Fassi F 240.24 User guide

c I

1

FASSI CRANE

F 240.24

use and maintenance

EXTRA CE version 20.04.98

INDEX

Chapter I INTRODUCTION page 2

II SAFETY NORMS page 3

III INSTRUCTIONS FOR CRANE USE page 6

IV IDENTIFICATION OF THE CRANE MODEL page 7

VTECHNICAL DATA page 8

VI CRANE NOMENCLATURE page 10

VII SAFETY AND PROTECTION DEVICES page 12

VIII LOAD LIMITING DEVICE - LIFTING MOMENT

LIMITING DEVICE (OPTIONAL) page 14

IX CONTROLS TO STABILIZE THE VEHICLE page 16

XCONTROLS TO OPERATE THE CRANE page 23

XI USE OF IMPLEMENTS page 26

XII MAINTENANCE INSTRUCTIONS page 31

XIII POSSIBLE FAULTS page 34

XIV HYDRAULIC SCHEMATICS page 35

XV OIL AND LUBRICANT CHARACTERISTICS page 38

AINSTRUCTION AND WARNING PLATES page 39

BCAPACITY PLATES page 41

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

FASSI CRANE

F 240.24

use and maintenance

This instruction manual describes the FASSI CRANE F240.24.

The fitment must be carried out in accordance with the instructions given

by the Manufacturer in the manual for hydraulic crane fitting.

The Manufacturer declines all responsibility and guarantee if the fitting is

entrusted to workshops without sufficient technical capability to carry out

the work in conformity.

As well as the principal safety norms, this manual contains a description

of the crane and the instructions for use and maintenance.

The crane must only be operated by responsible persons, previously

instructed and authorized.

THANK YOU FOR SELECTING ONE OF OUR CRANES.

c I

INTRODUCTION

F 240.24

2

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

SAFETY NORMS

( !) This symbol draws your attention on the points concerning safety.

It means: WARNING! BE CAREFUL!

IT CONCERNS YOUR SAFETY!

!ATTENTION!

READ THIS MANUAL CAREFULLY prior to use of the crane or any maintenance.

A few minutes spent now could save time and labour later.

Be sure that the unit has been installed, inspected and tested in accordance

with the local legal requirements.

Check that protections are in their place and that all safety devices are fitted

and active.

Warning plates, as well as instruction and operation plates must be repla-

ced when no longer readable or missing. (See chapters A - B)

Do not run the engine in a indoor area without first making sure there is

adequate ventilation. Fit a suitable extension tube to the vehicle exhaust pipe

to take the fumes away from the working area.

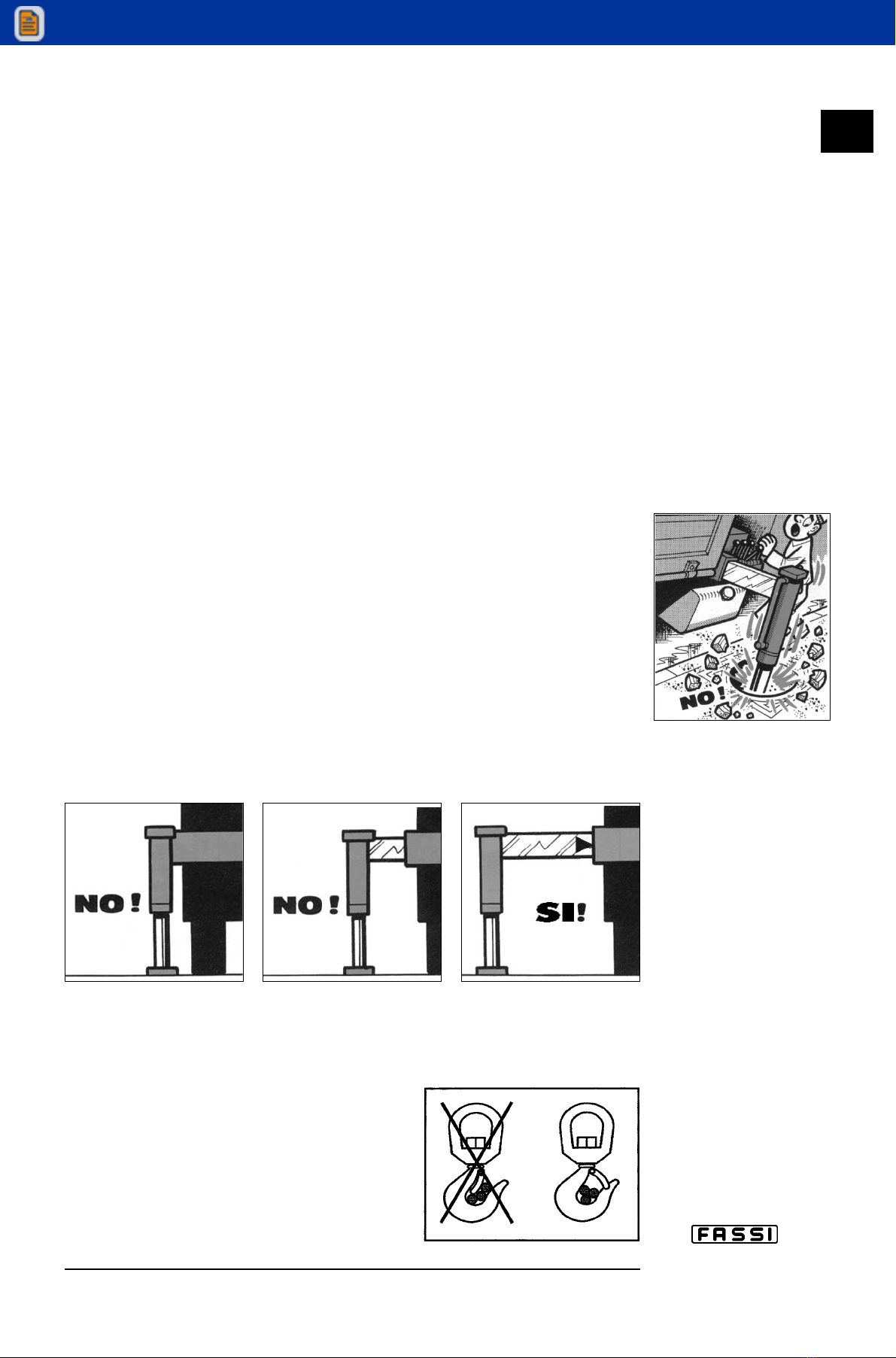

Stabilize the vehicle by means of the outrigger rams, checking that they rest

on a solid base; if in doubt use special larger outrigger base plates (available

on request). (See chapter IX)

Level the crane so as it is always operated on a horizontal plane.

Check that the taps of the outrigger rams safety check valves are closed.

Never operate the outriggers when the crane is loaded.

Remember that the stability of the unit (crane-vehicle) is only guaranteed by

the maximum lateral extension of the outriggers.

Should visibility be insufficient, make sure that control stations are properly

lighted so as to ensure safety while operating control functions and allow rea-

ding of the plates.

Before manoeuvering a load check that the

working area is adequate and properly lighted

for your crane.

Make sure that the hook is always free to rota-

te on its pin and that nothing obstructs its ver-

tical positioning.

Check the efficiency of the hook safety catch.

