Fassi F1000A User guide

1

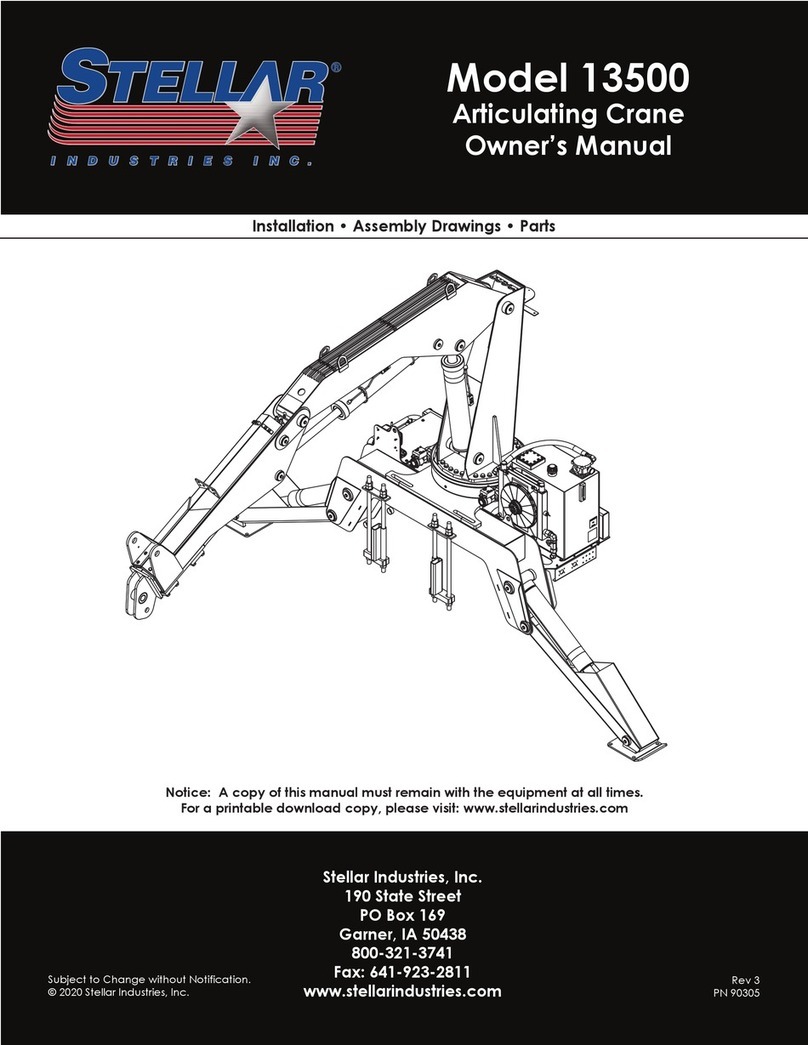

FASSI CRANE

F1000A/F1100AXP.28

use and maintenance

FROM SERIAL NUMBER *1119*

INDEX

1 INTRODUCTION

2 CLASSIFICATION OF THE CRANE MODEL

2.1 Generality

2.2 Hydraulic jibs

2.3 Technical data

3 CAPACITY PLATES

3.1 Generality

3.2 Capacity plates with lifting moment limiting device

4 HYDRAULIC SCHEMATICS

5 ELECTRIC SCHEMATICS

6 SAFETY NORMS

7 WARNING AND INSTRUCTIONS

7.1 Generality

7.2 Before operating

7.3 During operation

7.4 At the end of the operation (Prior to driving the vehicle)

7.5 Residual risks

8 IDENTIFICATION OF THE CRANE MODEL

8.1 Generality

8.2 Crane mark

9 CRANE NOMENCLATURE

9.1 Controls for crane and outriggers through push-button panel of the radio remote control

10 NOMENCLATURE OF THE SAFETY AND PROTECTION DEVICES

10.1 Controls for crane and outriggers through push-button panel of the radio remote control

11 SUPPLEMENTARY BEAMS

11.1 Generality

11.2 Identification of the supplementary beams

12 TILTABLE OUTRIGGER RAMS (not available)

13 MANOEUVRES AND CONTROLS TO STABILIZE THE VEHICLE

13.1 Generality

13.2.2 Functions of control levers for stabilization with radio-remote control

13.3 Controls to stabilize the vehicle

13.3.1 Crane with fixed or manually tiltable supports for outrigger rams

13.3.2 Crane with hydraulic tiltable supports (WITH CHAIN) for outrigger rams

14 CONTROLS TO OPERATE THE CRANE

14.1 Generality

14.2 Radio-remote control

14.2.1 Use of the radio-remote control

Edition 15.04.2008

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

14.2.2 Push-button panel of the radio remote control “RCH”

14.2.3 Push-button panel of the radio remote control “SCANRECO”

14.2.4 Icon legend

14.3 Emergency station from the column (if accessible) or

Control station (version with load limiting device) (not available)

