1. General introduction .................................................................................................................................. 1

1.1 Fancom Sales & Service Center..................................................................................................... 1

1.2 How to use this manual .................................................................................................................. 1

1.3 Safety instructions and warnings.................................................................................................... 2

2. Installing the iM.60...................................................................................................................................... 3

2.1 Mount the iM.60.............................................................................................................................. 3

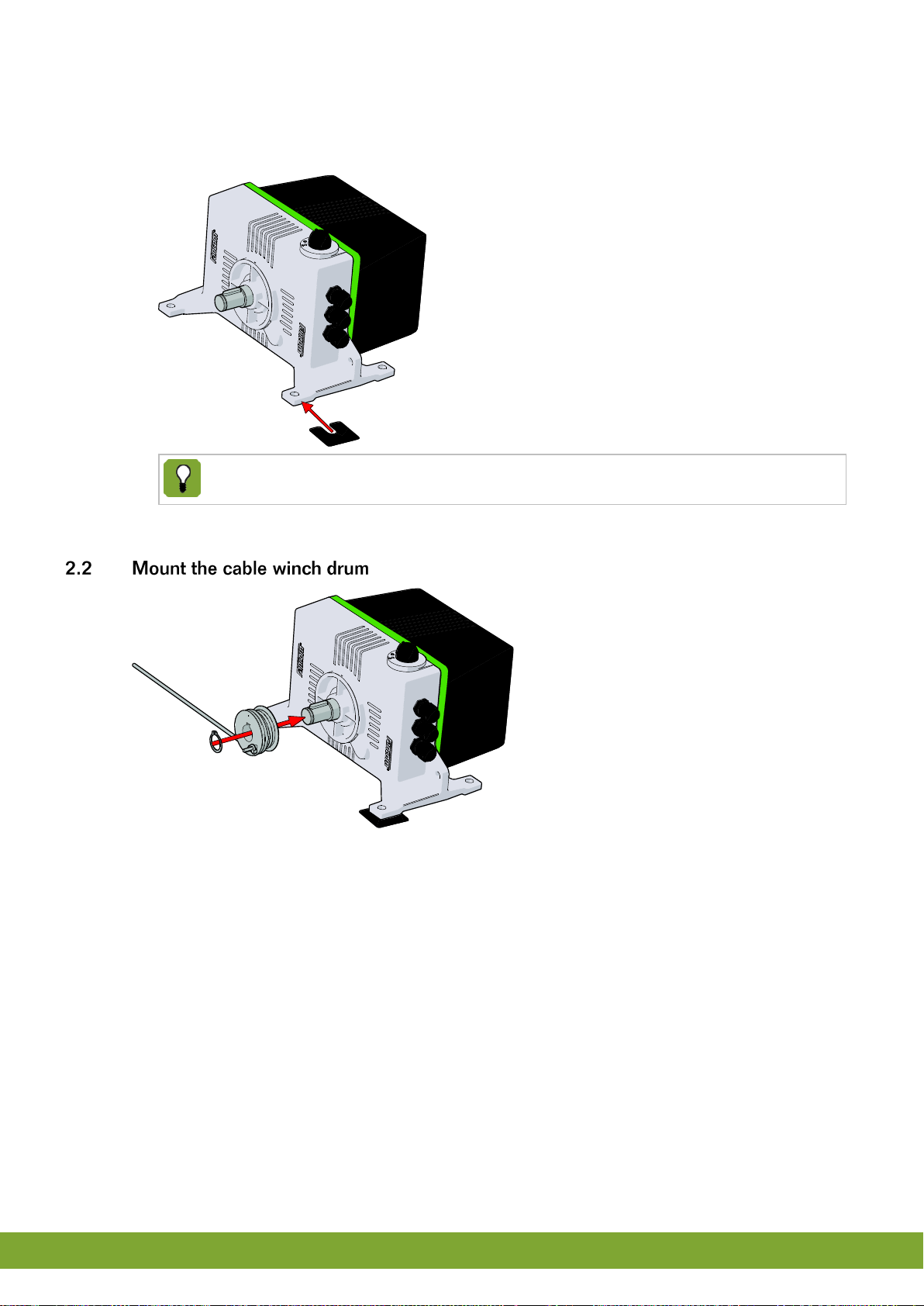

2.2 Mount the cable winch drum........................................................................................................... 4