c II

SAFETY NORMS

F 240

3

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

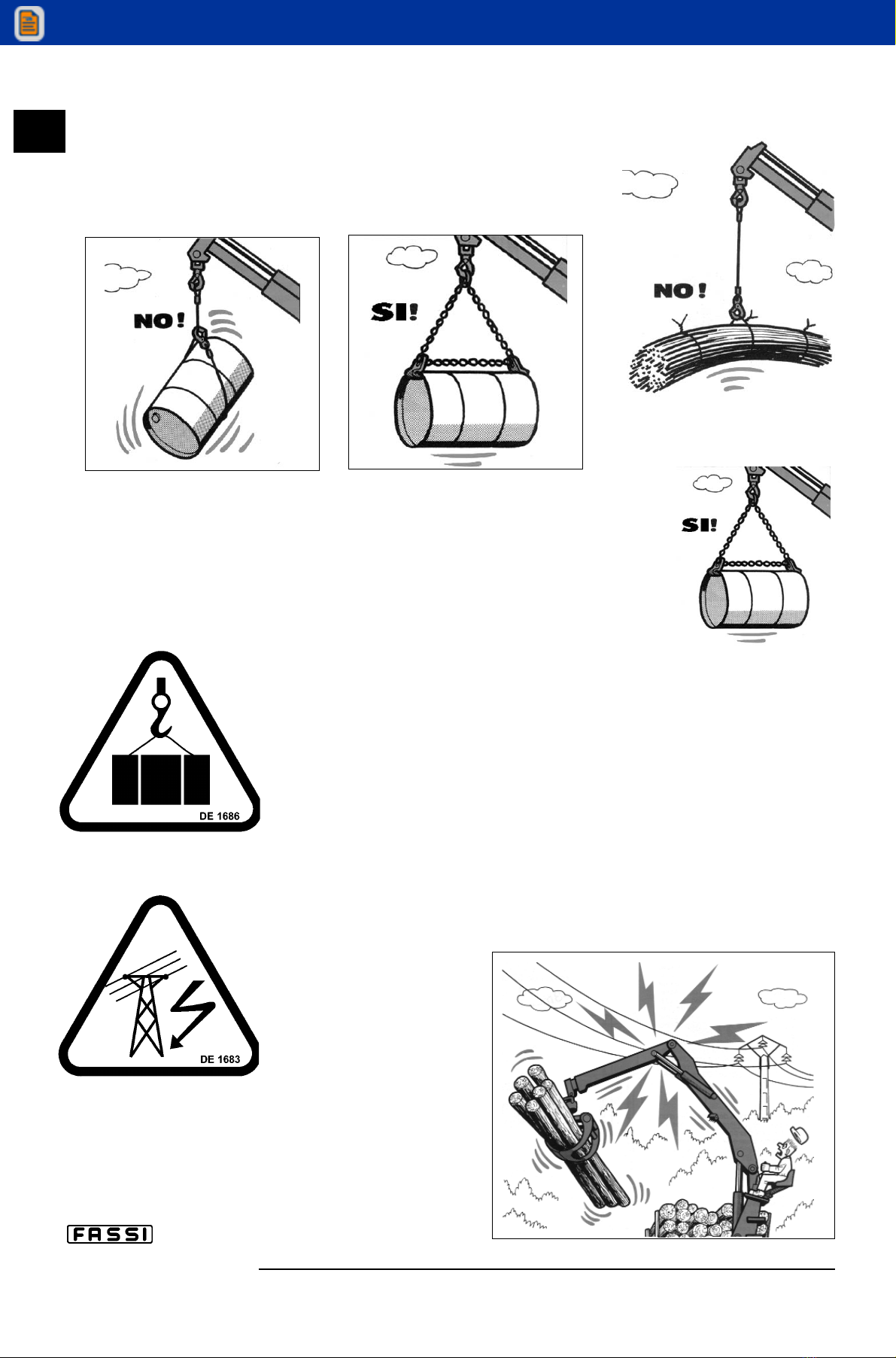

Carefully inspect the load rigging and the

condition of ropes or chains.

Make sure that the lifted load is balanced.

The pallet fork must be connected to the crane

hook by means of a chain having at least 3 rings.

Hook up the load, checking that it does not exceed

the capacity indicated on the lifting diagram specific

to each load configuration.

It is absolutely prohibited to walk or stop under a

suspended load and for unauthorized persons to

be within the working area.

Avoid swinging the load above the control

station; in cases where the load is too close, the

crane must be operated from the opposite side.

It is absolutely prohibited to load or unload under or in proximity of electric

lines.

(!) The minimum distance

from electric lines is,

according to CEN norms,

5 meters, except for

otherwise prescribed by

national norms.

For cranes with top seat

controls, it is necessary to

use a ladder to reach the

control station.

When operating from the

top seat, stay within its

side safety guards.

SAFETY NORMS

F 240

4

c II

}3

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

Do not rotate the crane befo-

re the load is lifted, do not

operate with sudden

movements, activate the

controls with slow and

progressive movements.

Rotate slowly and with care

paying attention to the

stability of the vehicle.

With vertical lift, on hydraulic

and mechanical extension,

rotate slowly in order to

avoid side-skidding.

Do not move the vehicle if a

load is suspended on the

crane

.

Do not utilize the crane for

pushpull, lateral or sideways

operations.

Under no circumstances interfere with the safety and protection devices.

The vehicle/crane are not left unless the power take off is disengaged

and the load is on the ground.

At the end of the job and prior to driving the

vehicle the crane must be folded.

If the booms are to be laid on the body or on

the load, they must be blocked to prevent

possible sideways movements.

Outrigger rams must be lifted and re-entered

within the overall width of the truck and safety

devices locked.

Check that the taps of the outrigger rams

safety check valves are closed.

Disengage the power take off.

To avoid hitting bridges or tunnels check and

record the overall height of your crane in the

folded position or in laid position in the body or

on the load. Always respect and pay proper

attention to road signs placed in proximity of

such obstacles.

SAFETY NORMS

F 240

5

c II

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

INSTRUCTIONS FOR

CRANE USE

F 240

6

INSTRUCTIONS FOR CRANE USE

The use of the crane is reserved to authorized personnel, instructed in

advance, who has to strictly conform to the safety norms and instruc-

tions contained in the instruction manual supplied with the crane.

1 — Only authorized persons are allowed to operate the crane.

2 — The crane must be used on firm, level ground.

3 — Check that the vehicle hand brake is on and that the wheels

are chocked.

4 — Before every operation make sure that:

— no-one is within the working area of the crane

— the safety devices are in place and operative

— the minimum safe working distances from power lines are observed.

— the load is correctly slung and hooked.

5 — Stabilize the vehicle by the outrigger rams, making sure that:

— the lateral supports are fully extended

— the wheels are in contact with the ground and the suspension is not

completely unloaded

— the outriggers safety taps are closed.

6 — Use the crane in accordance with the use and maintenance manual,

making sure that:

— the load and radii are within the maximum limits shown on

the crane capacity plate

— the crane is used progressively avoiding sudden load movements

— swinging or dragging of the load is avoided

— the load is lifted before rotating.

7 — When using implements protect the crane working area with a barrier.

8 — The vehicle/crane are not left unless the power take off is disenga-

ged and the load is on the ground.

9 — Before driving the vehicle make sure that the outriggers are fully

retracted and re-entered, the safety taps closed and the crane is in

folded position.

fig. 1

c III

THESE INSTRUCTIONS FOR THE USE OF THE CRANE COINCIDE WITH THOSE

OF THE PLATE DE1771 (FIG. 1) PLACED NEXT TO THE CRANE.

