Page iii

TABLE OF CONTENTS

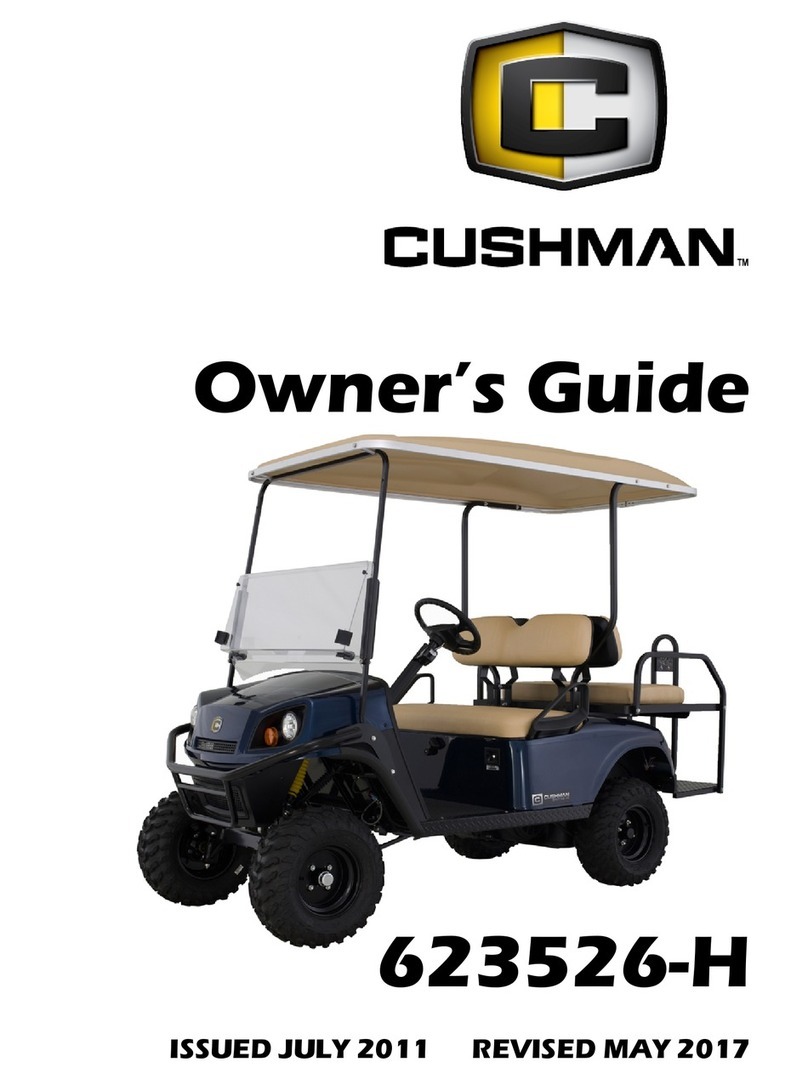

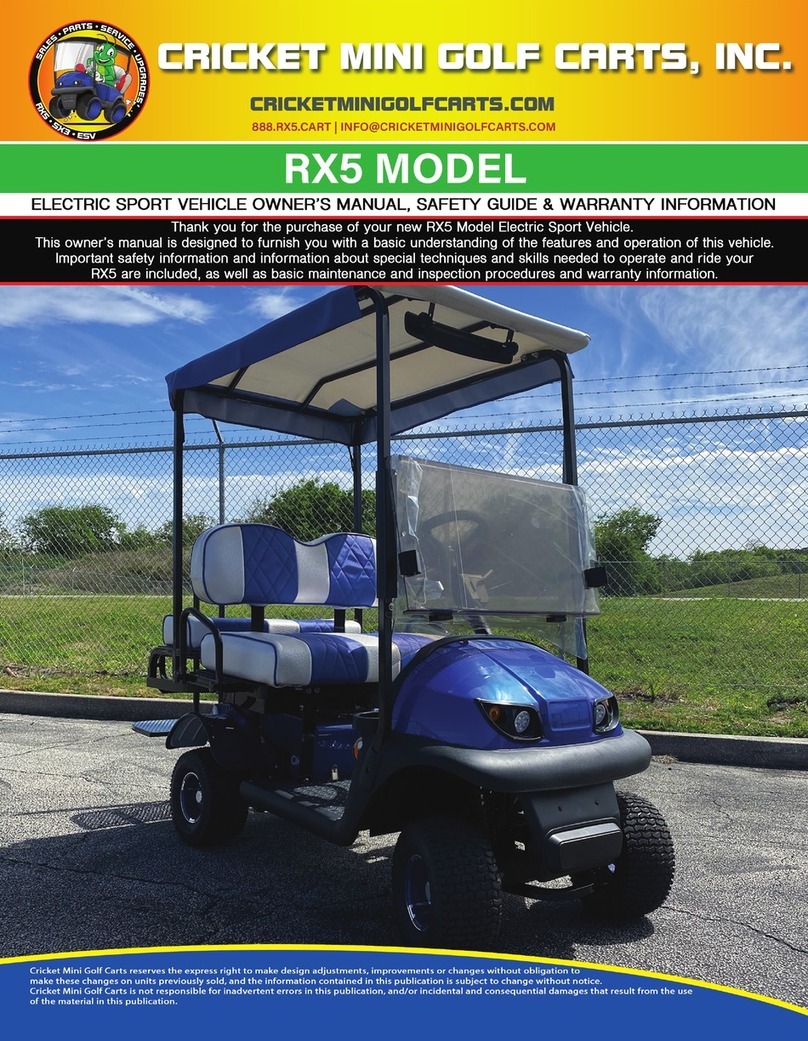

Owner’s Manual and Service Guide

SAFETY ................................................................................................................ Inside covers

GENERAL INFORMATION .......................................................................................................ii

SAFETY INFORMATION ........................................................................................................... v

GENERAL ................................................................................................................................. ix

BEFORE INITIAL USE ..............................................................................................................1

Fig. 1 Initial Service Chart .........................................................................................................1

PORTABLE CHARGER INSTALLATION ............................................................................................................1

Fig. 2 Proper Charger Installation .............................................................................................2

Fig. 3 Charger Receptacle Location .........................................................................................2

CONTROLS AND INDICATORS ............................................................................................... 2

KEY/LIGHT SWITCH ...........................................................................................................................................2

Fig. 4 Key/Light Switch & State of Charge Meter .....................................................................3

DIRECTION SELECTOR .....................................................................................................................................3

Fig. 5 Direction Selector Types .................................................................................................3

STATE OF CHARGE METER .............................................................................................................................3

HOUR METER ..................................................................................................................................................... 3

ACCELERATOR PEDAL .....................................................................................................................................3

Fig. 6 Accelerator and Brake Controls ......................................................................................3

COMBINATION SERVICE BRAKE AND PARK BRAKE PEDAL ........................................................................4

RUN - TOW/MAINTENANCE SWITCH (PDS VEHICLES ONLY) .............................................4

Fig. 7 Run-Tow/Maintenance Switch ........................................................................................4

PLASTIC LOADBED .................................................................................................................4

MANUAL LIFT BED OPERATION .......................................................................................................................5

Fig. 8 Manual Bed Latch ...........................................................................................................5

TAILGATE OPERATION .....................................................................................................................................5

OPERATING THE VEHICLE ..................................................................................................... 5

PRECISION DRIVE SYSTEM™ ..........................................................................................................................6

Regenerative Braking .............................................................................................................................6

Pedal-Up Braking ....................................................................................................................................6

Walk-Away Feature ................................................................................................................................7

Anti-Roll Back Feature ............................................................................................................................7

Anti-Stall Feature ....................................................................................................................................7

High Pedal Disable Feature ....................................................................................................................7

Default Mode Feature .............................................................................................................................7

STARTING AND DRIVING ..................................................................................................................................7

STARTING VEHICLE ON A HILL ........................................................................................................................8

COASTING ..........................................................................................................................................................8

