Fassi F 170A.23 User guide

1

FASSI CRANE

F 170A.23

use and maintenance

FROM SERIAL NUMBER *3001*

INDEX OF PARAGRAPHS

A0 INTRODUCTION

B0 SAFETY NORMS

C0 WARNING AND INSTRUCTIONS

C0.1 Before operating

C0.2 During operation

C0.3 At the end of the operation (Prior to driving the vehicle)

D0 CLASSIFICATION OF THE CRANE MODEL

D0.1 Technical data

D1 IDENTIFICATION OF THE CRANE MODEL

D1.1 Crane mark

D1.2 Crane mark

E0 CRANE NOMENCLATURE

E0.1 Crane with ground controls and (on request) Crane with ground controls

and with top seat controls by hand cables

E0.2 Crane with top seat controls and with ground controls for outriggers

F0 NOMENCLATURE OF THE SAFETY AND PROTECTION DEVICES

F0.1 Crane with ground controls and (on request) Crane with ground controls

and with top seat controls by hand cables

F0.2 Crane with top seat controls and with ground controls for outriggers

F1 NOMENCLATURE OF THE SAFETY AND PROTECTION DEVICES

F1.1 Crane with ground controls and (on request) Crane with ground controls

and with top seat controls by hand cables

F1.2 Crane with top seat controls and with ground controls for outriggers

G0 SUPPLEMENTARY BEAMS

G0.1 Identification of the supplementary beams

G1 TILTABLE OUTRIGGER RAMS

G2 MANOEUVRES AND CONTROLS TO STABILIZE THE VEHICLE

G2.1 Supplementary beam; manual extension of the outrigger supports

G2.2 Functions of control levers for stabilization

G2.3 Controls to stabilize the vehicle

G2.4 Bilateral controls to stabilize the vehicle

H0 CONTROLS TO OPERATE THE CRANE

H0.1 Manoeuvres to unfold the crane into a working condition

H0.2 Manoeuvres to fold the crane into the rest condition

Edition 25.09.2000

H0.3 Manoeuvres to unfold the crane "C" into a working condition

H0.4 Manoeuvres to fold the crane "C" into the rest condition

H1 MANOEUVRES OF THE CRANE LOADS

H1.1 Lifting moment limiting device “intelligent type”

H1.2 Lifting moment limiting device for two working sectors (optional)

H1.3 Control panels

H1.4 Reactivation button of crane functions with standard distributor in the

absence of the electric power

H1.5 Emergency exclusion screw of the lifting moment limiting device

(crane with standard distributor)

H1.6 Emergency tap lever of the lifting moment limiting device

(crane with Danfoss distributor)

H1.7 Rotation limiting device

H2 MANOEUVRES OF THE CRANE LOADS

H2.1 Load limiting device

H2.2 Lifting moment limiting device “intelligent type” (optional)

H2.3 Reactivation button of crane functions with standard distributor in the

absence of the electric power

H2.4 Emergency exclusion screw of the lifting moment limiting device

(crane with standard distributor)

H2.5 Emergency tap lever of the lifting moment limiting device

(crane with Danfoss distributor)

L0 USE OF IMPLEMENTS

L0.1 Hydraulic connections for implements - supplementary hoses

L1 MANUAL EXTENSIONS

L2 CONTROLS TO OPERATE THE HYDRAULIC IMPLEMENTS OF THE CRANE

L3 WINCH

L3.1 Winch for crane

L3.2 Winch for crane

L4 HYDRAULIC JIBS

L4.1 Identification of the hydraulic jib

L4.2 Nomenclature of the hydraulic jib

L4.3 Manoeuvres to unfold the jib in working condition

L4.4 Manoeuvres to fold the jib in rest condition

L4.5 Operations to remove the hydraulic jib from the crane

L4.6 Operations to mount the hydraulic jib on the crane

M0 MAINTENANCE INSTRUCTIONS

M0.1 At the end of every working day

M0.2 After the first 40 hours use

M0.3 After every working week

M0.4 After every 500 working hours

M0.4 Complete overhaul of the crane

N0 TABLE OF HYDRAULIC OIL and lubricants characteristics

P0 POSSIBLE FAULTS

P0.1 Operations which can be carried out by the user

P0.2 Operations to be carried out by a service center

R0 INSTRUCTION AND WARNING PLATES

S0 HYDRAULIC SCHEMATICS FOR CRANE

S1 HYDRAULIC SCHEMATICS FOR CRANE

T0 ELECTRIC SCHEMATICS FOR CRANE

T1 ELECTRIC SCHEMATICS FOR CRANE

V0 CAPACITY PLATES FOR CRANE WITH

LIFTING MOMENT LIMITING DEVICE

V1 CAPACITY PLATES FOR CRANE WITHOUT

LIFTING MOMENT LIMITING DEVICE

2

FASSI CRANE

F 170A.23

use and maintenance

THANK YOU FOR SELECTING ONE OF FASSI CRANES.

This crane is the result of FASSI philosophy: ongoing research, rigorous

testing, data verification, and analysis of performances.

Many years of experience has allowed us to grant you the maximum safety of

operation together with the optimization of machine performances.

All this represents the core of FASSI quality system.

FASSI quality system is in conformity with

UNI EN ISO 9001 - ISO 9001.

The fitment of the crane on the vehicle must be carried out in accordance with

the instructions given by FASSI in the manual for hydraulic crane fitting and

the relevant chassis manufacturers directives.

The Manufacturer declines all responsibility and guarantee if the fitting is

entrusted to workshops without sufficient technical capability to carry out the

work in conformity.

Be sure that the unit has been installed, inspected and tested in accordance

with the local legal requirements.

As well as the principal safety norms, this manual contains a description of the

crane and the instructions for use and maintenance.

The following instructions refer to mobile cranes in general and must be integrated

with the manual for use supplied by the centre responsible for the crane fitting on

truck, vehicle or other type of structure.

READ THIS MANUAL CAREFULLY prior to use or any maintenance. A few minu-

tes spent now could save time and labour later.

Always conform to the safety norms and the instructions for use and maintenance

contained in the present manual in order to guarantee a long life to the crane.

FASSI GRU IDRAULICHE

NOTE

All the paragraphs marked by the symbol refer to components required

within the europen community.

The above-said components may be optional in other countries in accor-

dance with the national regulations in force.

NOTE

The original version of the present manual is in italian.

A0

INTRODUCTION

F 170A.23

3

B0 SAFETY NORMS

Strictly conform to the norms reported by the plates DE4236 (fig. 1) placed

next to the controls, in order to avoid possible accidents while operating the

crane.

Only authorized persons are allowed to operate the crane.

The crane must be used on firm, level ground.

Check that the vehicle hand brake is on and that the wheels are chocked.

Before every operation make sure that:

- no-one is within the working area of the crane;

- the safety devices are in place and operative;

- the minimum safe working distances from power lines are observed;

- the load is correctly slung and hooked.

Stabilize the vehicle by the outrigger rams, making sure that:

- the lateral supports are fully extended;

- the wheels are in contact with the ground and the suspension is not

completely unloaded.

Use the crane in accordance with the use and maintenance manual,

making sure that:

- the load and radius are within the maximum limits shown on the

crane capacity plate;

- the crane is used progressively avoiding sudden load movements

- swinging or dragging of the load is avoided;

- the load is lifted before rotating.

When using implements protect the crane working area with a barrier.

The vehicle/crane are not left unless the power take off is disengaged and the

load is on the ground.

Before driving the vehicle make sure that the outriggers are fully retracted and

re-entered, the safety taps closed and the crane is in folded position.

B0

SAFETY NORMS

F 170A

4

fig. 1

C0 WARNING AND INSTRUCTIONS

The use of the crane is reserved to authorized personnel, instructed in advance,

who has to conform to the safety norms and instructions contained in the use

manual supplied with the crane. (See norms ISO 9926-1)

It is absolutely prohibited to walk or stop under a suspended load

It is prohibited for unauthorized persons to be within the working area.

Under no circumstances interfere with the safety and protection devices.

Warning plates, as well as instruction and operation plates must be replaced

when no longer readable or missing. See Paragraph R0 Instruction and warning

plates.

Do not use the outriggers to raise the vehicle.

To avoid hitting bridges or tunnels check and record the overall height of your

crane in the folded position or in laid position in the body or on the load. Always

respect and pay proper attention to road signs placed in proximity of such

obstacles.

C0.1 Before operating

(!) ATTENTION (!)

Check that protections are in their place and that all safety devices are fitted

and active. (See norms ISO 9927-1)

Keep the ladder and the control station on the top seat, clean; the seat can tilt

forward.

Make sure that control stations are properly lit so as to ensure safety while opera-

ting and allow instruction plates to be visible.

Check that the working area is adequate and pro-

perly lighted for your crane.

Make sure that the hook is always free to rotate on

its pin and that nothing obstructs its vertical positio-

ning.

Check the efficiency of the hook safety catch.

Carefully inspect the condition of ropes or chains.

