3

CHICK-INN

Revision date: 12.19.07

ASSEMBLY PROCEDURE

Following the instructions as presented will help ensure

the proper assembly of your shelter. Failing to follow these

steps may result in an improperly assembled and anchored

shelter and will void all warranty and protection the owner

is entitled.

The steps outlining the assembly process are as follows:

1. Verify that all parts are included in the shipment. Notify

Customer Service for questions or concerns.

2. Read these instructions, the Must Read document, and

all additional documentation included with the shipment

before you begin assembling the shelter.

3. Gather the tools, bracing, ladders (and lifts), and

assistance needed to assemble the shelter.

4. Check the weather before you install the roof cover

and any panels (if equipped). Do not install covers or

panels on a windy or stormy day.

5. Re-evaluate the location and site based on the

information and precautions presented in the

documentation included with the shipment.

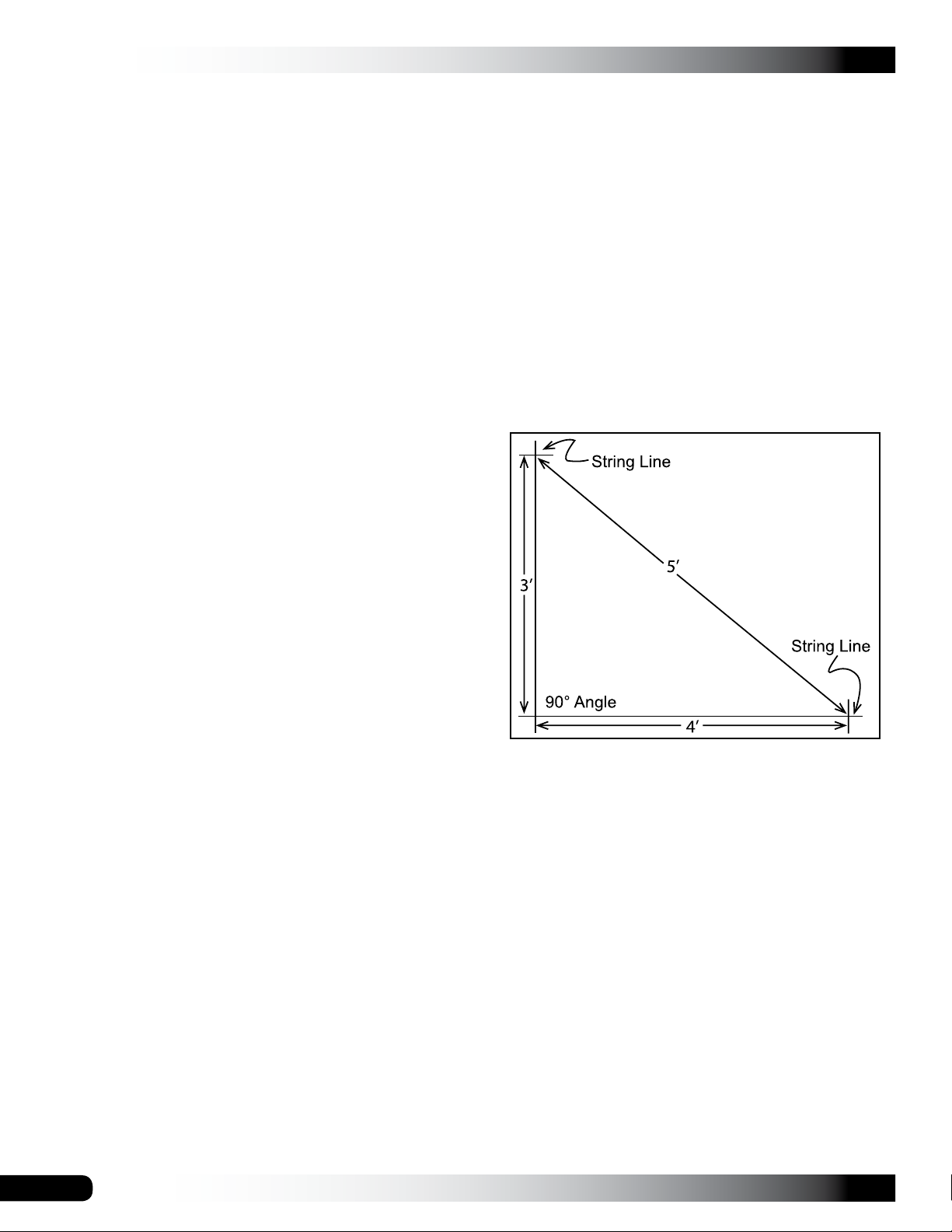

6. Lay out the site (if this has not been completed). This

may not apply to smaller shelters such as awnings that

are attached to buildings.