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

IDENTIFICATION OF

THE CRANE MODEL

F 240

7

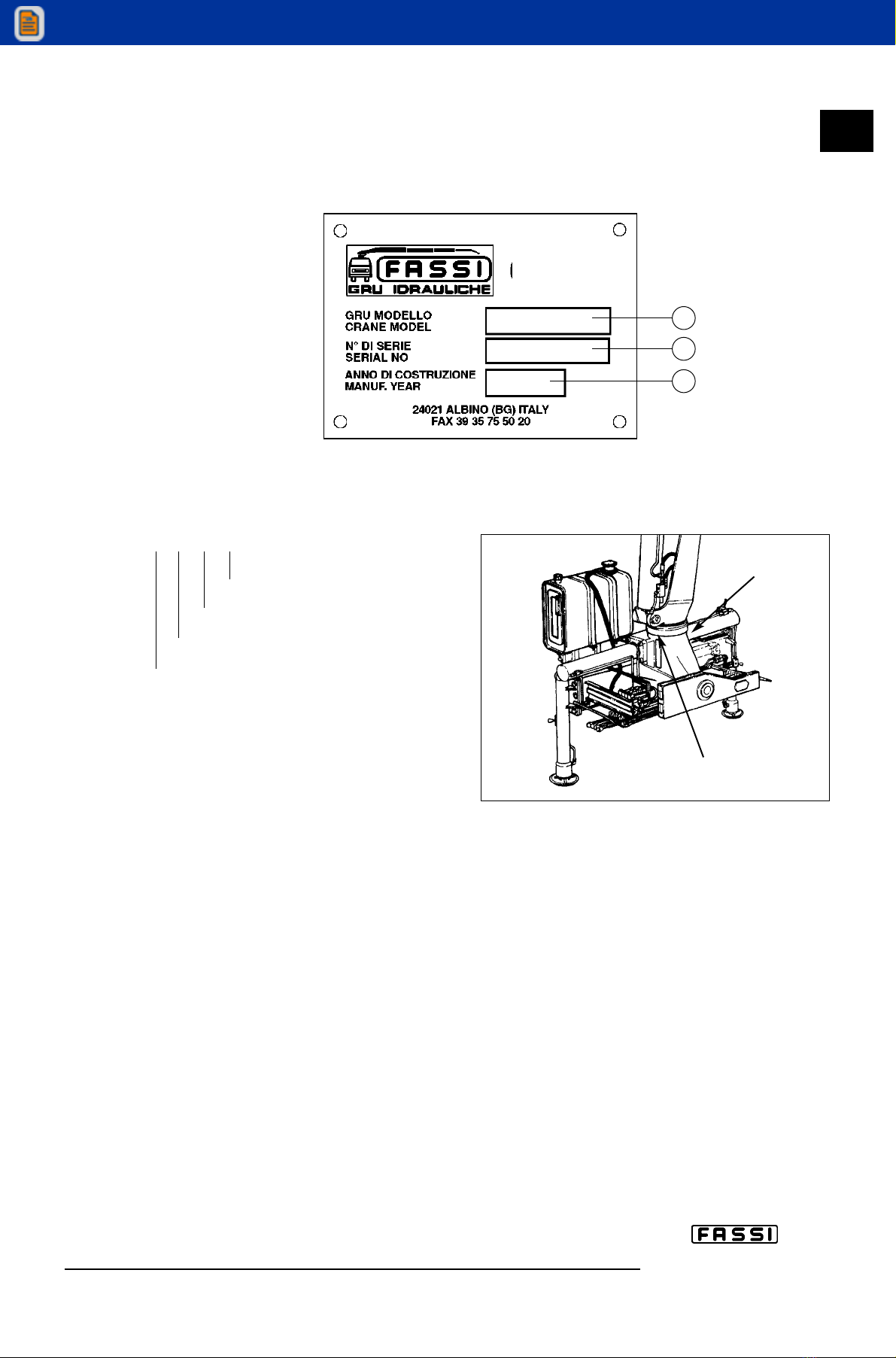

IDENTIFICATION OF THE CRANE MODEL

Essential data for the identification of the crane are given on the plate

DE2141, fixed to the base. (Fig. 2)

1—Crane model

2—Serial Number

3—Year of manufacturing

The model, the version of the crane, the year of manufacturing and the

serial number are stamped on the base (fig. 3) in the following

sequence:

*F240.22*06*0100*

( !)UNDER NO CIRCUMSTANCES SHOULD THE

DATA MARKED ON THE PLATE AND PUNCHED

ON THE BASE BE ALTERED.

It is essential to give the correct crane model and serial number, when you

contact the Service and Parts Department.

The exact crane model, serial number and description of implements will

enable FASSI Service Department to give a rapid and efficient response.

serial no.

year of manufacturing

version /.23/.24

model

fig. 2

1

2

Identification

plate

Punching

fig. 3

c IV

3

DE 2141

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

TECHNICAL DATA

The design of this crane has been carried out in respect of DIN 15018 norms,

fatigue test classification H1B3 .

The crane can operate, intermittently, with lifting devices other than the hook.

The dimensions and the capacity of the implements must be proportioned

with crane performances.

TECHNICAL DATA

F 240.24

8

c V

F240.24

Lifting

capacity

tm 22,0

F 240.24

Standard

reach

m 12,40

Hydraulic

extension

m 7,60

Rotation arc

400°

Rotation

torque

kNm 41,00

Working

pressure

MPa 29,0

Pump

capacity

l/min 40

Oil tank

capacity

l 120

Crane weight

kg 3200

12410 40’ 9”

4790 15’ 9”

2378 7’ 10”

1323 4’ 4”

3140 10’ 4”

*

**

+

++

SBRACCIO MAX

REACH MAX

BRAS MAX

MAXIMALE REICHWEITE

CO 1411

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

TECHNICAL DATA

F 240.24

9

c V

✱CON TUBAZIONI SUPPLEMENTARI

✱WITH SUPPLEMENTARY HOSES

✱ AVEC TUYAUTERIE

SUPPLEMENTAIRE

✱ MIT ZUSAETZLICHEN SCHLAEUCHEN

MASSIMA ALTEZZA SOTTOGANCIO.

HAUTEUR MAXIMUM SOUS CROCHET.

MAXIMUM HOOKING POSITION.

MAXIMALHOEHE BIS KRANHAKEN.

PESI, DIMENSIONI E POSIZIONE

BARICENTRO.

POIDS, DIMENSIONS ET POSITION

DU BARYCENTRE.

WEIGHT, DIMENSIONS AND

BARYCENTRE POSITION

GEWICHTE, ABMESSUNG UND POSITION

DES KRANSCHWERPUNKTE.

1848 6’ 1”

1848 6’ 1”

2264 7’ 5”

5960 19’ 7”

A

B

C

D

EXTRA

CO 1408

CO 1414

— MEZZERIA TIRANTI

— FIXING ROD CENTER

DISTANCE

— LIGNE MEDIANE

TIRANTS

— ABMESSUNG DER

BEFESTIGUNGSBRIDEN

M33 x 2

PESO GRU CON SERBATOIO NON RIFORNITO, STABILIZZATORI STANDARD

WEIGHT OF THE CRANE WITH EMPTY TANK, STANDARD STABILIZATION

POIDS DE LA GRUE AVEC RESERVOIR VIDE, STABILISATION STANDARD

KRANGEWICHT MIT LEEREM TANK UND STANDARDABSTUTZUNG

kg 3200

lbs 7055

F240.24

F240.24

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

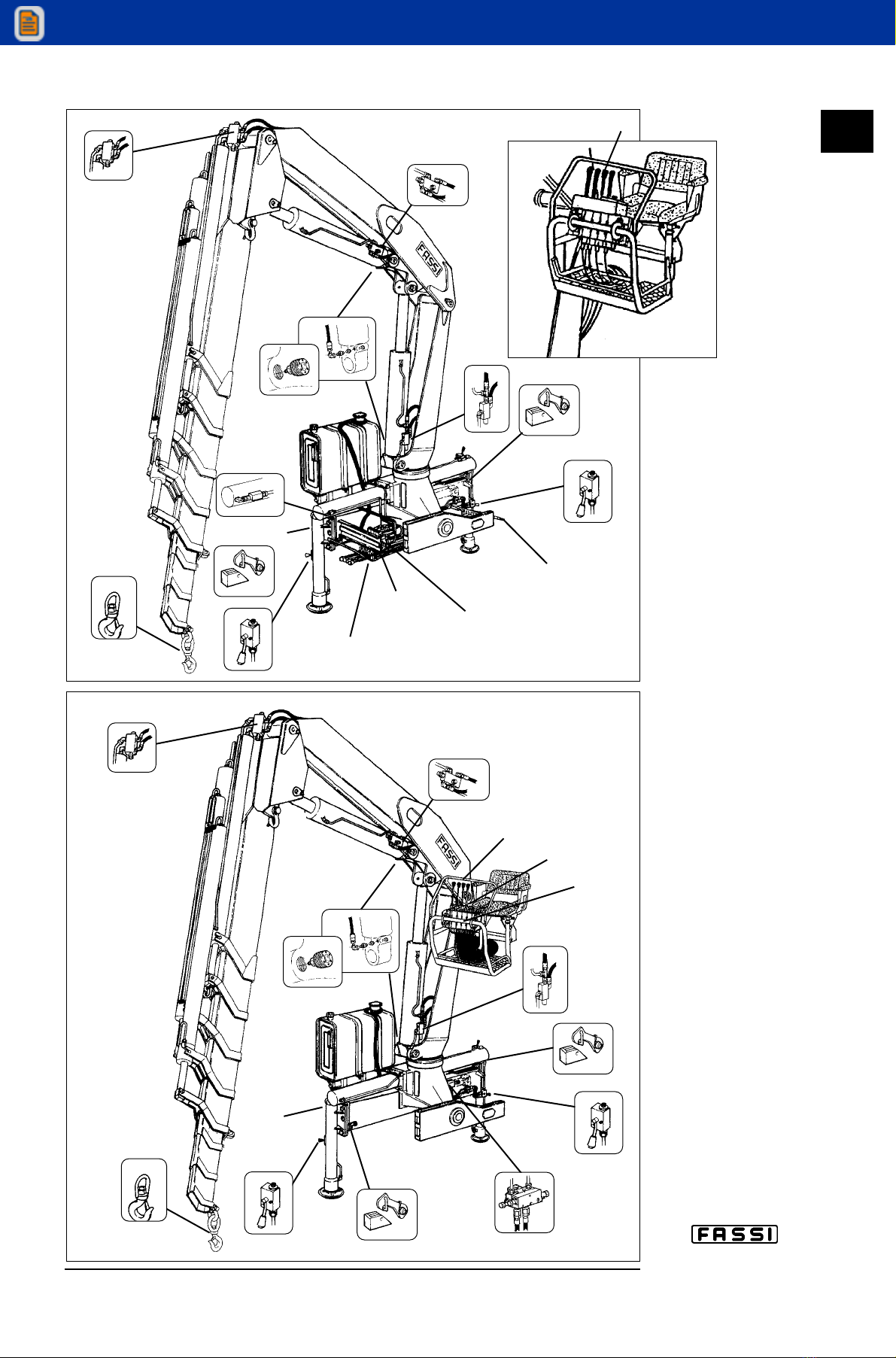

CRANE NOMENCLATURE

—Version with ground controls for crane and outriggers

—Version with top seat controls (fig. 4a) for crane by hand cables

(optional) (fig. 4)

