FC LIGHTING FCSL2000 Series User manual

CONFIDENTIAL

THIS DOCUMENT IS THE PROPRIETARY PROPERTY OF FC LIGHTING, INC. ANY UNAUTHORIZED TRANSFER, USE OR REPRODUCTION IS STRICTLY PROHIBITED. © FC LIGHTING, INC.

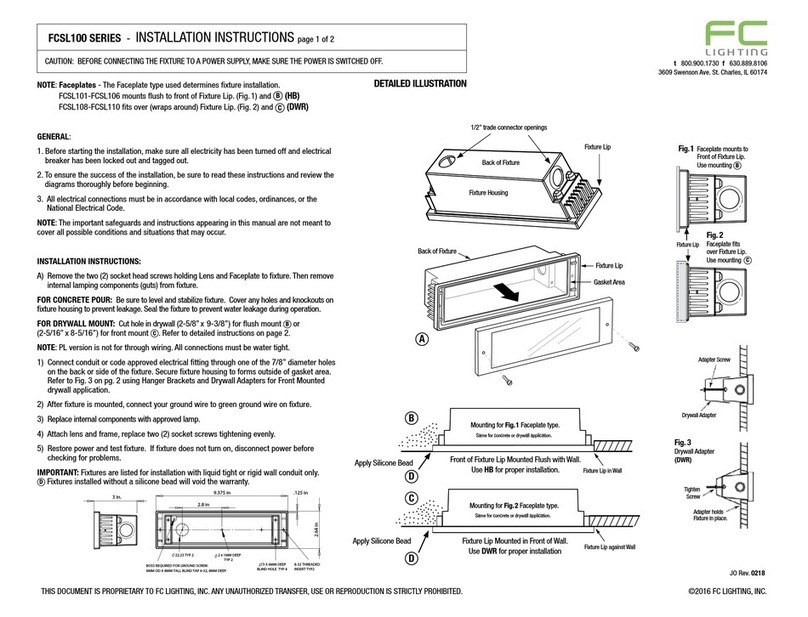

FCSL2000 Series - INSTALLATION INSTRUCTIONS

CAUTION: BEFORE CONNECTING THE FIXTURE TO A POWER SUPPLY, MAKE SURE THE POWER IS SWITCHED OFF.

DETAILED ILLUSTRATION

STUD WALL INSTALLATION

corporate

t800.900.1730

f630.889.8106

3609 Swenson Ave.

St. Charles, IL 60174

2458893

GENERAL:

1. Before starting the installation, make sure all electricity has

been turned off and electrical breaker has been locked out

and tagged out.

2. To ensure the success of the installation, be sure to read

these instructions and review the diagrams thoroughly before

beginning.

3. All electrical connections must be in accordance with local

codes, ordinances, or the National Electrical Code.

NOTE: The important safeguards and instructions appearing in

this manual are not meant to cover all possible conditions and

situations that may occur.

IMPORTANT: Temporarily remove Splatter Shield and contents

from Back Box housing and set aside.

1. Install Drywall Mounting Brackets onto Back Box using 6-32

screws provided. Orient Back Box as shown. Fig 1

2. Adjust brackets to align front face of backbox ush to face of

nished wall surface. Then fasten brackets to studs. Fig 2

3. Orient Back Box housing as shown to attach conduit.

Connect conduit to backbox using 3/4” K.O.s. Fig 3

4. Optional Hanger Bar Brackets can be used to hang the Back

Box between studs or braces to complete installation. Fig 4

6. Reinstall Splatter Shield and all contents using the (2) 8-32

screws provided. Fig 5

IMPORTANT: All wiring connections must be made in

accordance with local electrical codes, ordinances, and the

National Electric Code.

