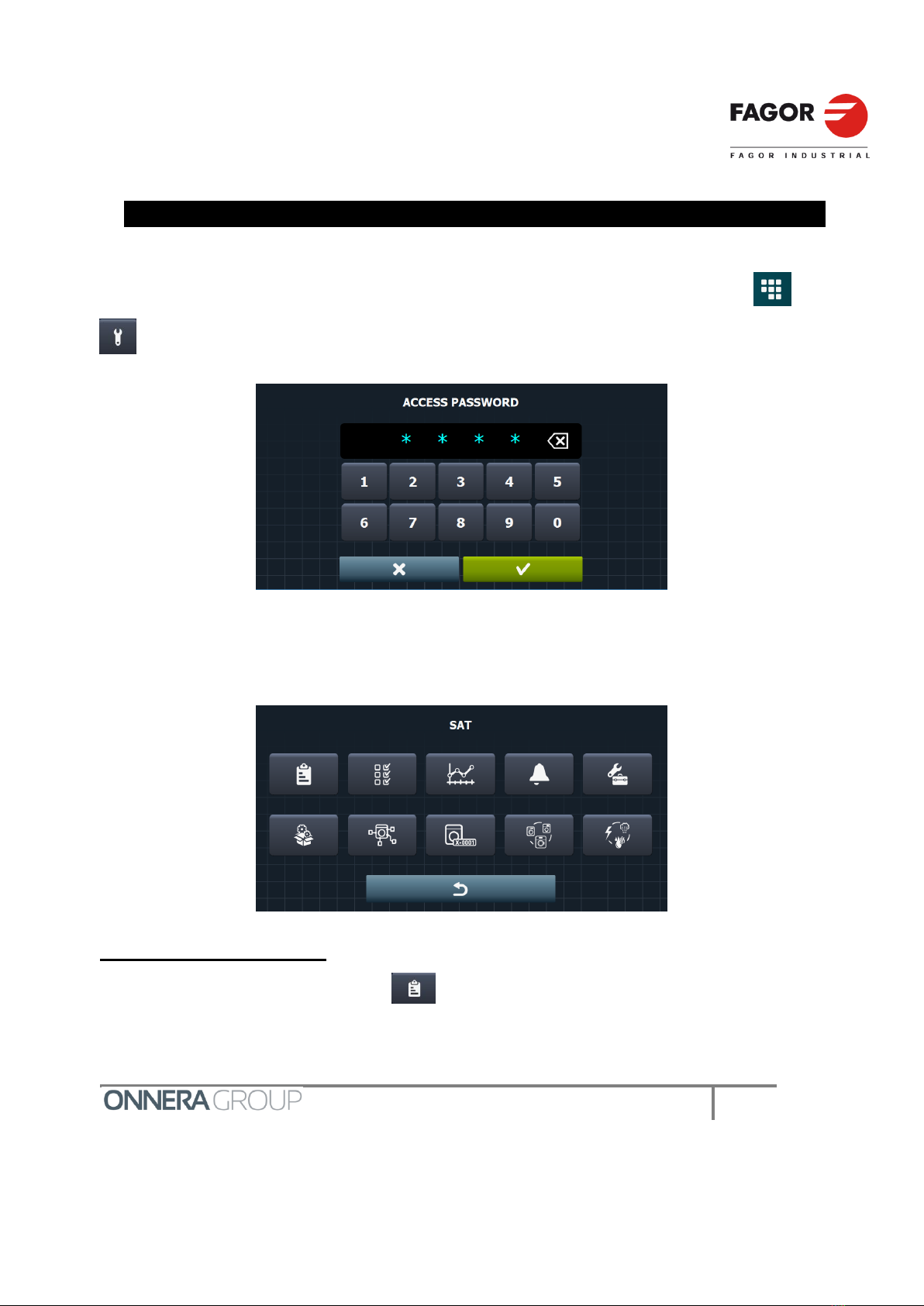

MAINTENANCE AND CONFIGURATION TP2

0. Maintenance .............................................................................................5

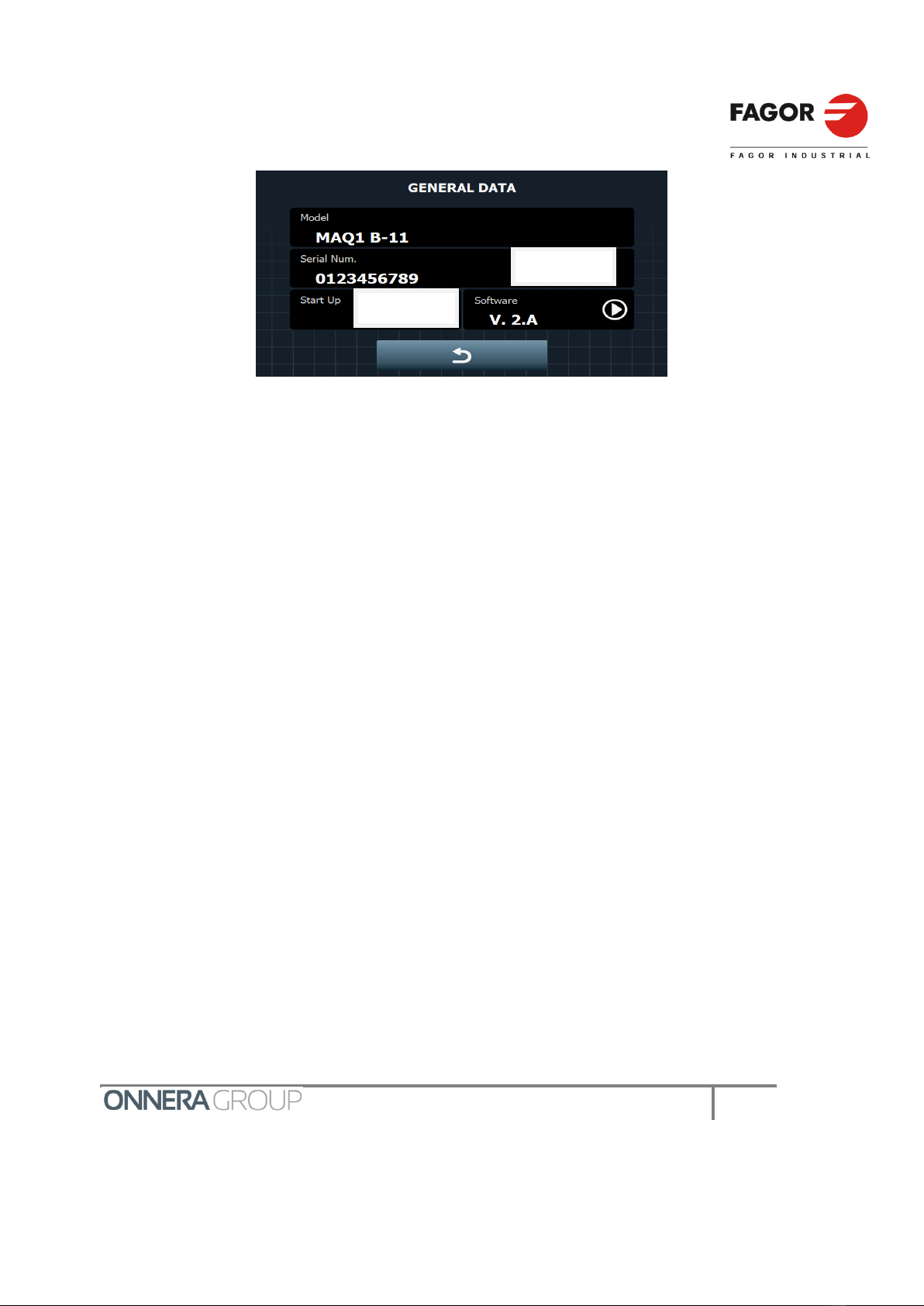

0.1 General information .................................................................................................5

0.1.1 Model ....................................................................................................................... 6

0.1.2 Serial No .................................................................................................................. 6

0.1.3 Start-up date............................................................................................................ 6

0.1.4 Software version ..................................................................................................... 6

0.1.5 Update software ...................................................................................................... 7