Make sure that the pallet fork is connected to the crane hook by means of a chain

having at least three (3) rings.

C0.2 During operation

Take the vehicle fumes away from the working area by fitting an extension tube of

a suitable diameter to the exhaust system.

Do not run the engine in a indoor area without first making sure there is adequate

ventilation.

When using the ladder to reach the control station on the top seat, avoid knocking

into the controls while going up or down the ladder.

The control station on the top seat is provided with side safety guards; stay within

these guards.

Make sure that no one is within the working area of the crane.

Avoid swinging the load above working and transit areas; any hidden danger

situation must be audibly alarmed.

C0

WARNING AND

INSTRUCTIONS

F 170A

5

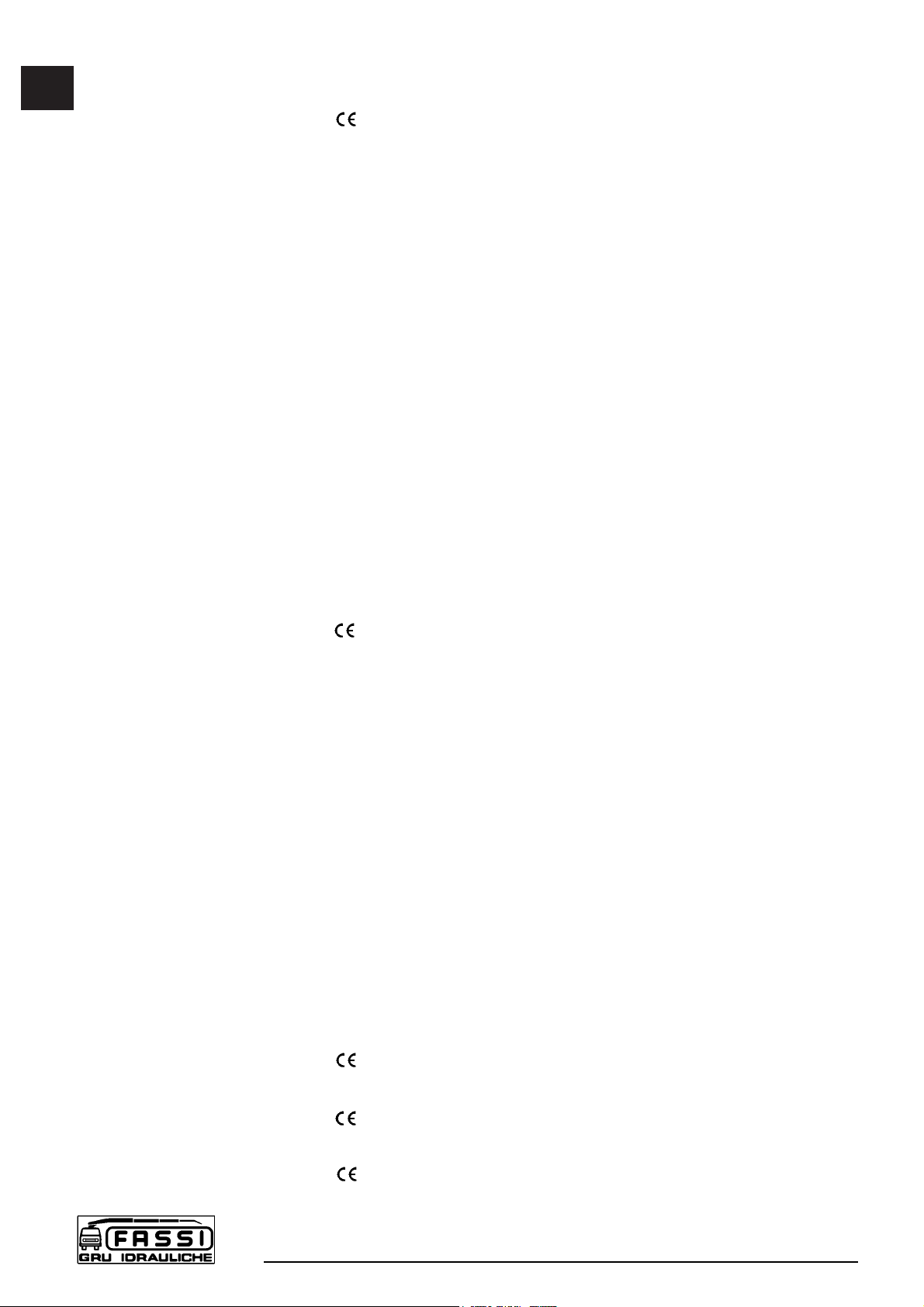

Avoid all those situations which may result in crushing during vehicle stabilization,

crane movement and load handling.

(In conformity with EN 349 standard the minimum safe working distances

to avoid crushing parts of the body)

The table indicates the minimum safety working distances concerning the various

parts of the body.

The figures illustrate circumstances which may turn out to be dangerous if you fail

to respect the minimum safe distances and if it is impossible to introduce larger

parts of the body.

(!) ATTENTION (!)

Failure to respect the minimum safe distances may result in a safety hazard

and a deadly risk.

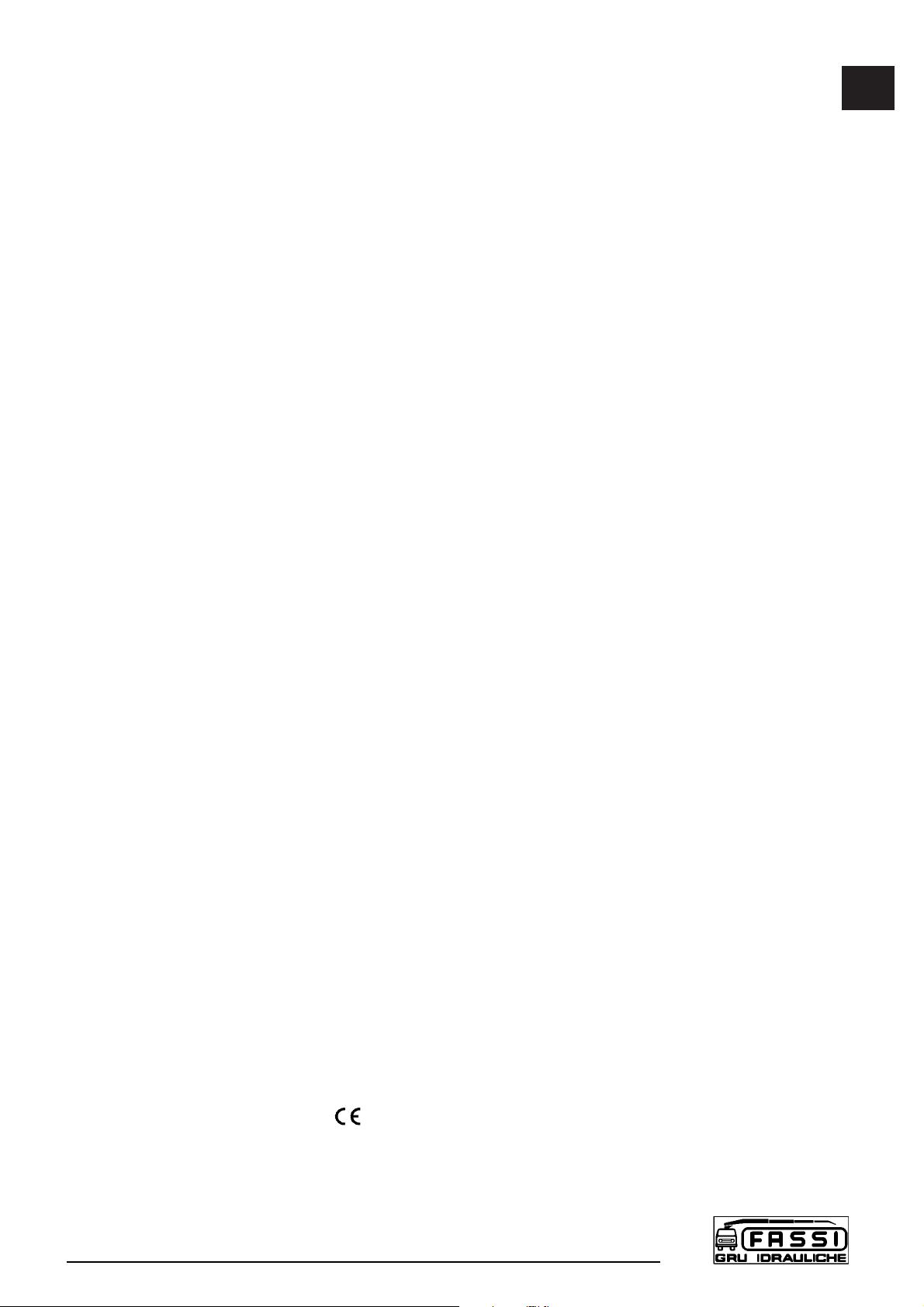

Remember that

the stability of

the unit (crane-

vehicle) is only

guaranteed by

the complete

lateral extension

of the outriggers

and by the observance of the capacity plates.

