2 Battery Packs and

UL Approved

Remote Charger

come with each

unit

ACCESSORIES

DELUXE SLING

The padded legs of the Deluxe

Sling offer support and comfort to

the patient while being lifted and

transferred.

DELUXE MESH SLING

The Deluxe Mesh Sling is de-

signed specifi cally for bathing

patients. It has very low moisture

absorption and a better “hold” on

wet skin. The Mesh Sling may

also be used for regular patient

transfers.

MULTI-PURPOSE SLING

The Multi-Purpose Sling is used

primarily for amputees, patients

with large thighs, or patients with

delicate skin.

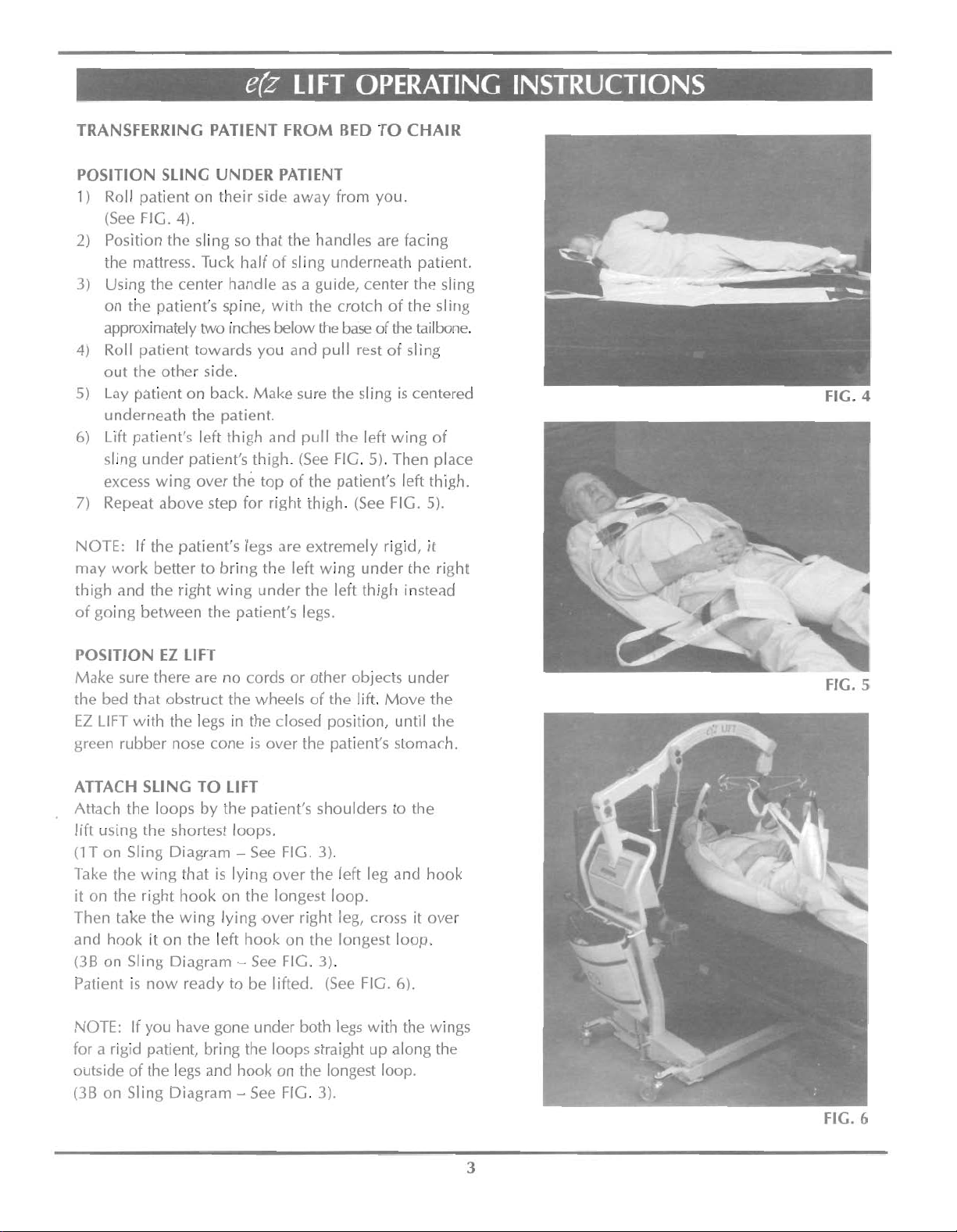

EZ LIFT SLINGS are designed

to maximize the comfort and

security of patients during trans-

fers. EZ Slings are made in a

wide assortment of sizes and will

support patients weighing up to

1000 lbs.; however, users must

only lift up to the weight capacity

limits of their EZ Lift. As patients

do vary in size, shape, weight and

temperament, these conditions

must be taken into consideration

when deciding which size of the

EZ Sling is most suitable for their

needs. The EZ Slings are con-

structed of durable and washable

100% synthetic fabrics. There are

three reinforced handles in the

back for positioning the patient,

and a large opening for toileting

and access to the perineal area.

