Fassi F 80A.23 User guide

1

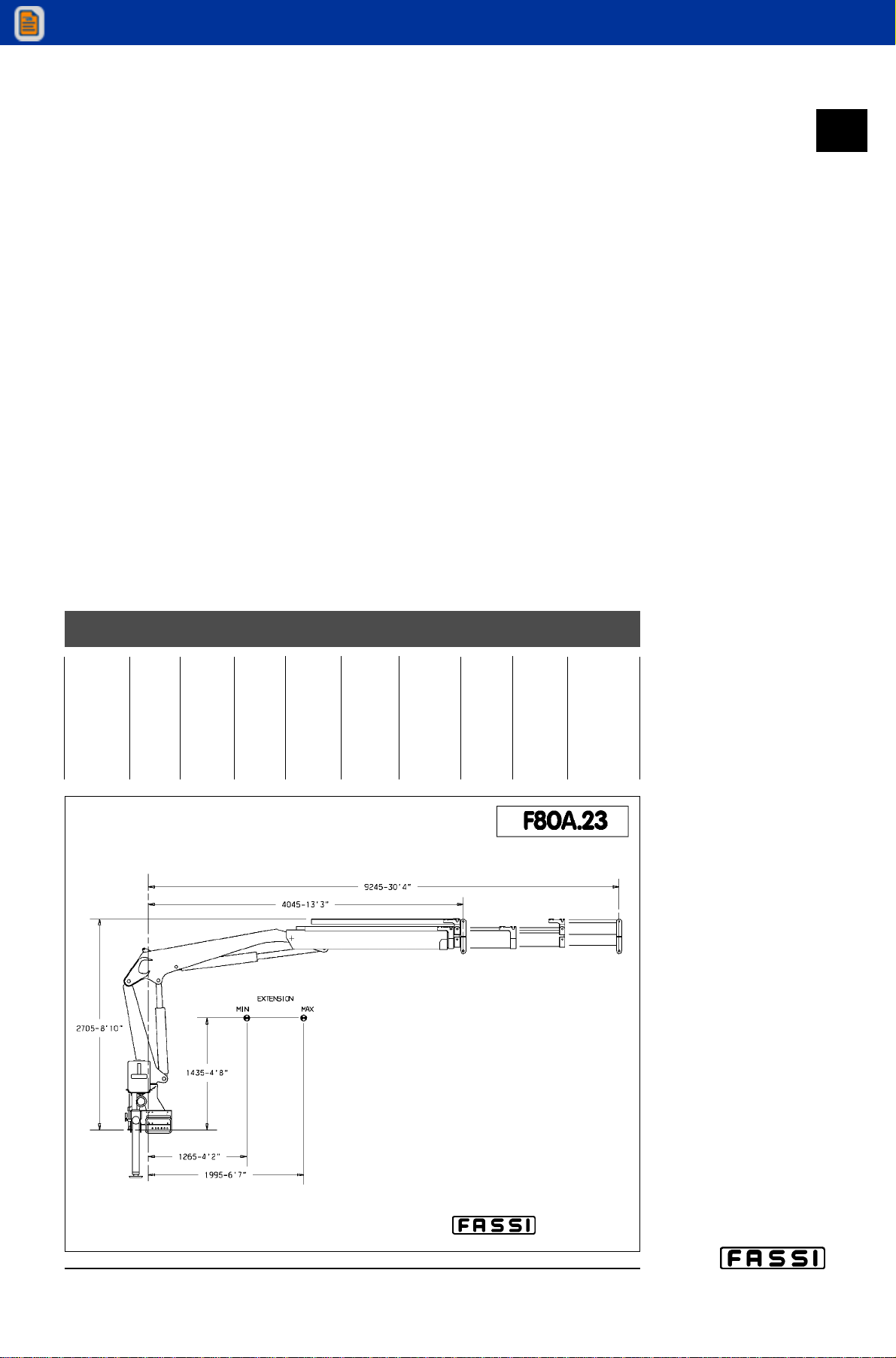

FASSI CRANE

F 80A.23

use and maintenance

FROM SERIAL NUMBER *4085*

INDEX

1 INTRODUCTION

2 CLASSIFICATION OF THE CRANE MODEL

2.1 Generality

2.2 Hydraulic jibs (not available)

2.3 Technical data

3 CAPACITY PLATES

3.1 Generality

3.1.1 Capacity plates with lifting moment limiting device

3.1.2 Capacity plates with load limiting device

4 HYDRAULIC SCHEMATICS ( ) (version with lifting moment limiting device)

4.1 HYDRAULIC SCHEMATICS (version with load limiting device)

5 ELECTRIC SCHEMATICS

6 SAFETY NORMS

7 WARNING AND INSTRUCTIONS

7.1 Generality

7.2 Before operating

7.3 During operation

7.4 At the end of the operation (Prior to driving the vehicle)

7.5 Residual risks

8 IDENTIFICATION OF THE CRANE MODEL

8.1 Generality

8.2 Crane mark

9 CRANE NOMENCLATURE

9.1 Crane with ground controls on both sides

Crane with ground controls on both sides and with top seat controls by hand cables

9.2 Crane with top seat controls and with ground controls for outriggers

10 NOMENCLATURE OF THE SAFETY AND PROTECTION DEVICES

10.1 Crane with ground controls on both sides

Crane with ground controls on both sides and with top seat controls by hand cables

10.2 Crane with top seat controls and with ground controls for outriggers

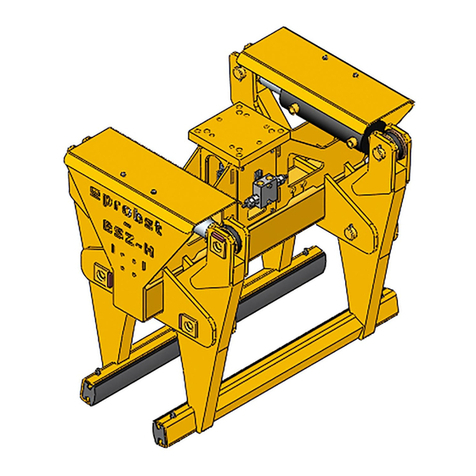

11 SUPPLEMENTARY BEAMS

11.1 Generality

11.2 Identification of the supplementary beams

12 TILTABLE OUTRIGGER RAMS

12.1 Manually tiltable outrigger rams

13 MANOEUVRES AND CONTROLS TO STABILIZE THE VEHICLE

13.1 Generality

Edition ExtraCE 01.04.2005

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

13.2 Manual extension and re-entry of the outrigger supports

13.3 Manoeuvres for the manual extension of the double outrigger supports

13.4 Functions of control levers for stabilization

13.5 Controls to stabilize the vehicle

14 CONTROLS TO OPERATE THE CRANE

14.1 Generality

14.2 Manoeuvres to unfold the crane into a working condition

14.3 Manoeuvres to fold the crane into the rest condition

14.4 Manoeuvres to unfold the crane "C" into a working condition (only for the crane version “C”)

14.5 Manoeuvres to fold the crane "C" into the rest condition (only for the crane version “C”)

14.6 Indicator of inner boom horizontal position (optional)

14.7 Third control station (optional)

15 MANOEUVRES OF THE CRANE LOADS (version with load limiting device)

Generality

16 MANOEUVRES OF THE CRANE LOADS (version with lifting moment limiting device)(optional)

16.1 Generality

16.2 Lifting moment limiting device “ELECTRONIC” (optional)

16.3 Control panels (optional)

16.4 Load handling (optional)

16.5 Lifting moment limiting device for two working sectors (optional)

16.6 Rotation limiting device (optional)

16.7 In the case of the appearance of the signal “ALARM” on the display of the control

panel or of the radio remote control or in case of an electrical failure (optional)

16.7.1 Diagnostic (Alarms/Input/Output) LME vers. 4-5 UC 01-7 (optional)

16.7.2 Temporary OVERIDE-Reactivation for the crane functions with standard distributor (optional)

16.7.3 OVERIDE-Reactivation lever for the crane functions (with Danfoss distributor) (optional)

16.8 XP device (if fitted, see the Use and Maintenance booklet)

16.8.1 Activation and instructions for use of the XP/V device (if fitted, see the Use and Maintenance booklet)

17 USE OF IMPLEMENTS

17.1 Generality

17.2 Hydraulic connections for implements - supplementary hoses

17.3 Oil cooler (heat exchanger)

18 MANUAL EXTENSIONS

18.1 Generality

18.2 Lifting moment limiting device “ELECTRONIC” for the manual extensions

(valid starting from the version 3.0 of the software)

