IGLOO TECH ST-GL IGLOO TECH ST-GL

54 FANANI / SEMI-FABRICATED COMPONENTS ASSEMBLY INSTRUCTIONSFANANI / SEMI-FABRICATED COMPONENTS ASSEMBLY INSTRUCTIONS

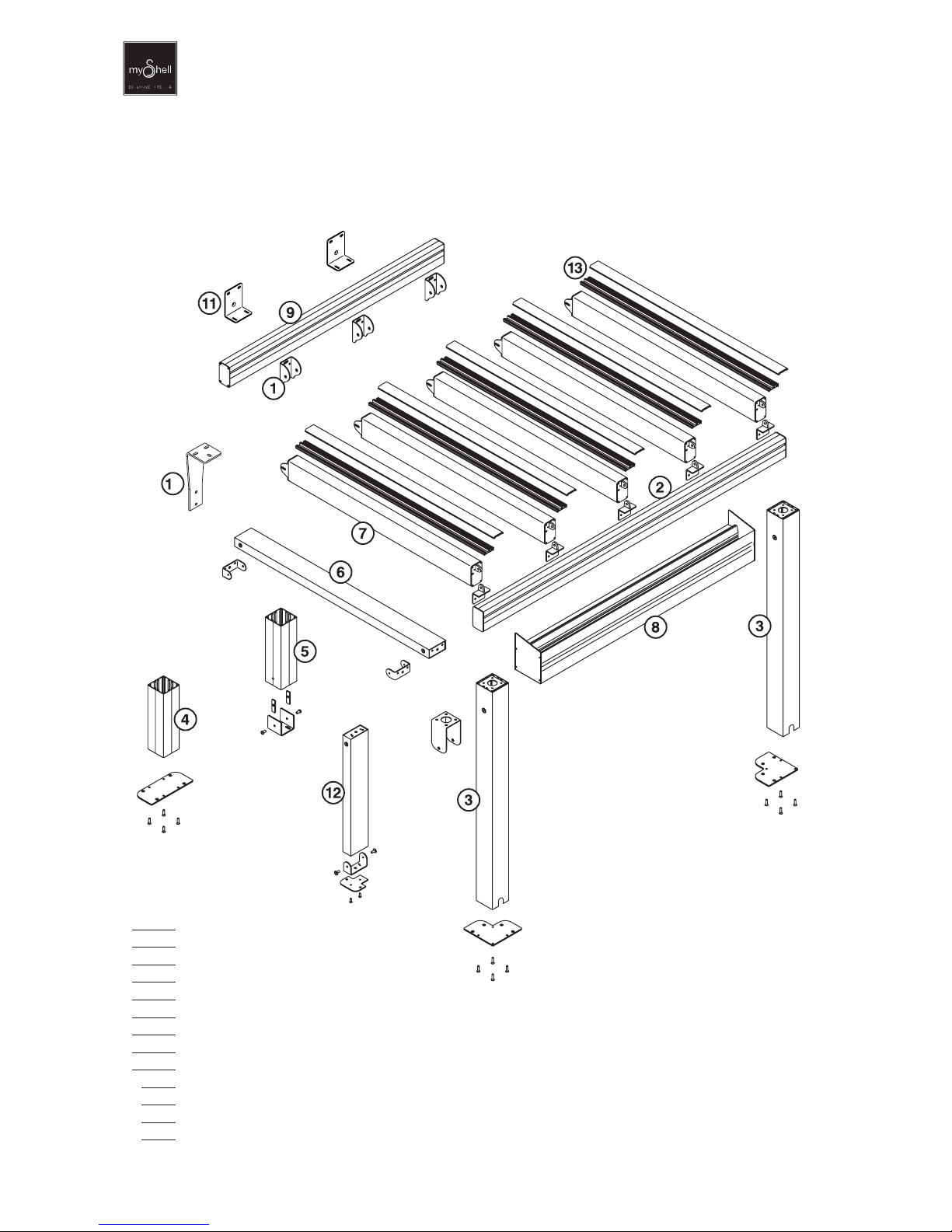

Checking material

Roller bind

set

THIS BOX

CONTAINS

CONTENTS LABEL

myShell IGLOO Class ST is packed in strapped, reinforced cartons.

The following labels are applied to all cartons:

SUMMARY LABEL

- customer (Name-Surname or Company)

- order number

- model

- dimensions

IMPORTANT: before unpacking check that the data on

the summary label is correct.

IMPORTANT: contents may change and be divided

between various boxes due to their lenght or other details.

IMPORTANT: carton also contains the following

documents

SUMMARY SCHEDULE FEATURES/DIMENSIONS

FITTING INSTRUCTIONS

MOTOR INSTRUCTIONS

USE AND MAINTENANCE MANUAL

CONTENTS LABEL

- roller blind set (box, bottom rail, fabric, etc.)

- side guides

- side beams and uprights

- frontal gutter

- others

EQUIPMENT BOX

- wall supports

- beam/uprights links

- wind break supports (when present)

- gutter equipments (when present)

- REMOTE CONTROL/S

-

-

- (manufacturer’s original)

- (to be left with the

customer)

i

i

i

Cartons: Delivery Note No.