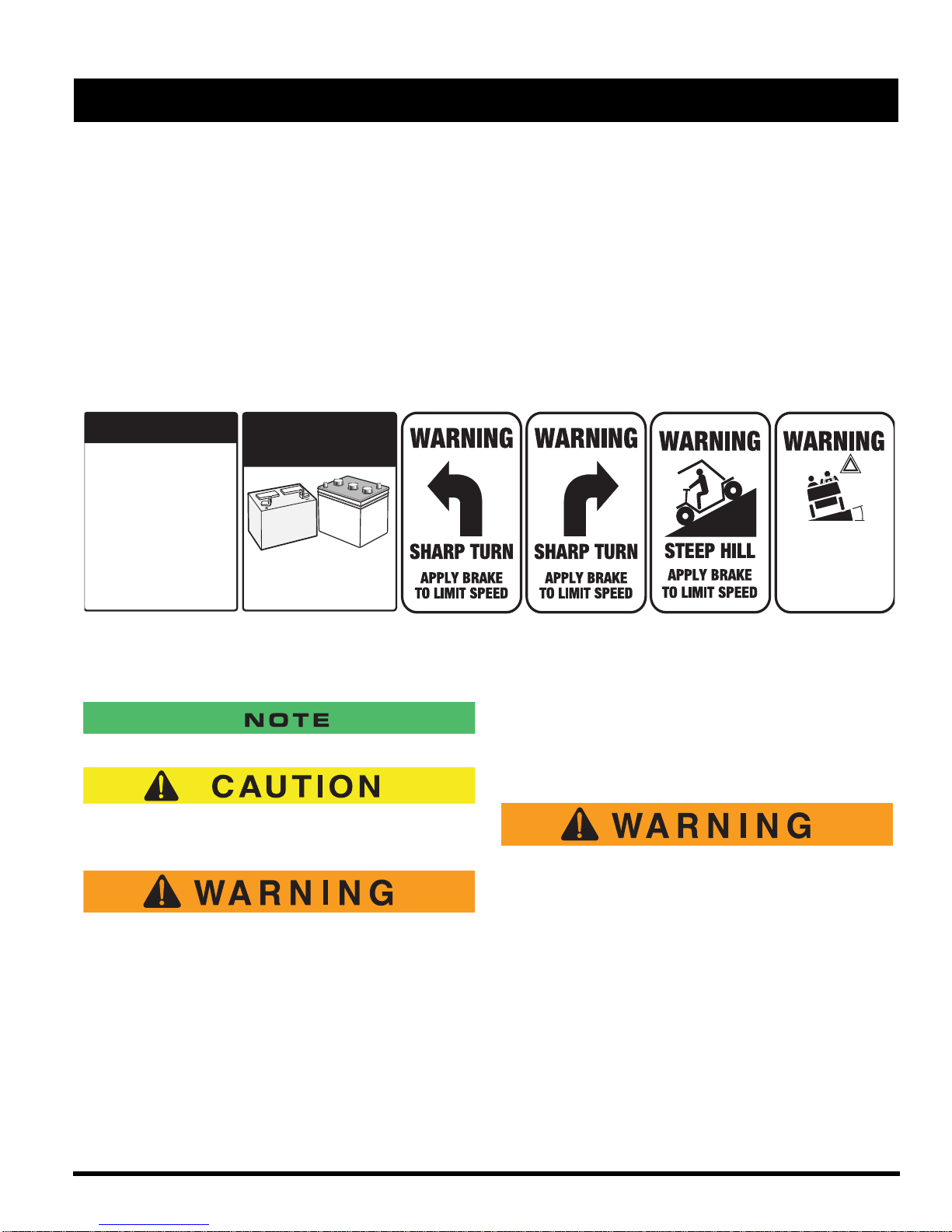

LABELS AND PICTOGRAMS .............................................................................................................................8

SUN TOP AND WINDSHIELD .............................................................................................................................8

TOWING A TRAILER ..........................................................................................................................................8

VEHICLE CLEANING AND CARE ............................................................................................9

VEHICLE CLEANING ..........................................................................................................................................9

REPAIR ......................................................................................................................................9

LIFTING THE VEHICLE ......................................................................................................................................9

Fig. 9 Lifting the Vehicle .........................................................................................................10

WHEELS AND TIRES ......................................................................................................................................10

Tire Repair ............................................................................................................................................10

Wheel Installation .................................................................................................................................11

Fig. 10 Wheel Installation .......................................................................................................11

LIGHT BULB REPLACEMENT ..........................................................................................................................11

Fig. 11 Headlight and Turn Signal Bulb Replacement ............................................................11

Fig. 12 Tail and Brake Light Bulb Replacement .....................................................................11

FUSE REPLACEMENT .....................................................................................................................................11

TRANSPORTING VEHICLE ....................................................................................................12

TOWING ............................................................................................................................................................12