ForCustomerService:Call1‐866‐GOFAGOR–www.fagorcommercial.com| P.II

Contents

SPECIFICATIONS...................................................................................................................................................3

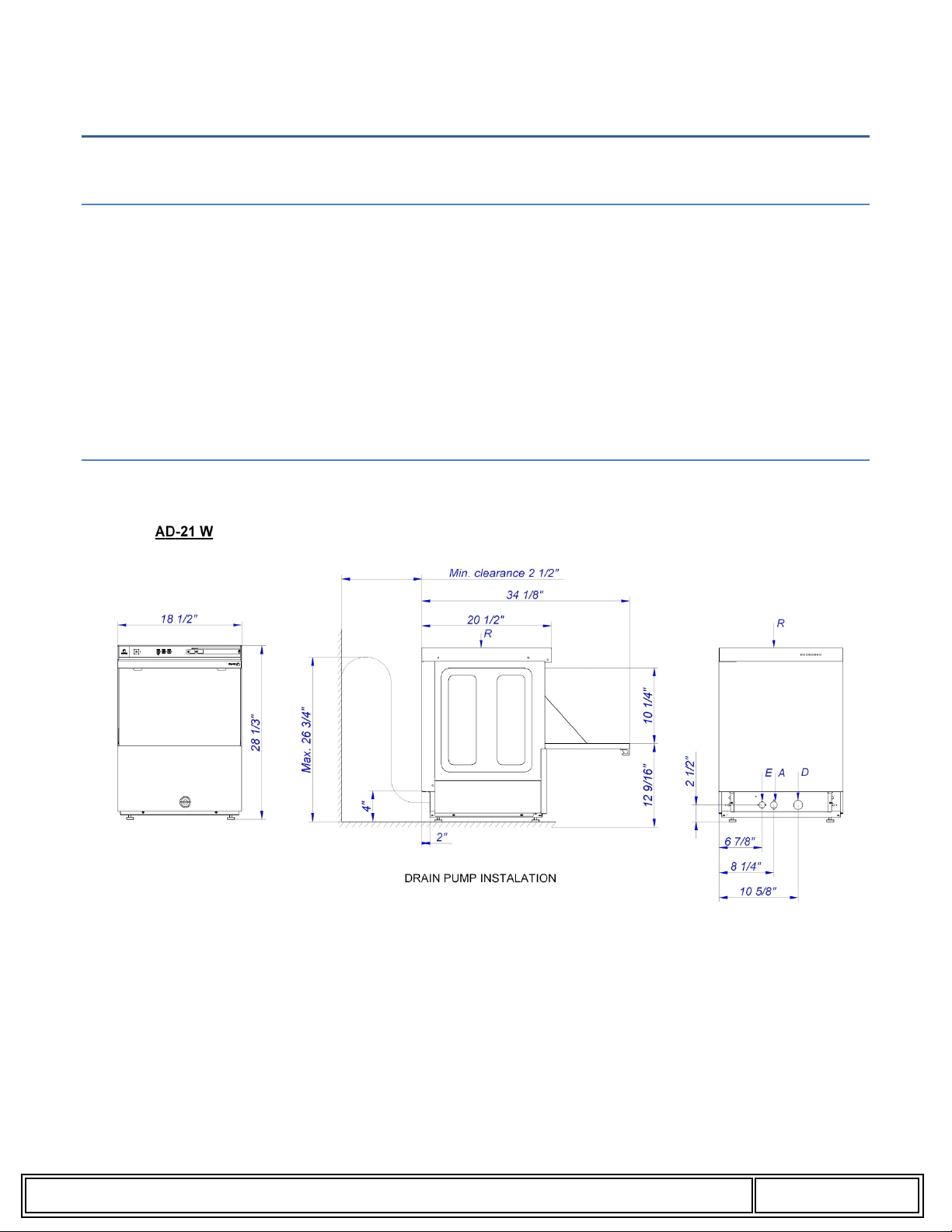

AD–21W........................................................................................................................................................3

INSTALLATION......................................................................................................................................................4

VISUALINSPECTION.........................................................................................................................................4