Stabilize the vehicle on a horizontal plane with a maxi-

mum tolerance of 1,5 degrees. Make sure that the outrig-

ger rams rest on a solid base, if necessary use larger

outrigger base plates (available on request) to avoid

sinking. If you adopt other means, make sure that they

are suitably sized for the load they must bear.

(!) ATTENTION (!)

Respect the distances di sicurezza from electric

lines; the minimum distance is, according to CEN

norms, five (5) meters, except for otherwise prescribed by national norms.

C0.2

WARNING AND

INSTRUCTIONS

F 170A

6

Parts Minimum safe Figure

of the working

Body distance mm

Body

500

Leg 180

Toes

50

Hand

Wrist

100

Fist

Parts Minimum safe Figure

of the working

Body distance mm

Head

300

Foot

120

Arm

120

Finger

25

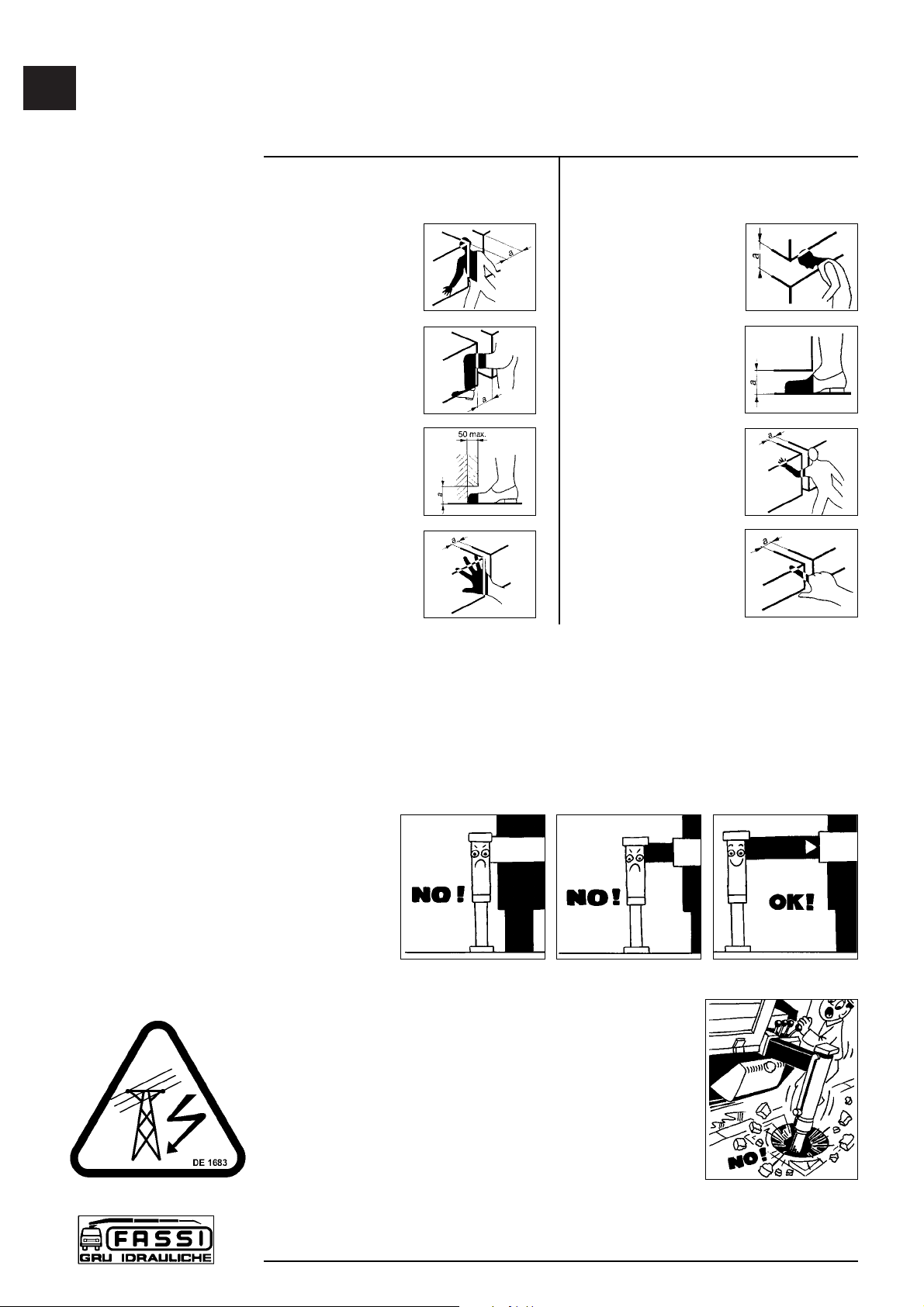

(!) ATTENTION (!)

Failure to respect the minimum safe distan-

ces may result in electrical hazards for the

operator and his assistants.

(!) ATTENTION (!)

Do not utilize the crane with wind speed

exceeding 12,5 m\s (value 6 of the Beaufort

scale).

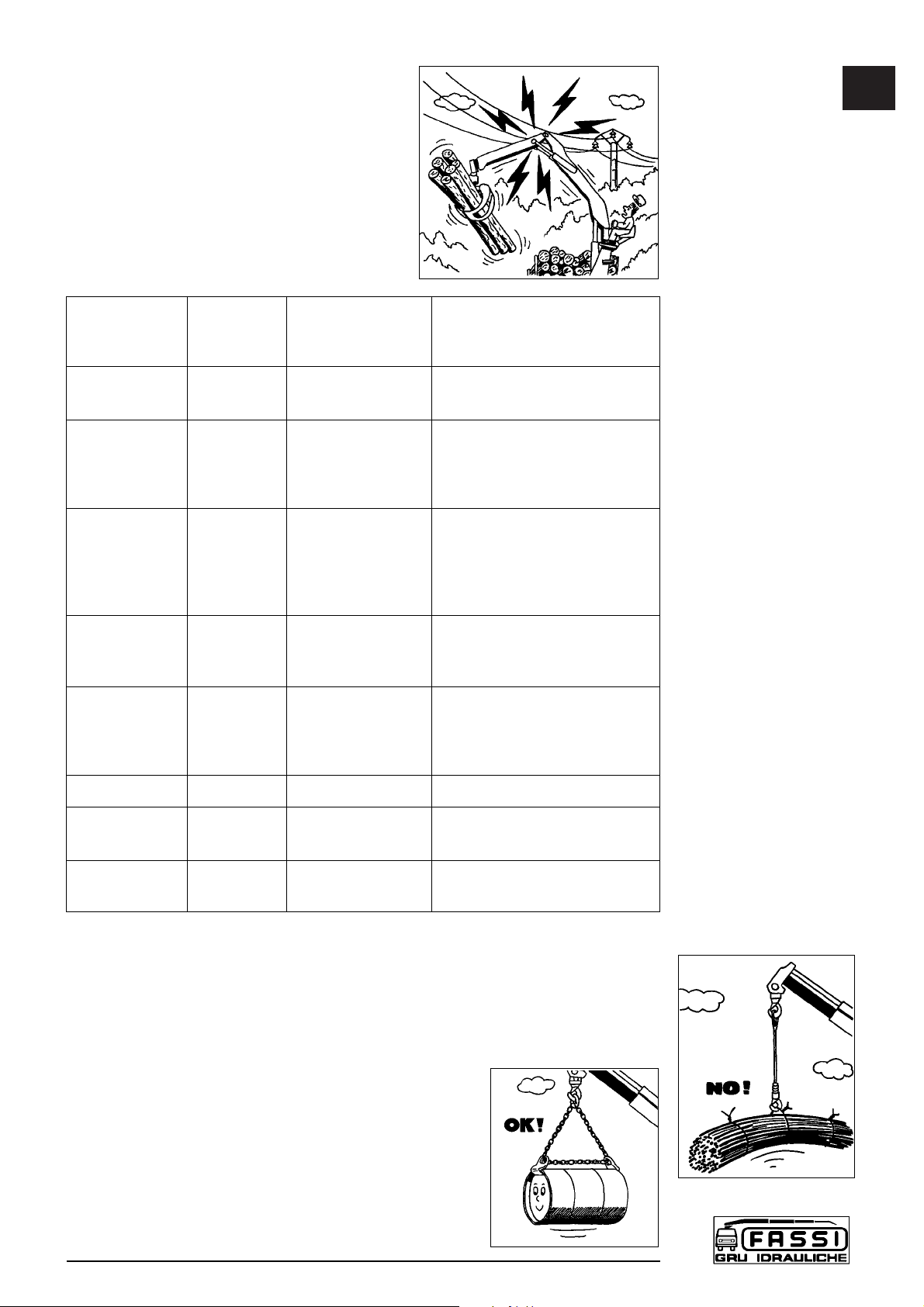

Indications about wind speed

Force of the Wind speed Classification Characteristics

wind m/s

Beaufort scale

0 0,0 - 0,2

Calm

Calm wind, smoke goes up

quite vertically

1 0,3 - 1,5

Light breeze

Smoke reveals the direction

2 1,6 - 3,3 of the wind, one can feel the

wind blowing, leaves start

fluttering.