19 CONTROLS TO OPERATE THE HYDRAULIC IMPLEMENTS OF THE CRANE

20 HYDRAULIC JIBS (not available)

21 WINCH (if fitted)

21.1 Generality (version with lifting moment limiting device) (optional)

21.2 Winch for crane

21.2.1 Winches equipped with a mechanical stroke end device

21.3 Generality (version with load limiting device)

21.4 Winch for crane

21.4.1 Winches equipped with a mechanical stroke end device

22 MAINTENANCE INSTRUCTIONS

22.1 Generality

22.2 Timer

22.3 After every 8 working hours or at the end of every working day

22.4 After every 40 working hours or atfter every working week

22.5 After every 100 working hours or more frequently in case of more intensive utilisation

22.6 After every 500 working hours or after every 6 working months

22.7 After every 1000 working hours or after every working year

22.8 Complete overhaul of the crane is required when 10.000 working hours or 10 years'life are reached

22.9 Instructions for the dismantlement and the demolition of a FASSI crane

23 TABLE OF HYDRAULIC OIL AND LUBRICANTS CHARACTERISTICS

24 POSSIBLE FAULTS

24.1 Generality

24.2 Only operations which can be carried out by the user

24.3 Operations to be carried out only by a service center

25 INSTRUCTION AND WARNING PLATES

1

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

1

INDEX

GRU FASSI

FASSI CRANE

use and maintenance

ORIGINAL INSTRUCTIONS

THANK YOU FOR SELECTING ONE OF FASSI CRANES.

This crane is the result of FASSI philosophy: ongoing research, rigorous

testing, data verification, and analysis of performances.

Many years of experience has allowed us to grant you the maximum safety of

operation together with the optimization of machine performances.

All this represents the core of FASSI quality system.

FASSI quality system is in conformity with

UNI EN ISO 9001:2000 (ISO 9001:2000)

The fitment of the crane on the vehicle must be carried out in accordance with

the instructions given by FASSI in the manual for hydraulic crane fitting and

the relevant chassis manufacturers directives.

The Manufacturer declines all responsibility and guarantee if the fitting is

entrusted to workshops without sufficient technical capability to carry out the

work in conformity.

Be sure that the unit has been installed, inspected and tested in accordance

with the local legal requirements.

As well as the principal safety norms, this manual contains a description of the

crane and the instructions for use and maintenance.

The following instructions refer to mobile cranes in general and must be inte-

grated with the manual for use supplied by the centre responsible for the crane

fitting on truck, vehicle or other type of structure.

READ THIS MANUAL CAREFULLY prior to use or any maintenance. A few

minutes spent now could save time and labour later.

Always conform to the safety norms and the instructions for use and mainte-

nance contained in the present manual in order to guarantee a long life to the

crane.

NOTE

The original version of the present manual is in italian.

The spare parts catalogue for the crane can be viewed in the Internet

site: www.fassicat.com

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

2 CLASSIFICATION OF THE CRANE MODEL

2.1 Generality

The design of this crane has been carried out in respect of DIN 15018 norms,

fatigue test classification H1B3.

The crane can operate, intermittently, with lifting devices other than the hook.

The dimensions and the capacity of the implements must be proportioned with

crane performances.

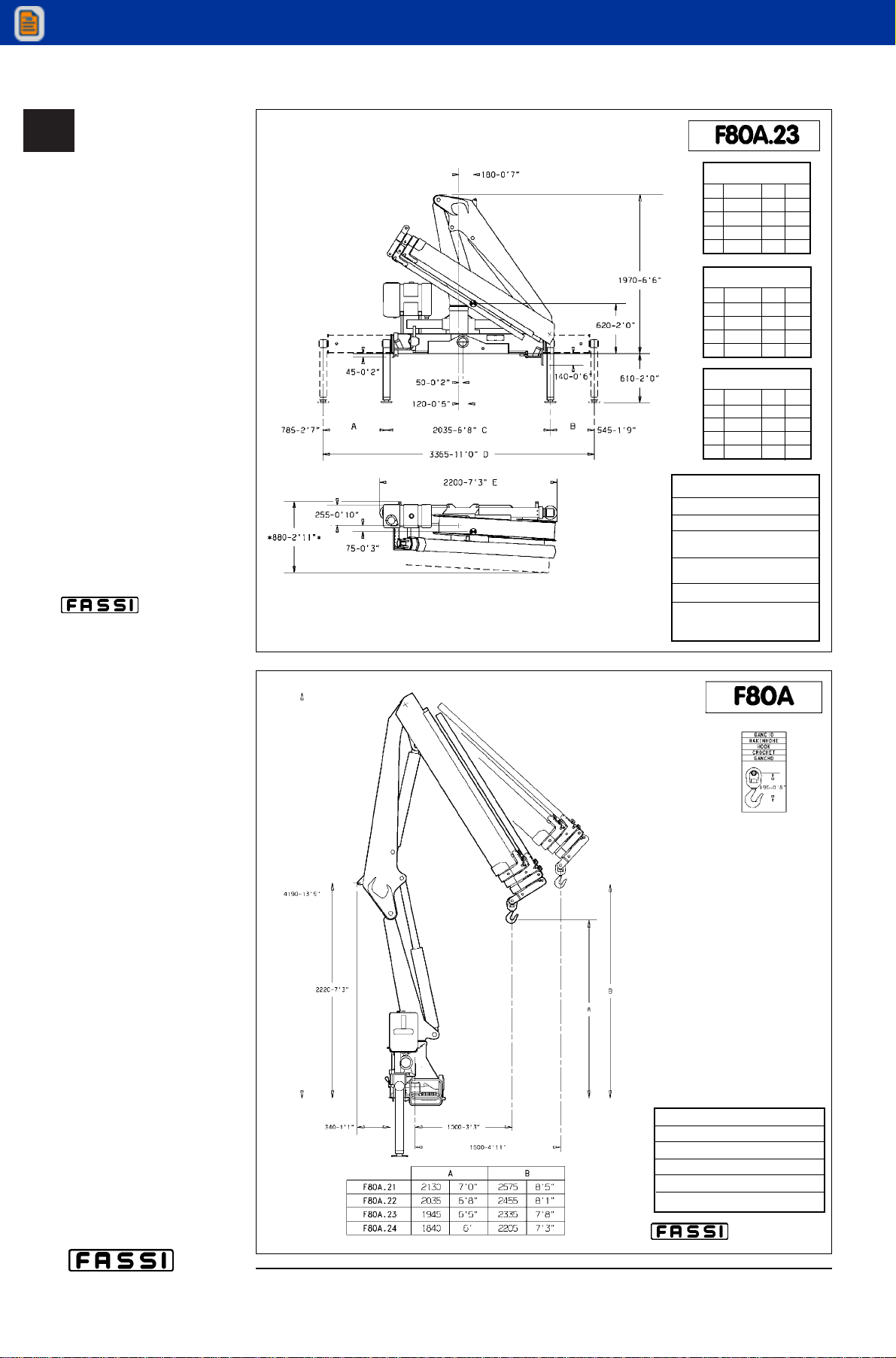

2.3 Technical data

2

CLASSIFICATION OF

THE CRANE MODEL

F 80A.23

ST 080

F 80A.23

Lifting Standard Hydraulic Rotation Rotation Working Pump Oil tank Crane Max. working

capacity reach extension arc torque pressure capacity capacity weight pressure

on the outrigger

(Φ140)

7,5 tm 9,30 m 5,20 m 370° 1,20 tm 30 MPa 20 l/min 60 l 1110 kg 43,2 daN\cm2

73,6 kNm 11,75 kNm

54.248 30’6” 17’0” 8.680 4.351 5,28 15,85 2.447 626,56 psi

lbf.ft ft/in ft/in lbs.ft psi gal/min gals lbs

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

2.2

CLASSIFICATION OF

THE CRANE MODEL

F 80A.23

MASSIMA ALTEZZA SOTTOGANCIO.

HAUTEUR MAXIMUM SOUS CROCHET.

MAXIMUM HOOKING POSITION.

MAXIMALHOEHE BIS KRANHAKEN.

MÁXIMA ALTURA DEBAJO DEL GANCHO.

