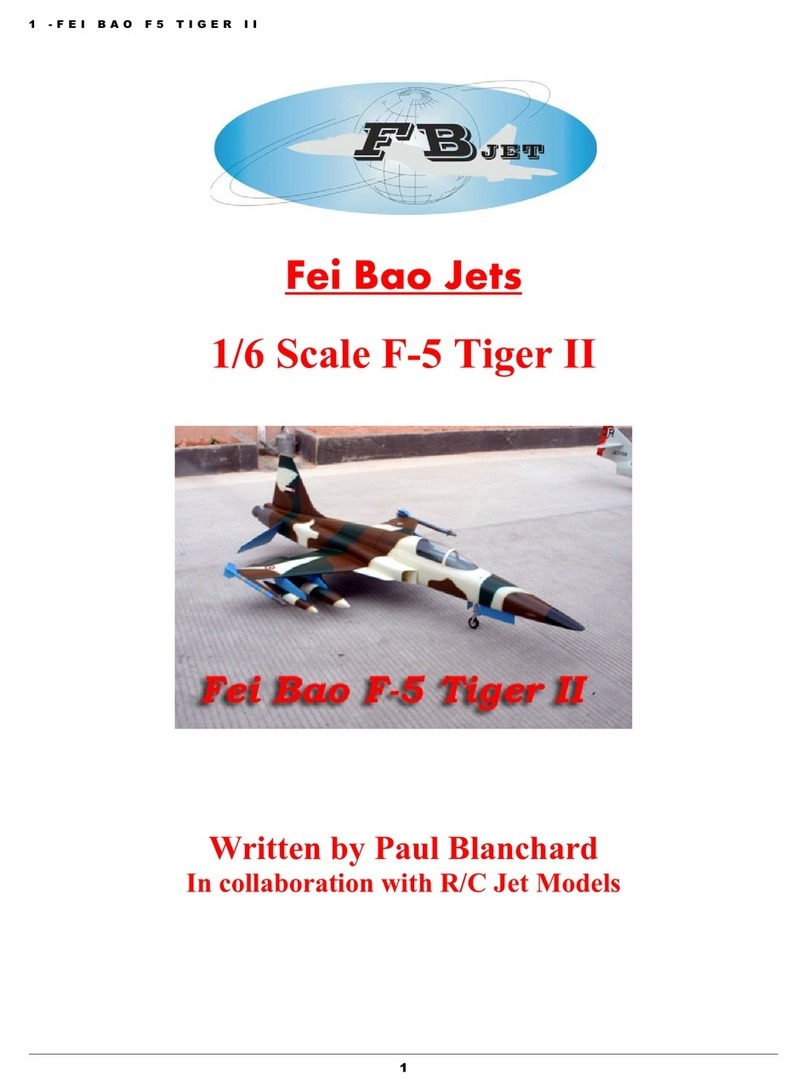

FB Jets Dolphin

DISCLAIMER:

THIS IS NOT A TOY

This is a high-performance miniature aircraft, capable of high speeds and damage to life, limb, and

property. The manufacturer and its distributors and author of this manual cannot control how you

assemble this model, what equipment you use to fit it out, or how you fly it, and can assume no

liability whatsoever for any damages that may occur when you fly your aircraft. By assembling this

model, you are agreeing to indemnify and hold blameless the manufacturer and/or his agents from

any and all torts and liability associated with the use of this product.

Please inspect all parts before beginning assembly. If any part appears to be suspect, contact your

dealer or the manufacturer for repair or replacement BEFORE you begin.

Once you have assembled the aircraft, you are the pilot in command and assume any and all

responsibility for the use of the model and any damages that might occur by flying or attempting to

fly this aircraft.

R/C model jets require a high level of skill in both their assembly and their flying. If you do not feel

confident in either your building or flying skills, PLEASE seek assistance from more experienced

modelers. It is a wise idea, no matter what level of skills you possess, to have a second

experienced modeler go over your installation after assembly. A second set of eyes may spot a

problem you have missed. If you have not flown a high performance model like this before, it is

HIGHLY recommended that you get an experienced turbine pilot to do your maiden flight. Very

often, the first few seconds of a maiden flight are critical until the aircraft is trimmed out, and having

an experienced pilot at the controls can make the difference between a wrecked aircraft and once

that enjoys many hundreds of flights. Be sure to select a suitable field for flying...take the time to

find a large paved runway if at all possible, especially for test flights, until you feel comfortable

getting the aircraft in and out of smaller grass fields.

