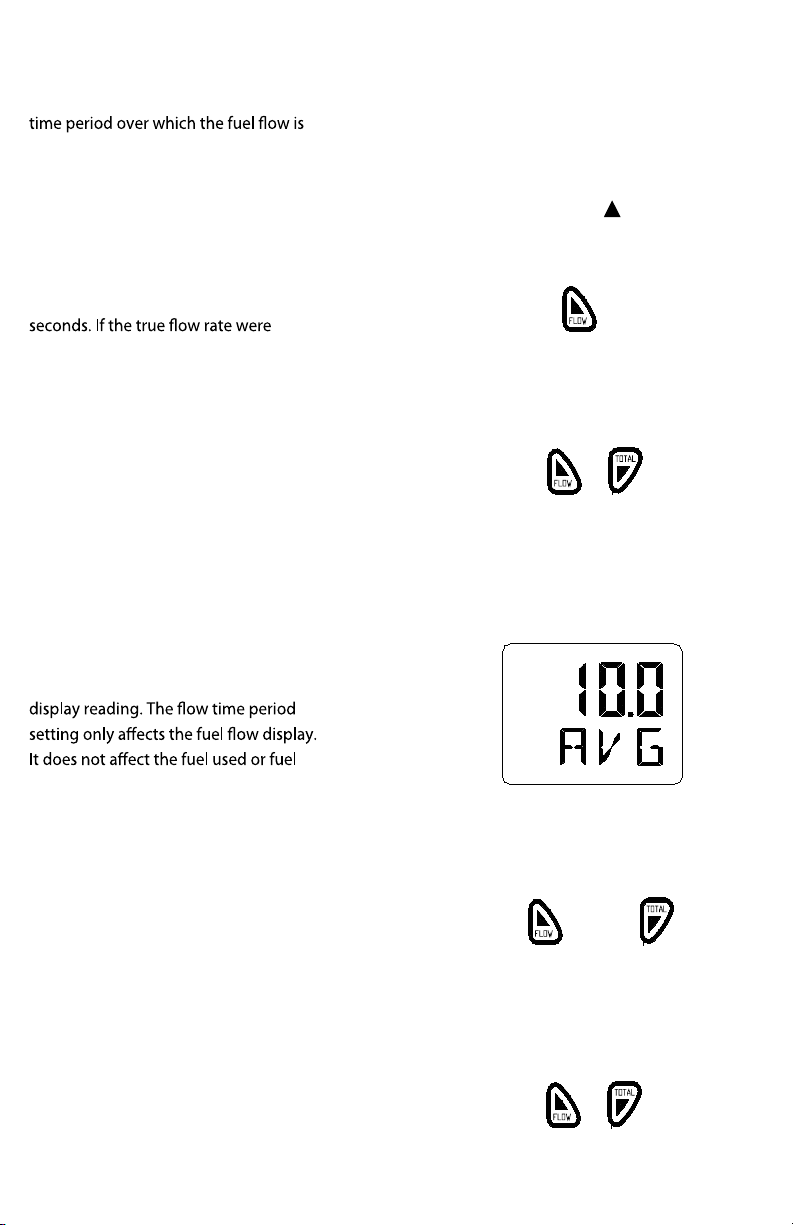

Flow Averaging

The Flow Averaging function sets the

averaged. The time period can be set in

the range of 1 to 99 seconds. Normally,

engines do not draw fuel from the tank

ata constant rate. An engine draws fuel

ata high rate for a short time until the

carburetor bowl or injection reservoir is

full and then draws no fuel for a few

displayed, it would be too erratic to read.

Usually, a value of 10 -15 seconds gives

satisfactory results for two stroke

naturally carburetored engines. Four

stroke and engines that use electronic

fuel injection may require longer

periods. If the readings seem erratic,

you can increase the time period.