ALTURA LIVRE MÁXIMA DEBAIXO DO GANCHO.

ST 080

ST 080

— MEZZERIA TIRANTI

— FIXING ROD CENTER DISTANCE

— LIGNE MEDIANE TIRANTS

— ABMESSUNG DER

BEFESTIGUNGSBRIDEN

— DISTANCIA ENTRE

ESPÁRRAGOS

— LINHA MEDIANA DOS TIRANTES

N° 4 M22 x 1,5

N° 4 M18 x 1,5

1.190 3’ 11”

1.190 3’ 11”

2.115 6’ 11”

4.500 14’ 9”

2.225 7’ 4”

A

B

C

D

E

EXTRA

1.370 4’ 6”

1.370 4’ 6”

2.230 7’ 4”

4.970 16’ 4”

2.370 7’ 9”

A

B

C

D

E

SUPER-EXTRA

1.790 5’ 10”

1.580 5’ 2”

2.230 7’ 4”

5.600 18’ 4”

2.370 7’ 9”

A

B

C

D

E

IPER-EXTRA

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

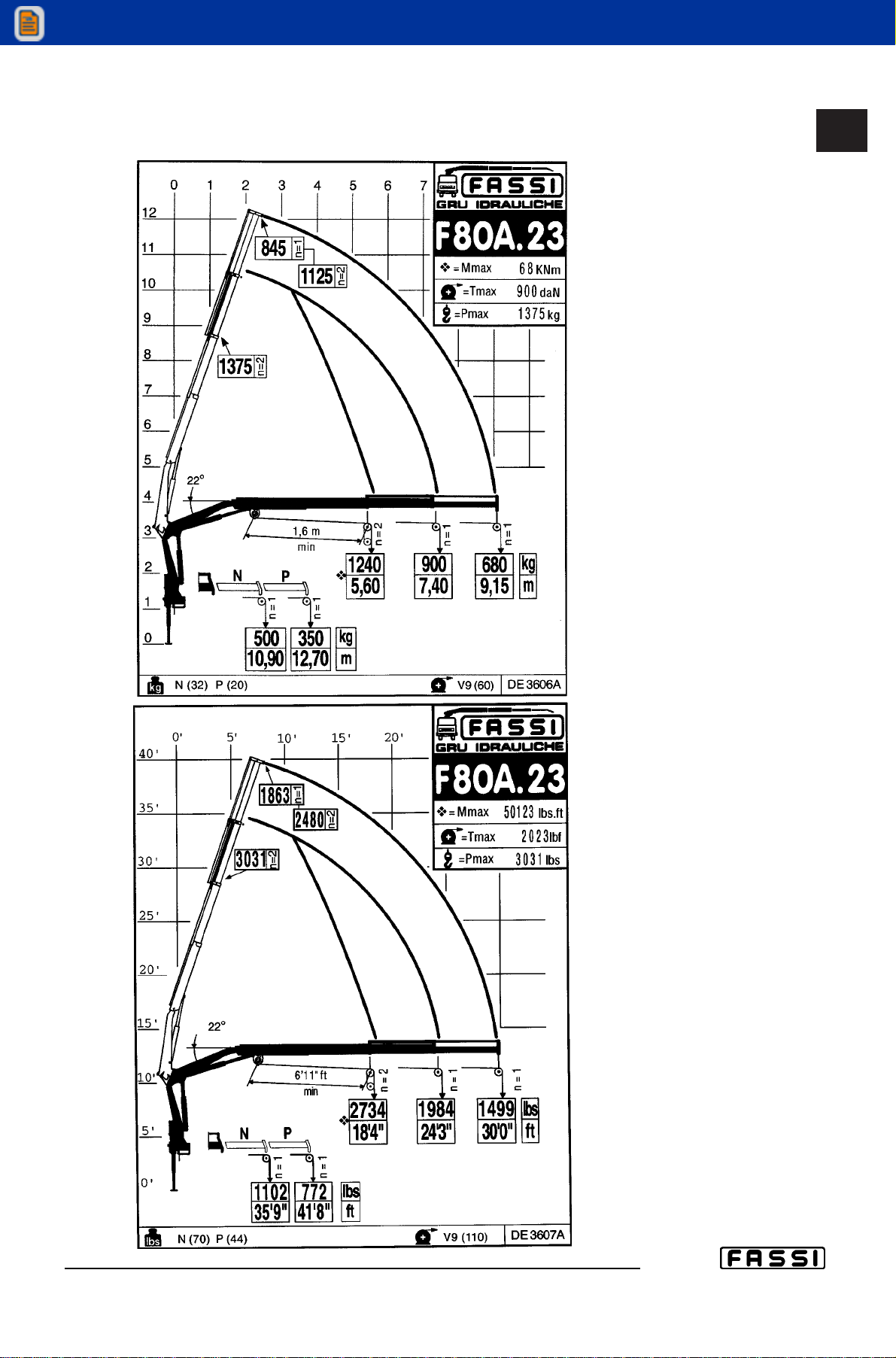

3 CAPACITY PLATES

3.1 Generality

The represented plates refer to the nominal design capacities.

(!) WARNING (!)

If the capacities are downgraded or partially reduced (e.g. sector in front of

vehicle cab) capacity plates must be applied in line with the final test figures.