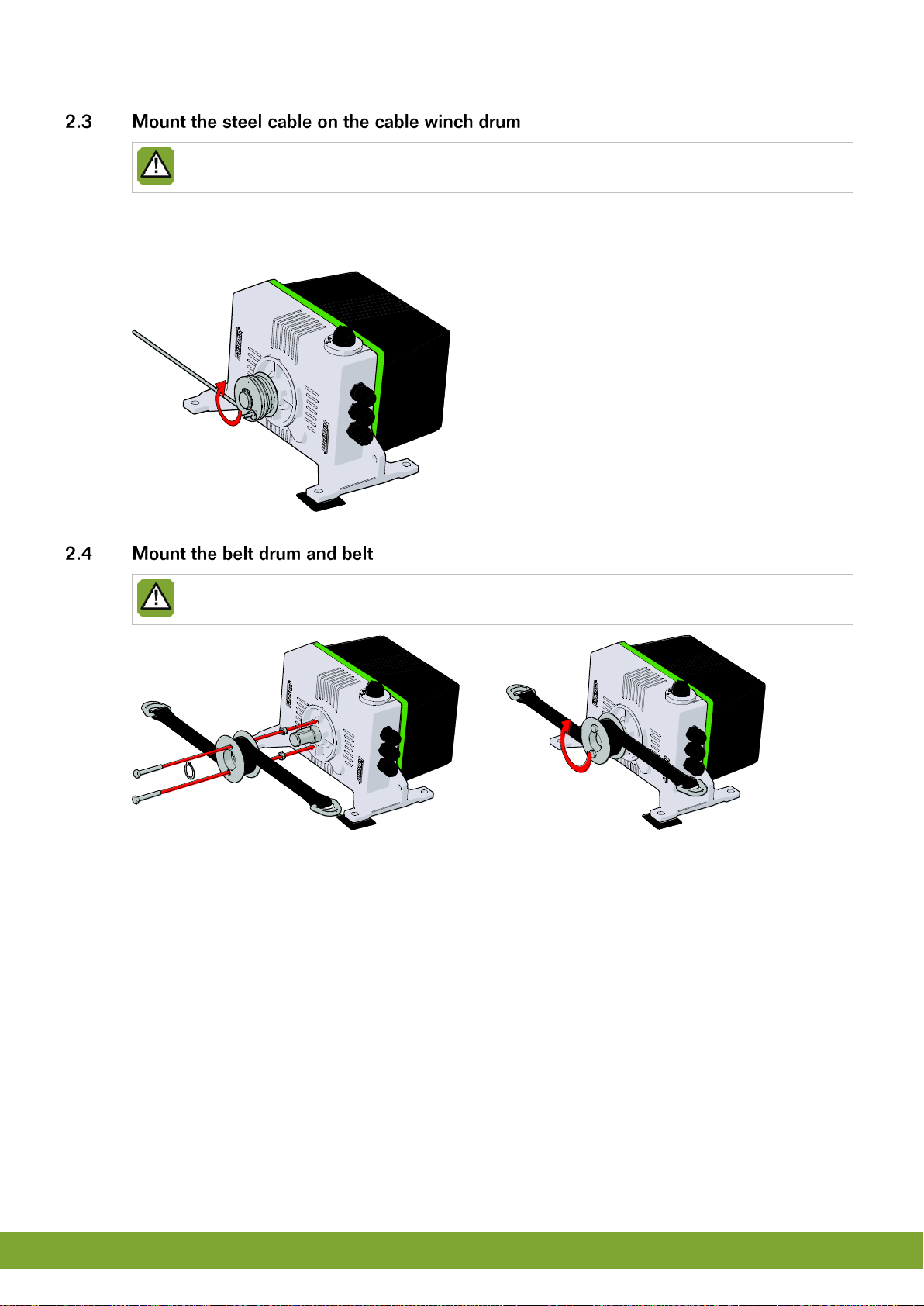

2.3 Mount the steel cable on the cable winch drum.............................................................................. 5

2.4 Mount the belt drum and belt.......................................................................................................... 5