A long time period means the fuel

display will have a slow response time

and a more accurate reading. A short

time period means the display will have

a quick response time but an erratic

remaining measurement in terms of

accuracy.

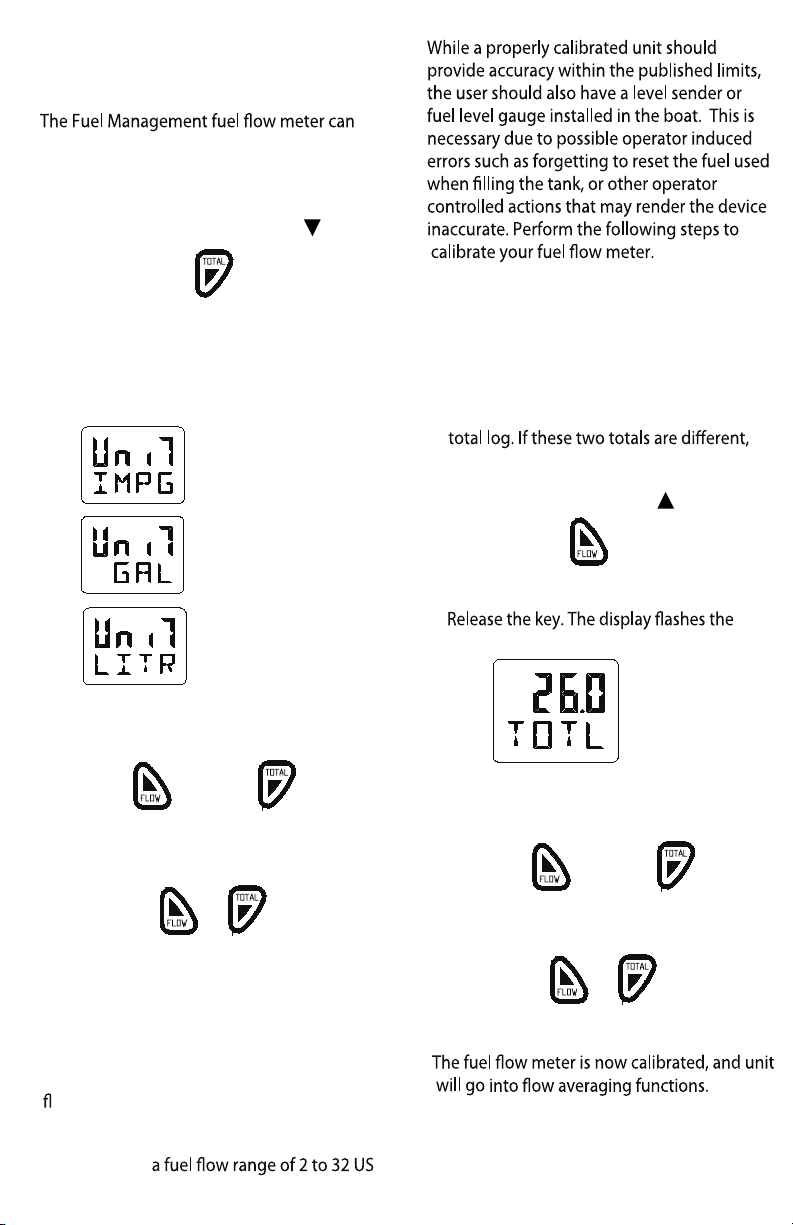

Flow Average Menu

Follow the steps outlined below to enter

the Flow Averaging Menu:

1.Press and hold the

key while

applying power to enter the Fuel

Calibration menu.

2. Press and hold both keys

simultaneously for 2 seconds to enter

the Flow Filter mode.

3. The Fuel Flow Average Period menu

AVG is displayed with the default

value of 10 seconds if you have not

previously changed it.

4. Use the up or down keys to change

the value between 1 and 99 seconds.

or

5. Press and hold both keys

simultaneously for 2 secondsto save

the new averaging time period and

return to normal operation

8