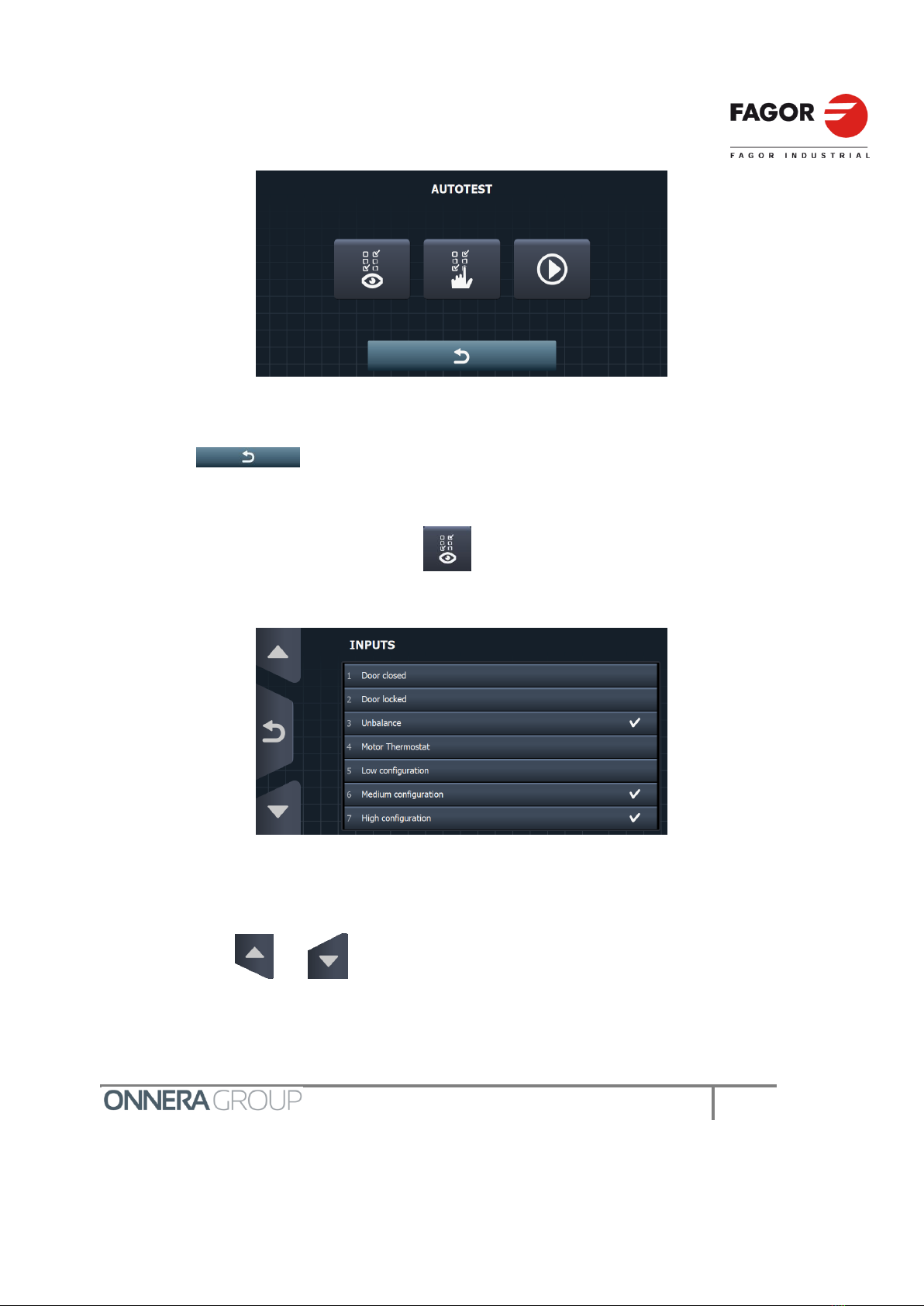

0.2 Autotest.....................................................................................................................7

0.2.1 Status of the inputs................................................................................................. 8

0.2.2 Updating the outputs .............................................................................................. 9

0.2.3 Autotest Programme............................................................................................... 9

0.3 Log...........................................................................................................................11

0.3.1 Error log................................................................................................................. 11

0.3.2 Partial values log................................................................................................... 12

0.3.3 Total values log..................................................................................................... 13

0.3.4 Download log to USB............................................................................................ 14

0.4 Configure alarms ....................................................................................................14

0.4.1 E4: Maximum water level reached ....................................................................... 14

0.4.2 E3: Drainge failure / water in tub.......................................................................... 14

0.4.3 E5: Water inlet fault............................................................................................... 15

0.4.4 E6: Heating fault.................................................................................................... 15

0.4.5 Set steam inertia ................................................................................................... 16

0.5 Advanced maintenance .........................................................................................16

0.5.1 Exhibition Mode .................................................................................................... 17

0.5.2 Continuous mode.................................................................................................. 18

0.6 Factory parameters ................................................................................................18

0.7 Kits...........................................................................................................................19

0.7.1 Weighing system................................................................................................... 19

0.7.2 Tilting system........................................................................................................ 20

0.7.3 Extra dosing .......................................................................................................... 21