14.4 Manoeuvres to unfold the crane into a working condition

14.5 Manoeuvres to fold the crane into the rest condition

14.6 Manoeuvres to unfold the crane “C” into a working condition (only for the crane version C)

14.7 Manoeuvres to fold the crane “C” into the rest condition (only for the crane version C)

14.8 Indicator of inner boom horizontal position (on request)

15 MANOEUVRES OF THE CRANE LOADS (version with load limiting device) (not available)

16 MANOEUVRES OF THE CRANE LOADS (version with lifting moment limiting device)

16.1 Generality

16.2 Lifting moment limiting device “EVOLUTION” (LMEV) and automatic dynamic control (ADC)

16.3 Control panels of the lifting moment limiting device (if fitted)

16.4 Load handling

16.4.1 “Block due to overload condition”

16.4.2 “Winch off” (when fitted)

16.4.3 “Lifting block” (Prolink)

16.4.4 Other functional characteristics

16.4.5 Visual indicator yellow/red light

16.5 Lifting moment limiting device for two working sectors

16.6 Rotation limiting device

16.7 Setting menu

16.8 Diagnostic: alarms and warnings

16.8.1 Emergency control station on the column and exclusion tap lever

16.8.2 Exclusion tap lever 7°/8° extension (if fitted)

16.9 XP device

16.9.1 Activation and instructions for use of the XP/CR device

16.10 "JDP" Function (if fitted)

17 USE OF IMPLEMENTS

17.1 Generality

17.2 Hydraulic connections for implements - supplementary hoses

17.3 Oil cooler (heat exchanger)

18 MANUAL EXTENSIONS

18.1 Generality

18.2 Lifting moment limiting device “ELECTRONIC” for the manual extensions

19 CONTROLS TO OPERATE THE HYDRAULIC IMPLEMENTS OF THE CRANE

20 HYDRAULIC JIBS

20.1 Generality

20.2 Identification of the hydraulic jib

20.3 Nomenclature of the hydraulic jib

20.4 Manoeuvres to unfold the jib in working condition

20.5 Manoeuvres to fold the jib in rest condition

20.6 Operations to remove the hydraulic jib from the crane

20.7 Operations to mount the hydraulic jib on the crane

20.8 Crane with lifting moment limiting device and "Prolink"

(if fitted)

21 WINCH (if fitted)

21.1 Generality (version with lifting moment limiting device)

21.2 Winch for crane (version with lifting moment limiting device)

21.2.1 Winches equipped with a mechanical stroke end device

22 MAINTENANCE INSTRUCTIONS

22.1 Generality

22.2 Timer

22.3 After every 8 working hours or at the end of every working day

22.4 After every 40 working hours or after every working week

22.5 After every 100 working hours or more frequently in case of more intensive utilisation

22.6 After every 500 working hours or after every 6 working months

22.7 After every 1000 working hours or after every working year

22.8 Complete overhaul of the crane is required when 10.000 working hours or 10 years'life

are reached

22.9 Instructions for the dismantlement and the demolition of a FASSI crane

23 TABLE OF HYDRAULIC OIL AND LUBRICANTS CHARACTERISTICS

24 POSSIBLE FAULTS

24.1 Generality

24.2 Only operations which can be carried out by the user

24.3 Operations to be carried out only by a service center

25 INSTRUCTION AND WARNING PLATES

1

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

1

INDEX

GRU FASSI

FASSI CRANE

Use and maintenance

ORIGINAL INSTRUCTIONS

THANK YOU FOR SELECTING ONE OF FASSI CRANES.

This crane is the result of FASSI philosophy: ongoing research, rigorous

testing, data verification, and analysis of performances.

Many years of experience has allowed us to grant you the maximum safety of ope-

ration together with the optimization of machine performances.

All this represents the core of FASSI quality system.

FASSI quality system is in conformity with

UNI EN ISO 9001:2000 (ISO 9001:2000)

FASSI cranes conform with the European Norm EN12999

The fitment of the crane on the vehicle must be carried out in accordance with

the instructions given by FASSI in the manual for hydraulic crane fitting and the

relevant chassis manufacturers directives.

The Manufacturer declines all responsibility and guarantee if the fitting is

entrusted to workshops without sufficient technical capability to carry out the

work in conformity.

Be sure that the unit has been installed, inspected and tested in accordance

with the local legal requirements.

