Description of operation

technical

7

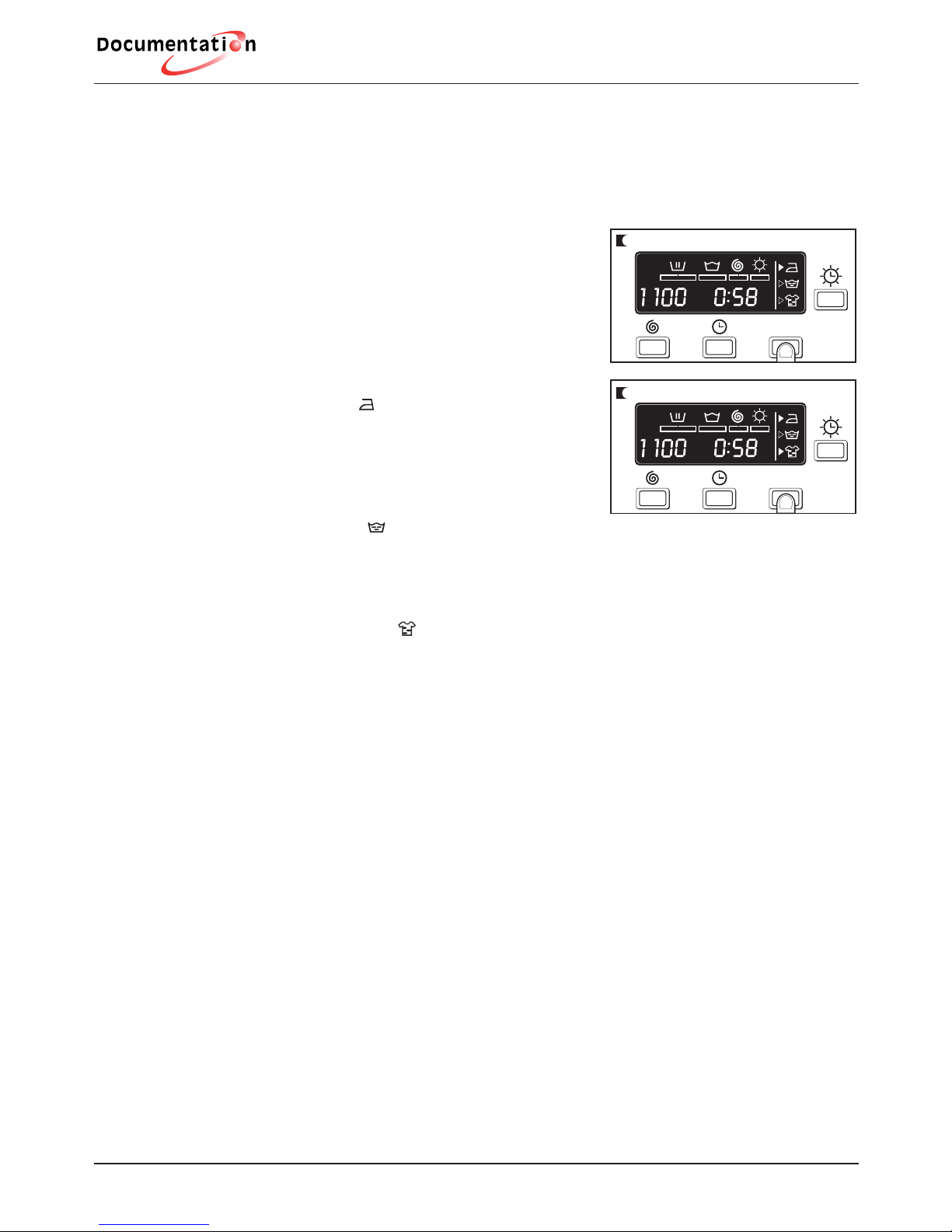

3.1.4.- Flot/Anti-crease Option

- With this option the programme stops before emptying the last rinse; for the

programme to continue, the Flot option must be unlocked

Note: The wash options must always be selected after selecting the wash

programme. A change of programme during the selection, or after the wash has

been started, cancels the options which were previously selected, and only the new

programme’s spin speed is lit up.

