SUMMARY

1. GENERAL INFORMATION 3

1.1. Contents: 3

1.2. Operating conditions and range: 3

1.3. Advantages o di erent modes: 3

1.4. Kind reminder: 4

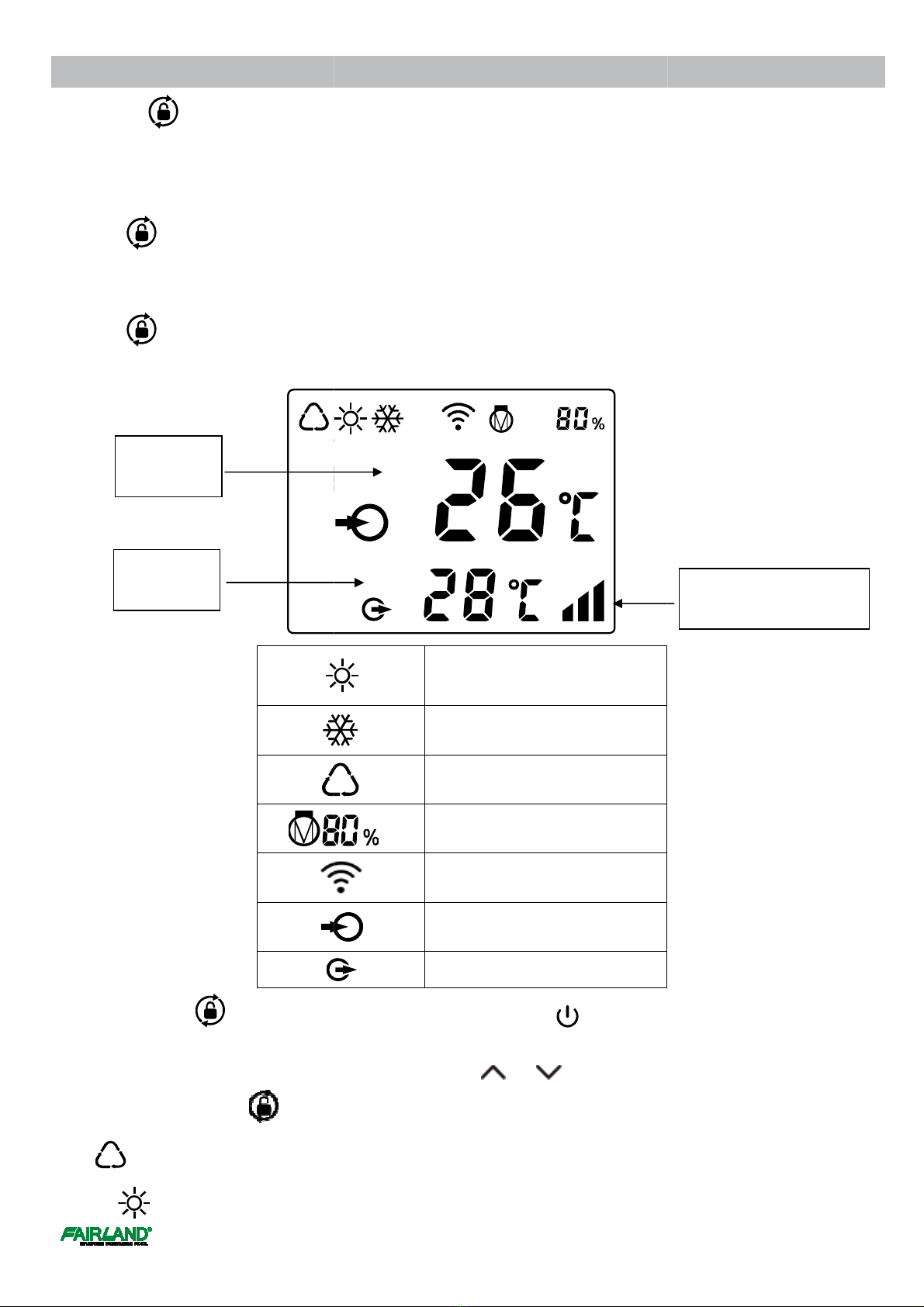

2. OPERATIONS 6

2.1. Notice be ore using 6

2.2. Operation instructions 6

2.3. Daily maintenance and winterizing 8

3. TECHNICAL SPECIFICATION 9

1. TRANSPORTATION 10

2. INSTALLATION AND MAINTENANCE 10

2.1. Notice be ore installation: 10

2.2. Installation instruction 11

2.3. Trial a ter installation 14

2.4. Maintenance and winterizing 14

3. TROUBLE SHOOTING FOR COMMON FAULTS 15

4. FAILURE CODE 16

APPENDIX 1: HEATING PRIORITY WIRING DIAGRAM (OPTIONAL) 17

APPENDIX 2: HEATING PRIORITY WIRING DIAGRAM (OPTIONAL) 18

APPENDIX 3: HEATING PRIORITY WIRING DIAGRAM (OPTIONAL) 19

5. WIFI SETTING 21

PLEASE READ IT CAREFULLY AND KEEP IT FOR SUBSEQUENT USE

This manual provides you necessary in ormation or optimal use and maintenance

For users .

For installers and professi