3.1-1 Capacity plates with lifting moment limiting device

3

CAPACITY PLATES

F 80A.23

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

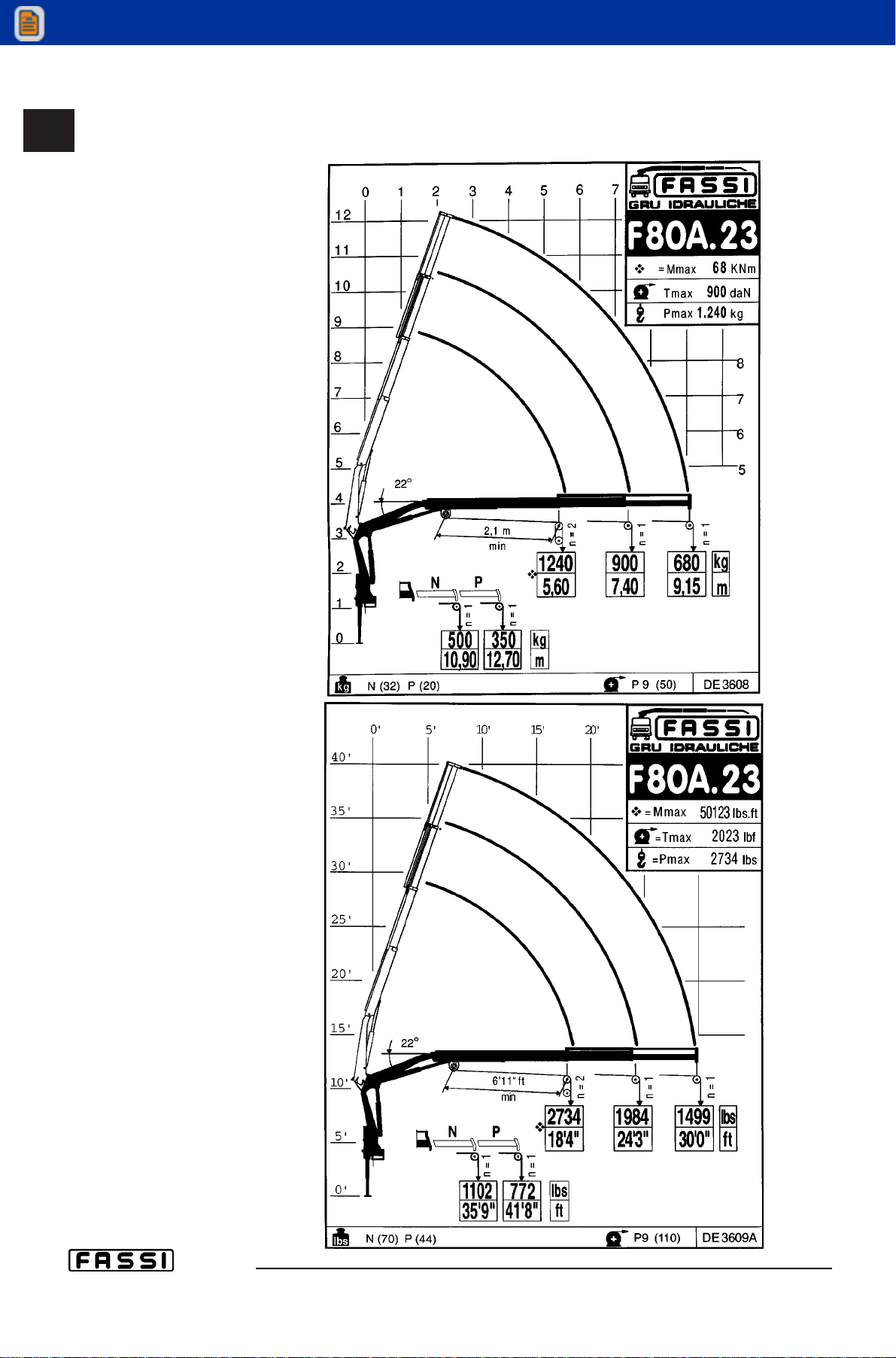

3.1-1

CAPACITY PLATES

F 80A.23 3.1-1 Capacity plates with lifting moment limiting device

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

3.1-1

CAPACITY PLATES

F 80A.23

3.1-1 Capacity plates with lifting moment limiting device

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

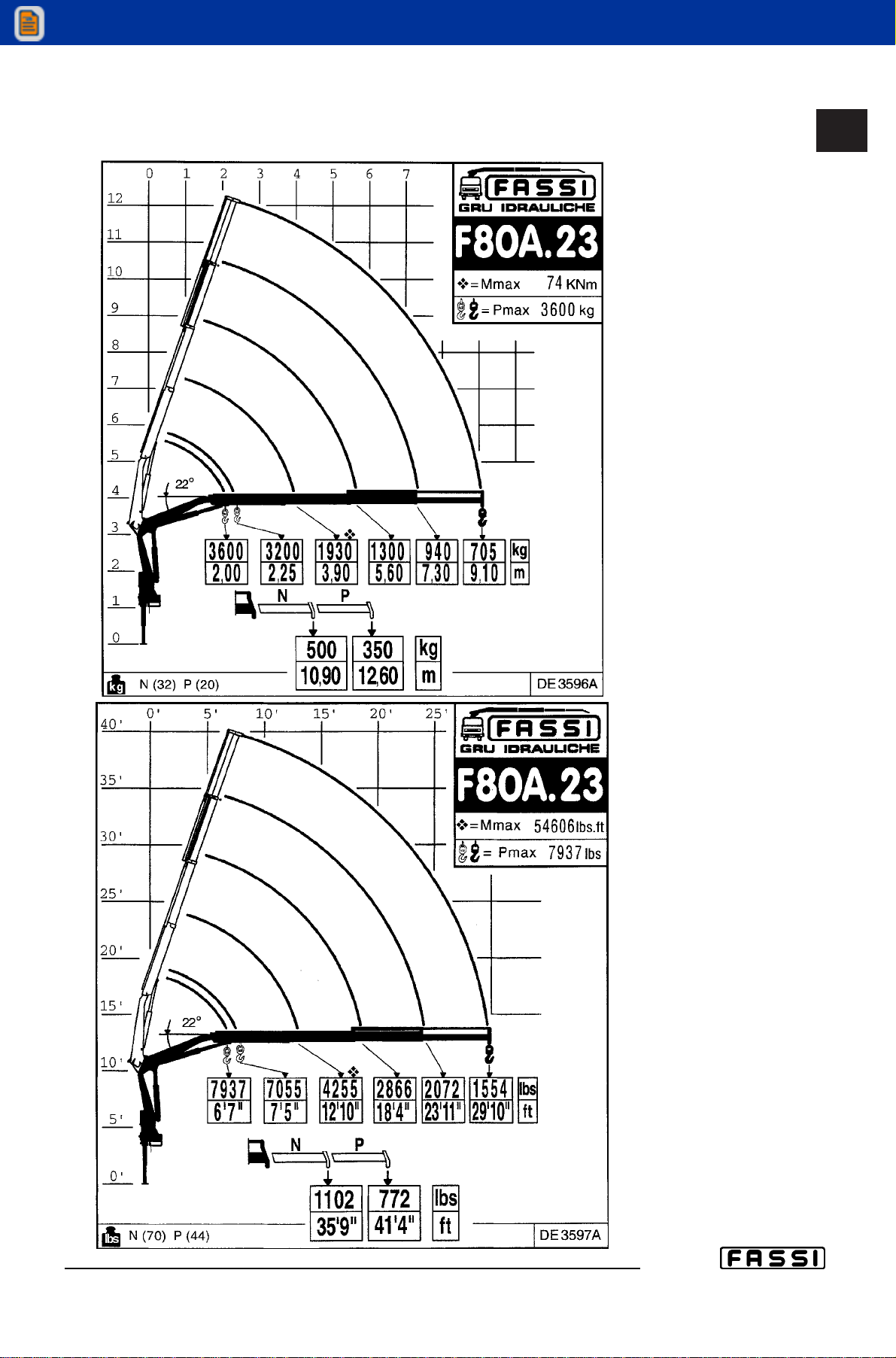

3.1-2

CAPACITY PLATES

F 80A.23

3.1-2 Capacity plates with load limiting device

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

3.1-2

CAPACITY PLATES

F 80A.23