STUD

Back Box

Adjustable Back Box

Position In / Out

Drywall

Mounting Brackets

Back Box

Adjustment Slots

6-32 screws

provided

Align to face of

nished wall

Fig 1

Fig 2

Back Box Conduit Entry____

Foam Block Insert to

Retain Back Box Form

Splatter Shield

Wing Nuts

Threaded Rod

SL2000 Series

Universal Back Box

Concrete Pour Form

(by others)

(4) 3/4” Knockouts -

(2) on back and

(1) on each side

Fig 3

Back Box Splatter Shield____

8-32 screws

provided

BACKBOX

STUD

MOUNTING BRACKETS

Figure 2 (stud wall)

MOUNTING BRACKETS

BACKBOX

ADJUSTMENT SLOTS

Figure 1 (stud wall)

Figure 3 (stud wall)

SPLATTER GUARD

SL 2000 series backbox installation in hollow

(stud) wall construction (2” x 4” min.):

1. Install the (2) slotted mounting brackets

provided as shown in Figure 1, using the (4) 6-

32 screws provided.

2. Adjust the brackets (by loosening the

screws) so that the front face of the backbox

will be flush or slightly in front of the finished

wall surface after installation (see Figure 2).

3. Orient fixture housing electrical

connections as directed on inisde label.

Failure to do so will result in faceplate not

installed in the correct oreintation (critical

STEP for SL2003, SL2040, and SL2041 models).

4. Secure the mounting brackets to wood or

metal studs (hardware by others) so that the

front face of the back box will be flush or

slightly in front of the finished wall surface

after installation (see Figure 2).

5. Connect conduit to backbox using 3/4”

NPT fittings. Pull wires into back housing for

electrical connections to be made later.

6. Install splatter guard provided as shown in

Figure 3, using the (2) 8-32 screws provided

securely and finish wall.

7. Before continuing, remove splatter guard

and debris from backbox to allow for proper

fitment.

SL 2000 SERIES

STUD WALL INSTALLATION

FILE NAME: SL 2000 SERIES INSTALLATION INSTRUCTIONS.SLDDRW

Foam Block Insert to

Retain Back Box Form

Splatter Shield

Wing Nuts

Threaded Rod

SL2000 Series

Universal Back Box

Concrete Pour Form

(by others)

BACKBOX

STUD

MOUNTING BRACKETS

Figure 2 (stud wall)

MOUNTING BRACKETS

BACKBOX

ADJUSTMENT SLOTS

Figure 1 (stud wall)

Figure 3 (stud wall)

SPLATTER GUARD

SL 2000 series backbox installation in hollow

(stud) wall construction (2” x 4” min.):

1. Install the (2) slotted mounting brackets

provided as shown in Figure 1, using the (4) 6-

32 screws provided.

2. Adjust the brackets (by loosening the

screws) so that the front face of the backbox

will be flush or slightly in front of the finished

wall surface after installation (see Figure 2).

3. Orient fixture housing electrical

connections as directed on inisde label.

Failure to do so will result in faceplate not

installed in the correct oreintation (critical

STEP for SL2003, SL2040, and SL2041 models).

4. Secure the mounting brackets to wood or

metal studs (hardware by others) so that the

front face of the back box will be flush or

slightly in front of the finished wall surface

after installation (see Figure 2).

5. Connect conduit to backbox using 3/4”

NPT fittings. Pull wires into back housing for

electrical connections to be made later.

6. Install splatter guard provided as shown in

Figure 3, using the (2) 8-32 screws provided

securely and finish wall.

7. Before continuing, remove splatter guard

and debris from backbox to allow for proper

fitment.

SL 2000 SERIES

STUD WALL INSTALLATION

FILE NAME: SL 2000 SERIES INSTALLATION INSTRUCTIONS.SLDDRW

Fig 5

Fig 4

Optional - Hanger Bar (HB)______

26” Max Length

(14.25” Min Length)

Horizontal Adjustment

26” Max Length

Wall Stud

Wall Bracing

Wall Stud

Hanger Bar

Hanger Bar

(14.25” Min Length)

Vertical Adjustment

Drywall Mounting Brackets

included w/ Back Box Kit

CONFIDENTIAL

THIS DOCUMENT IS THE PROPRIETARY PROPERTY OF FC LIGHTING, INC. ANY UNAUTHORIZED TRANSFER, USE OR REPRODUCTION IS STRICTLY PROHIBITED. © FC LIGHTING, INC.

FCSL2000 Series - INSTALLATION INSTRUCTIONS

CAUTION: BEFORE CONNECTING THE FIXTURE TO A POWER SUPPLY, MAKE SURE THE POWER IS SWITCHED OFF.