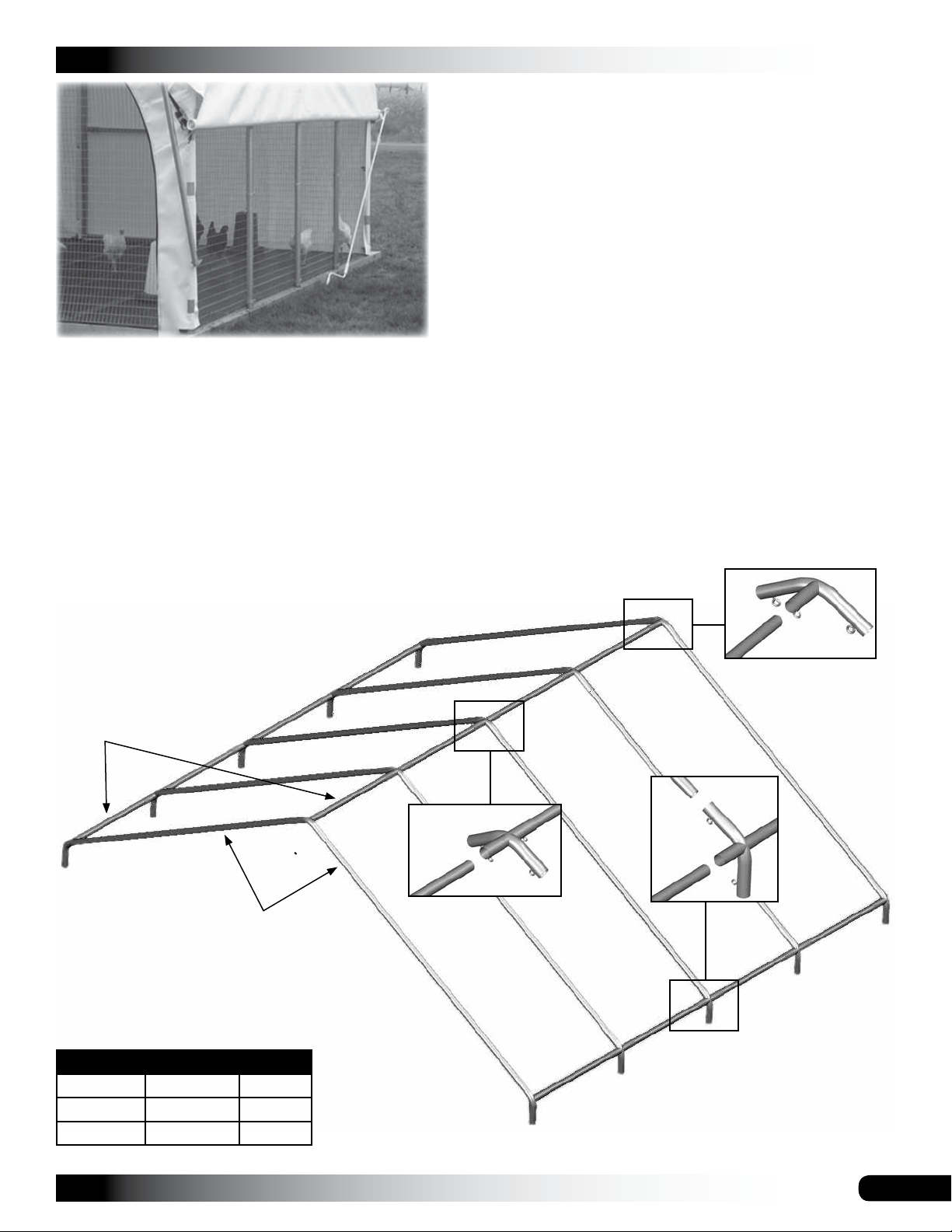

7. Assemble the frame components in the order they are

presented in these instructions.

8. Assemble the frame including the struts (if equipped).

9. Consult the MUST READ document and properly

anchor the assembled frame.

10. Install, tighten, and secure the main cover and panels

(if equipped). This applies to fabric covers that stretch

over the frame assembly. Your shelter may include roof

panels or side panels or both.

11. Read the care and maintenance information at the end

of these instructions.

12. Complete and return all warranty information as

instructed.

LIST OF WORDS AND PHRASES

Before you begin, it is important to become familiar with the

words and phrases used in this instruction manual.

These words and phrases are common to most

FarmTek® shelters and identify the dierent parts of the

shelter. (Some are used in this document. Others may

not apply to this particular shelter.) These terms describe

the shipped parts and can also be found on the materials

list/spec sheets included with the shipment. To aid in the

assembly, read through the following denitions before you

begin to assemble your shelter.