Pos. Description

1 — Outrigger rams

2 — Outrigger supports

3 — Base

4 — Rotation cylinders

5 — Deviator outriggers - crane

6 — Outrigger multifunction deviator

7 — Outrigger multifunction transmission

8 — Distributor bank

9 — Double control

10 — Column

11 — Inner ram

12 — Inner boom

13 — Outer ram

14 — Outer boom

15 — Booms extension rams

16 — Booms extension rams

17 — Lifting hook

18 — Oil tank

19 — Manual extensions (optional)

20 — Seat (optional)

21 — Hand-cables for crane (optional)

—Version with ground controls for outriggers and top seat controls

for crane (fig. 5)

Pos. Description

1 — Outrigger rams

2 — Outrigger supports

3 — Base

4 — Rotation cylinders

5 — Deviator outriggers - crane

6 — Outrigger multifunction deviator

7 — Outrigger multifunction transmission

8 — Column

9 — Seat

10 — Distributor bank

11 — Inner ram

12 — Inner boom

13 — Outer ram

14 — Outer boom

15 — Booms extension rams

16 — Extension boom sections

17 — Lifting hook

18 — Oil tank

19 — Manual extensions (optional)

CRANE NOMENCLATURE

F 240

10

c VI

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

CRANE NOMENCLATURE

F 240

11

c VI

fig. 4

fig. 5

12

21

20

7

64

2

9

10

1

1

3

8

4

2

5

18

11

13

14

16

19

17

15

fig. 4a

12

7

64

2

8

9

10

1

1

3

2

5

4

18

11

13

14

16

19

17

15

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

SAFETY AND

PROTECTION

DEVICES

F 240

12

c VII

SAFETY AND PROTECTION DEVICES

— Version with ground controls for crane and outriggers

—Top seat controls (fig. 6a) for crane by hand-cables (optional) (fig. 6)

Pos. Description

1 — Tap and check valve for outrigger rams

2 — Check valves for rotation control (flow regulators)

3 — Check valve for inner ram

4 — Check valve for outer ram

5 — Check valve for booms extension rams

6 — Main pressure valve (outriggers - crane)

7 — Main pressure valve (crane)

8 — Auxiliary valves (crane)

9 — Levers guard

10 — Hook safety device

11 — Safety device for outriggers supports

12 — Lifting moment limiting device assembly (optional)

13 — Parachute valves (if the lifting moment limiting device is fitted)

— Version with ground controls for outriggers and top seat controls

for crane (fig. 7)

Pos. Description

1 — Tap and check valve for outrigger rams

2 — Check valve for rotation control

3 — Check valve for inner ram

4 — Check valve for outer ram

5 — Check valve for booms extension rams

6 — Main pressure valve (outriggers - crane)

7 — Main pressure valve (crane)

8 — Auxiliary valves (crane)

9 — Levers guard

10 — Hook safety device

11 — Safety device for outriggers supports

12 — Lifting moment limiting device assembly (optional)

13 — Parachute valves (if the lifting moment limiting device is fitted)

(!) Before crane use check that safety and protection devices

are fitted and active.

(!) Under no circumstances interfere with the safety and

protection devices.

(!) Interference with the check valves and removal of the lead

seals remove the Manufacturer and invalidate the warranty.

(!) Use the ladder for the access to the top seat.

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

SAFETY AND

PROTECTION

DEVICES

F 240

13

c VII

fig. 6

fig. 7

13

11

11

5

7-8

12

9

6

9

fig. 6a

9

10

2

1

1

3

4

13

9

12

5

6

10

1

1

3

4

11 2

11

7-8

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

LOAD LIMITING DEVICE - LIFTING MOMENT LIMITING

DEVICE “INTELLIGENT TYPE” (optional)

A characteristic which permits the classification of cranes is their lifting

capacity or maximum lifting moment. The moment is defined by the

value obtained from the product of the load to be lifted (in kg) by its

distance (in meters) from the centerline of the crane rotation.

LOAD

LIMITING DEVICE

The device called “load limiting device” utilizes a small main pressure valve insered

on the safety check valves of the crane inner and outer rams and of the jib outer

ram. Whe the intervention values are reached, these valves are activated, permit-

ting the slow descent of one of the two, or both, lifting rams (or of the jib outer ram,

when fitted) and preventing use of the crane in an overloaded condition. To stop the

load descent, it is compulsory to raduce the load radius towards the column, opera-

ting the control lever to re-enter the boom extension rams of the crane (or of the

extension when fitted) or with an alternative manoeuvre which reduce the moment

on the column axis.

(!) This operation must be carried out within and not over 5 seconds

from the beginning of the load descent.

(!) ATTENTION (!)

The presence of the lifting moment limiting device does not release the user from

the obligation to respect what is indicated on capacity plates and lifting curves.

LIFTING MOMENT LIMITING DEVICE “INTELLIGENT TYPE”

(optional)

The device called “lifting moment limiting device” preserves the crane structure

from overloads, as it prevents any movement which

increases the value of the moment up to the maxi-

mum established value. This device is fitted close to

the distributor, whose specific functions it uses. It utili-

ses an electrohydraulic technology, preventing any

movement which causes an increase in the pressure

induced by the load in the inner and outer rams of the

crane (and in the outer ram for the hydraulic extension

if fitted), up to the “critical values” which have been

established in the structural test. These values, which

are non-exceedable, determine the intervention levels

and provide the data for setting the device.

The lifting moment limiting device concernes the following

manoeuvres:

— Inner boom descent; the inner boom lift is controlled

by the general main pressure valve of the distributor.

— Outer boom lift.

— Outer boom descent.

— Extension of extension boom sections.

— Winch rope lift (if fitted).

—

If hydraulic extension is fitted: extension outer boom lift.

— Extension outer boom descent.

— Extension of the jib extension booms section.

The device is based on hydraulic controls which are activated

when the intervention value is reached and block the move-

ments of the relevant distributor levers in one or both direc-

tions. Please remember that the device will return the

lever of the element being used to neutral

position.The condition of intervention is operated by

the position of the outer boom (or, if hydraulic exten-

sion is fitted, the position of the extension outer

boom), on which the electronic signal position (mer-

cury level switch) is read by a special electrovalve.

This determines the controls of the locking or

unlocking (resetting) of the controls concerned.