Note: In the USA it is mandatory that you belong to the Academy of Model Aeronautics and hold a valid Turbine Waiver, please check

the local governing rules for operation of R/C model jets of your location before flying.

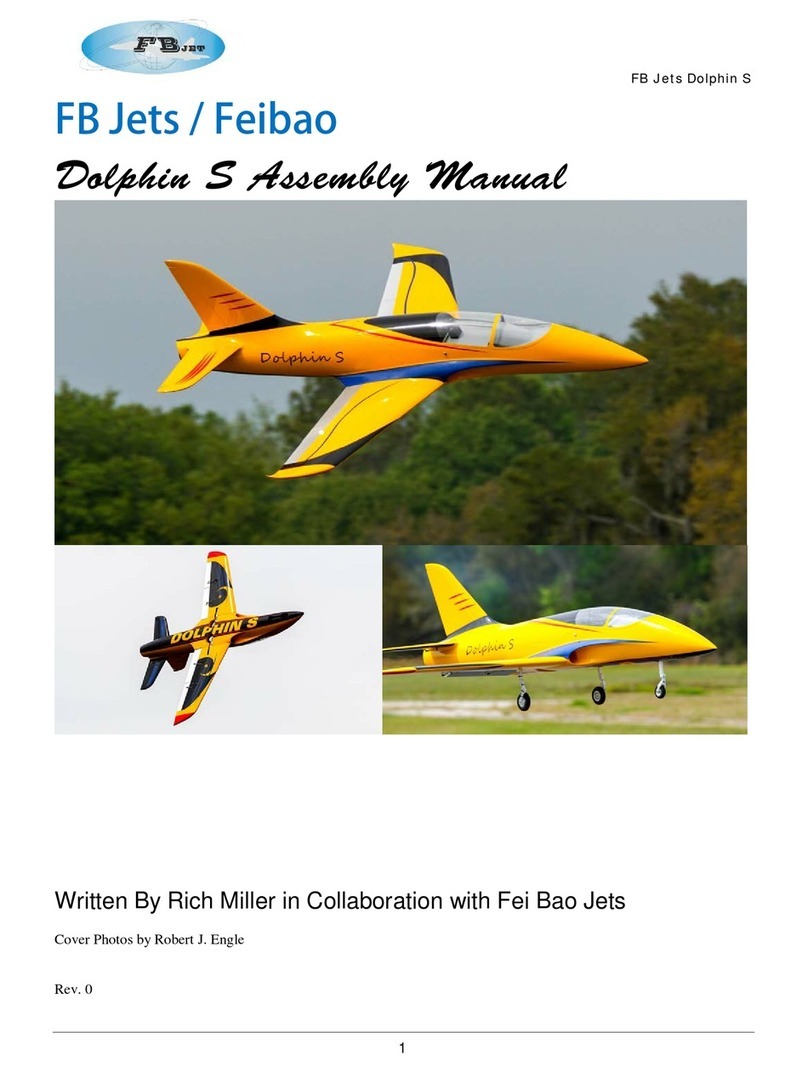

Congratulations on your purchase of the FB Jets Dolphin

Introduction

You have chosen a model that represents the pinnacle of ARF technology and factory testing with

the new manufacturing processes implemented by FB Jets. While there is not a lot of building to

do, there is enough to keep you busy for quite a few evenings. Even if you have assembled other

ARF jets, we highly recommend following the assembly sequence and procedures presented in

this manual.

Please remember that just because the model is almost completely built it does not mean that you

can rush through the final install / assembly. It is this authors recommendation that any factory