• Conduit: An assembly of pipes used to secure the

main cover and end panels (if equipped). Purlins and

some strut assemblies also consist of connected pipes

to form a conduit. Each pipe joint of a conduit assembly

is secured with a self-tapping Tek screw.

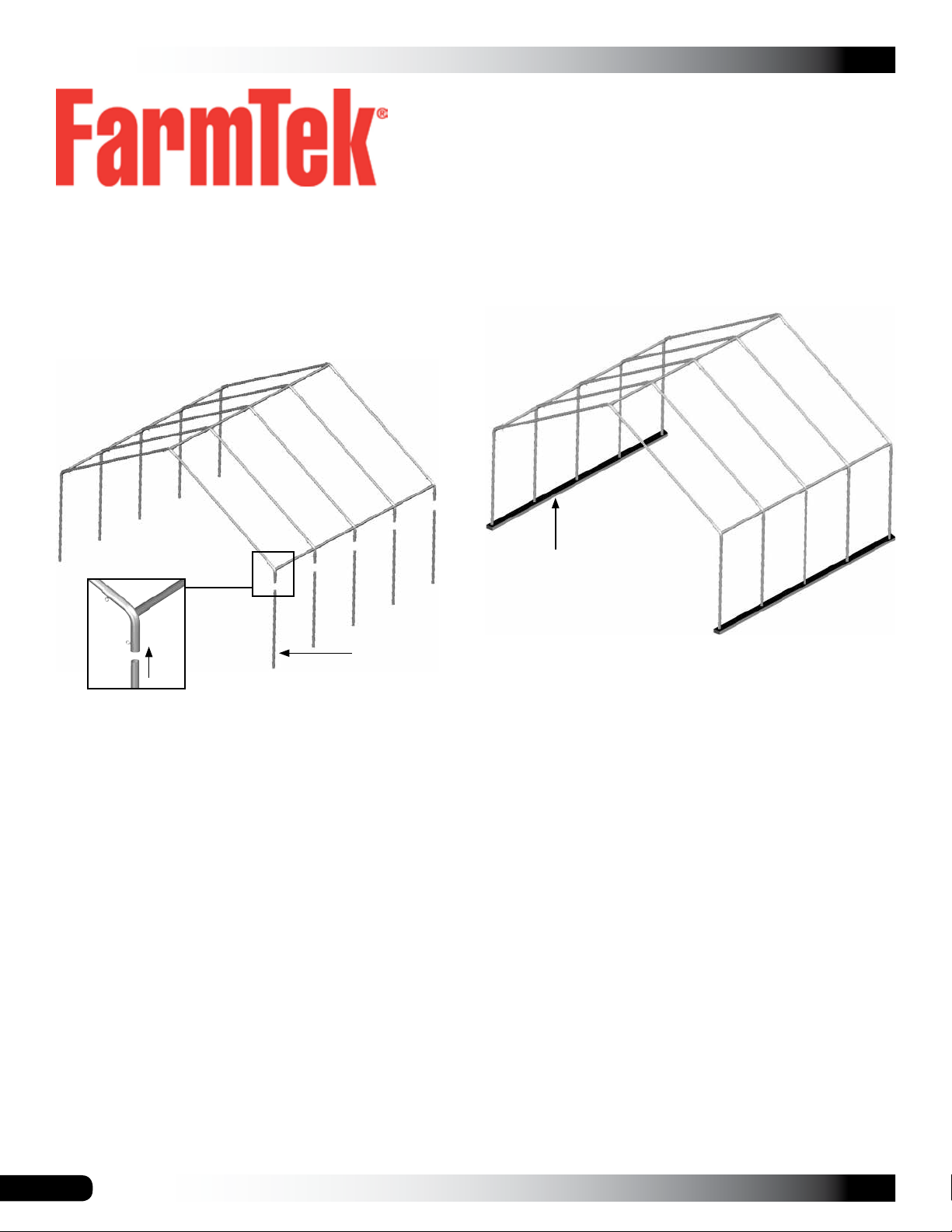

• Coupler or Fitting: A part of the frame assembly

where legs, purlins and rafter pipes are inserted and

secured. In most instances, 3-way and 4-way couplers

are used. In some larger applications, couplers are

used to secure the joints of the dierent rafter sections

during the assembly of the rafters. Some shelters do

not use couplers.

• Foot or Rafter Foot: The part attached to and found

at the base of the rafter or leg of the shelter.

Depending on the shelter, the foot is an optional

purchase. Some shelters do not oer an optional foot.

Some use 1-way connectors; others use ground posts.

• Must Read Document: This document includes

building and shelter anchoring instructions, steps for

end wall reinforcement, safety precautions, and notices

and warnings. The Must Read document is sent with all

shelters and buildings. If you did not receive a Must

Read document, contact Customer Service to request

one.