3 3,4 - 5,4 Moderate breeze Leaves and branches are

4 5,5 - 7,9 in constant motion, small

branches start fluttering.

Dust and papers dance on

the ground.

5 8,0 - 10,7 Fresh breeze Small green branches bend,

the surface of waterways and

lakes are wavy.

6 10,8 - 13,8 Near gale Big branches bend, wind

whistles through high-tension

cables, it's difficult to walk

keeping the umbrella open.

7 13,9 - 17,1 Moderate gale Trees sway, it's hard to walk.

8 17,2 - 20,7 Storm wind Branches get broken,

it's hard to walk.

9 20,8 - 24,4 Storm It damages houses (antennas

and roof tiles fall down)

(!) ATTENTION (!)

Carefully inspect the load rigging.

Hook up the load, checking that it does not exceed the capacity indicated on the

lifting diagram specific to each load configuration.

Make sure that the lifted load is balanced.

Avoid swinging the load above the control station; in

cases where the load is too close, the crane must be

operated from the opposite side.

When operating through a winch, lift the load vertically

using the cable and not the booms in order to avoid

swinging the load.

C0.2

WARNING AND

INSTRUCTIONS

F 170A

7

Do not rotate the crane before the load

is lifted.

Do not operate with sudden move-

ments, activate the controls with slow

and progressive movements; rotate

slowly and with care paying attention to

the stability of the vehicle.

With vertical lift, on hydraulic and

mechanical extension, rotate slowly in

order to avoid side-skidding.

(!) ATTENTION (!)

Do not utilize the crane for pushpull

(F), lateral (F) or sideways (F) opera-

tions.

(!) ATTENTION (!)

Crushing (F) or push (F) manoeuvres

are not permitted.

(!) Never operate the outriggers

when the crane is loaded.

(!) ATTENTION (!)

The vehicle\crane must not be left

unless the load is on the ground, the

booms of the crane (and of the

hydraulic jib), are folded and laid on

a solid base and the power take-off

is disengaged.

Do not move the vehicle if a load is suspended on the crane.

C0.3 At the end of the operation (Prior to driving the vehicle)

Fold the crane.

If the booms of the crane of the crane

(or of the hydraulic jib) are to be laid on

the body or on the load, they must be

suitably blocked to prevent possible

sideways movements.

Make sure that the indications about

the overall dimensions are respected.

NOTE

Implements can be left mounted on the booms of the crane (or of the hydraulic

jib) only if the overall dimensions are respected; they must be suitably blocked to

prevent possible sideways movements.

Make sure that the outrigger supports and rams are re-entered within the overall

width of the truck and locked by the safety devices.

Disengage the power take off.

C0.3

WARNING AND

INSTRUCTIONS

F 170A

8

D0 CLASSIFICATION OF THE CRANE MODEL

The design of this crane has been carried out in respect of DIN 15018 norms,

fatigue test classification H1B3.

The crane can operate, intermittently, with lifting devices other than the hook.

The dimensions and the capacity of the implements must be proportioned with

crane performances.

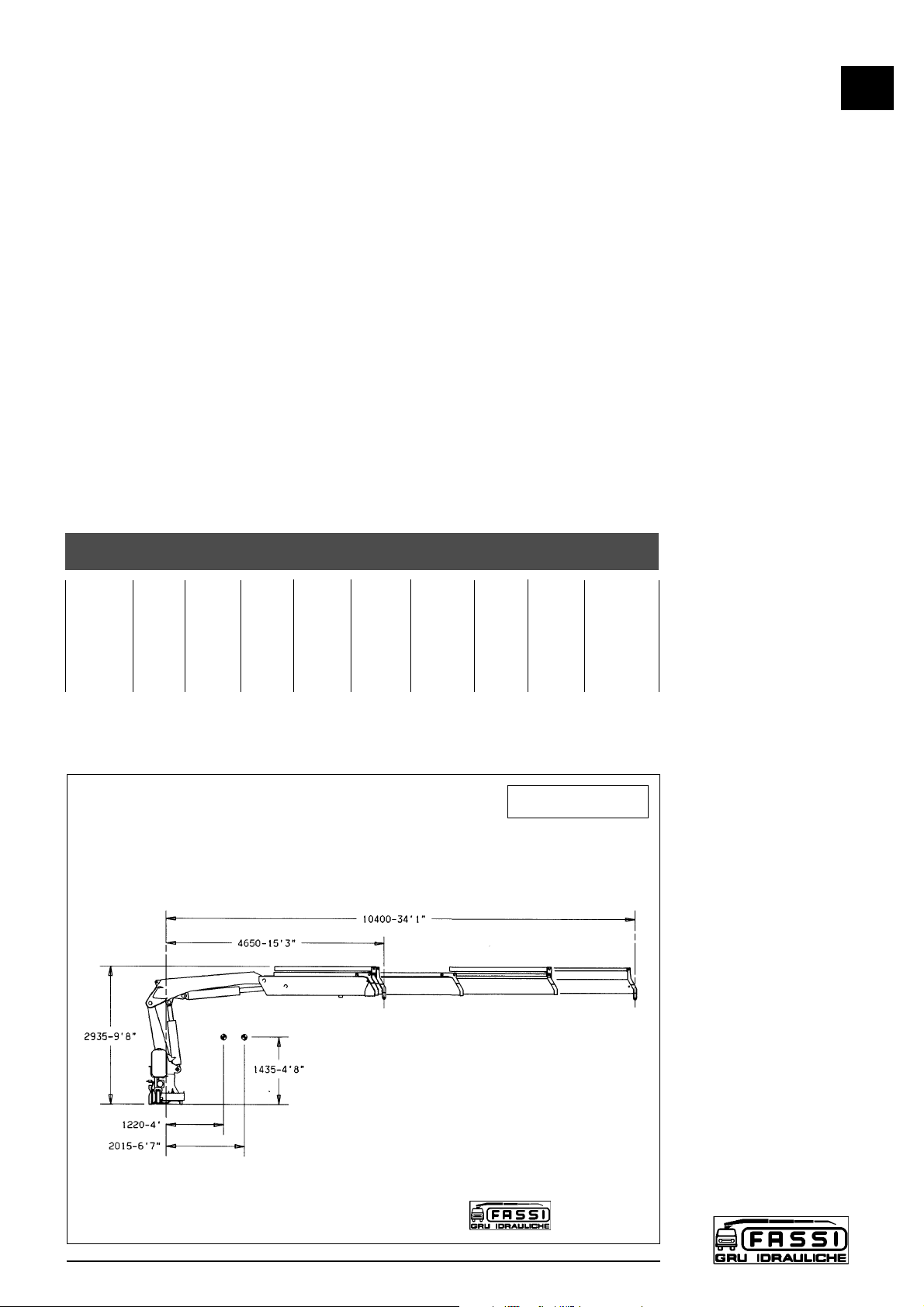

D0.1 Technical data

D0

CLASSIFICATION OF

THE CRANE MODEL

F 170A.23

9

ST 170

F170A.23

F 170A.23

Lifting Standard Hydraulic Rotation Rotation Working Pump Oil tank Crane Max. working

capacity reach extension arc torque pressure capacity capacity weight pressure

on the outrigger

(Φ200)

15,39 tm 10,40 m 5,75 m 400° 2,86 tm 29,5 MPa 40 l/min 120 l 2305 kg 30 daN\cm2

151,0 kNm 28,1 kNm

D0.1

CLASSIFICATION OF

THE CRANE MODEL

F 170A.23

10

ST 170

MASSIMA ALTEZZA SOTTOGANCIO.

HAUTEUR MAXIMUM SOUS CROCHET.

MAXIMUM HOOKING POSITION.

MAXIMALHOEHE BIS KRANHAKEN.

