7

ENGLISH ENGLISH

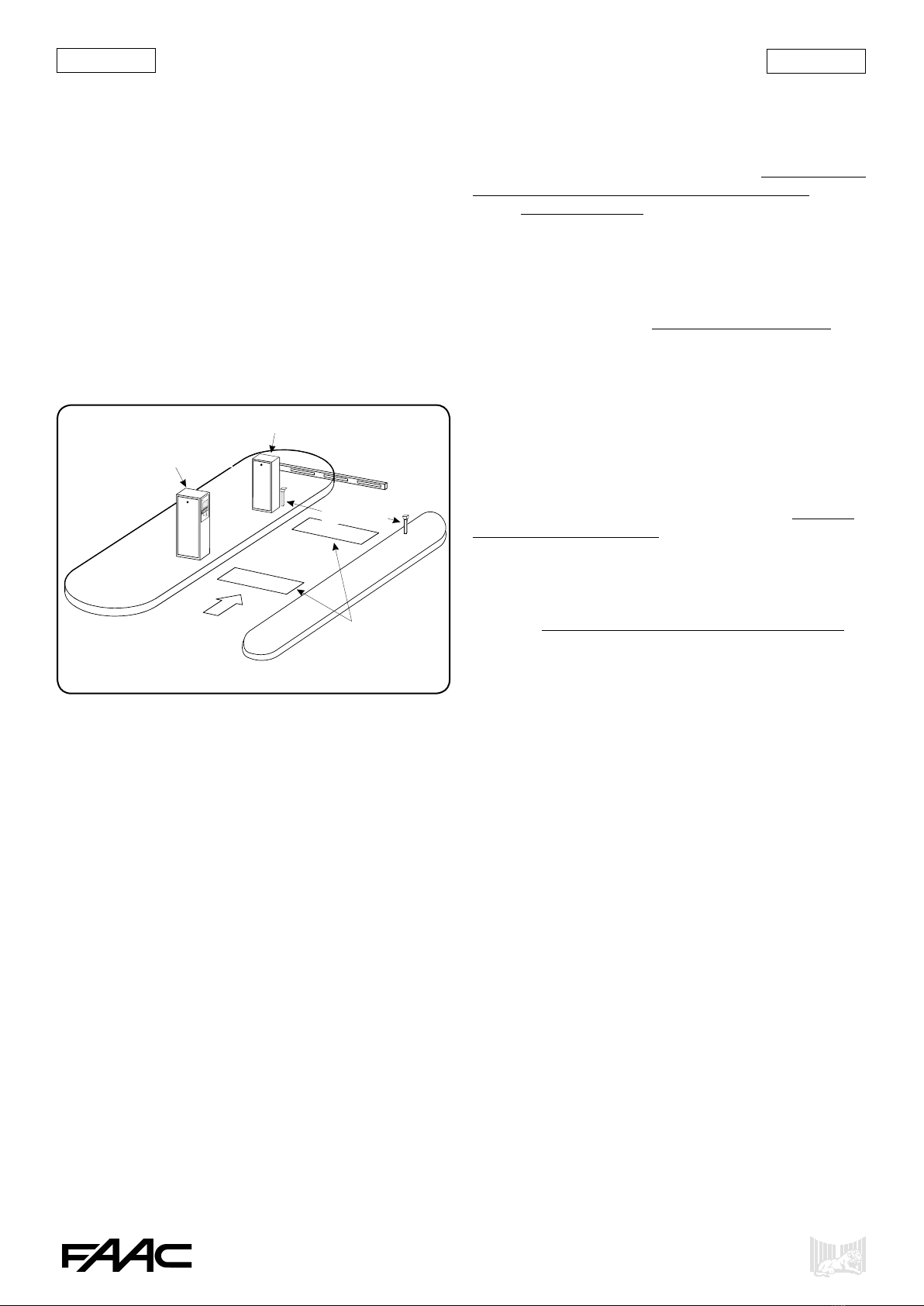

All the components of an exit lane of a ParkLite automated

parking system, are directly managed by the Ticket Dispenser.

The exit lane of a parking area consists of:

• Nr. 01 ParkLite Ticket Reader.

•Nr. 01 620 rapid barrier RH.

•Nr. 02 Magnetic loops.

•Nr. 01 Pair of photocells.*

•The exit lane from a parking area managed by the Ticket

Reader must be constructed so that the vehicles coming from

different directions can easily get close to the column, to

enable the user to read the ticket or a valid card without any

difculty.

• The equipment must be installed on an island 15 cm. above

road level. If this is not possible, protective structures must be

installed around the base of the two columns (TR and barrier

620) and the Ticket Reader must be raised 15 cm. above the

lane paving, so that the devices for reading and treating the

tickets for exit from the parking area are located at the right

height.