3.1-2 Capacity plates with load limiting device

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

3.1-2

CAPACITY PLATES

F 80A.23 3.1-2 Capacity plates with load limiting device

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

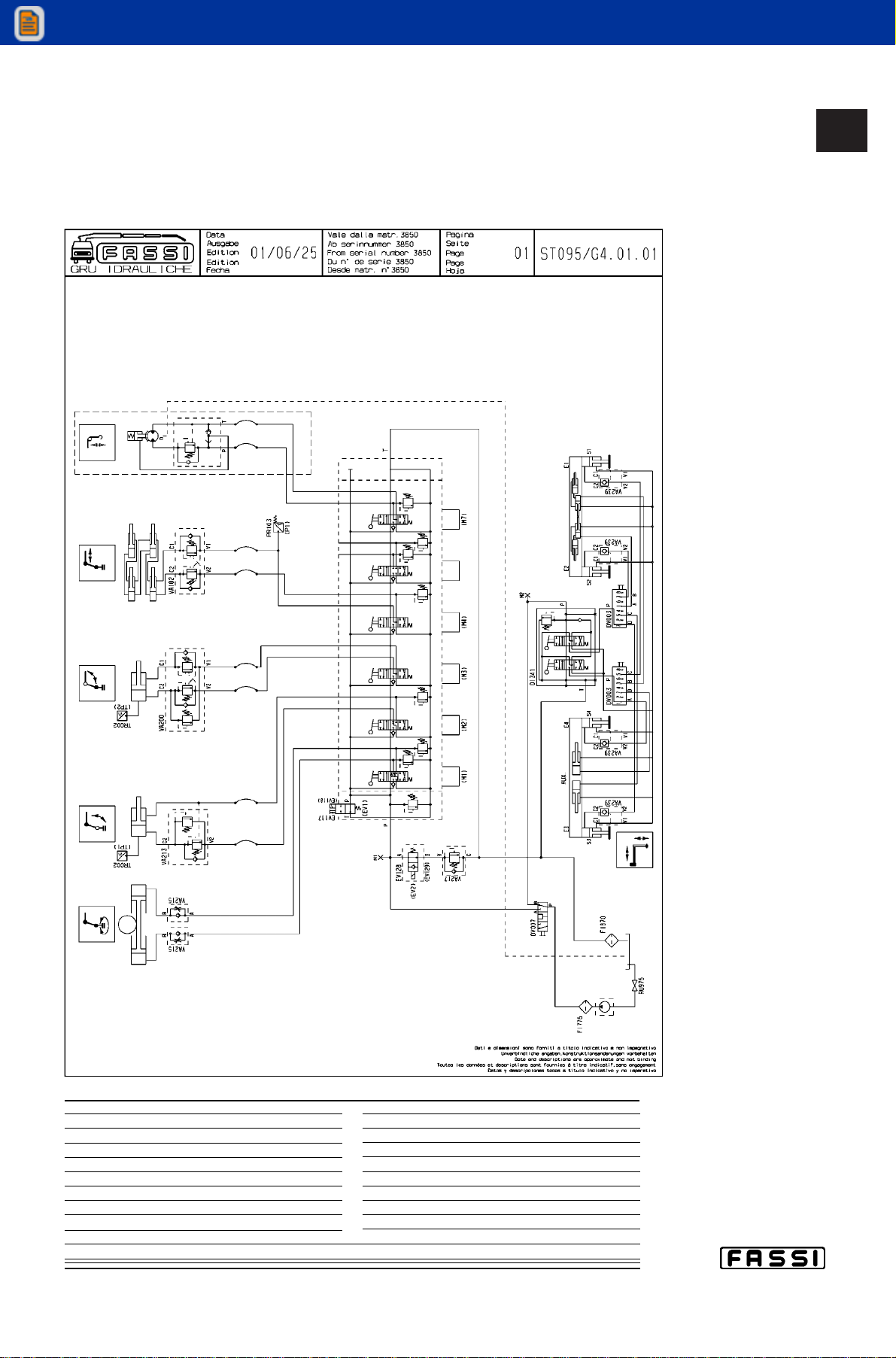

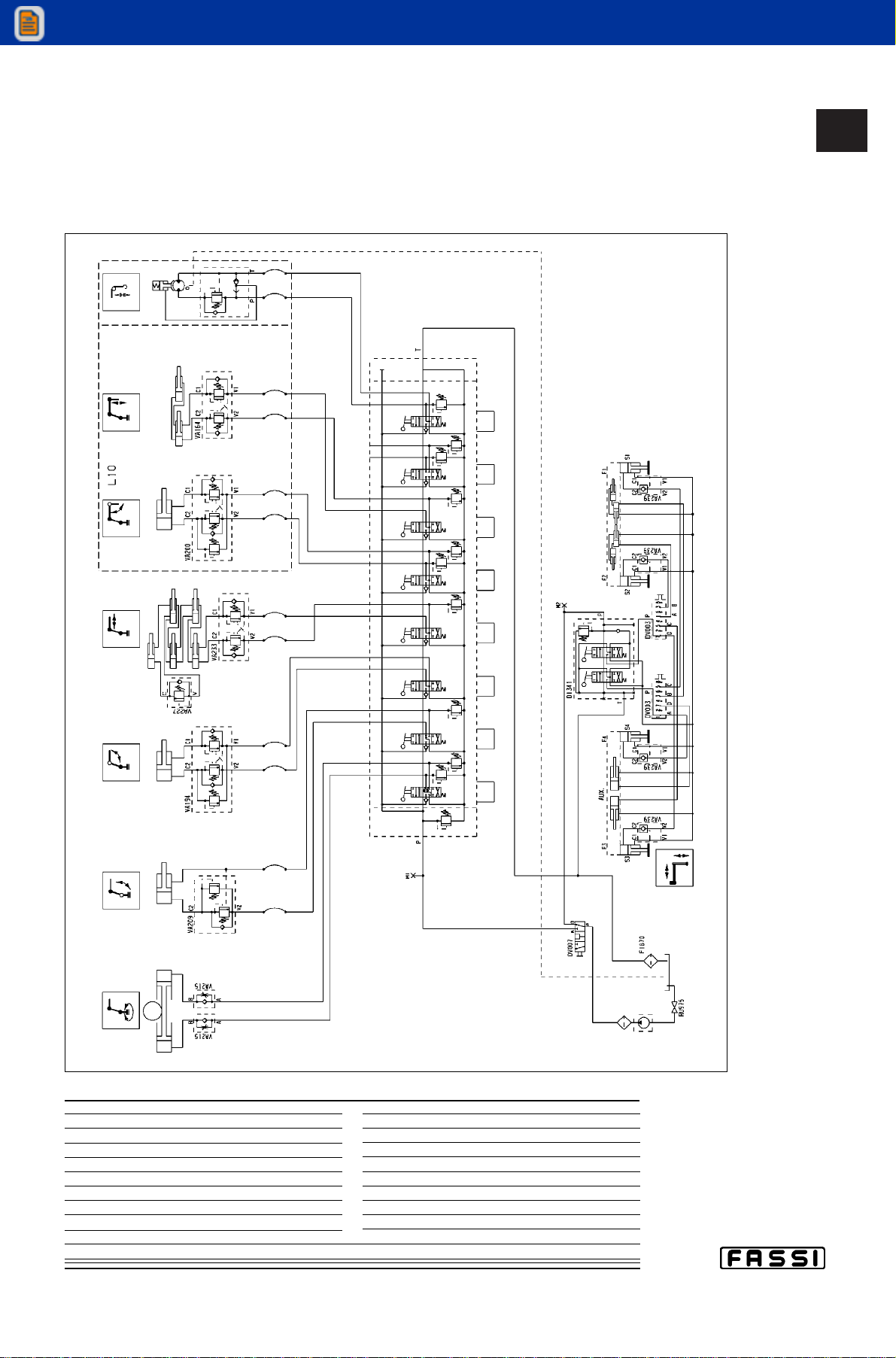

4

HYDRAULIC

SCHEMATICS

GR3_080»095

4 HYDRAULIC SCHEMATICS

(version with lifting moment limiting device)

Hydraulic schematic for crane -HCD3M/HCD4 distributor - ground controls - “electronic”

lifting moment limiting device (F80A from s.n. *4085* - F95A from s.n. *3850*)

CODE DESCRIPTION

DI341 DISTRIBUTOR

DV003

DEVIATOR

DV007

DEVIATOR

EV128

ELECTROVALVE

EV117

ELECTROVALVE

FI870

FILTER

(RETURN)