As well as the principal safety norms, this manual contains a description of the

crane and the instructions for use and maintenance.

The following instructions refer to mobile cranes in general and must be inte-

grated with the manual for use supplied by the centre responsible for the crane

fitting on truck, vehicle or other type of structure.

Some of the options described in the use and maintenance manual are availa-

ble only on request; therefore they may not be on your crane.

READ THIS MANUAL CAREFULLY prior to use or any maintenance. A few

minutes spent now could save time and labour later.

Always conform to the safety norms and the instructions for use and mainte-

nance contained in the present manual in order to guarantee a long life to the

crane.

NOTE

The original version of the present manual is in italian.

The spare parts catalogue for the crane can be viewed in the Internet

site: www.fassicat.com

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

2 CLASSIFICATION OF THE CRANE MODEL

2.1 Generality

The design of this crane has been carried out in respect of fatigue test classification H1B3 of the

EN12999 norm. The crane can operate, intermittently, with lifting devices other than the hook. The

dimensions and the capacity of the implements must be proportioned with crane performances.

2.2 Hydraulic jibs

Hydraulic jibs

Extension type Weight=kg Manual Weight=kg Manual Weight=kg Manual Weight=kg Manual Weight=kg

L414 850 ------------------ PL41 31 QL41 21 ------------------

L425 1050 QL42 55 RL42 36 SL42 25 ------------------

L426 1200 ------------------ RL42 36 SL42 25 TL42 15

L516 1400 ------------------ RL51 36 SL51 25 TL51 15

L616 1420 ------------------ RL61 36 SL61 25 TL61 16

2.3 Technical data

2

CLASSIFICATION OF

THE CRANE MODEL

F 1000A/1100AXP.28

F 1000A/1100AXP.28

Lifting Standard Hydraulic Rotation Rotation Working Pump Oil tank Crane Max. working

capacity reach extension arc torque pressure capacity capacity weight pressure

on the outrigger

(Φ400)

78,0 / 85,8 tm 20,00 m 15,25 m 360° 10,20 tm 31,0 / 33,5 90+110 265 l 9600 kg 21,7 / 23,0

764,92 kNm / continuous 100 kNm MPa l/min daN\cm2

841,41 kNm

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

2.3

CLASSIFICATION OF

THE CRANE MODEL

F 1000A/1100AXP.28

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

3

CAPACITY PLATES

F 1000A/1100AXP.28

3 CAPACITY PLATES

3.1 Generality

The represented plates refer to the nominal design capacities.

(!) WARNING (!)

If the capacities are downgraded or partially reduced (e.g. sector in front of vehi-

cle cab) capacity plates must be applied in line with the final test figures.

(!)

WARNING

(!)

Some cranes with more than 6 extensions have two hooks :

- the first hook ( ) has to be positioned on the hook connection of the sixth

hydraulic extension and it has to be used for the greatest loads, represented

on the plate with the black hook.

- the second hook ( ) has to be positioned on the hook connection of the last

hydraulic extension and it has to be used for the other loads, represented on

the plate with the white hook.

3.2 Capacity plates with lifting moment limiting device

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

3.2

CAPACITY PLATES

F 1000A/1100AXP.28

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

3.2

CAPACITY PLATES

F 1000A/1100AXP.28

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

3.2

CAPACITY PLATES

F 1000A/1100AXP.28

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

3.2

CAPACITY PLATES

F 1000A/1100AXP.28

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

3.2

CAPACITY PLATES

F 1000A/1100AXP.28

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

3.2

CAPACITY PLATES

F 1000A/1100AXP.28

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

3.2

CAPACITY PLATES

F 1000A/1100AXP.28

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

3.2

CAPACITY PLATES

F 1000A/1100AXP.28

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

3.2

CAPACITY PLATES

F 1000A/1100AXP.28

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

3.2

CAPACITY PLATES

F 1000A/1100AXP.28

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

3.2

CAPACITY PLATES

F 1000A/1100AXP.28

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

3.2

CAPACITY PLATES

F 1000A/1100AXP.28

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

3.2

CAPACITY PLATES

F 1000A/1100AXP.28

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

This manual suits for next models

3

Table of contents

Other Fassi Construction Equipment manuals

Popular Construction Equipment manuals by other brands

STS

STS M4-G Operator's manual

Komatsu

Komatsu 450FXL-1 Operation & maintenance manual

XtremepowerUS

XtremepowerUS 196CC/635HP manual

PANDROL

PANDROL Rosenqvist SL400 Operation and maintenance manual

Ransomes

Ransomes ZJ Series Safety & operation manual

Palfinger

Palfinger Clocktower PK2400 TK Operating and maintenance manual