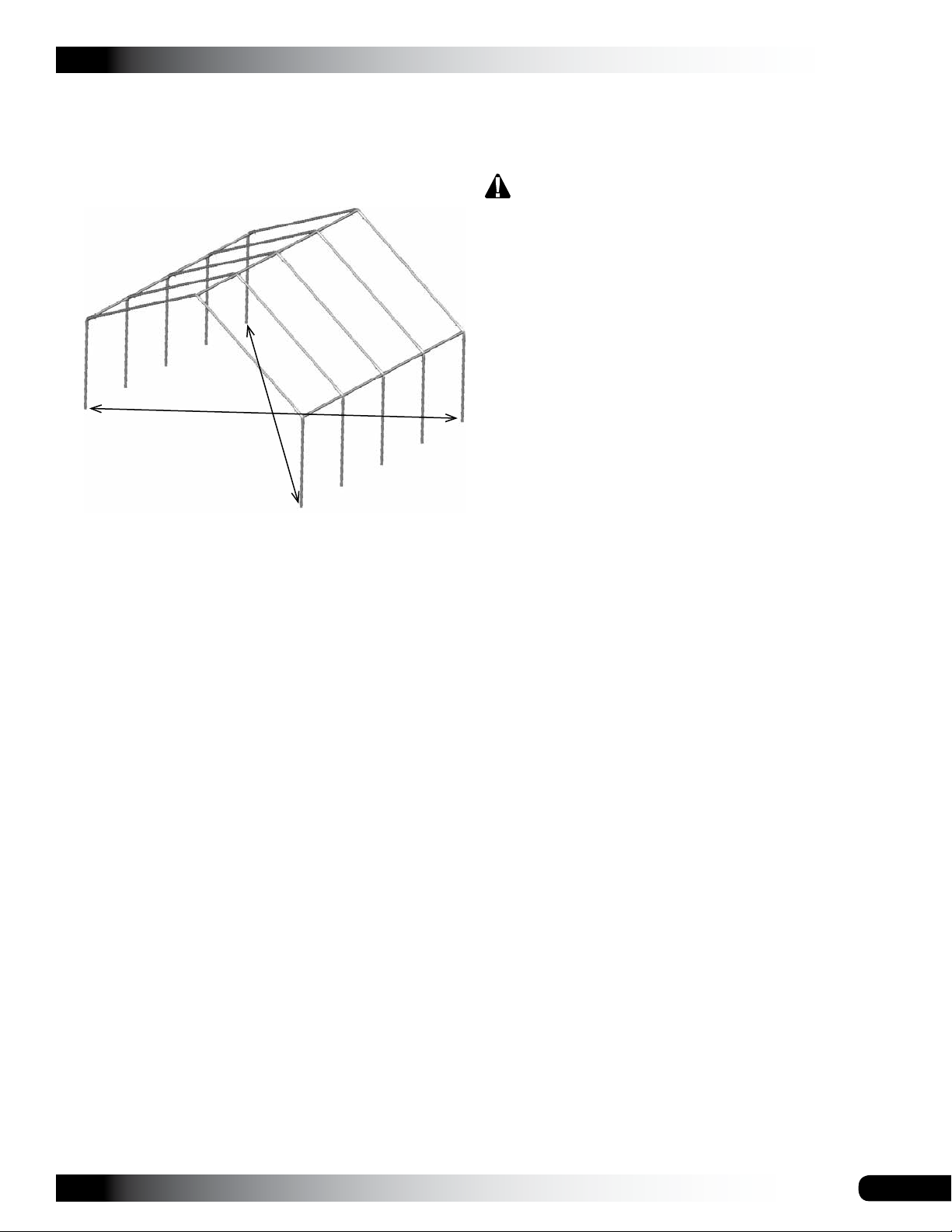

• On-Center: Term used to describe a measurement

taken from the vertical center of the rafter or frame

member to the vertical center of another.

• Purlin: The pipe assembly that runs perpendicular to

the rafters or framework that supports the main cover.

Purlins are found on the sides and roof areas of the

assembled frame, are evenly spaced, and typically run

from the front to the back of the shelter.

• Plain or Straight Pipe: A term used to describe a pipe

that has the same diameter or width throughout its

entire length.

• Strut: A strut is usually a length of pipe with two

attened ends and is used for diagonal bracing of the

shelter frame. A strut is typically secured to the frame

work by special brackets and bolts.

• Swaged End or Swaged Pipe: The term “swaged”

refers to the tapered end of the pipe or tube. Swaged

ends of a pipe can be inserted into couplers and the

straight ends of other pipes.

• Tek screw: A self-tapping fastener used to secure pipe

joints and to fasten brackets to rafters.