I Contents

Table of contents

1Overview .................................................................................................... 1

2Safety instructions .................................................................................... 2

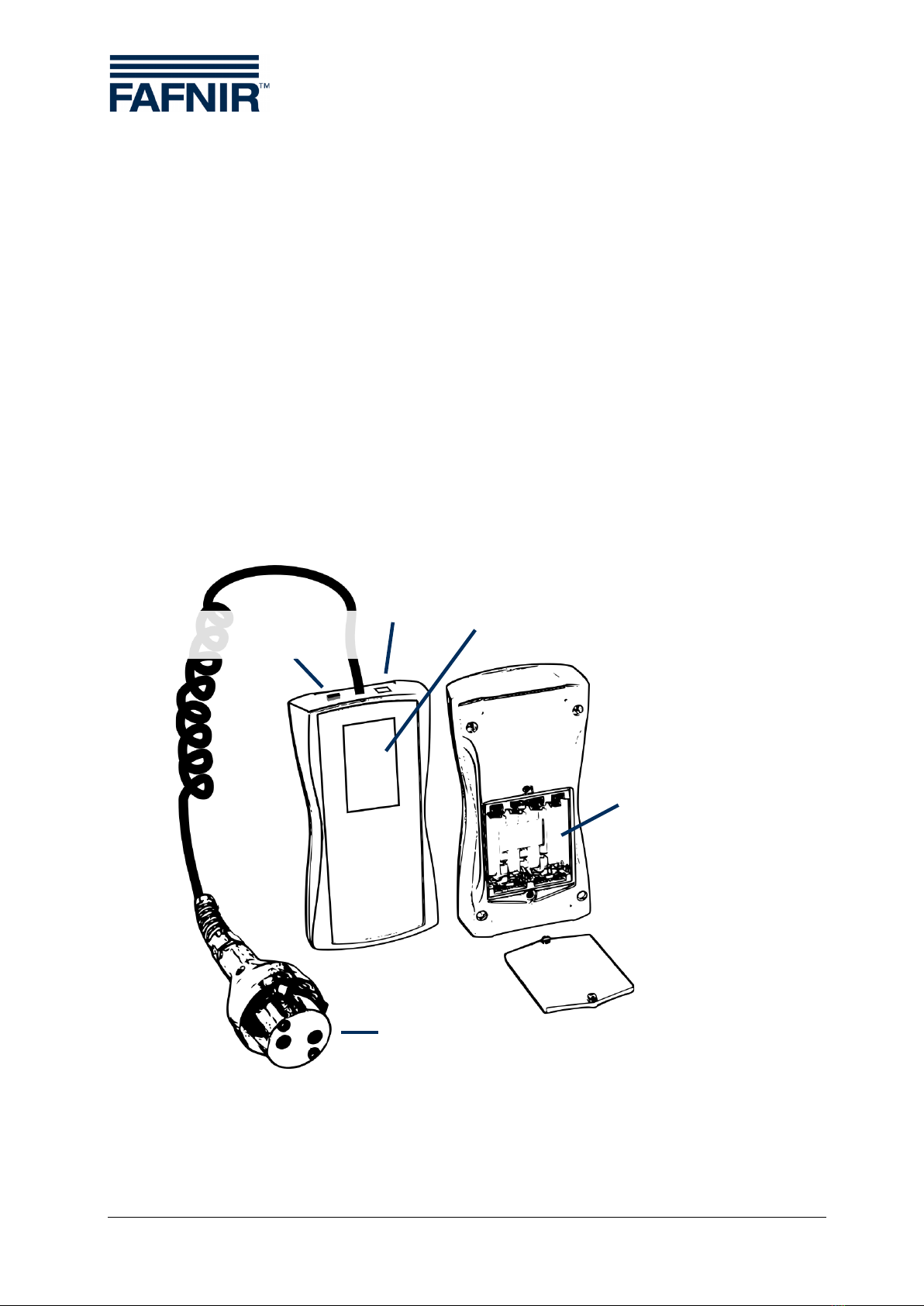

3The ME 6 ... overfill prevention sensor testing device ......................... 3

3.1 Design and construction .................................................................................................................3

3.2 Function .................................................................................................................................................4

3.3 Scope of delivery................................................................................................................................5