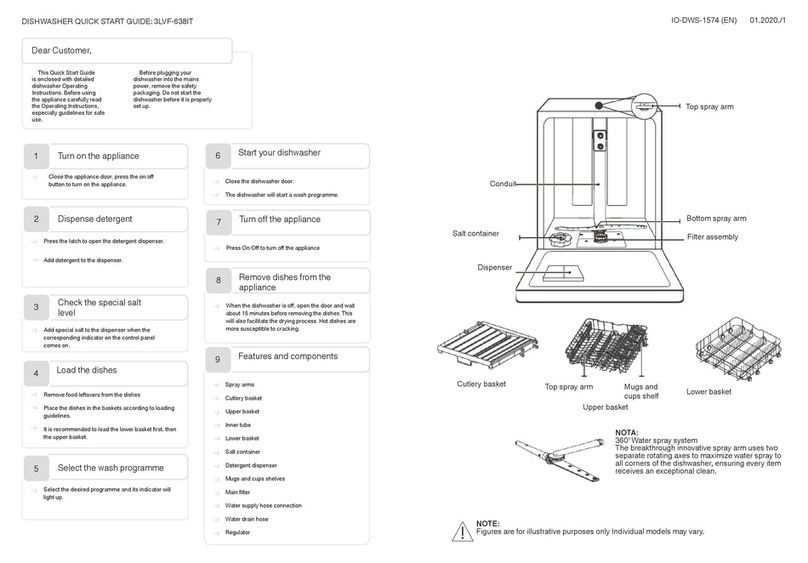

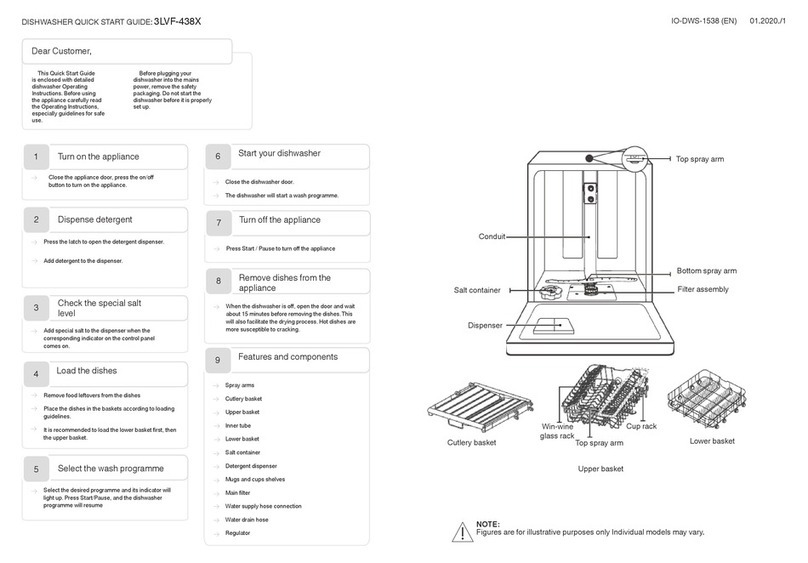

INSTALLATIONDIAGRAMS...............................................................................................................................4

POSITIONING...................................................................................................................................................5

WATERINSTALLATION.........................................................................................................................................6

REQUESTEDQUALITYOFTHEWATER.............................................................................................................7

WATERDRAINAGEINSTALLATION.......................................................................................................................7