DETAILED ILLUSTRATION

corporate

t800.900.1730

f630.889.8106

3609 Swenson Ave.

St. Charles, IL 60174

2458893

BRICK WALL INSTALLATION

GENERAL:

1. Before starting the installation, make sure all electricity has

been turned off and electrical breaker has been locked out

and tagged out.

2. To ensure the success of the installation, be sure to read

these instructions and review the diagrams thoroughly

before beginning.

3. All electrical connections must be in accordance with local

codes, ordinances, or the National Electrical Code.

NOTE: The important safeguards and instructions appearing in

this manual are not meant to cover all possible conditions and

situations that may occur.

IMPORTANT: Temporarily remove Splatter Shield and contents

from Back Box housing and set aside.

1. Install (2) slotted Masonry Mounting Brackets onto each

side of the Back Box using (4) 6-32 adjustment screws

provided. Orient Back Box as shown. Fig 1

NOTE: Ensure Back Box face is ush with Brick face. Fig 2

2. Then fasten brackets to brick using appropriate hardware

(by others). Adjust Back Box vertical position for optimal

spacing between upper and lower bricks. Then tighten

adjustment screws.

3. Connect conduit to backbox using 3/4” K.O.s. Fig 3

4. Reinstall Splatter Shield and all contents using the (2) 8-32

screws provided. Fig 4

IMPORTANT: All wiring connections must be made in

accordance with local electrical codes, ordinances, and the

National Electric Code.

Back Box Conduit Entry____

Foam Block Insert to

Retain Back Box Form

Splatter Shield

Wing Nuts

Threaded Rod

SL2000 Series

Universal Back Box

Concrete Pour Form

(by others)

(4) 3/4” Knockouts -

(2) on back and

(1) on each side

Fig 3

Masonry Mounting Brackets

Included w/ Back Box Kit

Flush Mounting to Brick Face

MOUNTING BRACKETS

BACKBOX

BRICK

Figure 4 (brick wall)

SPLATTER GUARD

Figure 6 (brick wall)

FLUSHED WITH FINISHED SURFACE

Figure 5 (brick wall)

BRICK

SL 2000 SERIES

BRICK WALL INSTALLATION

SL 2000 series backbox installation in

brick wall construction (Utility Brick

shown):

1. Install the (2) slotted mounting

brackets provided as shown in Figure

4, using the (4) 6-32 screws provided.

2. Adjust the brackets vertically for

optimal gap spaces between upper

and lower brick surfaces and back

housing

3. Orient fixture housing electrical

connections as directed on inisde

label. Failure to do so will result in

faceplate not installed in the correct

oreintation (critical STEP for SL2003,

SL2040, and SL2041 models).

4. Secure the mounting

brackets to the top of the brick

(hardware by others) so that the

front face of the back box will

be flush or slightly in front of the

finished wall surface after

installation (see Figure 5).

5. Connect conduit to backbox using

3/4” NPT fitting with teflon tape on

conduit. Pull wires into back housing for

electrical connections to be made

later.

6. Install Internal support block and

splatter guard provided as shown in

Figure 6, using the (2) 8-32 screws

provided securely and finish wall.

7. Before continuing, remove splatter

guard and debris from backbox to

allow for proper fitment.

FILE NAME: SL 2000 SERIES INSTALLATION INSTRUCTIONS.SLDDRW

Fig 2

Orient Back Box As Shown

6-32 adjusment

screws provided

MOUNTING BRACKETS

BACKBOX

BRICK

Figure 4 (brick wall)

SPLATTER GUARD

Figure 6 (brick wall)

FLUSHED WITH FINISHED SURFACE

Figure 5 (brick wall)

BRICK

SL 2000 SERIES

BRICK WALL INSTALLATION

SL 2000 series backbox installation in

brick wall construction (Utility Brick

shown):

1. Install the (2) slotted mounting

brackets provided as shown in Figure

4, using the (4) 6-32 screws provided.

2. Adjust the brackets vertically for

optimal gap spaces between upper

and lower brick surfaces and back

housing

3. Orient fixture housing electrical

connections as directed on inisde

label. Failure to do so will result in

faceplate not installed in the correct

oreintation (critical STEP for SL2003,

SL2040, and SL2041 models).

