3

2

3

4

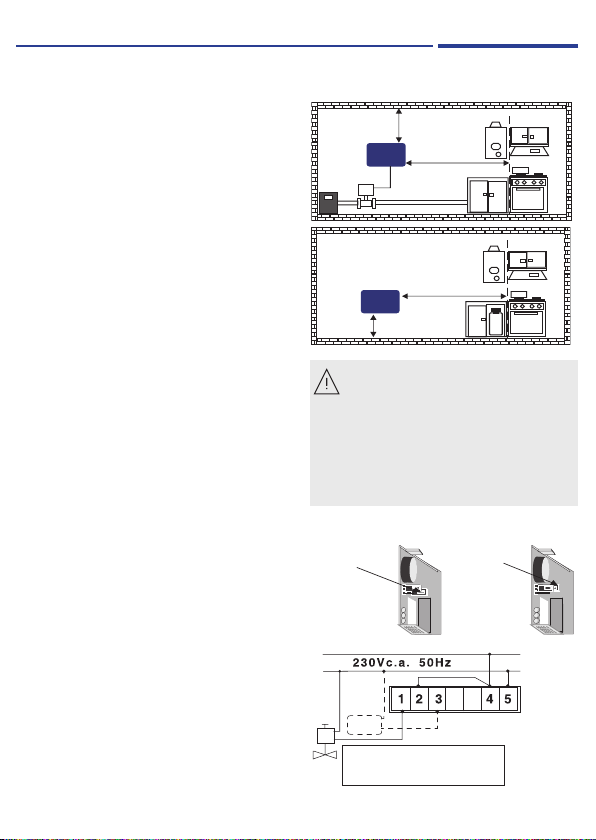

SICURGAS PLACEMENT

EXAMPLES OF CONNECTION

ELECTRICAL CONNECTIONS

Sicurgas P11 must be fixed on the wall, about 30

cm from the ceiling and at a distance from gas

user device, between a minimum of 1 meter and a

maximum of 4 meters, in such position as to allow

natural air circulation.

Sicurgas P12 must be installed approximately 2

meters (minimum 1m maximum 4m) from the gas

user device and about 30 cm from the floor.

Sicurgas P11 is already equipped with two internal

alarms: one visible and one acoustic.

Just connect the line 230V c.a. 50Hz to the

terminals 4 and 5 to ensure the gas presence

signaling in the environment.

It is recommended to use a valve with manual

reset to stop the gas supply when there is an alarm

situation.

The internal relay can control all kind of power

supplied valves with manual reset:

normally closed (NC), always power supplied,

which require a commutating stable relay;

normally opened (NO), which require an

impulse relay.

Example of connection with stable relay, always

power supplied, to control a normally closed valve

with manual reset (down switch).

The system guarantees maximum safety, the gas

inflow will be stopped in case of:

gas concentration threshold exceeding;

power supply lack of the valve only or of the

detector;

connection breakdown between the detector

and the valve. For device power supply, connect

the terminals 4 - 5 to the circuit

230V-50Hz.

Relay operating mode can be chose in the

installation moment, by moving a switch (JP6) on

the printed circuit, normally supplied for functioning

with stable relay for NC valves (down switch).

GAS LEAK DETECTORS

FOR METHANE AND LPG

ATTENTION!

DO NOT place the device behind or under

cabinets or shelves that are not allowing the

natural air circulation in environment.

DO NOT place it near aerators (minimum distance 2

meters).

DO NOT place it on the vertical bakery surfaces,

steam sources, in places where can be achieved by

splashing water, near sinks, etc.

DO NOT place where environmental conditions are

different from the prescribed operation conditions.

NC

L

N

switch JP6 in

down position

(B)

predisposed in the

factory

stable relay for normally

closed NC valves with

manual reset

switch JP6 in

up position (A)

impulse relay for

normally opened NO

valves

with manual reset

possible

external

alarm

P11-P12

Sicurgas

max. 30 cm

min. 1 mt

max. 4 mt

GPL

max. 30 cm

min. 1 mt

max. 4 mt