ST 170

— MEZZERIA TIRANTI

— FIXING ROD CENTER

DISTANCE

— LIGNE MEDIANE

TIRANTS

— ABMESSUNG DER

BEFESTIGUNGSBRIDEN

M24 x 2

1395 4’ 7’’

5010 16’ 5’’

780 4’ 7’’

A

B

C

STANDARD

1705 5’ 7’’

5630 18’ 6’’

765 2’ 6’’

A

B

C

EXTRA

2040 6’ 8’’

6300 20’ 8’’

765 2’ 6’’

A

B

C

SUPER-EXTRA

F170A.23

F170A

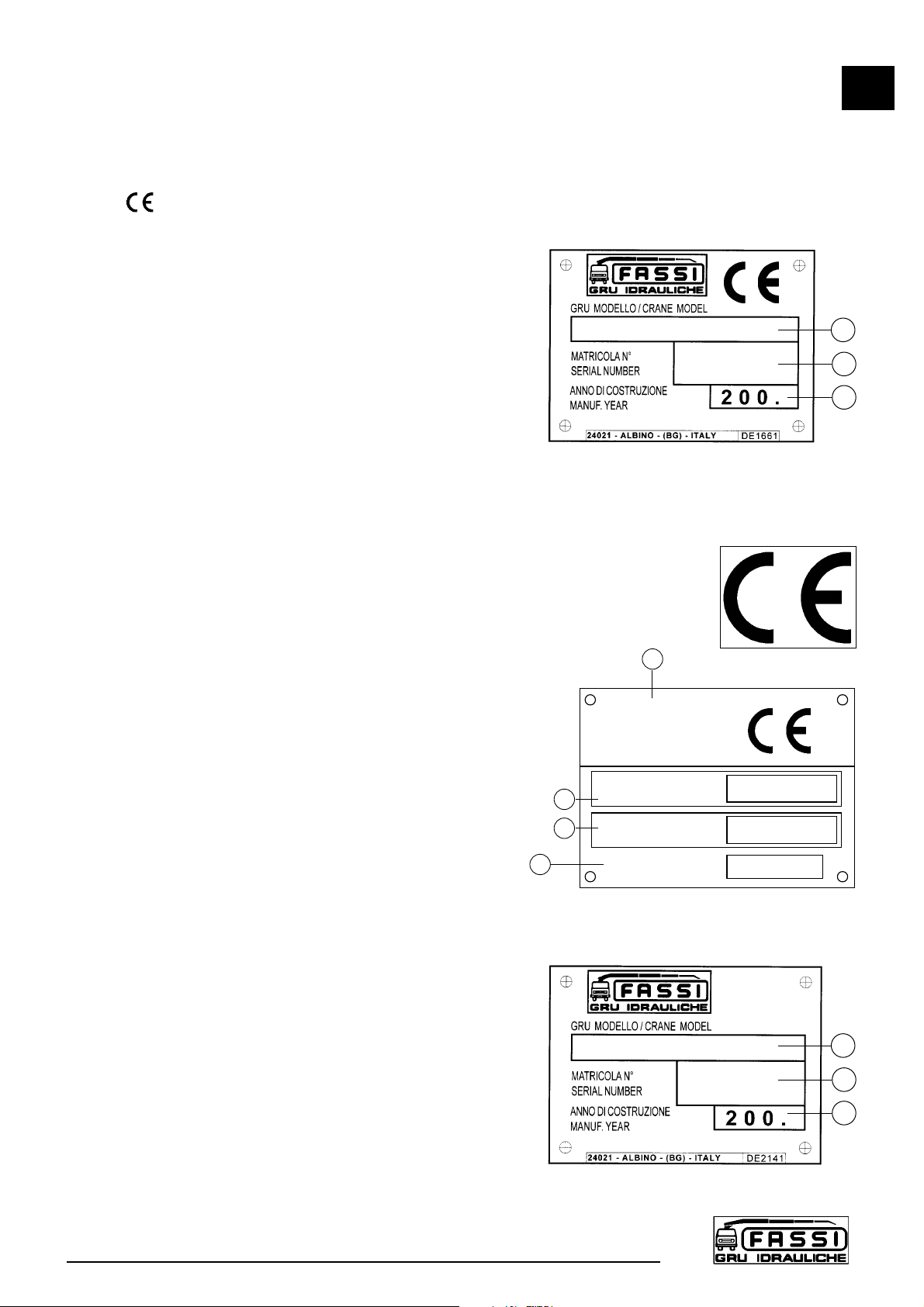

D1 IDENTIFICATION OF THE CRANE MODEL

The exact crane model, serial number and description of implements will

enable FASSI Service Department to give a rapid and efficient response.

D1.1 Crane mark

The CE indicates that the crane complies with the Machines

Directive (D.M.) 98/37; it can be considered effective only

with a written declaration of conformity enclosed. The crane

affixed with the CE mark is supplied with a lifting moment

limiting device to preserve the crane structure from over-

loads.

Identification data are marked on the plate DE1661 used for

the CE mark (fig. 2) and fixed on the base

1 - Crane model

2 - Serial Number

3 - Year of manufacturing

The crane must not be put into service within the European Community unless

the machine on which it is mounted also conforms with the prescribed Directive.

Ever change of use, modification or addition of accessories, not specified

by this manual must be affixed with a new CE mark in accordance with the

Machinery Directive.

A further metallic plate (fig. 3) fixed to the crane by the installer,

quotes the identifying data of the equipment and the final CE

mark.

1 - Name of the installer who applied the final

CE mark

2 - Crane mark, model and serial number

3 - Vehicle mark, model and chassis number

4 - Year of mounting

D1.2 Crane mark

Identification data of the crane are marked on the plate

DE2141 and fixed on the base. (fig. 4)

1 - Crane model

2 - Serial Number

3 - Year of manufacturing

(!) UNDER NO CIRCUMSTANCES SHOULD THE DATA

MARKED ON THE PLATES BE ALTERED.