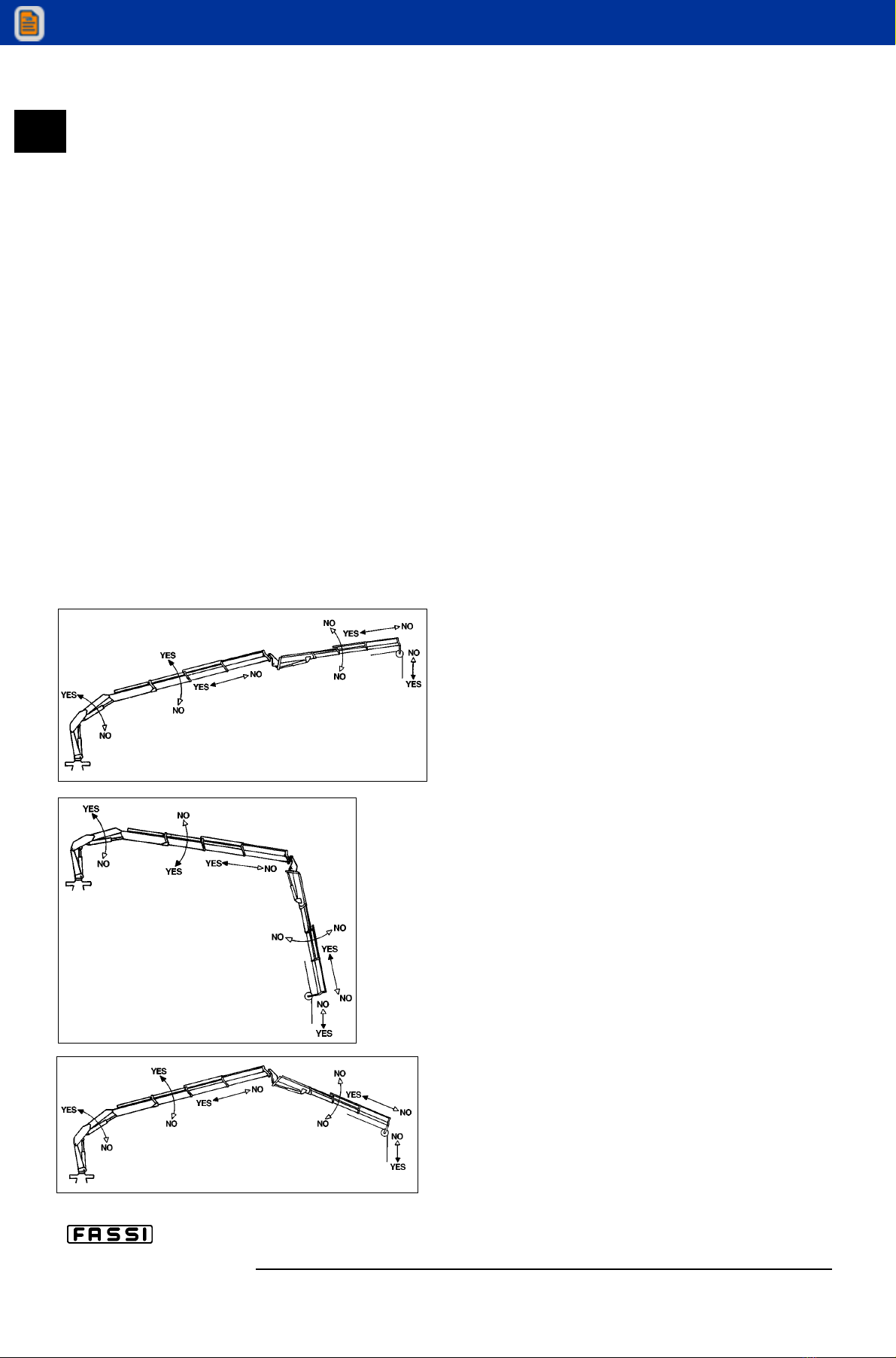

The crane configurations (fig. 8a-b-c) (and the eventual

hydraulic extension) indicate the manoeuvres which are allowed and not allowed

by the device, in connection with the horizontal position of the crane and exten-

sion outer booms.

LOAD LIMITING DEVICE -

LIFTING MOMENT LIMITING

DEVICE “INTELLIGENT TYPE”

F 240

14

c VIII

fig. 8 a

fig. 8 b

fig. 8 c

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

REACTIVATION button of crane functions in the absence of the electric

power.

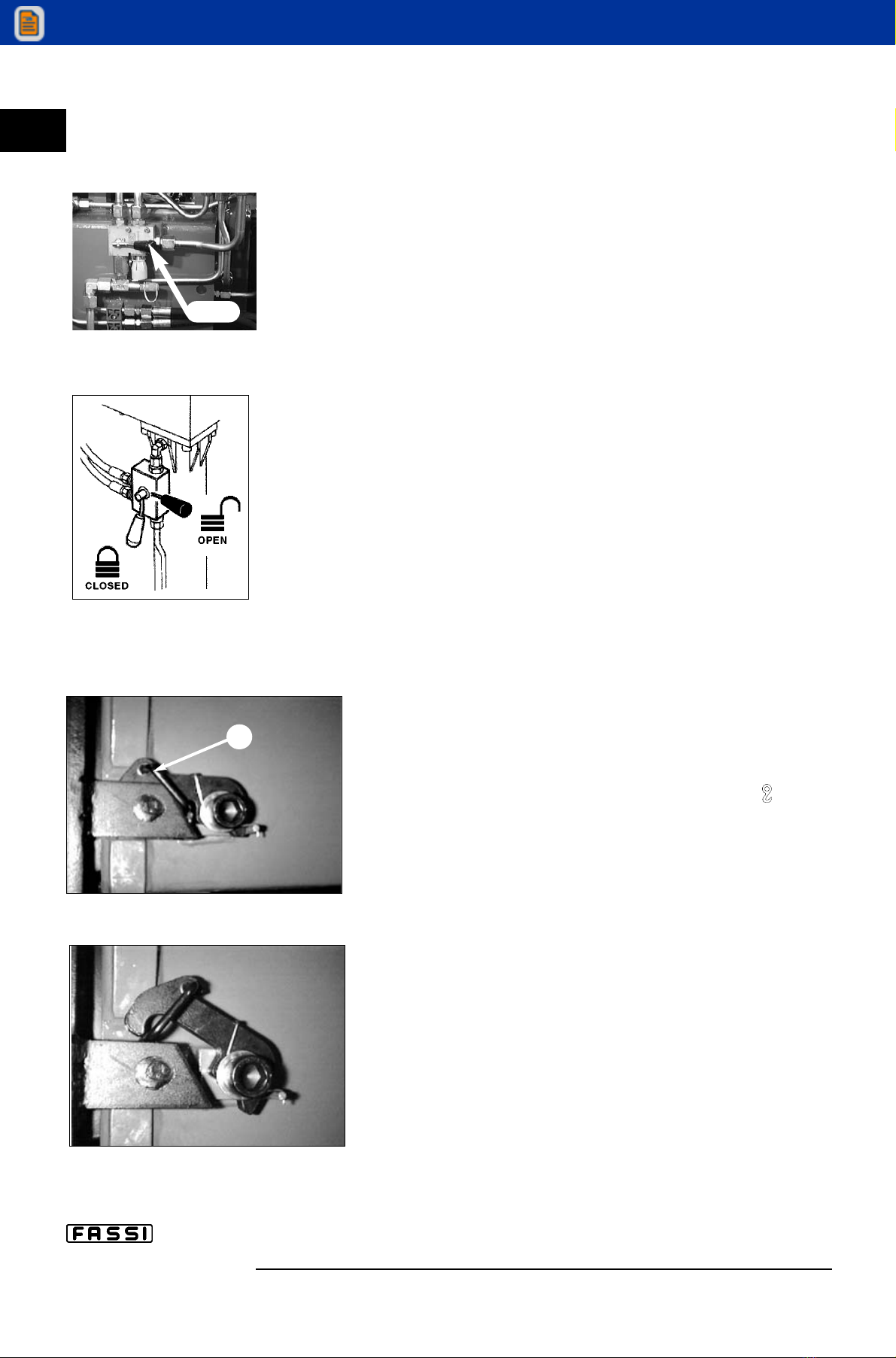

(!) On the distributor it has been installed an electro-valve with a manual locking

function (fig. 9-9a) which allows to reactivate all the crane functions in case of

absence of the electric power.

Only in these conditions it is permitted to remove the lead seals which protects

the device. Push the button and turn it into the clockwise sense; the button

stays in stable and closed position.

(!) When the electric power is restablished, remember to put the button in its

original position, turning it into the anti-clockwise sense. (Fig. 9b pos.3-4)