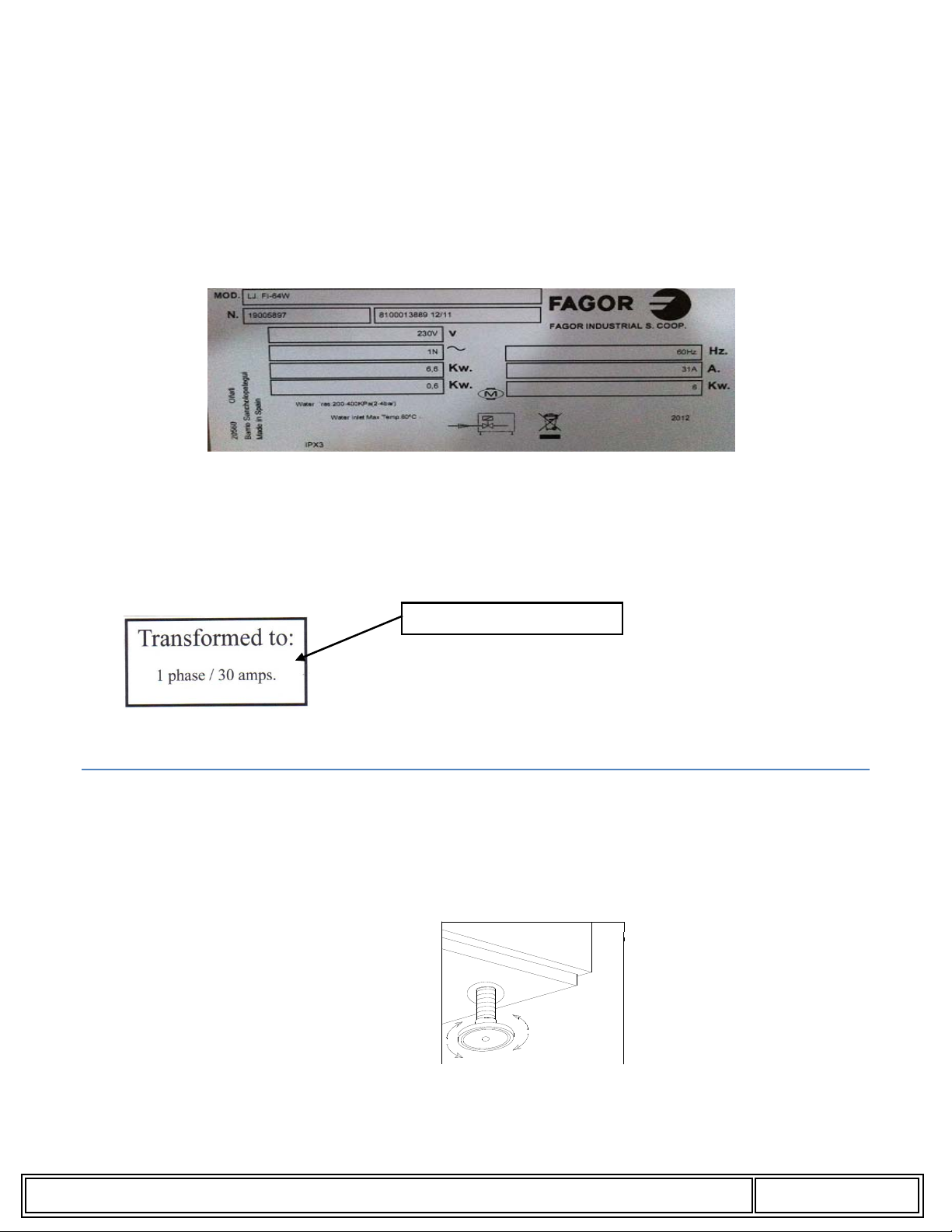

ELECTRICALCONNECTION...................................................................................................................................8

INSTALLATIONCHECKLIST....................................................................................................................................9

OPERATION..........................................................................................................................................................9

TURNINGTHEMACHINEON.........................................................................................................................10

PREPARINGTHEMACHINE...........................................................................................................................10

WASHING......................................................................................................................................................10

COOLRINSE.......................................................................................................................................................11

DRAININGANDCLEANING................................................................................................................................11

DETERGENTCONTROL......................................................................................................................................12

PREPARINGTHEWARE......................................................................................................................................13

DELIMING......................................................................................................................................................13

TROUBLESHOOTING..........................................................................................................................................14

DIAGNOSTICS................................................................................................................................................17

ELECTRICALDIAGRAM......................................................................................................................................18

WIRINGSCHEMATIC..........................................................................................................................................19

RECOMMENDEDSPAREPARTS.........................................................................................................................20

LIMITEDWARRANTY.........................................................................................................................................21