D1

IDENTIFICATION OF

THE CRANE MODEL

F 170A

11

fig. 2

fig. 4

2

1

3

2

1

3

fig. 3

CRANE - MARK AND MODEL

SERIAL NUMBER

TRUCK - MARK AND MODEL

TRUCK FRAME SERIAL NUMBER

YEAR OF MOUNTING

2

3

1

4

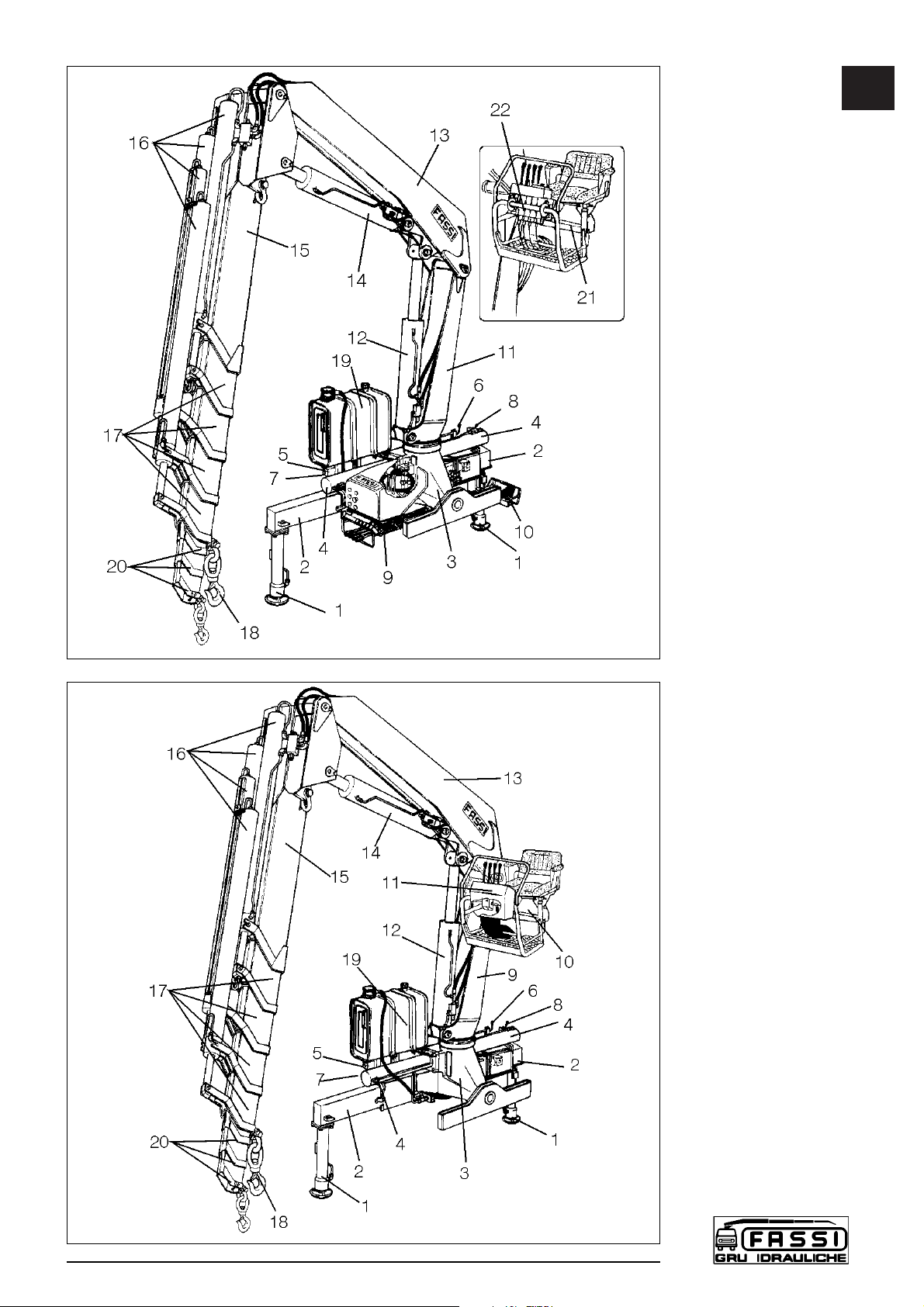

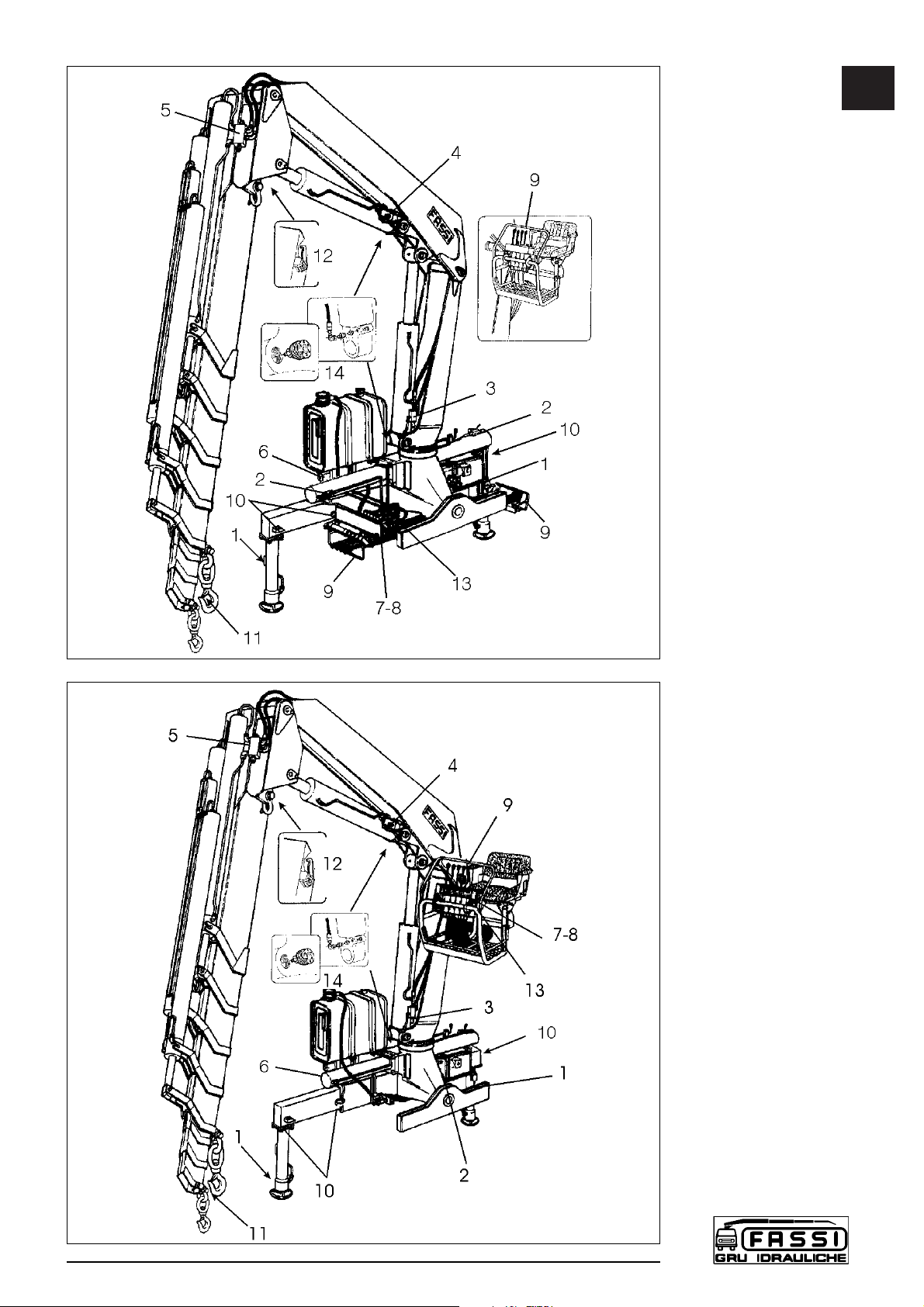

E0 CRANE NOMENCLATURE

E0.1 Crane with ground controls.

Crane with ground controls and with top seat

controls by hand cables (on request) (fig. 5).

Pos. Description

1. Outrigger rams

2. Outrigger supports

3. Base

4. Rotation cylinders

5. Deviator crane - outriggers

6. Dual control for deviator crane - outriggers

7. Multifunction deviator

8. Multifunction transmission

9. Distributor bank

10. Double control

11. Column

12. Inner ram

13. Inner boom

14. Outer ram

15. Outer boom

16. Booms extension rams

17. Extension boom sections

18. Lifting hook

19. Oil tank

20. Manual extensions (optional)

21. Seat (optional)

22. Hand-cables for crane (optional)

E0.2 Crane with top seat controls and with ground

controls for outriggers. (fig. 6)

Pos. Description

1. Outrigger rams

2. Outrigger supports

3. Base

4. Rotation cylinders

5. Deviator crane - outriggers

6. Dual control for deviator crane - outriggers

7. Multifunction deviator

8. Multifunction transmission

9. Column

10. Seat

11. Distributor bank

12. Inner ram

13. Inner boom

14. Outer ram

15. Outer boom

16. Booms extension rams

17. Extension boom sections

18. Lifting hook

19. Oil tank

20. Manual extensions (optional)

E0

CRANE

NOMENCLATURE

F 190A

12

E0

CRANE

NOMENCLATURE

F 170A

13

fig. 5

fig. 6

F0

NOMENCLATURE OF

THE SAFETY AND

PROTECTION DEVICES

F 170A

14

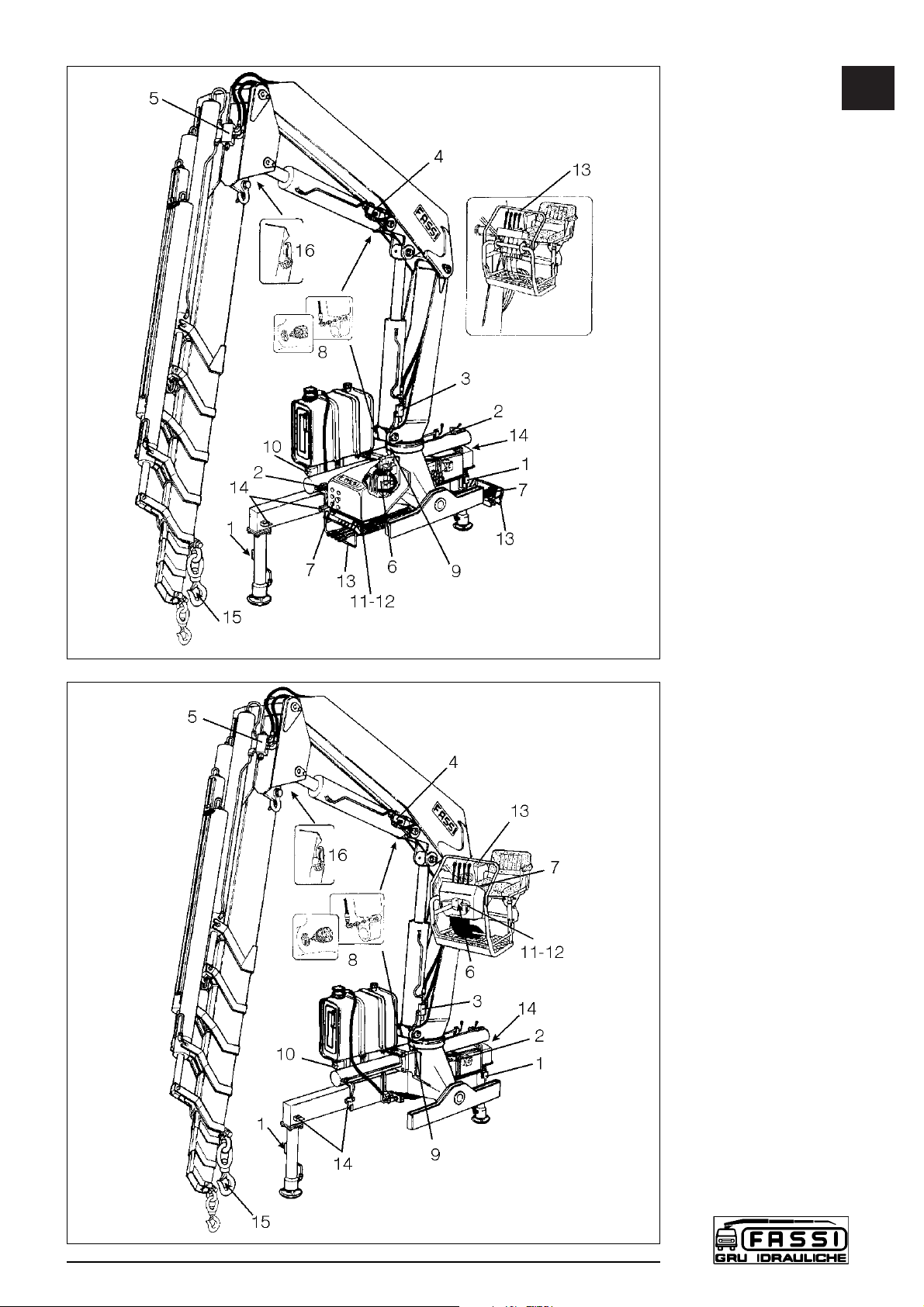

F0 NOMENCLATURE OF THE SAFETY AND

PROTECTION DEVICES

F0.1 Crane with ground controls.