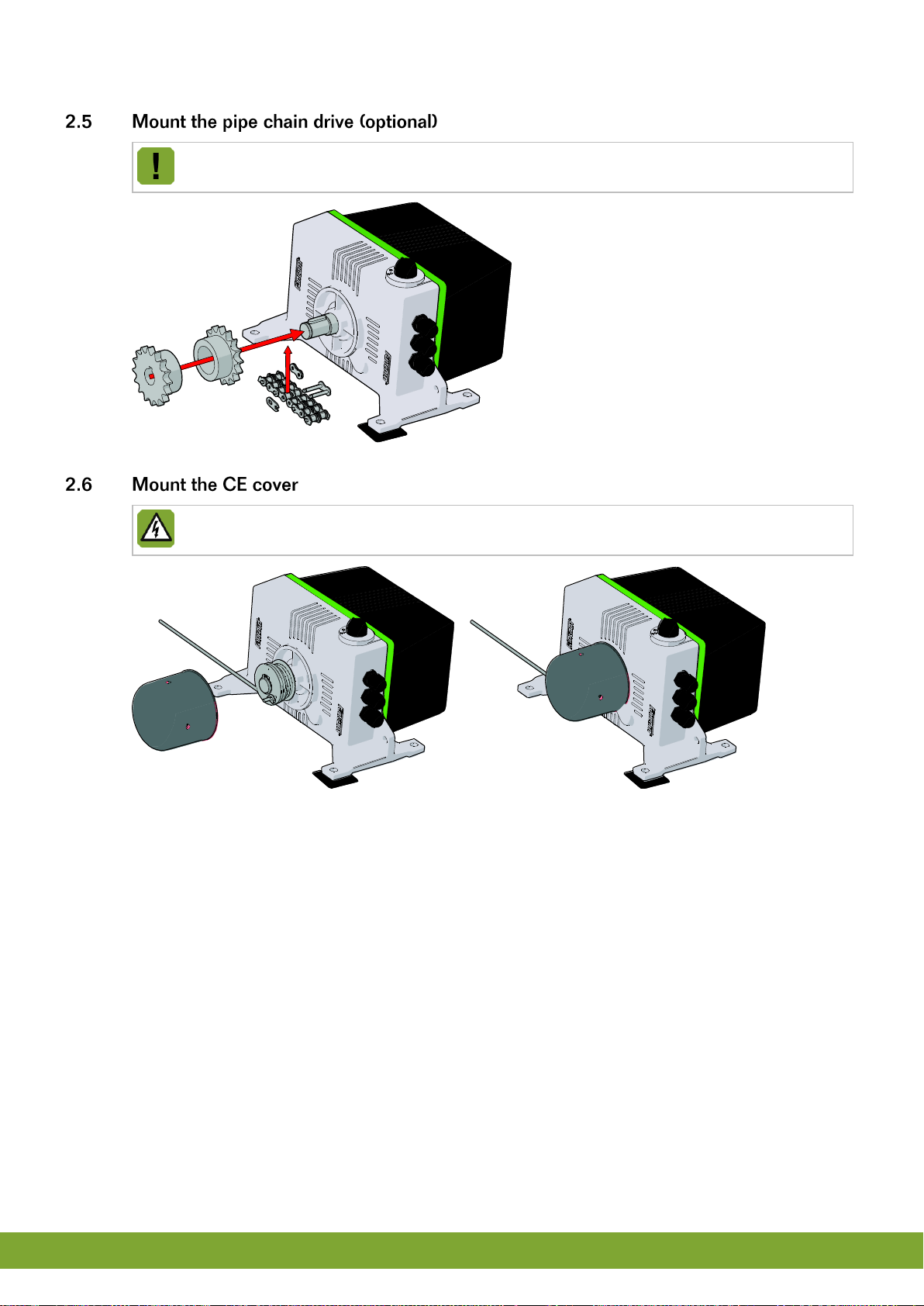

2.5 Mount the pipe chain drive (optional).............................................................................................. 6

2.6 Mount the CE cover........................................................................................................................ 6

2.7 Mount the CE protection cover on the belt drum ............................................................................ 7

2.8 Connect the iM.60 .......................................................................................................................... 7

2.9 Test the iM.60............................................................................................................................... 10

3. Using the iM.60 ......................................................................................................................................... 11

3.1 Set the switch............................................................................................................................... 11

3.2 Remote manual operation ............................................................................................................ 11

3.3 Disposal / recycling....................................................................................................................... 11

4. Adjusting the iM.60................................................................................................................................... 12

4.1 Adjust limit switches ..................................................................................................................... 14

4.2 Adjust the CLOSE position........................................................................................................... 16

4.3 Adjust the OPEN position (if CLOSE already is adjusted)............................................................ 17

4.4 Adjust the PREDEFINED position ................................................................................................ 17

4.5 Complete adjustments.................................................................................................................. 17

5. Extra possibilities..................................................................................................................................... 18

5.1 Using the emergency battery (optional)........................................................................................ 18

5.2 Predefined position / adjusting independently .............................................................................. 18

5.3 Reversing the direction of rotation................................................................................................ 19

5.4 Maximum thermostat (optional).................................................................................................... 19

5.5 External alarm led (optional)......................................................................................................... 20

5.6 Fantura air inlet............................................................................................................................. 20

5.7 Restore factory settings................................................................................................................ 20

6. Alarms ....................................................................................................................................................... 21

7. Technical specifications .......................................................................................................................... 22

8. Appendix: connection diagram............................................................................................................... 24

9. EC declaration of conformity................................................................................................................... 25