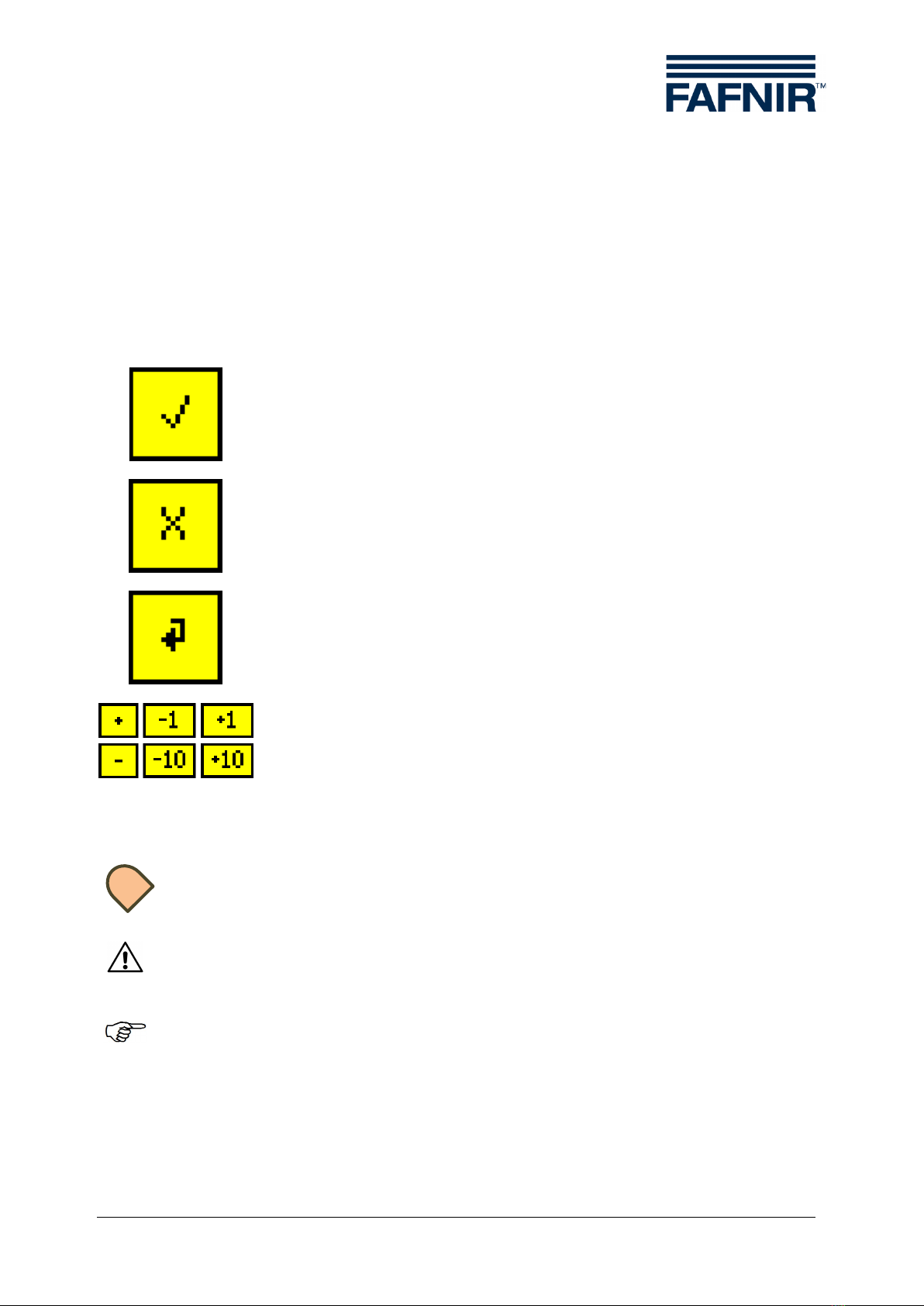

4Operation ................................................................................................... 6

4.1 Fundamentals ......................................................................................................................................6

4.2 Start-Up .................................................................................................................................................8

4.2.1 Basic settings .......................................................................................................................................9

4.3 Testing the Overfill Prevention Sensor.....................................................................................11

4.3.1 Heating-up time ...............................................................................................................................13

4.3.2 Switch-off time..................................................................................................................................13

4.3.3 QSS Code (ME 6 P) ..........................................................................................................................15

4.4 Power saving (stand-by) mode and reactivation..................................................................15

4.5 Settings ................................................................................................................................................16

4.5.1 Country selection .............................................................................................................................17

4.5.2 Date and time....................................................................................................................................17

4.5.3 Backlight ..............................................................................................................................................18

4.5.4 Touch screen calibration................................................................................................................18

4.5.5 QSS code identifiers........................................................................................................................20

4.5.6 Readings archive...............................................................................................................................21

4.5.7 Delete readings.................................................................................................................................21

4.5.8 Resetting to factory settings........................................................................................................22

4.6 Power supply......................................................................................................................................22

4.6.1 Changing the rechargeable batteries .......................................................................................22

4.6.2 Regular charging of the rechargeable batteries necessary ..............................................23

5PC software..............................................................................................24

5.1 Driver installation .............................................................................................................................24

5.2 Starting the ME 6 Software...........................................................................................................24

5.2.1 Settings ................................................................................................................................................24

5.2.2 Records ................................................................................................................................................26