Crane with ground controls and with top seat

controls by hand cables (on request) (fig. 7).

Pos. Description

1. Check valves for outrigger rams

2. Check valves for rotation control (flow regulators)

3. Check valve for inner ram

4. Check valve for outer ram

5. Check valve for booms extension rams

6. Lifting moment limiting device assembly

7. Control panels

8. Parachute valves

9. Rotation limiting device (optional)

10. Main pressure valve (outriggers)

11. Main pressure valve (crane)

12. Auxiliary valves (crane)

13. Levers guard

14. Safety device for outriggers supports

15. Hook safety device

16. Safety device for extension booms (only for the crane version “C”)

F0.2 Crane with top seat controls and with ground

controls for outriggers. (fig. 8)

Pos. Description

1. Check valves for outrigger rams

2. Check valve for rotation control

3. Check valve for inner ram

4. Check valve for outer ram

5. Check valve for booms extension rams

6. Lifting moment limiting device assembly

7. Control panel

8. Parachute valves

9. Rotation limiting device (optional)

10. Main pressure valve (outriggers)

11. Main pressure valve (crane)

12. Auxiliary valves (crane)

13. Levers guard

14. Safety device for outriggers supports

15. Hook safety device

16. Safety device for extension booms (only for the crane version “C”)

Before crane use check that safety and protection devices are fitted and

active.

Under no circumstances interfere with the safety and protection devices.

Interference with the check valves and removal of the lead seal remove

the Manufacturer and invalidate the warranty.

Use the ladder for the access to the top seat.

F0

NOMENCLATURE OF

THE SAFETY AND

PROTECTION DEVICES

F 170A

15

fig. 7

fig. 8

F1

NOMENCLATURE OF

THE SAFETY AND

PROTECTION DEVICES

F 170A

16

F1 NOMENCLATURE OF THE SAFETY AND

PROTECTION DEVICES

F1.1 Crane with ground controls.

Crane with ground controls and with top seat

controls by hand cables (on request) (fig. 9).

Pos. Description

1. Check valves for outrigger rams

2. Check valves for rotation control (flow regulators)

3. Check valve for inner ram

4. Check valve for outer ram

5. Check valve for booms extension rams

6. Main pressure valve (outriggers)

7. Main pressure valve (crane)

8. Auxiliary valves (crane)

9. Levers guard

10. Safety device for outriggers supports

11. Hook safety device

12. Safety device for extension booms (only for the crane version “C”)

13. Lifting moment limiting device assembly (optional)

14. Parachute valves (when the lifting moment limiting device is fitted)

F1.2 Crane with top seat controls and with ground

controls for outriggers. (fig. 10)

Pos. Description

1. Check valves for outrigger rams

2. Check valve for rotation control

3. Check valve for inner ram

4. Check valve for outer ram

5. Check valve for booms extension rams

6. Main pressure valve (outriggers)

7. Main pressure valve (crane)

8. Auxiliary valves (crane)

9. Levers guard

10. Safety device for outriggers supports

11. Hook safety device

12. Safety device for extension booms (only for the crane version “C”)

13. Lifting moment limiting device assembly (optional)

14. Parachute valves (when the lifting moment limiting device is fitted)

Before crane use check that safety and protection devices are fitted and

active.

Under no circumstances interfere with the safety and protection devices.

Interference with the check valves and removal of the lead seal remove

the Manufacturer and invalidate the warranty.

Use the ladder for the access to the top seat.

F1

NOMENCLATURE OF

THE SAFETY AND

PROTECTION DEVICES

F 170A

17

fig. 9

fig. 10

G0 SUPPLEMENTARY BEAMS

Supplementary beams are used in conjunction with the crane outriggers to

ensure the vehicle stability during load handling.

Code outrigger ram outrigger extension Weight

stroke mm interaxis mm type Kg

52185 550 2132 Fixed 115

42049 550 3098 Manual 220

56681 550 3558 Manual 250

115B073 450 3098 Manual 190

115B076 450 3098 Manual-Rotating-“H” 190

145B068 650 4142 Hydraulic-“H” variable 340

145B070 340 4142 Hydraulic-“H” variable 310

330B054 520 4984 Hydraulic-“H” variable 520

330B055 340 4984 Hydraulic-“H” variable 490

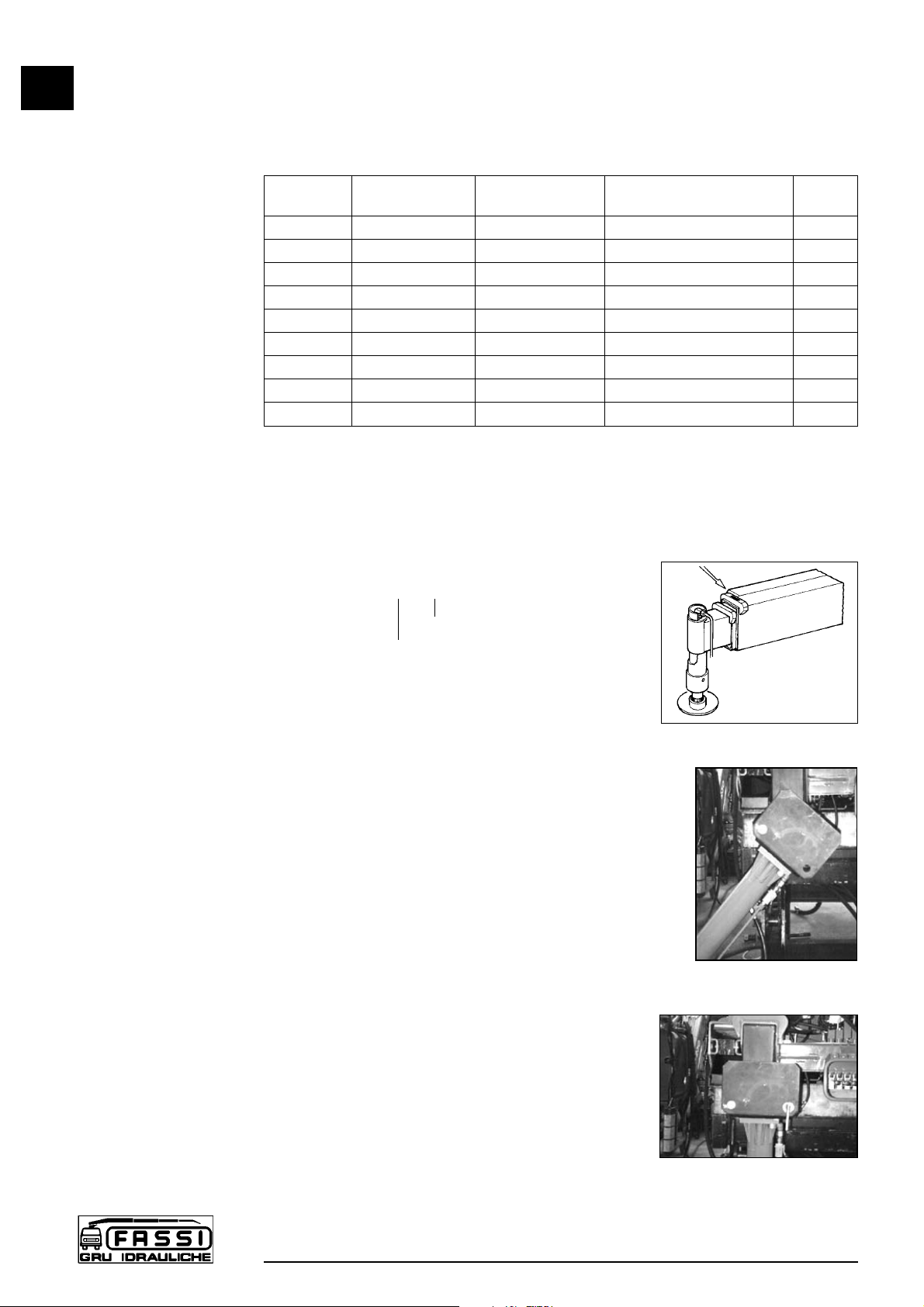

G0.1 Identification of the supplementary beams

Identification data of the supplementary beam is punched on the beam (fig. 11) in

the following sequence:

Ex. *145B070*0001

serial no.

identification code

G1 TILTABLE OUTRIGGER RAMS

Outrigger rams are allowed to be stored in an inclined

position, when obstructions on the vehicle chassis prevent

their vertical stowability. These hinged supports are placed

between the outrigger supports and the rams; the fixed

part is screwed to the supports while the mobile part is

screwed to the rams. (fig. 12-12a)

To place the rams in a working condition.