4. Secure the mounting

brackets to the top of the brick

(hardware by others) so that the

front face of the back box will

be flush or slightly in front of the

finished wall surface after

installation (see Figure 5).

5. Connect conduit to backbox using

3/4” NPT fitting with teflon tape on

conduit. Pull wires into back housing for

electrical connections to be made

later.

6. Install Internal support block and

splatter guard provided as shown in

Figure 6, using the (2) 8-32 screws

provided securely and finish wall.

7. Before continuing, remove splatter

guard and debris from backbox to

allow for proper fitment.

FILE NAME: SL 2000 SERIES INSTALLATION INSTRUCTIONS.SLDDRW

Fig 1

Align to face of

nished wall

Proper Orientation

Position

Proper

Orientation

Position

Back Box Splatter Shield____

Fig 4

Back Box

8-32 screws

provided

Foam Block Insert to

Retain Back Box Form

Splatter Shield

Wing Nuts

Threaded Rod

SL2000 Series

Universal Back Box

Concrete Pour Form

(by others)

BACKBOX

STUD

MOUNTING BRACKETS

Figure 2 (stud wall)

MOUNTING BRACKETS

BACKBOX

ADJUSTMENT SLOTS

Figure 1 (stud wall)

Figure 3 (stud wall)

SPLATTER GUARD

SL 2000 series backbox installation in hollow

(stud) wall construction (2” x 4” min.):

1. Install the (2) slotted mounting brackets

provided as shown in Figure 1, using the (4) 6-

32 screws provided.

2. Adjust the brackets (by loosening the

screws) so that the front face of the backbox

will be flush or slightly in front of the finished

wall surface after installation (see Figure 2).

3. Orient fixture housing electrical

connections as directed on inisde label.

Failure to do so will result in faceplate not

installed in the correct oreintation (critical

STEP for SL2003, SL2040, and SL2041 models).

4. Secure the mounting brackets to wood or

metal studs (hardware by others) so that the

front face of the back box will be flush or

slightly in front of the finished wall surface

after installation (see Figure 2).

5. Connect conduit to backbox using 3/4”

NPT fittings. Pull wires into back housing for

electrical connections to be made later.

6. Install splatter guard provided as shown in

Figure 3, using the (2) 8-32 screws provided

securely and finish wall.

7. Before continuing, remove splatter guard

and debris from backbox to allow for proper

fitment.

SL 2000 SERIES

STUD WALL INSTALLATION

FILE NAME: SL 2000 SERIES INSTALLATION INSTRUCTIONS.SLDDRW

CONFIDENTIAL

THIS DOCUMENT IS THE PROPRIETARY PROPERTY OF FC LIGHTING, INC. ANY UNAUTHORIZED TRANSFER, USE OR REPRODUCTION IS STRICTLY PROHIBITED. © FC LIGHTING, INC.

FCSL2000 Series - INSTALLATION INSTRUCTIONS

CAUTION: BEFORE CONNECTING THE FIXTURE TO A POWER SUPPLY, MAKE SURE THE POWER IS SWITCHED OFF.

DETAILED ILLUSTRATION

corporate

t800.900.1730

f630.889.8106

3609 Swenson Ave.

St. Charles, IL 60174

2458893

POURED CONCRETE INSTALLATION

Back Box Conduit Entry____

Foam Block Insert to

Retain Back Box Form

Splatter Shield

Wing Nuts

Threaded Rod

SL2000 Series

Universal Back Box

Concrete Pour Form

(by others)

(4) 3/4” Knockouts -

(2) on back and

(1) on each side

Fig 2

Masonry Mounting Brackets

Included w/ Back Box Kit

MOUNTING BRACKETS

BACKBOX

BRICK

Figure 4 (brick wall)

SPLATTER GUARD

Figure 6 (brick wall)

FLUSHED WITH FINISHED SURFACE

Figure 5 (brick wall)

BRICK

SL 2000 SERIES

BRICK WALL INSTALLATION

SL 2000 series backbox installation in

brick wall construction (Utility Brick

shown):

1. Install the (2) slotted mounting

brackets provided as shown in Figure

4, using the (4) 6-32 screws provided.

