TABLE OF CONTENTS

Introduction ............................................................................................................................................................. 2

Technical Specifications .......................................................................................................................................... 3

74v1 Spray Controller.............................................................................................................................................. 4

Parts List................................................................................................................................................................... 5

Installation of Terminal –Smart Switch - UniPOD ................................................................................................. 7

Installation (Sensors) ............................................................................................................................................. 12

Control Bank Installation....................................................................................................................................... 14

Explanation of Components.................................................................................................................................. 16

Start Guide ............................................................................................................................................................. 21

74V1 General Overview ........................................................................................................................................ 22

Device Menu Overview ......................................................................................................................................... 25

Machine Setup....................................................................................................................................................... 31

Tank Setup ............................................................................................................................................................. 50

Jobs (2) ................................................................................................................................................................... 63

Alarms (3)............................................................................................................................................................... 69

Maintenance > System (4-1)................................................................................................................................. 74

Maintenance > Users (4-2).................................................................................................................................... 80

Maintenance > About (4-3)................................................................................................................................... 83

Maintenance > Test (4-4)...................................................................................................................................... 84

Screen & Layout Setup .......................................................................................................................................... 85

Display .................................................................................................................................................................... 90

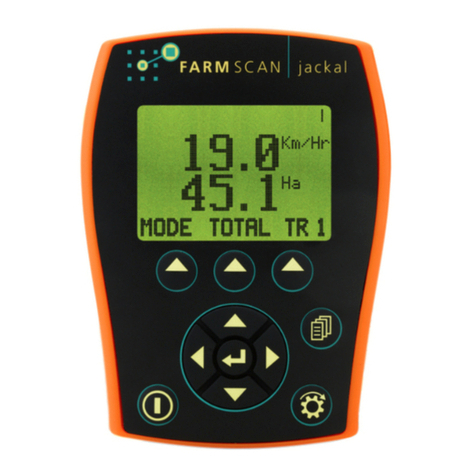

Front Screen Control ............................................................................................................................................. 93

Spray Section Control Operation .......................................................................................................................... 94

74V1 Menu Layout (Tank)..................................................................................................................................... 97

74V1 Menu Layout (Machine) .............................................................................................................................. 98

74V1 Menu Layout (Display)................................................................................................................................. 99

UniPOD Pinout..................................................................................................................................................... 100