Rubinetto esclusore di EMERGENZ

Adel limitatore

Every electrovalve is installed with a screwed tap (emergency exclusion

tap), which must only be used in case of emergency, testing or other

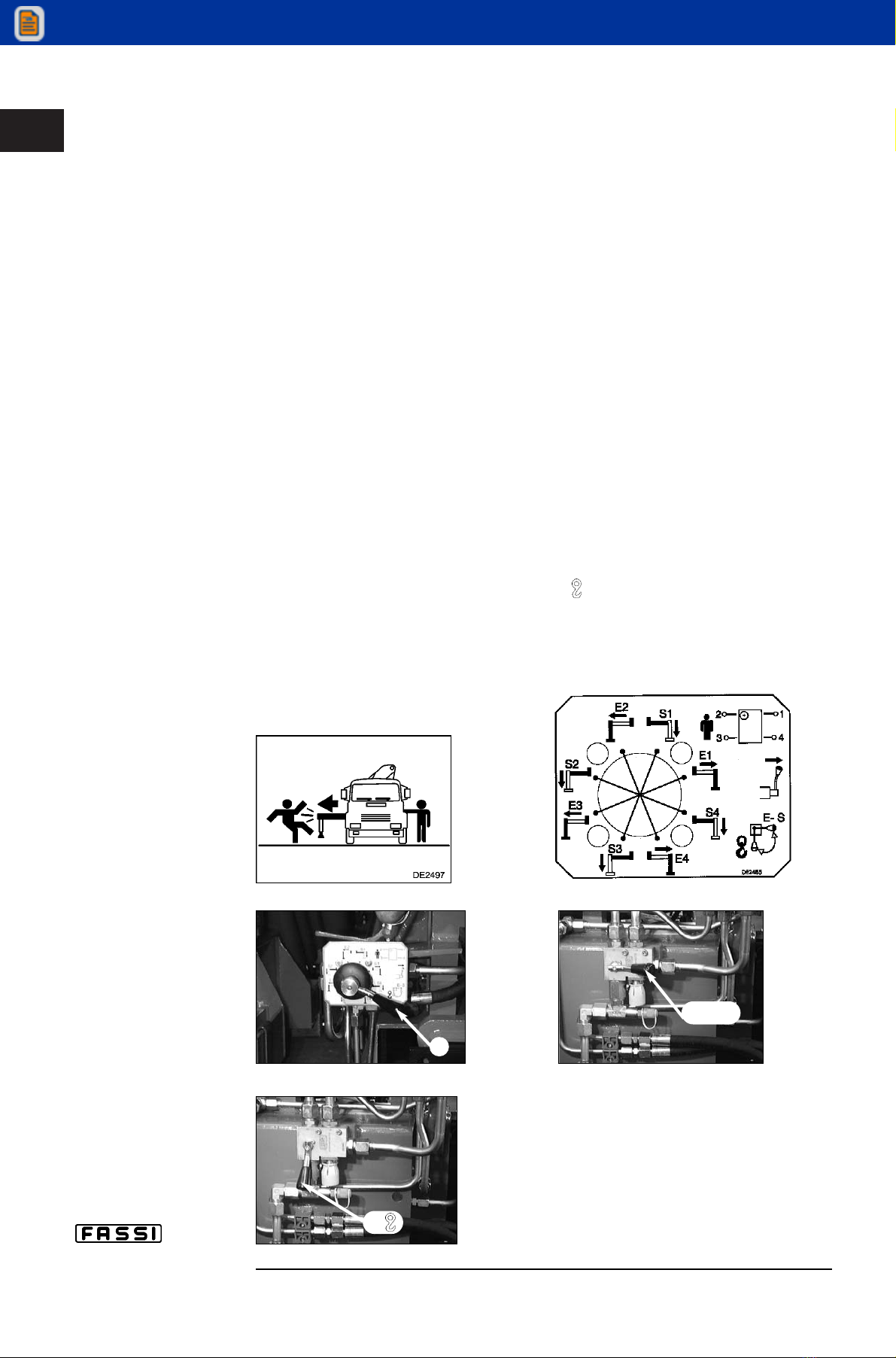

abnormal situations when it is not possible to carry out any of the move-

ments allowed by the device. (Such a probability generally occurs when

the extension booms are completely re-entered or the loads are conside-

rable and voluminous.) Only In these situations it is permitted to remove

the lead seals which protect the device. Slacken the lock nut of the

screwed tap fig. 10-11 (14 mm hexagonal spanner), completely screw in

the tap (5 mm allen key) and re-tighten the lock nut.

(!) ATTENTION (!)

When the operator uses this device, it means that he wishes to over-

ride the lifting moment limiting device in order to make some manoeuvres

(which would be impossible with the device active) that bring the moment

to within the level, but involve an overload condition. In such an emer-

gency condition (where the lifting moment limiting devicehas been

disabled), the operator must be:

- carefully consider the manoeuvres required to return to normal

working condtions;

- calmly and carefully assess the type and scale of the hazards

arising from these manoeuvres and the possible reaction of the

crane (tipping over, frame overload, uncontrolled fall of the load due

to a hydraulic system overload etc...);

- make all movements as slowly as possible to reduce the dynamic

overload to the minimum.

After such emergency operations and prior to re-use of the crane, you must

immediately go to FASSI authorised Center for testing the structure and

re-sealing of the device.

(!) Interferences with the valves or removal of the lead seals release the

Manufacturer from any responsibility and invalidate the warranty.

(!) ATTENTION (!)

The presence of the lifting moment limiting device does not release the

user from the obligation to respect what is indicated on capacity plates

and lifting curves.

LOAD LIMITING DEVICE -

LIFTING MOMENT LIMITING

DEVICE “INTELLIGENT TYPE”

F 240

15

c VIII

fig. 9

fig. 9a

fig. 11

fig. 10

Crane with top seat controlCrane with ground controls

Crane with top seat control

Crane with ground controls

fig. 9b

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

CONTROLS TO STABILIZE THE VEHICLE

The outriggers rams prevent hurmful stresses both to the frame and to the

vehicle suspensions on which the crane is mounted and assure the stability

of the unit during load handling.

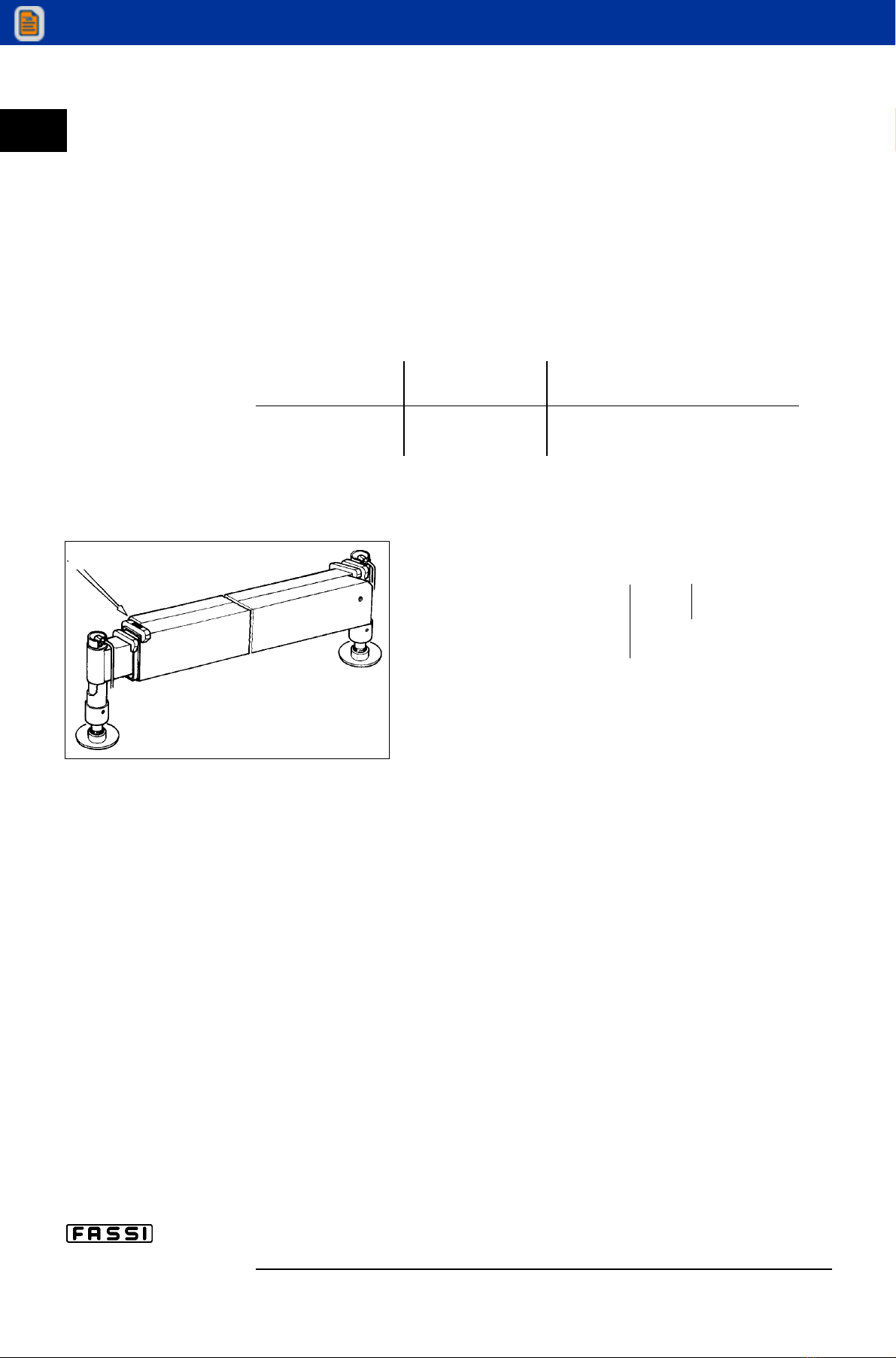

Supplementary beams (optional)

Supplementary beams (supplementary outriggers) are used in conjunction

with the crane outriggers to ensure the vehicle stability during load handling.

They are hydraulically extendable.

Supplementary outrigger ram extension max.

beam code stroke interaxis

190B070 340 mm 4142 mm hydraulic extension

190B072 550 mm 4142 mm hydraulic extension

Identification data of the supplementary beam are punched on the beam (fig. 12)

in the following sequence:

Example *190B070*0001*

serial no.

identification code

! ATTENTION !

(!) The crane stability is only guaranteed by the maximum lateral

extension of the outrigger supports of the crane and supplementary

outriggers

Be very careful during vehicle stabilization operation; make sure that no one

is or transits in close proximity of the working area of the outriggers.

Check that they are applied on a solid base; the maximum plate pressure of

the rams is:

25,1 daN/cm2on a plate which diameter is 230 mm

If needed use the special base plates (on request).