2. Adjust the brackets vertically for

optimal gap spaces between upper

and lower brick surfaces and back

housing

3. Orient fixture housing electrical

connections as directed on inisde

label. Failure to do so will result in

faceplate not installed in the correct

oreintation (critical STEP for SL2003,

SL2040, and SL2041 models).

4. Secure the mounting

brackets to the top of the brick

(hardware by others) so that the

front face of the back box will

be flush or slightly in front of the

finished wall surface after

installation (see Figure 5).

5. Connect conduit to backbox using

3/4” NPT fitting with teflon tape on

conduit. Pull wires into back housing for

electrical connections to be made

later.

6. Install Internal support block and

splatter guard provided as shown in

Figure 6, using the (2) 8-32 screws

provided securely and finish wall.

7. Before continuing, remove splatter

guard and debris from backbox to

allow for proper fitment.

FILE NAME: SL 2000 SERIES INSTALLATION INSTRUCTIONS.SLDDRW

Orient Back Box As Shown

Proper

Orientation

Position

Back Box Face Flush to Concrete_ Back Box Face Flush to Composite

Fig 4

Fig 3

GENERAL:

1. Before starting the installation, make sure all electricity has

been turned off and electrical breaker has been locked out

and tagged out.

2. To ensure the success of the installation, be sure to read

these instructions and review the diagrams thoroughly

before beginning.

3. All electrical connections must be in accordance with local

codes, ordinances, or the National Electrical Code.

NOTE: The important safeguards and instructions appearing in

this manual are not meant to cover all possible conditions and

situations that may occur.

IMPORTANT: Temporarily remove Splatter Shield and contents

from Back Box housing and set aside.

1. Install the (2) Threaded Rods provided in through the

Splatter Shield and to the Back Box as shown. Fig 1

2. Ensure that face of Back Box is ush with face of nished

surface. Connect conduit to backbox using 3/4” K.O.s. Fig 2

Orient Back Box in proper position as shown.

NOTE: Ensure front of Back Box is ush with nished wall face.

2. Reinstall the Splatter Shield and contents into the Back Box

and allow Threaded Rods to pass through the Pour Form.

Fasten the Back Box assembly to the Pour Form using (2)

Wing Nuts provided on the already installed Threaded Rods.

Refer to Fig 3.

4. For additional Composite or Topcoat nish, again ensure

front of Back Box is ush with nished wall face. Fig 4

IMPORTANT: All wiring connections must be made in

accordance with local electrical codes, ordinances, and the

National Electric Code.

Figure 7 (concrete pour)

INTERNAL SUPPORT BLOCK

SPLATTER GUARD

WING NUTS

THREADED ROD

Figure 8 (concrete pour)

POUR FORM

SL 2000 SERIES

POURED CONCRETE INSTALLATION

SL 2000 series backbox

installation in poured

concrete construction:

1. Install the (2) threaded

rod provided as shown in

Figure 7, using the (2) 8-32

x 2" long rods provided.

2. Attach assembly to

pour form ensuring the

Orientation of the

backbox housing

electrical connections is

followed per inside label

instructions. Failure to do

so will result in faceplate

not installed in the correct

oreintation (critical STEP

for SL2003, SL2040, and

SL2041 models).

FILE NAME: SL 2000 SERIES INSTALLATION INSTRUCTIONS.SLDDRW

Proper Orientation

Position

Fig 1

Figure 7 (concrete pour)

INTERNAL SUPPORT BLOCK

SPLATTER GUARD

WING NUTS

THREADED ROD

Figure 8 (concrete pour)

POUR FORM

SL 2000 SERIES

POURED CONCRETE INSTALLATION

SL 2000 series backbox

installation in poured

concrete construction:

1. Install the (2) threaded

rod provided as shown in

Figure 7, using the (2) 8-32

x 2" long rods provided.

2. Attach assembly to

pour form ensuring the

Orientation of the

backbox housing

electrical connections is

followed per inside label

instructions. Failure to do

so will result in faceplate

not installed in the correct

oreintation (critical STEP

for SL2003, SL2040, and

SL2041 models).

