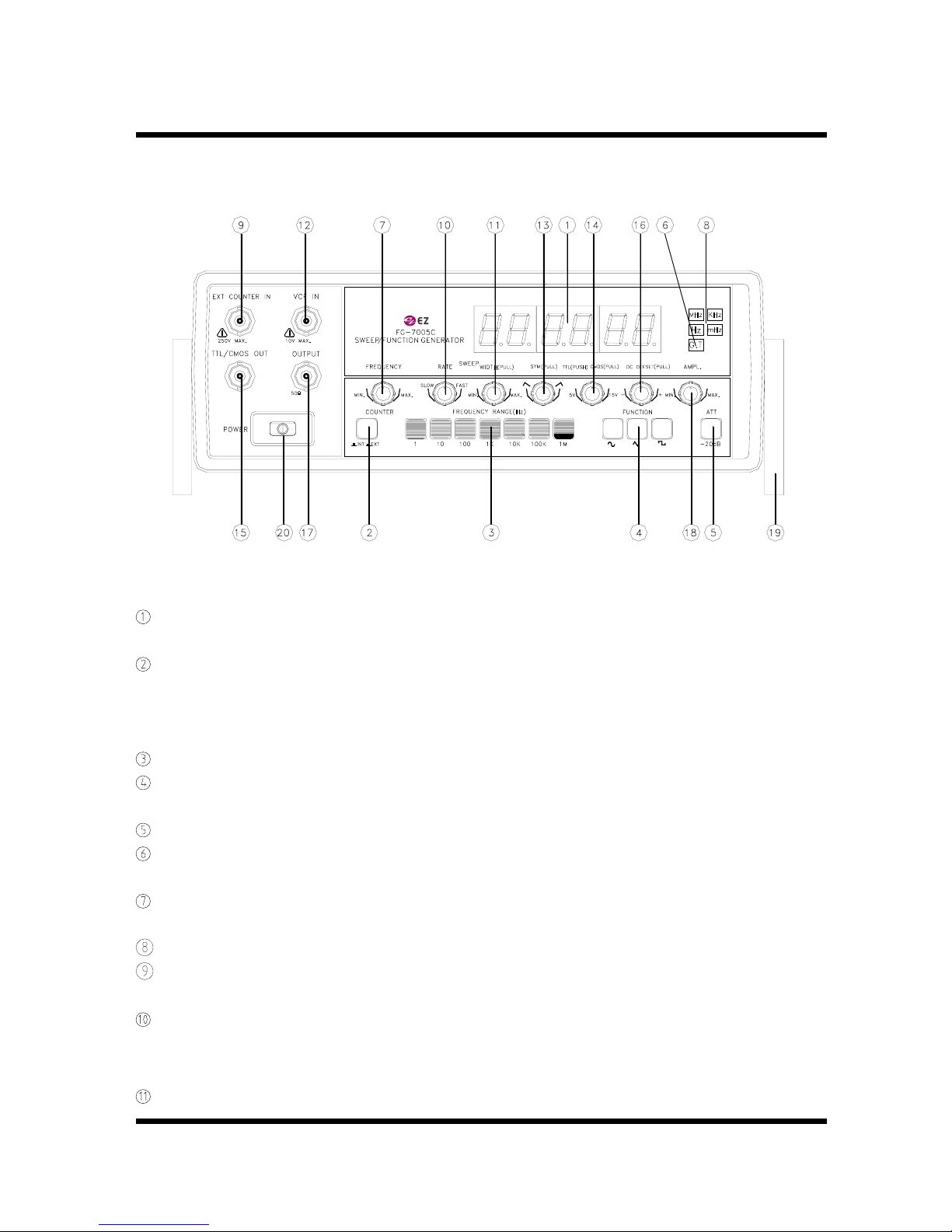

1-1. Introduction

This instrument is the Most Versatile Signal Source used as FUNCTION

GENERATOR, SWEEP GENERATOR, PULSE GENERATOR and a FREQUENCY

COUNTER, offering a wide range of applications in both analog and digital electro-

nics such as engineering, manufacturing, servicing, education and hobbyist fields.

VCF(voltage controlled frequency) produces precision sine, square and triangle

waves over the 0.05 Hz to 5 MHz for sub-audible, audio, ultrasonic and RF

applications. A continuously variable DC offset allows the output to be injected

directly into circuits at the correct bias level.

Variable symmetry of the output waveforms converts the instrument to a pulse

generator capable of generating rectangular waves or pulses, ramp or sawtooth

waves and skewed sine waves of variable duty cycle. The sweep generator offers

linear sweep with variable sweep rate and sweep width up to 100:1 frequency

change. The frequency response of any active or passive device up to 5 MHz can

be determined.

1-2. Technical Specifications

OUTPUT CHARACTERISTICS

Waveforms : Sine, Square, Triangle, Ramp, Pulse, Sawtooth,

TTL/CMOS Leveled Square, DC

Frequency Range : 0.05 Hz to 5 MHz in 7 Range(1,10,100,1K,10K,100K,1M)

Frequency Accuracy : ±5% (1,10,100,1K,10K,100K,1MHz Range ) (Full Scale)

Output Level : 20 Vp-p in open circuit, 10 Vp-p into 50 ΩLoad

Output Impedance : 50 Ω±5%

Attenuator : 20 dB fixed and continuously variable

WAVEFORM CHARACTERISTICS

Sine wave -Flatness : ±2.5V to 5 MHz

-Distortion : Less than 1% at 0.5 Hz to 100 KHz

Square wave -Rise and Fall Time : Less than 25 nS

Triangle wave -Linearity : More than 99% at 0.2 Hz to 100 KHz

TTL Output -Rise and Fall time : Less than 25 nS

-Output Level : TTL Level(H 2.4V, L 0.4V)

CMOS Output -Rise and Fall Time : Less than 150 nS(Max. Out)

(DC – to 2MHz) -Output Level : 4V to 15V ±1V, Variable

DUTY RATIO : 1:1 to 10 : 1