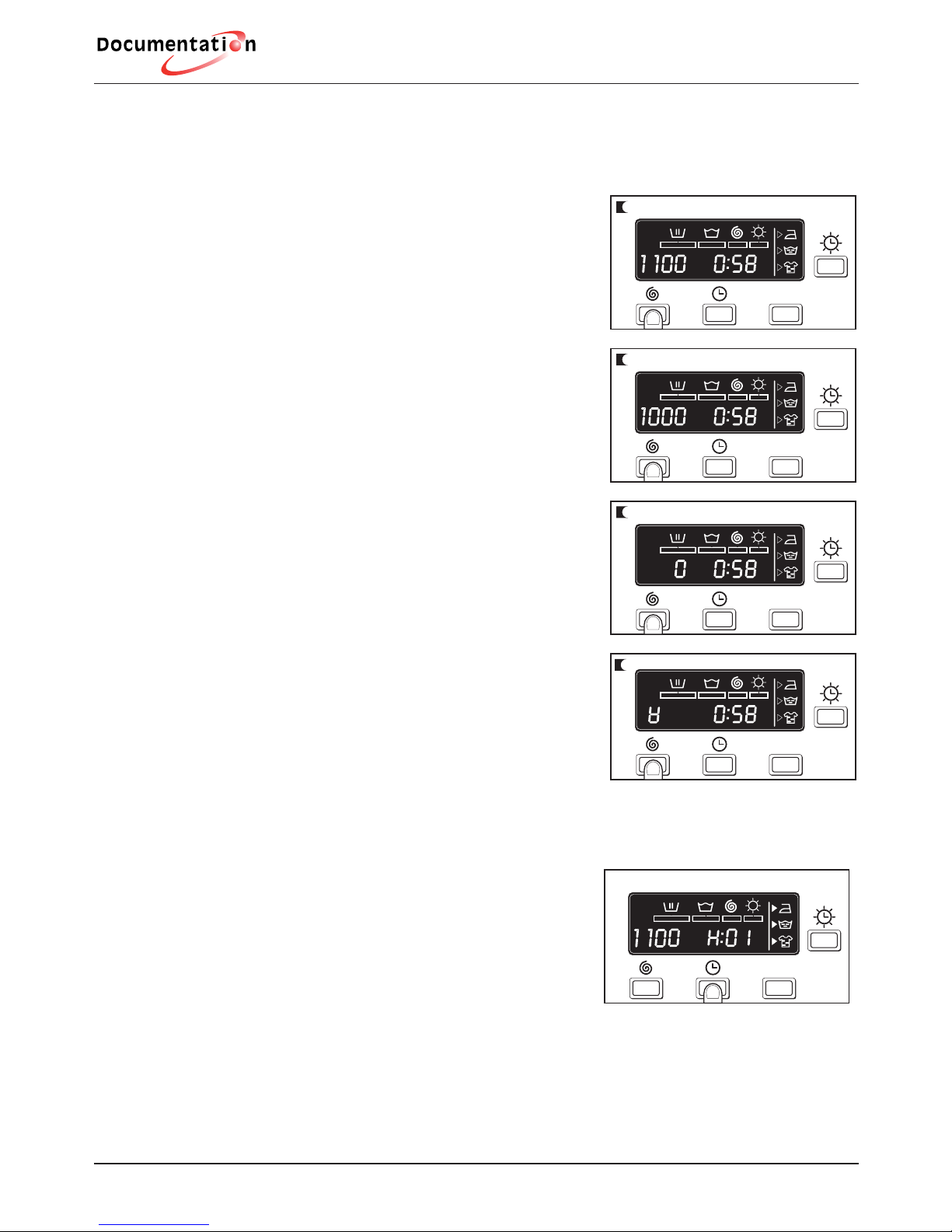

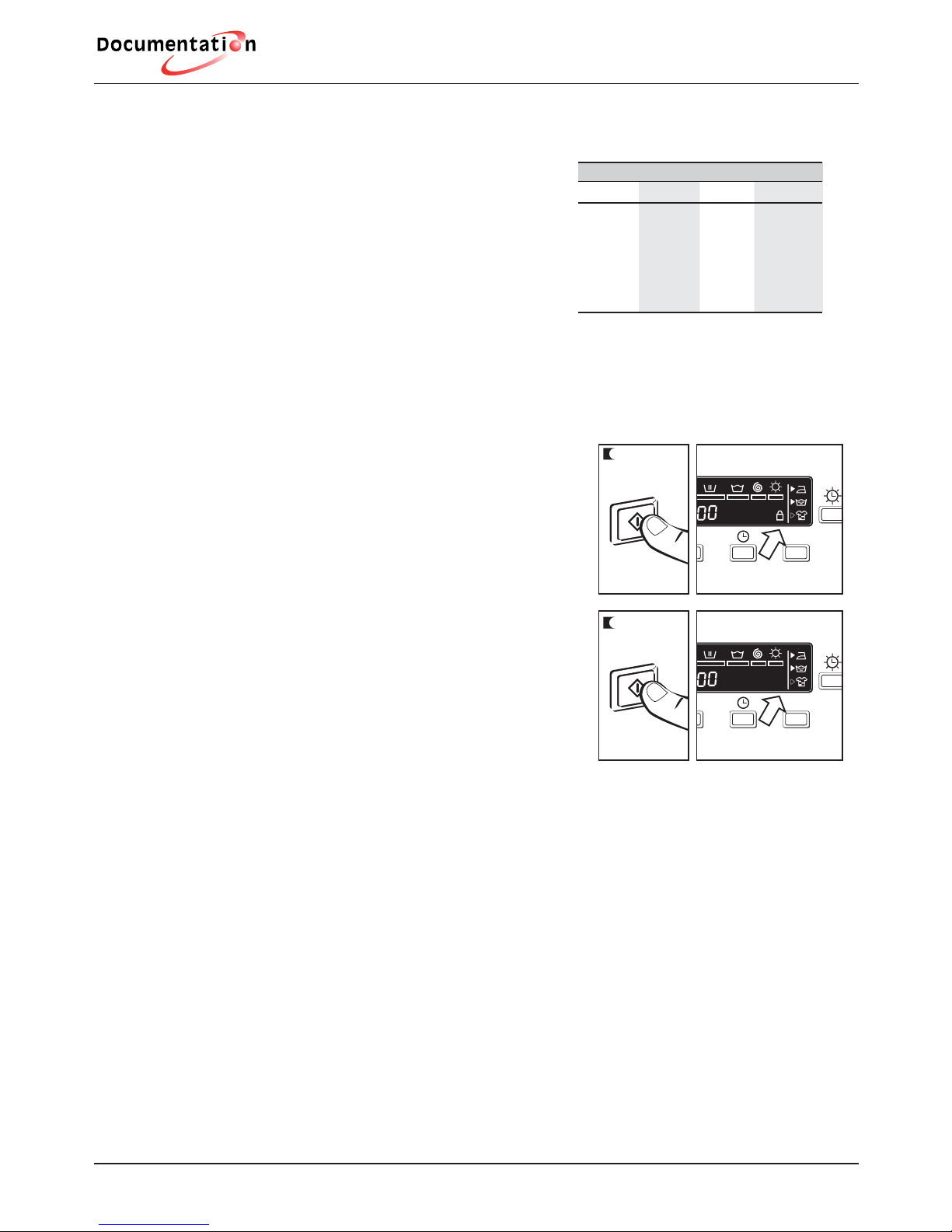

3.1.5.- Programme progress

When the programme has started, the screen can

display the current wash phase, as well as the

remaining time. As the programme continues, the

active phases will be displayed successively in the

upper part of the screen. The remaining program-

me time is also displayed in the screen. It is upda-

ted periodically, but not minute-by-minute.

Any option button may be selected, as long as

the wash phase in which it takes effect has not passed, and when the programme

permits that option. Pressing the delay button during the wash has no effect on the

washer-dryer. Pressing the Start/Pause button during the wash puts the washer in

the PAUSE state.

Important: If during the wash and dry cycle the programme is changed using

the selector, the washer-dryer is left in the PAUSE state, and the programme is

annulled. To add or remove an article, press the start/pause button and make sure

that the water is not above the door overflow level, and that the interior temperature

is not high. Press the start/pause button again to re-start the washer from the same

phase of the cycle in which it was stopped.

3.1.6.- Power failure

When the supply returns after a power failure, the washer continues to work as

normal, from the point at which it stopped (its memory lasts a few hours). The same

thing happens if the ON/OFF button is pressed.