FILE NAME: SL 2000 SERIES INSTALLATION INSTRUCTIONS.SLDDRW

Finished Wall

Surface

Align housing to

face of nished wall Align housing to

face of nished wall

Finished Wall

Surface

Concrete, Block

or Brick Structure

Stucco or other

surface topcoat

18 AWG Anti-wicking Cable

Waterproof Wire Nuts (3) Included

IP68 Rated Sealed

Optical/Driver Unit

Hanger Bar Thru KO

Horizontal & Vertical

6-32 Threaded

Inserts for

Mounting Brackets

(4) Ø 3/4” KO

(Ø 1-1/8 True Size)

(2 in back & 1@ each end)

TRS

Tamper Resistant

Screw (Optional)

CONFIDENTIAL

THIS DOCUMENT IS THE PROPRIETARY PROPERTY OF FC LIGHTING, INC. ANY UNAUTHORIZED TRANSFER, USE OR REPRODUCTION IS STRICTLY PROHIBITED. © FC LIGHTING, INC.

FCSL2000 Series - INSTALLATION INSTRUCTIONS

CAUTION: BEFORE CONNECTING THE FIXTURE TO A POWER SUPPLY, MAKE SURE THE POWER IS SWITCHED OFF.

DETAILED ILLUSTRATION

corporate

t800.900.1730

f630.889.8106

3609 Swenson Ave.

St. Charles, IL 60174

2458893

GENERAL:

1. Before starting the installation, make sure all electricity has

been turned off and electrical breaker has been locked out

and tagged out.

2. To ensure the success of the installation, be sure to read

these instructions and review the diagrams thoroughly

before beginning.

3. All electrical connections must be in accordance with local

codes, ordinances, or the National Electrical Code.

NOTE: The important safeguards and instructions appearing in

this manual are not meant to cover all possible conditions and

situations that may occur.

1. To nish step light installation, remove the Splatter Shield

and all contents from the Back Box. Complete all wiring in

the Back Box, then snap the xture assembly into the back

box using the Snap-In Captures & Leads. Fig 1

2. Use Shims to compensate for misalignment of the front of

the Back Box and the nished wall surface. Fig 2

3. Ensure proper orientation of Back Box as shown.

Connect conduit to backbox using 3/4” K.O.s. Fig 3

4. Splatter Shield and standard mounting installation hardware

are included in and ship with the Back Box assembly.

(2) 8-32 screws provided to secure and remove the Splatter

Shield and contents. Fig 3

7. Optional Tamper Resistant Screws (TRS) can be usd

for additional security using Torx Pin screws, painted to

complement the faceplate. Fig 4

3) WIRING:

Make wiring connections. All wiring connections must be

made in accordance with local electrical codes, ordinances,

and the National Electric Code.

Fixture Snaps into Back Box

Fixture

Assembly

Snap-In Capture

Right Side

Left Side Universal Back Box

Top

Fixture Wiring

Out

Snap-In Lead

Fig 1

Back Box Splatter Shield____

Distance recessed = X

Snap-In Lead

Snap-In Capture

Wall surface

Wall surface

Added Shims to equal “X” X

Torx screws w/ pin, nished to complement faceplate nish.

Optional - Tamper Resistant Screws (TRS)

Tamper Resistant Torx Screws

(TR20 w/Pin)

Shims provided to compensate for Back Box misalignment.

Shims - (8 ea.) included w/ Fixture

Fig 2

FIXTURE & BACK BOX ASSEMBLY

Foam Block Insert to

Retain Back Box Form

Splatter Shield

Wing Nuts

Threaded Rod

SL2000 Series

Universal Back Box

Concrete Pour Form

(by others)

(4) 3/4” Knockouts

(2) on back,

(1) on each side

Fig 3

BACKBOX

STUD

MOUNTING BRACKETS

Figure 2 (stud wall)

MOUNTING BRACKETS

BACKBOX

ADJUSTMENT SLOTS

Figure 1 (stud wall)

Figure 3 (stud wall)

SPLATTER GUARD

SL 2000 series backbox installation in hollow

(stud) wall construction (2” x 4” min.):

1. Install the (2) slotted mounting brackets

provided as shown in Figure 1, using the (4) 6-

32 screws provided.

2. Adjust the brackets (by loosening the

screws) so that the front face of the backbox

will be flush or slightly in front of the finished

wall surface after installation (see Figure 2).