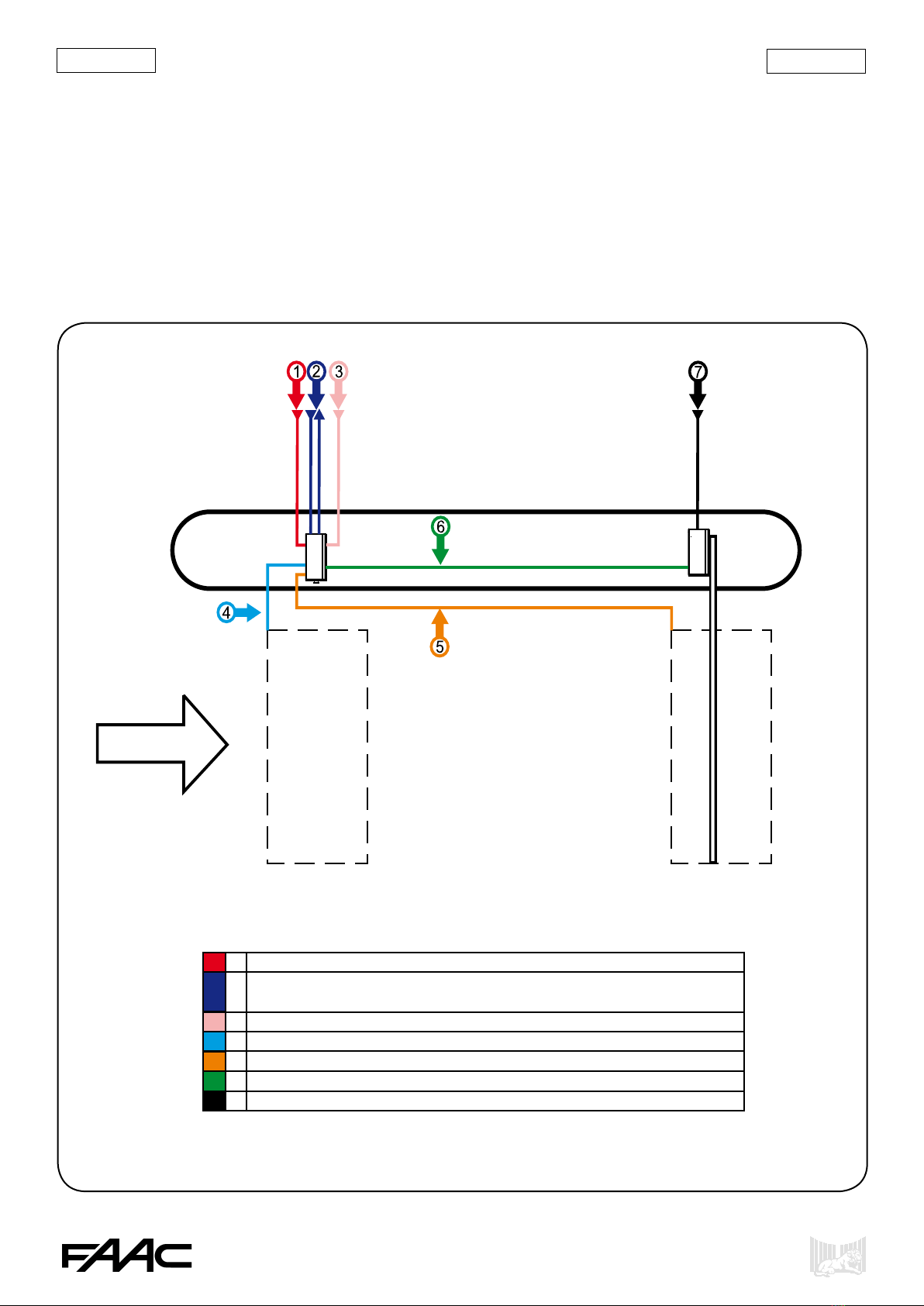

• The Ticket Reader operates only if the magnetic loops have

been correctly connected to it. In fact, the column was desi-

gned to manage all the user exit from lane stages, exploiting

thesetwoelements,whicharegenerallydenedas:presence

loop and transit loop.

g.2Exitlane

The construction and deployment of the loops is fundamentally

important to ensure that the system functions correctly. For this

reason, observe to the letter all the instructions described in the

following paragraphs:

2.3 Making the Magnetic Loops

2.7 Positioning the equipment.

• The power cables and the cables for connecting the equi-

pment in the parking system must have the characteristics

indicated in paragraph:

3.2 Type of cables.

Furthermore, all the instructions in paragraph “General safety

rules” on page 3 must be respected, and, with reference to the

specicelectricalpreparations,asdescribedinparagraph:

3.1 Safety rules.

• The Ticket Reader was designed to manage automatically

the exit of vehicles from a parking area. Therefore, transit by

pedestrians must be forbidden in the area reserved for transit

of vehicles. Moreover, appropriate signs prohibiting transit by

pedestrians must be installed. Where it is not possible to have

an entrance/exit gate reserved exclusively for pedestrians, the

current legal regulations on the subject must be absolutely

observed; (in particular standards: EN 12453 and EN 12445)

• The lane must not allow the exit by two or more vehicles

side by side. For this reason, the width of the lane must be

appropriately sized, according to the type of vehicle generally

used.

• Sufcientspacemustbeprovidedforeveryequipmentof

the parking system, so that all the necessary installation and

maintenance operations can be smoothly carried out.

• Position the Ticket Reader so that it (laser scanner) is not

directly exposed to luminous radiation, which could be source

of disturbance during reading.

• Appropriate signs (not supplied by FAAC), indicating the

tariffs and the car park rules must be visibly shown on the

entrance lane to the car park.

* optional

NB.: All the equipment which can be used in the ParkLite

parking system, were designed and tested by FAAC, in

observance of the points mentioned above. In order to avoid

any kind of unforeseen behaviour, all the rules shown in this

manual must be observed.

2.2 ESSENTIAL REQUIREMENTS

620 rapid barrier RH

Photocells

Magnetic

Loops

Ticket Reader

2. INSTALLATION OF COMPONENTS

2.1 LANE CHARACTERISTICS