M1/M2

GAUGE QUICK CONNECTION

PR103

PRESSURE SWITCH

RU975

FAUCET

TR002

PRESSURE TRANSDUCER

VA102

DOUBLE EFFECT BLOCK VALVE

VA164

DOUBLE EFFECT BLOCK VALVE

VA185

SELECTOR VALVE

VA200

DOUBLE EFFECT BLOCK VALVE

VA213

SIMPLE EFFECT BLOCK VALVE

VA215

OIL FLOW CHECK VALVE

VA217

SEQUENCE VALVE

VA239

SIMPLE EFFECT BLOCK VALVE

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

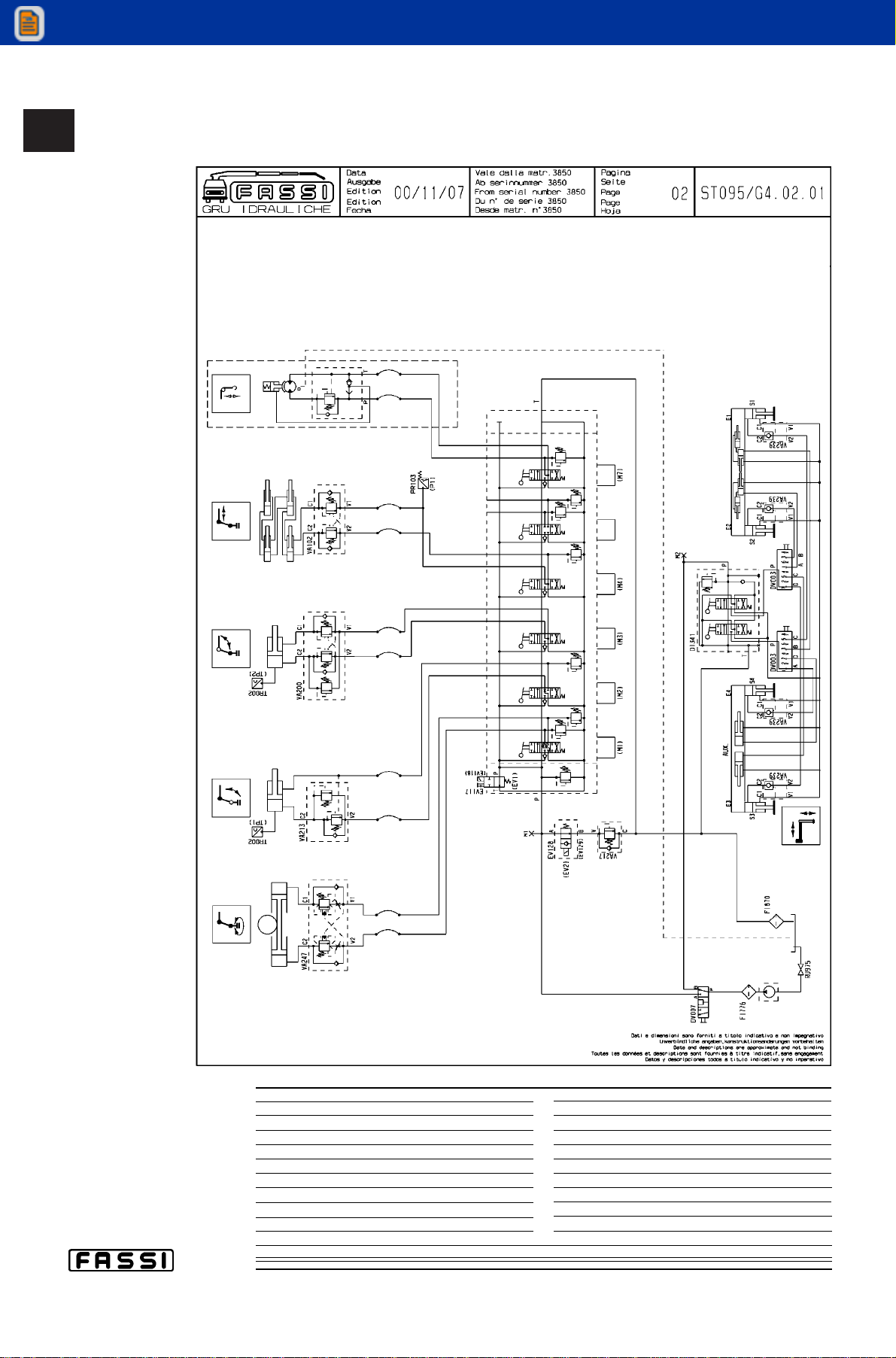

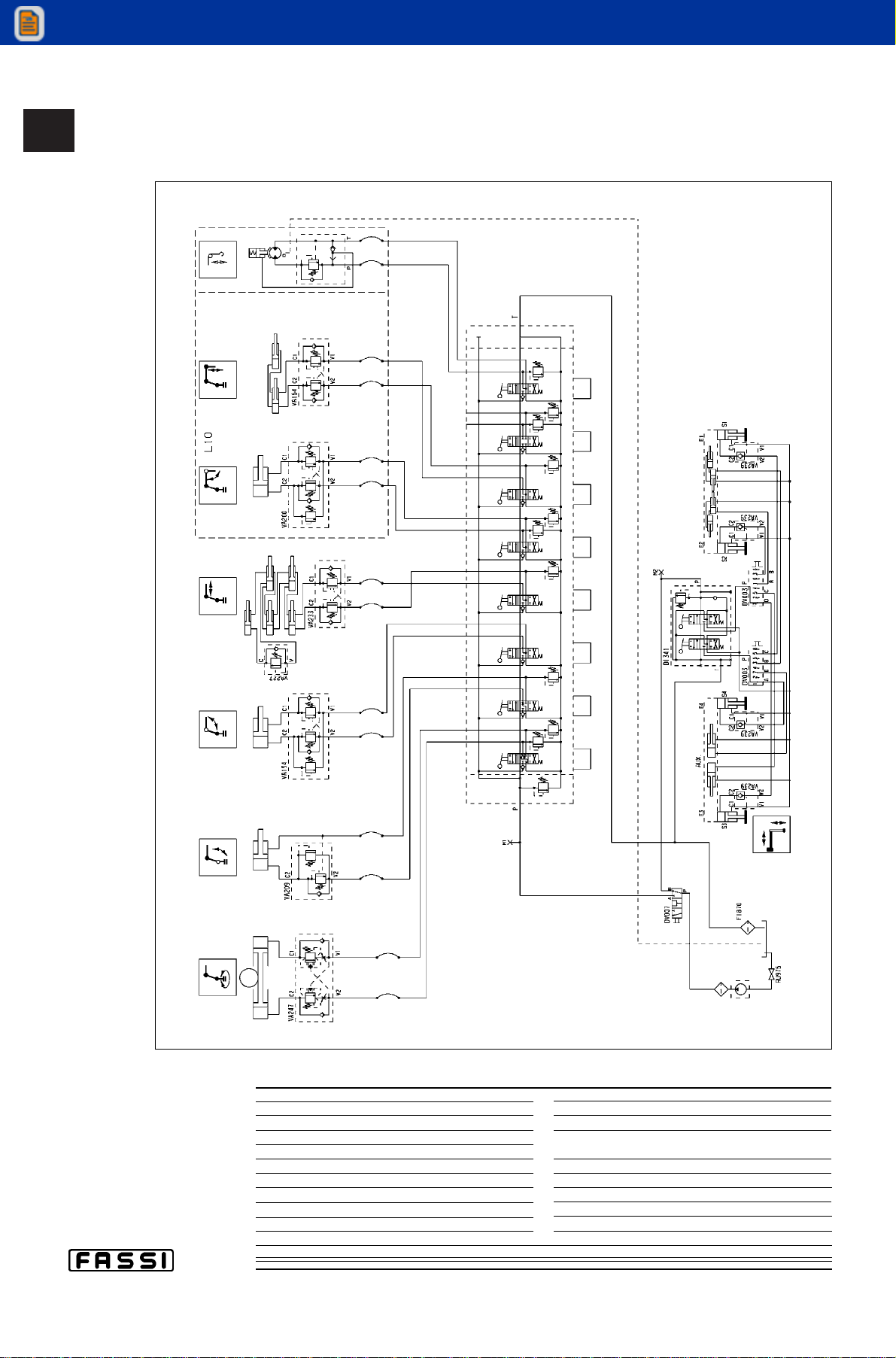

4

HYDRAULIC

SCHEMATICS

GR3_080»095

Hydraulic schematic for crane - HCD3M/HCD4 distributor - top seat controls - “electronic”

lifting moment limiting (F80A from s.n. *4085* - F95A from s.n. *3850*)

CODE DESCRIPTION

DI341 DISTRIBUTOR

DV003 DEVIATOR

DV007 DEVIATOR

EV128 ELECTROVALVE

EV117 ELECTROVALVE

FI870 FILTER (RETURN)