When stabilization is complete the wheels of the vehicle must still be in

contact with the ground and the suspensions must not be fully

unloaded.

Level the crane so as to operate on a horizontal plane.

The crane is supplied with outrigger supports having hydraulic side

extension. (On request hydraulic extra extendable supports).

The controls to stabilize the vehicle are activated only on ground level and on

both sides of the crane base.

c IX

CONTROLS

TO STABILIZE

THE VEHICLE

F 240

16

fig. 12

Punching

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

(!) The controls to stabilize the vehicle are in conformity with the safety

directives and enable the operator to activate the lateral extension of the

outriggers (outrigger supports and rams) only from the side where he can

visually check the operation.

The special construction concept of the outrigger control group

which combines the functions of an 8 positions deviator with

those of a distributor segment, allows to use the control lever for

selecting and operating the supports and the outrigger rams.

- The selection (support or ram) is effected, like on a devia-

tor, by positioning the lever on the corresponding position

indicated by the function schematic (plates DE2298 and

DE2297) placed on the controls.

- The control is effected by operating the lever like on a distri-

butor; the stability of the selected position is guaranteed by

an internal device.

The extension and re-entering of the support and outrigger rams

indicated on the fig. 13-14 coincide with what indicated on the plates

DE2298 and DE2297 placed in dual side position on the base.

The symbols reported at side of each lever indicate the operating

levers in relation to their movement.

Lever function D- C

- Lever DDeviator crane - outriggers ( - E/S). Fig. 15a - 15b

- Lever CMultifunction deviator for selecting and operating the

supports and the outrigger rams of the crane as well as the

supplementary outriggers. Fig. 15-16

Control for outrigger support extension for the crane and the sup-

plementary outriggers.

- Position lever Dof oil diverter crane-outriggers

(- E/S) on E/S. Fig. 15b

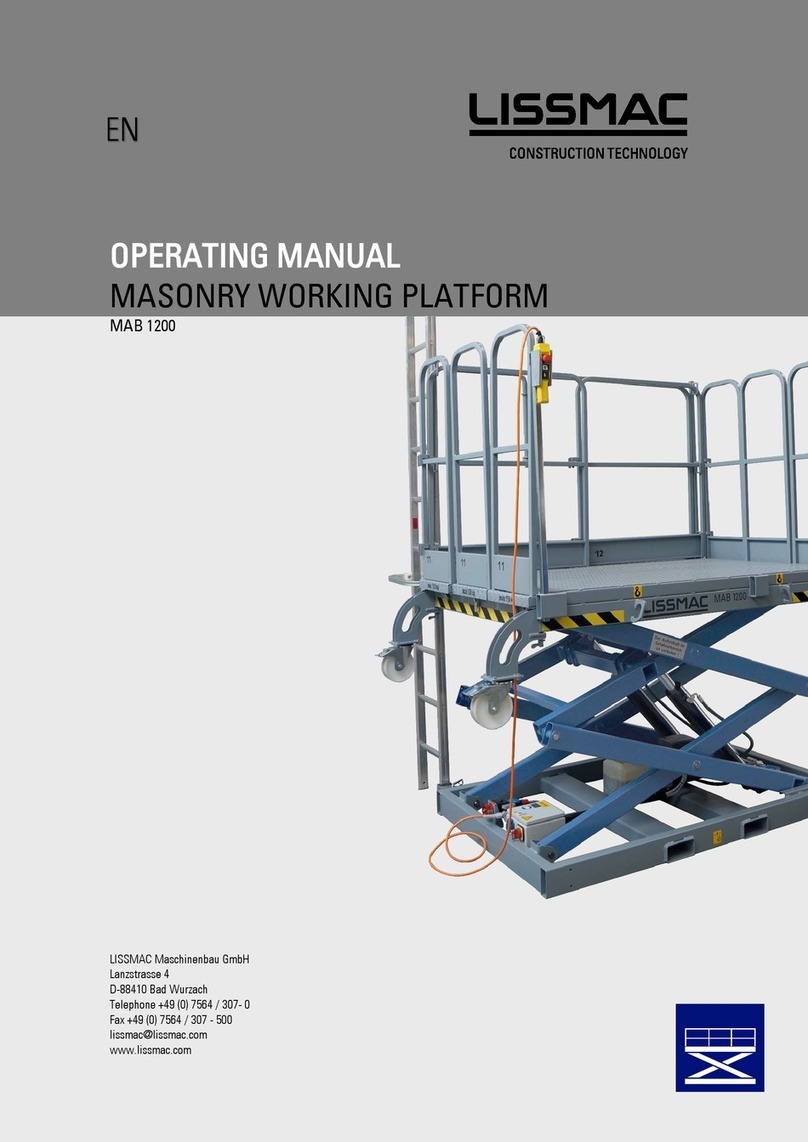

- Open all the taps of the valves placed on the

outrigger rams fig. 17.

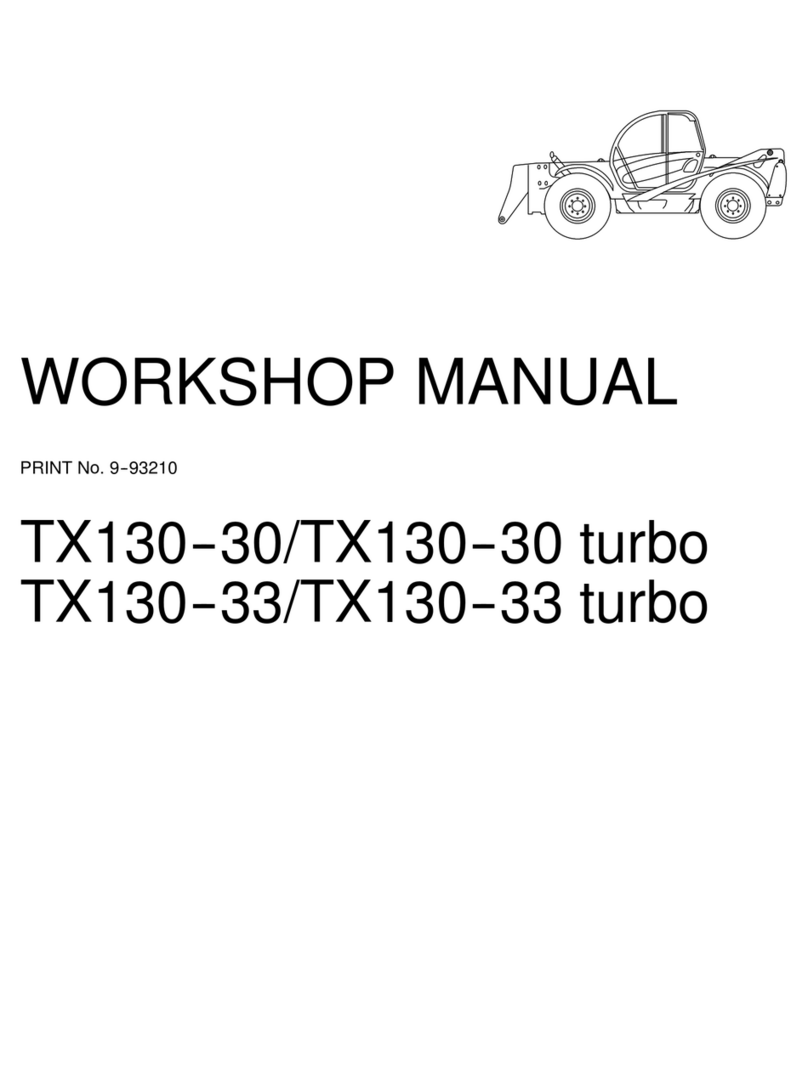

- Disengage the locking devices of the outrigger

supports by putting the levers Afrom the

position of the fig. 18 to the one of the fig. 18a.

Crane distributor side DE2298 fig. 15.

- Select the outrigger support E2 positioning the

lever Cof the multifunction deviator on E2.

- Operate the lever to extend the support E2.

- Select the outrigger ram S2 positioning the

lever Con S2.

- Operate the lever to control the ram descent

S2.

- Select the support E3 positioning the lever C

on E3.

- Operate the lever to extend the support E3.

- Select the ram S3 positioning the lever C on

S3.

- Operate the lever to control the ram descent

S3.

c IX

17

CONTROLS

TO STABILIZE

THE VEHICLE

F 240

Distributor side

fig. 13

C

fig. 15

fig. 15a

D

Double control side

fig. 14

C

fig. 16

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

N.B. The lever, if in other positions, does not allow any operations as a

security device keeps it in free position.

Crane double control side DE2297 fig.14-16

- Select the support E1 positioning the lever Con E1.

- Operate the lever to extend the support E1.

- Select the ram S1 positioning the lever Con S1.

- Operate the lever to control the ram descent S1.