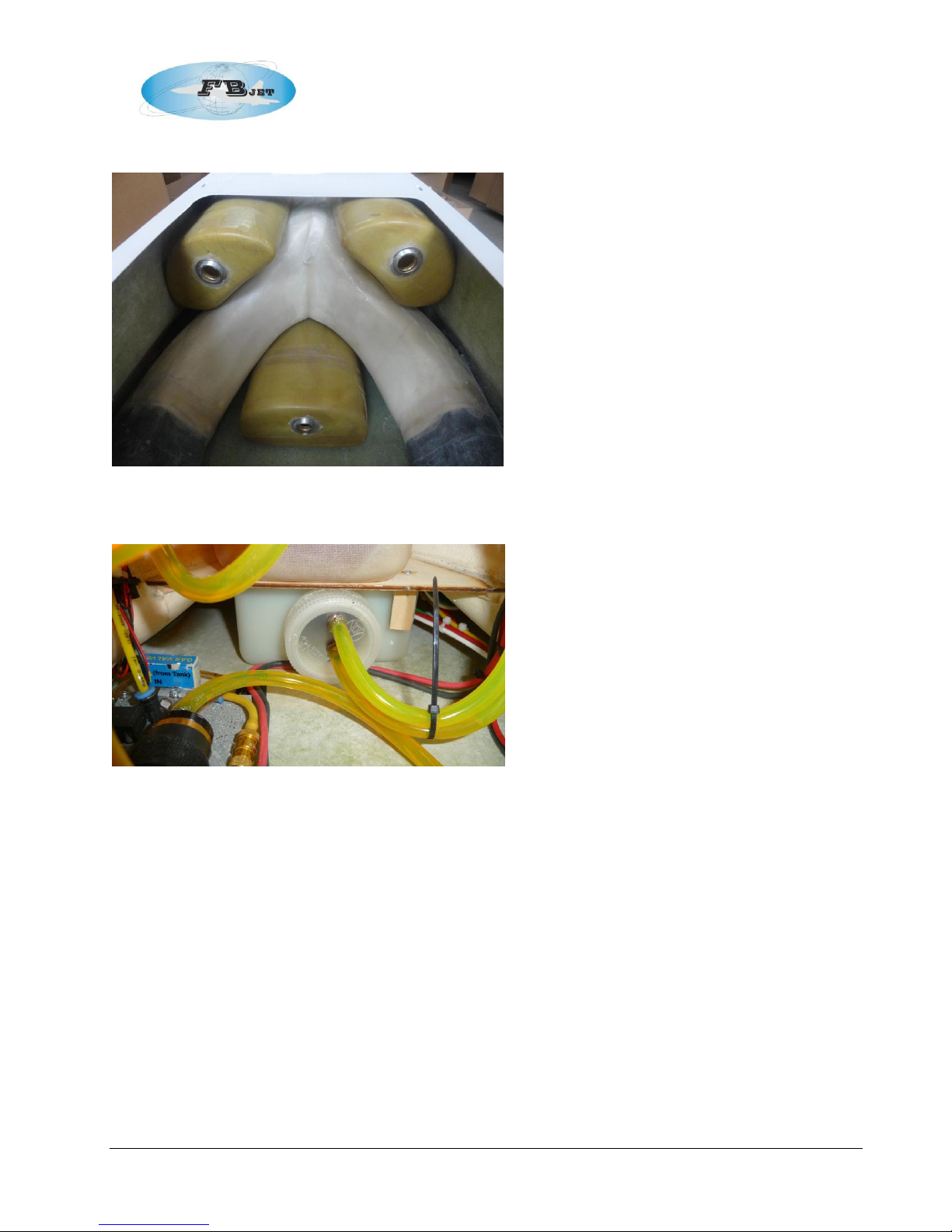

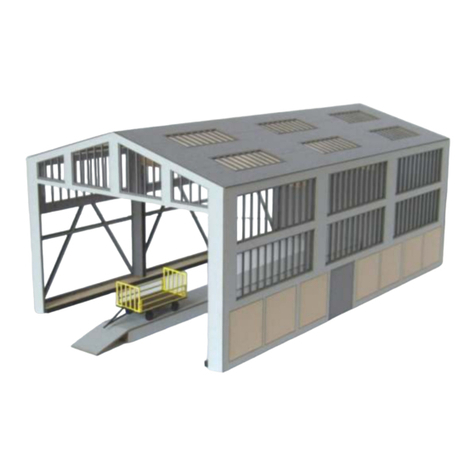

installed systems such as hardware, linkages, fuel lines, retracts, wheels and brakes, be inspected

for any possible defects, loose parts etc., and all fasteners should be secured with Loctite. Wheels

and brakes should be checked for lubrication and for proper fit to the axel; threads on linkages

should be inspected for tightness.