M1/M2 GAUGE QUICK CONNECTION

PR103 PRESSURE SWITCH

RU975 FAUCET

TR002 PRESSURE TRANSDUCER

VA102 DOUBLE EFFECT BLOCK VALVE

VA164 DOUBLE EFFECT BLOCK VALVE

VA185 SELECTOR VALVE

VA200 DOUBLE EFFECT BLOCK VALVE

VA213 SIMPLE EFFECT BLOCK VALVE

VA217 SEQUENCE VALVE

VA239 SIMPLE EFFECT BLOCK VALVE

VA247 OIL FLOW REGULATOR VALVE FOR ROTATION

CYLINDER

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

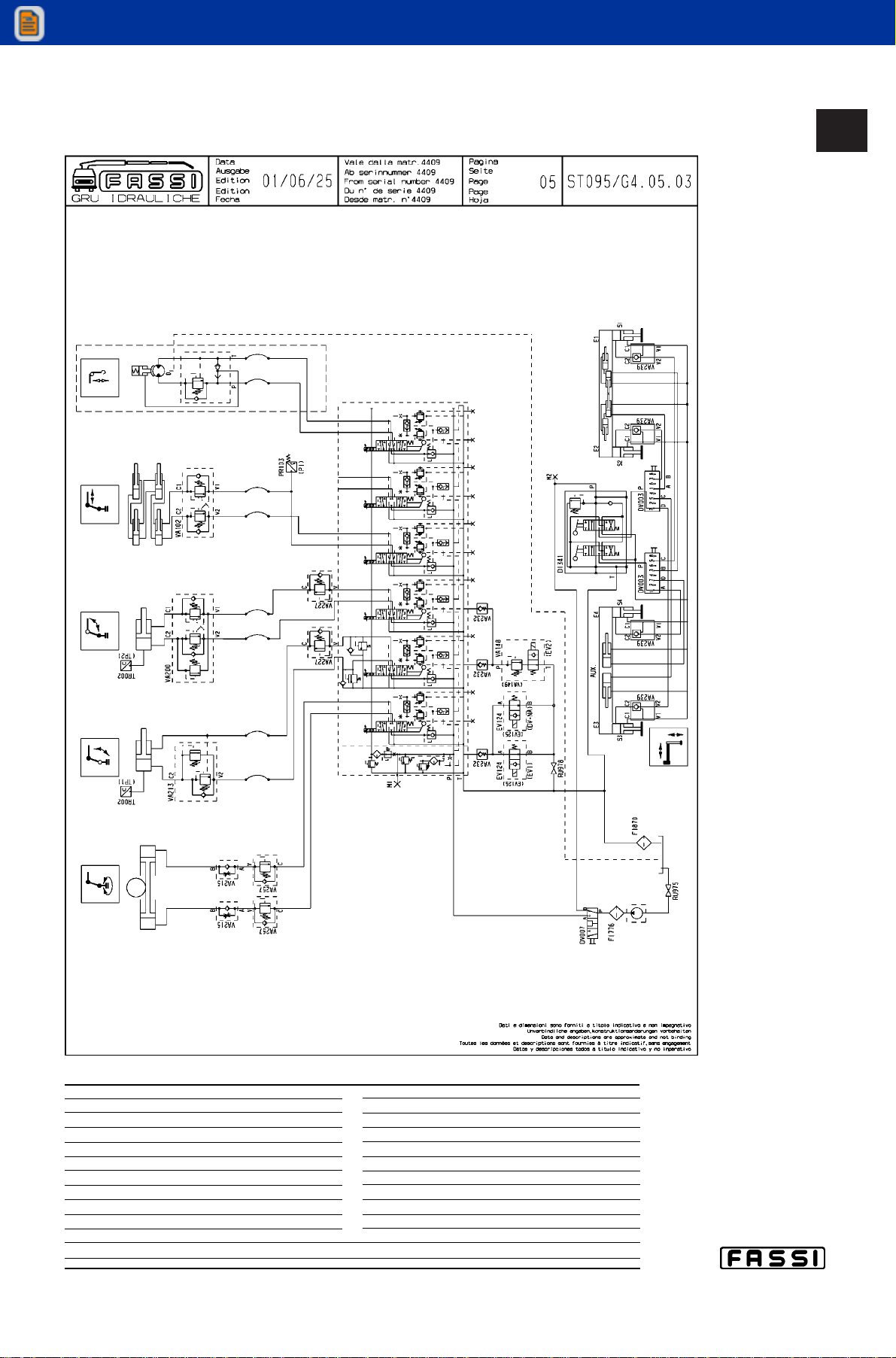

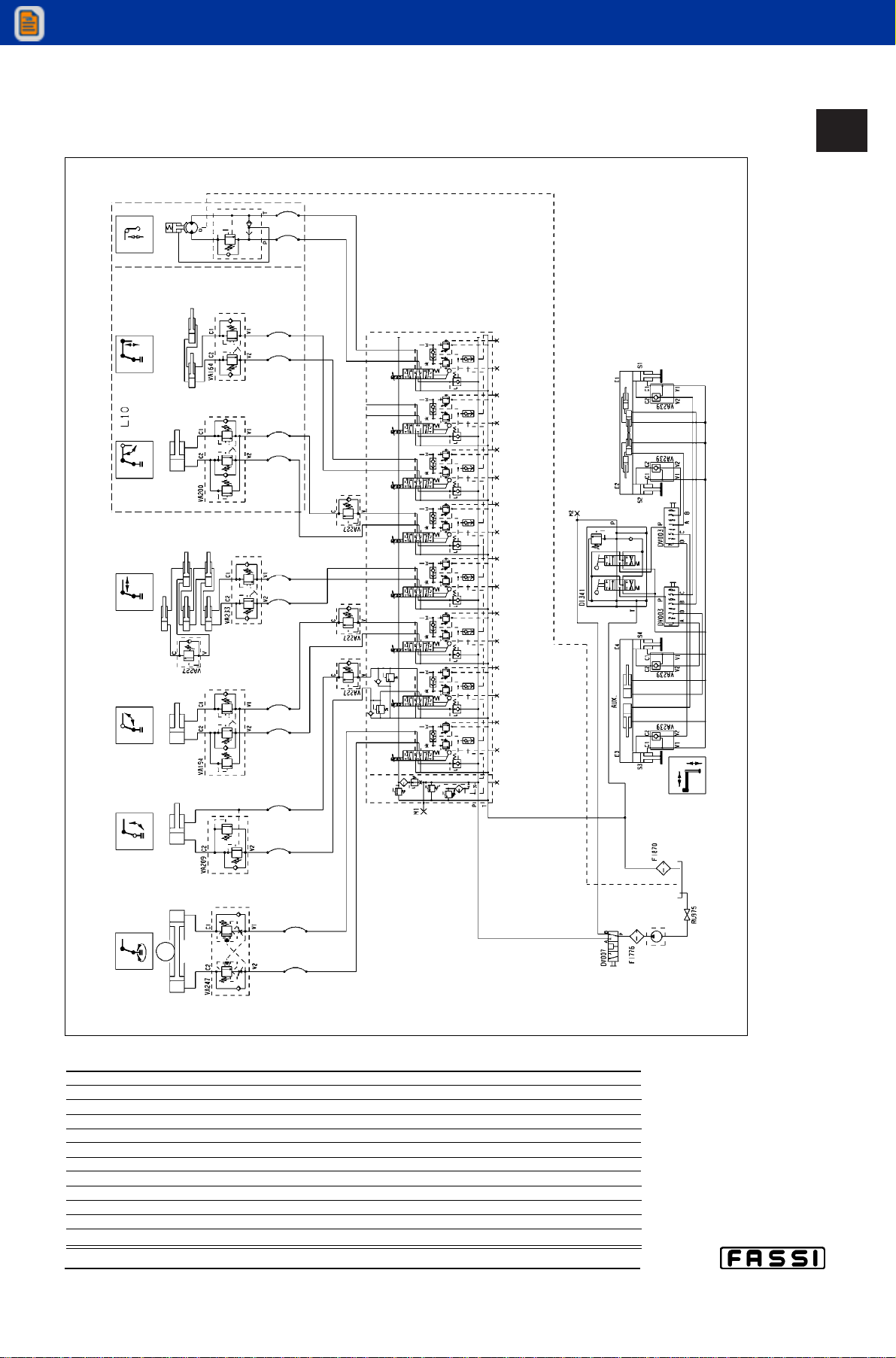

4

HYDRAULIC

SCHEMATICS

GR3_080»095

Hydraulic schematic for crane - Danfoss distributor - “electronic” lifting moment limiting

(F80A from s.n. *4759* - F95A from s.n. *4409*)

CODE DESCRIPTION

DI341 DISTRIBUTOR

DV003

DEVIATOR

DV007

DEVIATOR

EV124

ELECTROVALVE

FI776 FILTER (HIGH PRESSURE)

FI870 FILTER (RETURN)