- Select the support E4 positioning the lever Con E4.

- Operate the lever to extend the support E4.

- Select the ram S4 positioning the lever Con S4.

- Operate the lever to control the ram descent S4.

N.B. The lever, if in other positions, does not allow any operations

as a security device keeps it in free position.

(!) ATTENTION (!)

During the stabilisation operations, for each outrigger ram, it is

recommended to DESCENT the outrigger as last manoeuvre.

(!) ATTENTION (!)

The complete extension of the outrigger supports is visually indicated by

the yellow triangle which is found at the end of the beam. (Fig. 18b)

The stabilization has to be carried out with care and gradually keeping

the vehicle in horizontal levelled condition to prevent springs overloads

and chassis torsions.

After having completed the descent and stabilisation manoeuvres, close

the taps of the valves placed on the outrigger rams.

Manoeuvres for re-entry of the crane outriggers and

supplementary outriggers within the overall vehicle

width after crane use.

- Position lever Dof oil diverter crane-outriggers ( - E/S)

on E/S. Fig. 15b

- Open all the taps of the valves placed on the outrigger rams

(fig. 17).

(!) WARNING (!)

Under no circumstances put the hands on the locking devi-

ces of the outrigger supports; the device re-hook (lever A

from position of fig. 18b to fig. 18) is automatic.

Crane distributor side

- Select the outrigger ram S2 positioning the lever Con S2.

- Operate the lever to control the re-entry of the ram S2.

- Select the outrigger support E2 positioning the lever Con

E2.

- Operate the lever to control the re-entry of the support E2.

- Select the ram S3 positioning the lever Con S3.

- Operate the lever to control the re-entry of the ram S3.

- Select the support E3 positioning the lever Con E3.

- Operate the lever to control the re-entry of the support E3.

NB The lever, if in other positions, cannot be operated as a

safety device keeps it in neutral position.

c IX

CONTROLS

TO STABILIZE

THE VEHICLE

F 240

18

A

fig. 18

fig. 18a

fig. 17

fig. 15b

D:E-S

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

Double control side

- Select the ram S1 positioning the lever Con S1.

- Operate the lever to control the re-entry of the ram S1.

- Select the support E1 positioning the lever Con E1.

- Operate the lever to control the re-entry of the support E1.

- Select the ram S4 positioning the lever Con S4.

- Operate the lever to control the re-entry of the ram S4.

- Select the support E4 positioning the lever Con E4.

- Operate the lever to control the re-entry of the support E4.

NB The lever, if in other positions, cannot be operated as a

safety device keeps it in neutral position.

(!) Always check that the outriggers supports, once in their

rest position, are locked in their seat by the safety devices,

so as to assure the impossibility of accidental movements.

(Fig. 18)

(!) It is compulsory to close the outriggers rams valves taps

before moving the truck. (Fig. 17)

Tiltable outrigger rams (on request) fig. 19 - 19a

Outrigger rams which allow to be rested in an inclined position, when obstruc-

tions on the vehicle chassis prevent their vertical stowability. They are sup-

ports with articulation to be put between the outrigger supports and rams; the

fixed part is screwed to the outrigger supports and the mobile one to the

outrigger rams.

After the extension of the lateral outrigger supports, place the outrigger ram in

a working condition as follows:

— Remove the check pin and the locking pin from their position (fig. 19),

hand carrying the ram.

— Carefully position the ram, insert the locking pin in its new seat and secure

it with the check pin (Fig. 19a)

To re-position the rams in folded condition:

- Remove the check pin and the locking pin from their position.

- Carefully rotate the ram in a upward direction, insert the locking pin in its

new seat and secure it with the check pin.

(!) The locking pin is constructed from special material

- do not replace it with a non original part

- your security depends on it

c IX

CONTROLS

TO STABILIZE

THE VEHICLE

F 240

19

fig. 17

fig. 18b

fig. 19 fig. 19a

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

c IX

CONTROLS

TO STABILIZE

THE VEHICLE

F 240

20

VERSION WITH BOTH SIDES CONTROLS 01 - 09 (optional)

The controls to stabilize the vehicle are activated only at ground level and

are on both sides of the crane base.

The control of the stabilizers is operated by a special “8 functions” oil-diver-

ter. With the same lever, of the oil-diverter, it is possible to select the function

and to control the outrigger supports or the outrigger rams.

–

To select a function (outrigger support or ram) operate as on a oil-diverter

positioning the lever as indicated in the plate DE2455 and DE2456 placed

on the controls.

–

To control a lever operate it as on a distributor; an internal device of the

oil-diverter assure the positionning and the selecting stability.

The extension and re-entry of the outrigger supports and rams indicated on

the plates of the fig. 20-23 coincide with what reported on the plates

(DE2455 distributor side and DE2456 double control side) placed on the

controls on both sides of the base.

The symbols placed on the plates define the function in relation with their

movement.

Lever function D- C

–

Lever DOil diverter crane-outriggers ( - E/S).

Fig. 22 - 22a

–

Lever CMultifunction oil diverter to select and control the outrigger

support and ram application for crane and supplementary beam.

Fig. 21 - 24

C

D E/S

fig. 20a fig. 20

fig. 21 fig. 22

fig. 22a

DISTRIBUTOR

SIDE

D

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

This manual suits for next models

1

Table of contents

Other Fassi Construction Equipment manuals

Popular Construction Equipment manuals by other brands

GÜDE

GÜDE GRW 1811.1 TWIN Translation of the original instructions

BUFFALO TURBINE

BUFFALO TURBINE BT-CYC8KKM Original instructions and parts manual

METBERG

METBERG T3000 Operation manual

Lissmac

Lissmac MAB 1200 operating manual

Case

Case TX130--30 Workshop manual

Rocol

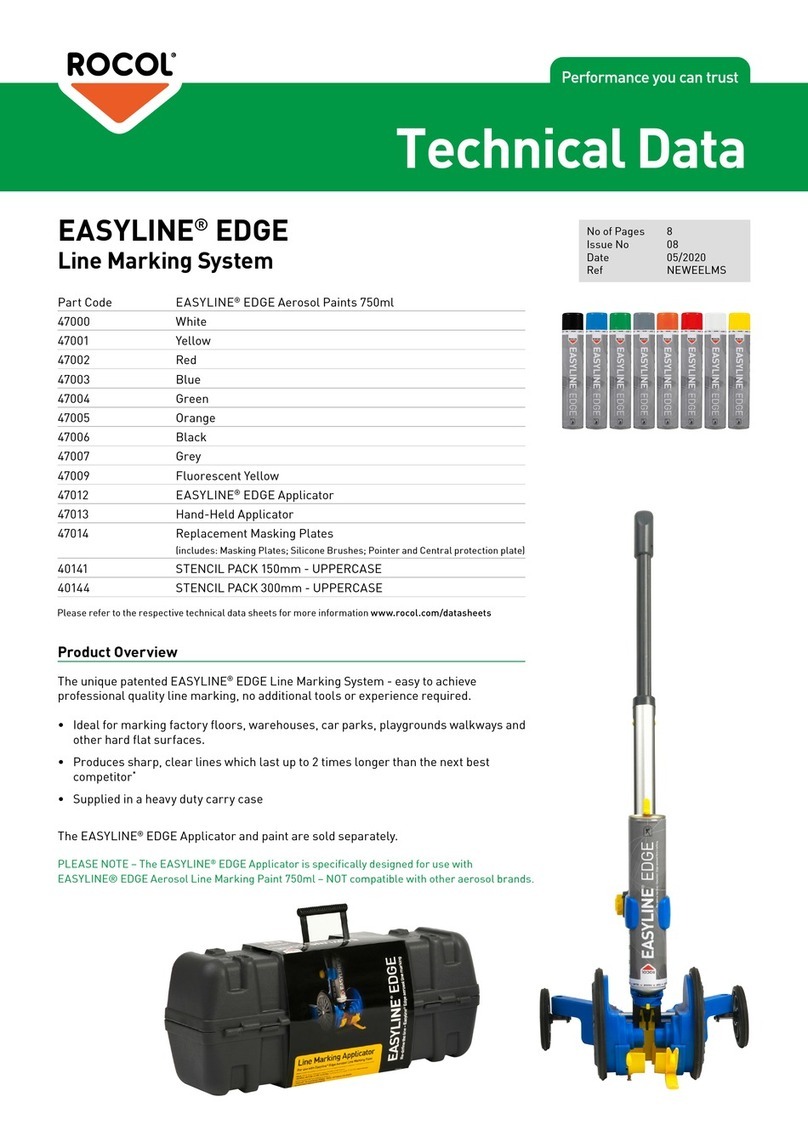

Rocol EASYLINE EDGE Line Marking System Technical data