- Supporting the ram, remove the check pin and the

locking pin from their positions.

- Position, carefully, the ram in working condition,

insert the locking pin in its new position and secure

it with the check pin.

To re-position the rams to the folded position.

- Remove the check pin and the locking pin.

- Position, the ram in a upward direction and

supporting the ram, insert

- the locking pin in its new position and secure

it with the check pin

(!) The locking pin is constructed from special material

- do not replace it with a non original part

- your security depends on it

G0

SUPPLEMENTARY BEAMS

F 170A

18

fig. 11

fig. 12

fig. 12a

G2 MANOEUVRES AND CONTROLS TO STABILIZE

THE VEHICLE

The outriggers rams prevent damaging stresses both to the frame and to the

vehicle suspensions on which the crane is mounted to and assure the stability

of the unit during load handling.

Be very careful when stabilizing the vehicle; make sure that no one is or tran-

sits in close proximity of the working area of the outriggers.

(!) ATTENTION (!)

The crane stability is maintained by the maximum extension of the outrigger

supports

, by the solidity of the base underneath the plates of the outrigger rams

and by the observance of the capacity plates. To check the maximum working

pressure see Paragraph D0.1 Technical data

Check that the outrigger rams are applied on a solid base; if necessary use

larger outrigger base plates (available on request) to avoid sinking.

When stabilization is complete the wheels of the vehicle must still be in contact

with the ground and the suspensions must not be fully unloaded.

Stabilize the crane so as to operate on a horizontal plane with a maximum

tolerance of 1,5 degrees.

While loading, it may be necessary to vertically adjust the outrigger rams to

prevent an overload on the outriggers, then stabilize again.

While unloading, the outrigger rams may not be perfectly in contact

with the ground because of a rise in the suspension; it is therefore

recommended to stabilize the vehicle during operation to avoid an

overturn.

G2.1 Supplementary beam; manual extension

of the outrigger supports

(!) ATTENTION (!)

To manoeuvre the supports hands must only grab the handles

placed on the outrigger rams.

Position the lever Bof the outrigger locking device from the

pos. 1 to the pos. 2 (released position) fig. 13.

Put the lever Aof the outrigger security check from the posi-

tion of the fig. 14 to the one of the fig. 14a.

Extend the outrigger support from the base and position the

lever B to the pos. 1.

Extend the outrigger support till the coupling of the pin of the

lever B.

By the same sequence, repeat the operations described to extend the other

support.

(!) ATTENTION (!)

The complete extension of the outrigger support is visually indicated by the yellow

triangle which is found at the end of the beam. (Fig.14b)

The outrigger support is locked in position by the security pin; this will ensure the

complete extension of the outrigger support and the impossibility of accidental

movements.

G2

SUPPLEMENTARY BEAMS

F 170A

19

fig. 13

fig. 14 fig. 14a

fig. 14b

Lever B

To re-enter the outriggers repeat the operations previously described in reverse.

(!) WARNING (!)

Keep hands clear of automatic safety device (lever Afrom the position of the

fig. 14a to the one of the fig. 14).

Always make sure that the locking and security devices are correctly locked in

position so as to assure the impossibility of accidental movement.

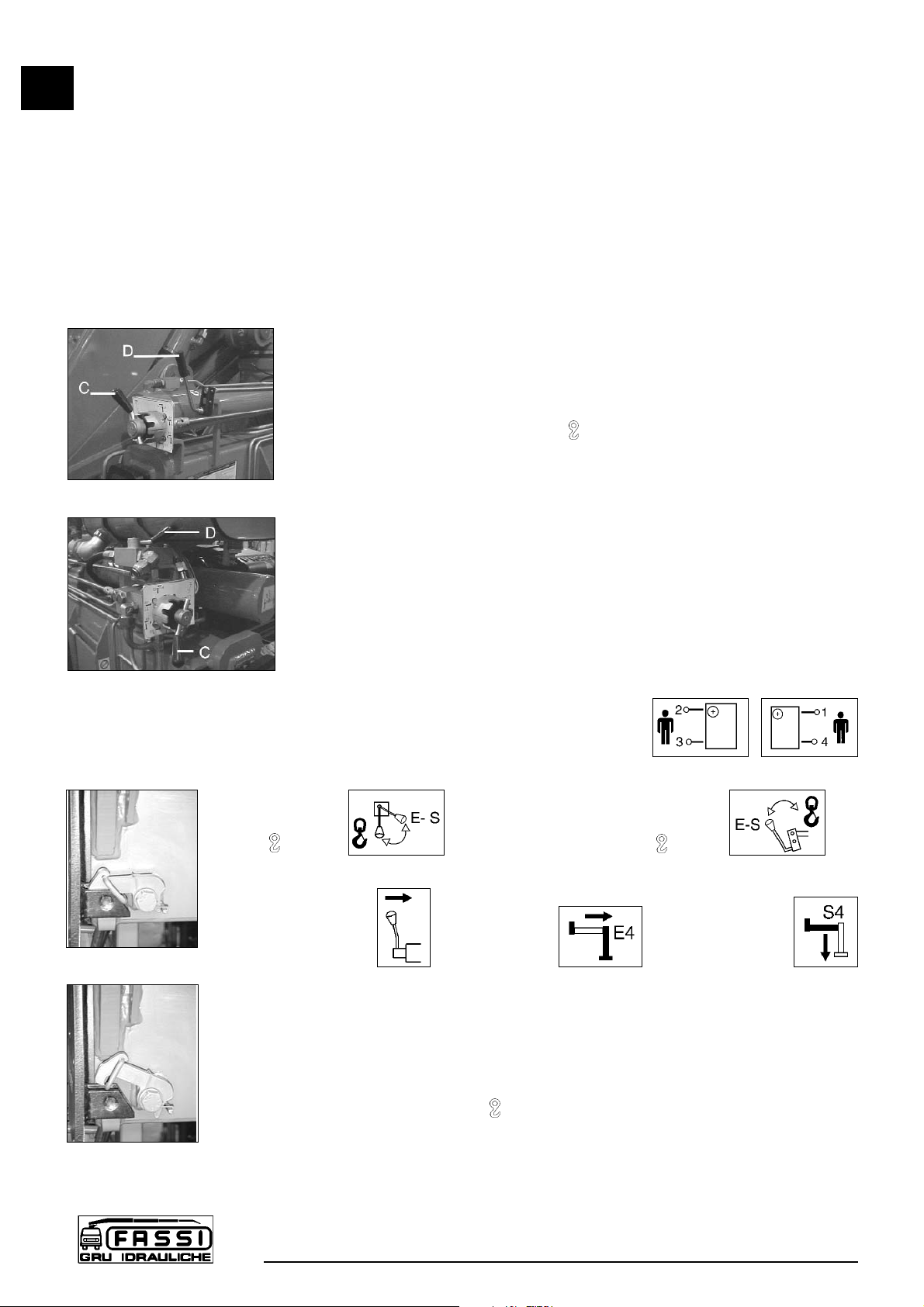

G2.2 Functions of control levers for stabilization

The controls to stabilize the vehicle are activated only from ground level and

on both sides of the crane base.

Lever function D - C (fig. 15-15a)

Levers DControl for deviator and deviator transmission

crane-outriggers ( - E/S ).

Levers CControl for multifunction deviator and multifunction

transmission for selecting and operating the supports

and the outrigger rams.

Operate the levers clockwise to select the control (multi-function deviator)

and in alternate direction to operate the required function (ram).

The deviator and the multifunction transmission are fitted with lever guide

which ensures accurate selection and operation.

NOTE The graphic symbols illustrated hereunder are marked on the

plates affixed on the deviator and on the dual or remote side

and indicate with the following symbolism

They indicate the position of the operator in relation

to the vehicle and the crane.

Lever DLever D

Deviator D/control

- E/S Deviator - E/S

Lever C

Multifunction Hydraulic

Deviator and extension Outrigger

D/control control ram control

See Paragraph R0 Instruction and warning plates.

Disengage the locking devices of the outrigger supports by putting the levers A

from the position of the fig. 14 to the one of the fig. 14a.

Position lever Dof oil diverter ( -E/S) on E/S.

G2.2

SUPPLEMENTARY BEAMS

F 170A

20

fig. 15

fig. 15a

fig. 14

fig. 14a

Table of contents

Other Fassi Construction Equipment manuals

Popular Construction Equipment manuals by other brands

Ashland

Ashland CDLR16F Installation and maintenance manual

Baileigh Industrial

Baileigh Industrial RDB-050 Operator's manual

Hog Technologies

Hog Technologies Stripe Hog SH8000 Operation manual

Dynapac

Dynapac CA 252 maintenance

Fast

Fast 8295RT INSTALLATION AND PARTS MANUAL

Torin BIG RED

Torin BIG RED TR9010 owner's manual