DELUXE HEAD SUPPORT

SLING

The Deluxe Head Support Sling

is designed with the addition of

a head support, providing extra

support for patients with weak or

poor head control.

SLING SIZES

A full range of sling sizes are

available to fi t a range of body

types.

and access to the perineal area.and access to the perineal area.

Hanger Bar Covers

are available as an

additional safety

option

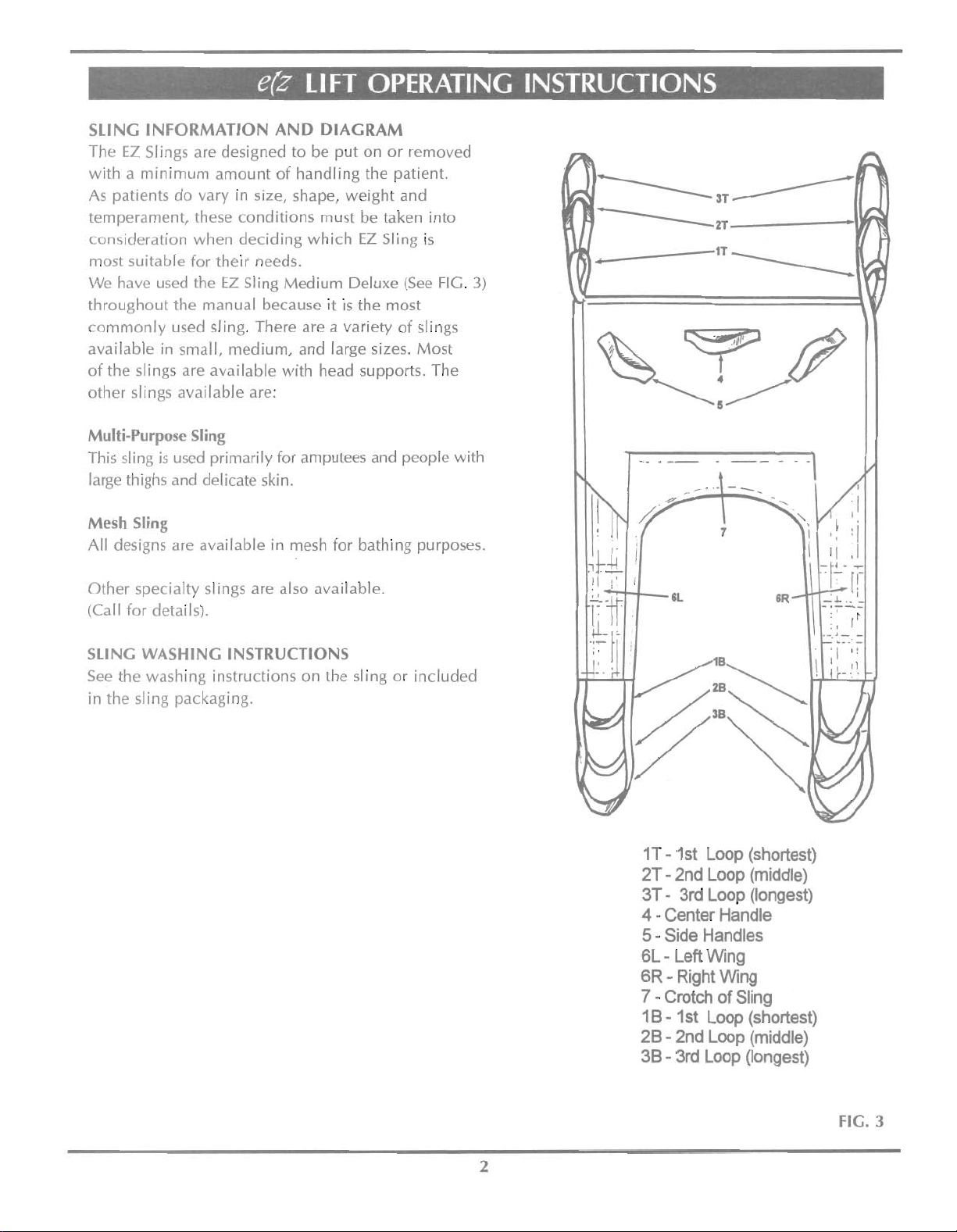

Control Panel LCD

screen and buttons

are easy to read and

understand