M1/M2

GAUGE QUICK CONNECTION

PR103

PRESSURE SWITCH

RU975

FAUCET

RU978

FAUCET

TR002

PRESSURE TRANSDUCER

VA102

DOUBLE EFFECT BLOCK VALVE

VA148

ELECTRIC MAIN WITH BY PASS VALVE

VA164

DOUBLE EFFECT BLOCK VALVE

VA185

SELECTOR VALVE

VA200

DOUBLE EFFECT BLOCK VALVE

VA213

SIMPLE EFFECT BLOCK VALVE

VA215

OIL FLOW CHECK VALVE

VA227

SEQUENCE VALVE

VA232

UNIDIRECTIONAL VALVE

VA239

SIMPLE EFFECT BLOCK VALVE

VA257

SEQUENCE VALVE

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

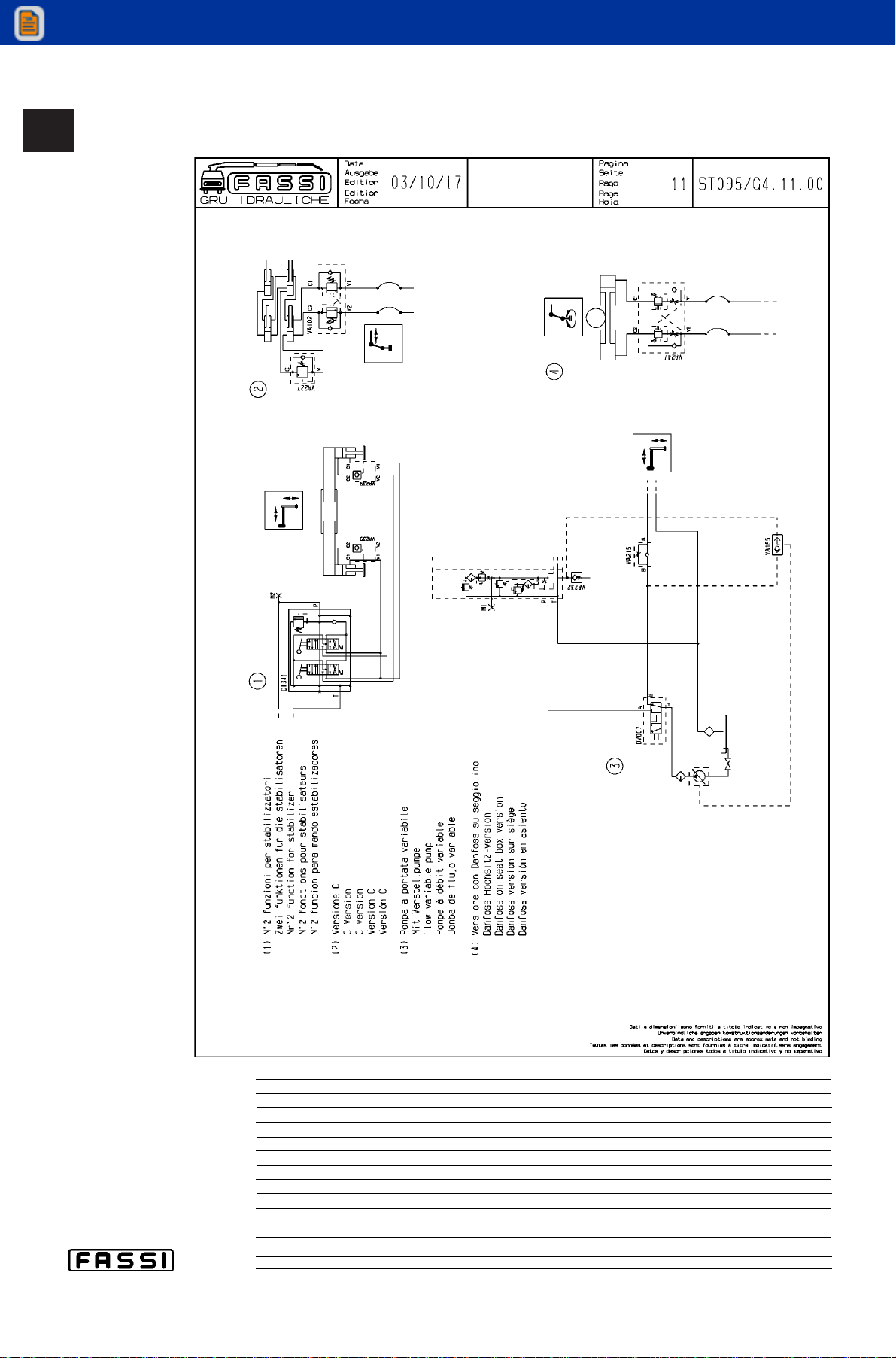

4

HYDRAULIC

SCHEMATICS

GR3_080»095

Hydraulic schematic for crane - versions

CODE DESCRIPTION

DI341 DISTRIBUTOR

DV007 ELECTROVALVE

VA102 DOUBLE EFFECT BLOCK VALVE

VA185 SELECTOR VALVE

VA215 OIL FLOW CHECK VALVE

VA227 SEQUENCE VALVE

VA232 UNIDIRECTIONAL VALVE

VA239 SIMPLE EFFECT BLOCK VALVE

VA247 OIL FLOW REGULATOR VALVE FOR ROTATION CYLINDER

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

4.1

HYDRAULIC

SCHEMATICS

GR3

4.1 HYDRAULIC SCHEMATICS

(version with load limiting device)

Hydraulic schematic for crane - HCD4 distributor - ground controls - load limiting device

CODE DESCRIPTION

DI341

DISTRIBUTOR

DV003 DEVIATOR

DV007 DEVIATOR

FI870 FILTER

(RETURN)

RU975 FAUCET

VA164 DOUBLE EFFECT BLOCK VALVE

VA194 DOUBLE EFFECT BLOCK VALVE

VA200 DOUBLE EFFECT BLOCK VALVE

VA209 SIMPLE EFFECT BLOCK VALVE

VA215 OIL FLOW CHECK VALVE

VA227 SEQUENCE VALVE

VA233 DOUBLE EFFECT BLOCK VALVE

VA239 SIMPLE EFFECT BLOCK VALVE

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

4.1

HYDRAULIC

SCHEMATICS

GR3

Hydraulic schematic for crane - HCD4 distributor - top seat controls - load limiting device

CODE DESCRIPTION

DI341

DISTRIBUTOR

DV003 DEVIATOR

DV007 DEVIATOR

FI870 FILTER (RETURN)

RU975 FAUCET

VA164 DOUBLE EFFECT BLOCK VALVE

VA194 DOUBLE EFFECT BLOCK VALVE

VA200 DOUBLE EFFECT BLOCK VALVE

VA209 SIMPLE EFFECT BLOCK VALVE

VA227 SEQUENCE VALVE

VA233 DOUBLE EFFECT BLOCK VALVE

VA239 SIMPLE EFFECT BLOCK VALVE

VA247 OIL FLOW REGULATOR VALVE FOR ROTATION

CYLINDER

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

4.1

HYDRAULIC

SCHEMATICS

GR3

Hydraulic schematic for crane - Danfoss distributor - load limiting device

CODE DESCRIPTION

DI341

DISTRIBUTOR

DV003 DEVIATOR

DV007 DEVIATOR

FI870 FILTER

(RETURN)

VA164 DOUBLE EFFECT BLOCK VALVE

VA209 SIMPLE EFFECT BLOCK VALVE

VA227 SEQUENCE VALVE

VA233 DOUBLE EFFECT BLOCK VALVE

VA239 SIMPLE EFFECT BLOCK VALVE

VA247 OIL FLOW REGULATOR VALVE FOR ROTATION CYLINDER

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

4.1

HYDRAULIC

SCHEMATICS

GR3

Hydraulic schematic for crane - versions

CODE DESCRIPTION

DI341

DISTRIBUTOR

DV007 DEVIATOR

VA102 DOUBLE EFFECT BLOCK VALVE

VA185 SELECTOR VALVE

VA215 OIL FLOW CHECK VALVE

VA227 SEQUENCE VALVE

VA232 UNIDIRECTIONAL VALVE

VA239 SIMPLE EFFECT BLOCK VALVE

VA247 OIL FLOW REGULATOR VALVE FOR ROTATION CYLINDER

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

Other Fassi Construction Equipment manuals

Popular Construction Equipment manuals by other brands

Fraco

Fraco FRSM-8000 user guide

MULTIQUIP

MULTIQUIP MC94SH Operation and parts manual

Tigercat

Tigercat T234B Operator's manual

Manitowoc

Manitowoc 2000 Operator's manual

Amco Veba

Amco Veba 804 WARNING, OPERATING AND MAINTENANCE MANUAL

felton industries

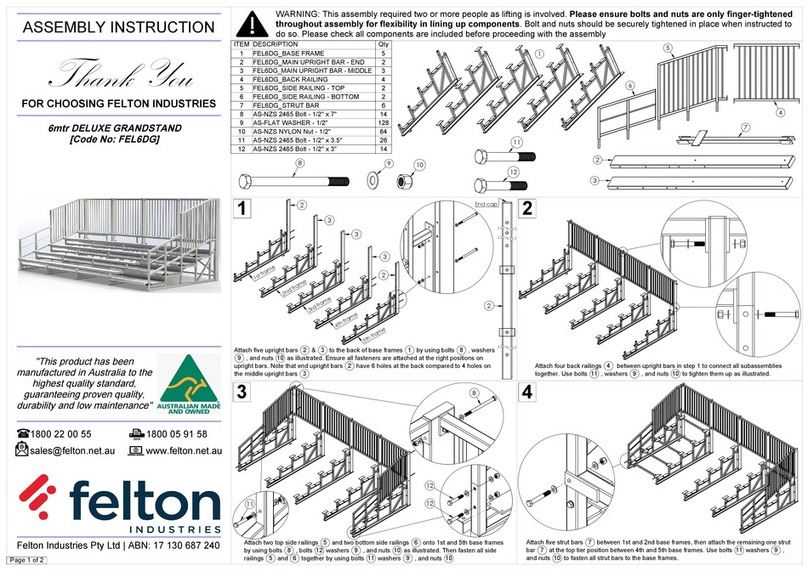

felton industries DELUXE GRANDSTAND FEL6DG Assembly instruction