To

Deliver to

carrier:

freight:

weight:

X/X 0000

NAME SURNAME / COMPANY

ADDRESS

POST CODE TOWN - PROVINCE

NAME SURNAME / COMPANY

ADDRESS

POST CODE TOWN - PROVINCE

SHIPPER’S NAME

CARRIAGE FORWARD

XX KG

SUMMARY LABEL

iIMPORTANT :

screws, plugs and other fitting elements are not supplied; it is up to the installer to supply suitable

screws and supports (wall/ceiling), bases (floor mounted uprights), hardware or other suitable parts

for a safe and proper installation. The installer will certify the completed assembly by signing the

use and maintenance manual.

Before starting

SAFETY

The areas under the roller blind are deemed dangerous during installation. It is the installer's responsibility to

ensure that during these operations no person is wholly or partially in the danger zone. It is a good idea to display

the sign "WORK IN PROGRESS". Access the roller bind’s highest parts with suitable means in order to carry out the

installation safely. If the safety standards are complied with, no special personal protection equipment is needed.

There are no particular residual risks if not due to negligence by the operator. When working at great heights there

are risks of falling: take adequate precautions (harnesses and / or other safety devices).

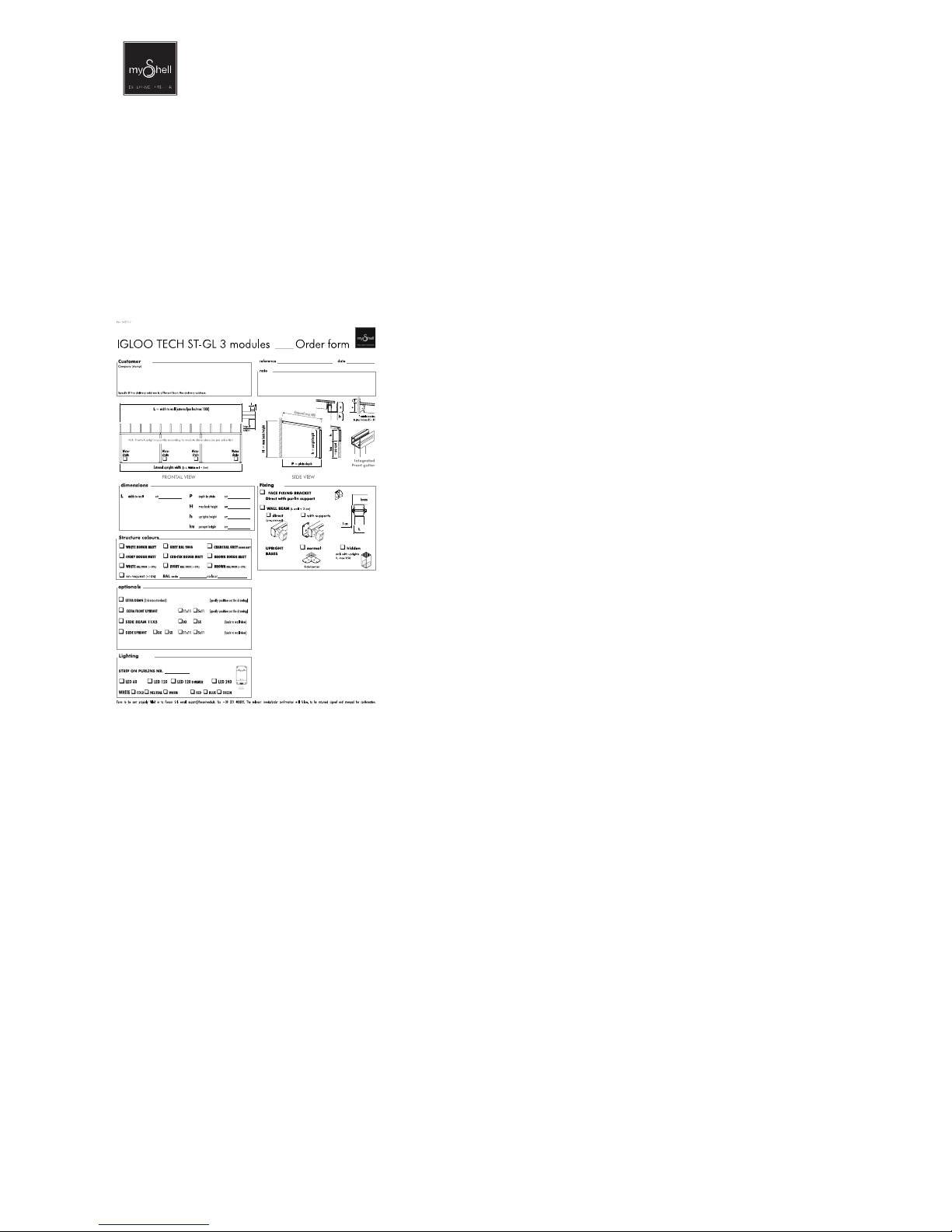

PRELIMINARY CHECKS

Compare the documentation on hand (order form) to verify that the order is consistent in size and general

characteristics (structure colour, fabric colour, fastener types, optionals, etc., etc.)

PREAMBLE

Before installation is necessary to read carefully the assemby instructions attached. The mounting as the working

operations have to be execute by skilled personel only in scrupulous mode respectin the current security laws.

TRANSPORT, HANDLING, STORAGE

The roller blind is properly packed for a safe transport. In case of a not immediate mounting the package have to be

stored in a closed place with the intact package protected from hits and/or thumps and doesn’t have to be in contact

with corrosive substances. To prevent damages to components (examples : dents on the alluminuim profiles) handle

and move packages with care. If it is possible in case of manual handling of the packages the maximal weight per

person shouldn’t be more than 25 kg.

UNBOXING

At the receiving of the goods check the materials integrality. In case of anomalys do not proceed to the mounting

and inform the vendor company for the retrieval or the substitution.

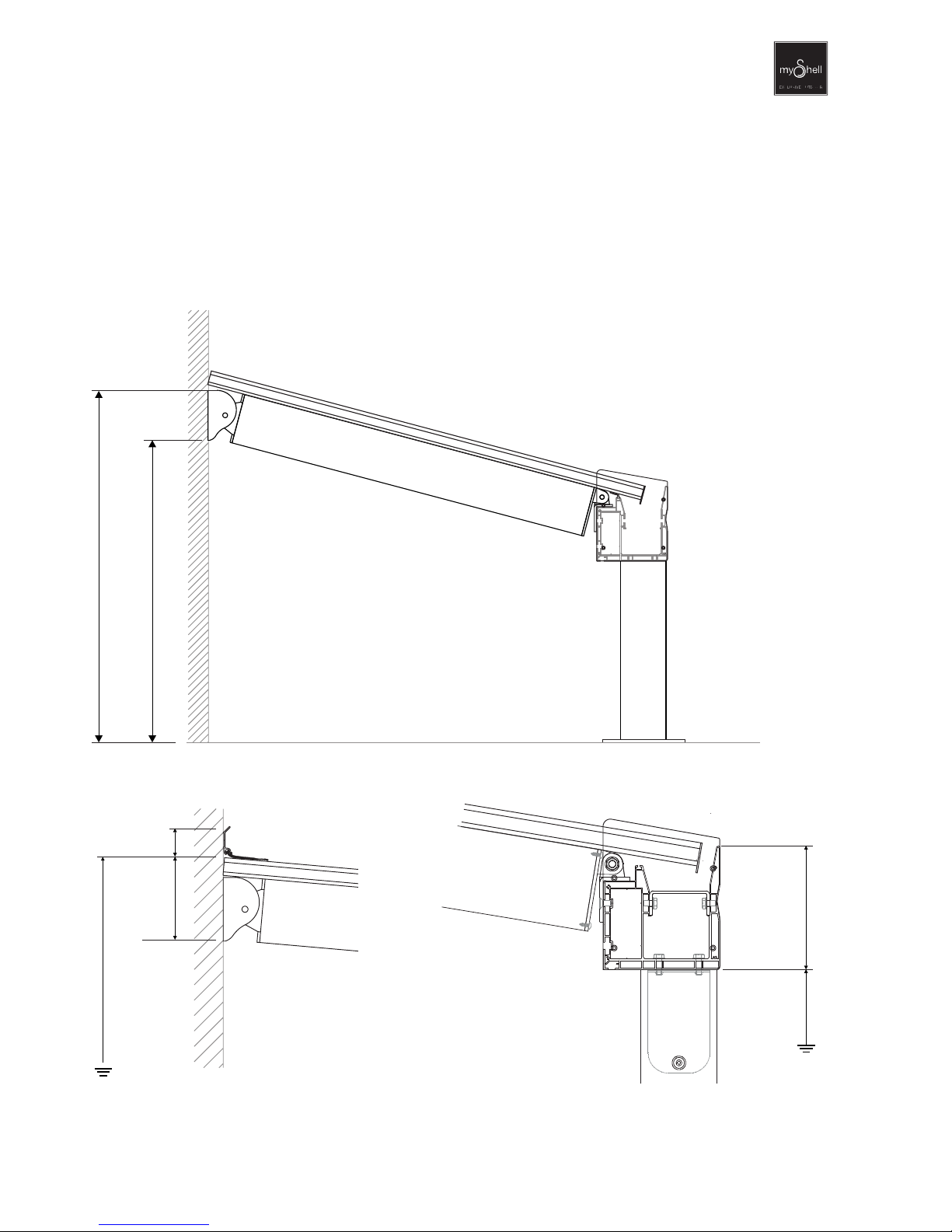

INSTALLATION

It is installer’s responsability to check walls, floor or whatever else fastening support tho whom the roller blind is

settled.

The mounting is at installer’s charge qualified to release the document of THE CORRECT INSTALLATION

DECLARATION.

The electrical connections are at electrician’s charge qualified to release the document of THE CONFORMITY

DECLARATION.