3. Orient fixture housing electrical

connections as directed on inisde label.

Failure to do so will result in faceplate not

installed in the correct oreintation (critical

STEP for SL2003, SL2040, and SL2041 models).

4. Secure the mounting brackets to wood or

metal studs (hardware by others) so that the

front face of the back box will be flush or

slightly in front of the finished wall surface

after installation (see Figure 2).

5. Connect conduit to backbox using 3/4”

NPT fittings. Pull wires into back housing for

electrical connections to be made later.

6. Install splatter guard provided as shown in

Figure 3, using the (2) 8-32 screws provided

securely and finish wall.

7. Before continuing, remove splatter guard

and debris from backbox to allow for proper

fitment.

SL 2000 SERIES

STUD WALL INSTALLATION

FILE NAME: SL 2000 SERIES INSTALLATION INSTRUCTIONS.SLDDRW

8-32 screws

provided

Proper Orientation

Position

Fig 4

Other FC LIGHTING Light Fixture manuals

Popular Light Fixture manuals by other brands

American DJ

American DJ Accu UFO PRO User instructions

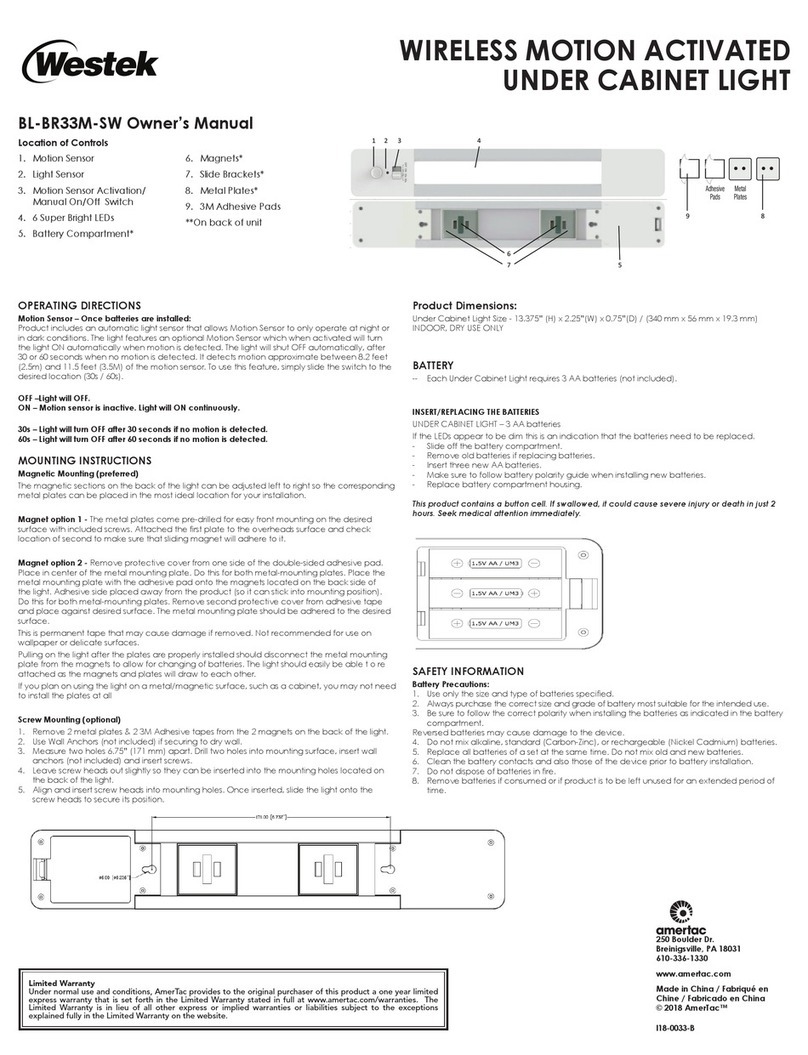

AmerTac

AmerTac Westek BL-BR33M-SW owner's manual

LeuchtKraft

LeuchtKraft TWIST-150LED instruction manual

Chauvet

Chauvet SlimPAR 64 RGBA Quick reference guide

Lightolier

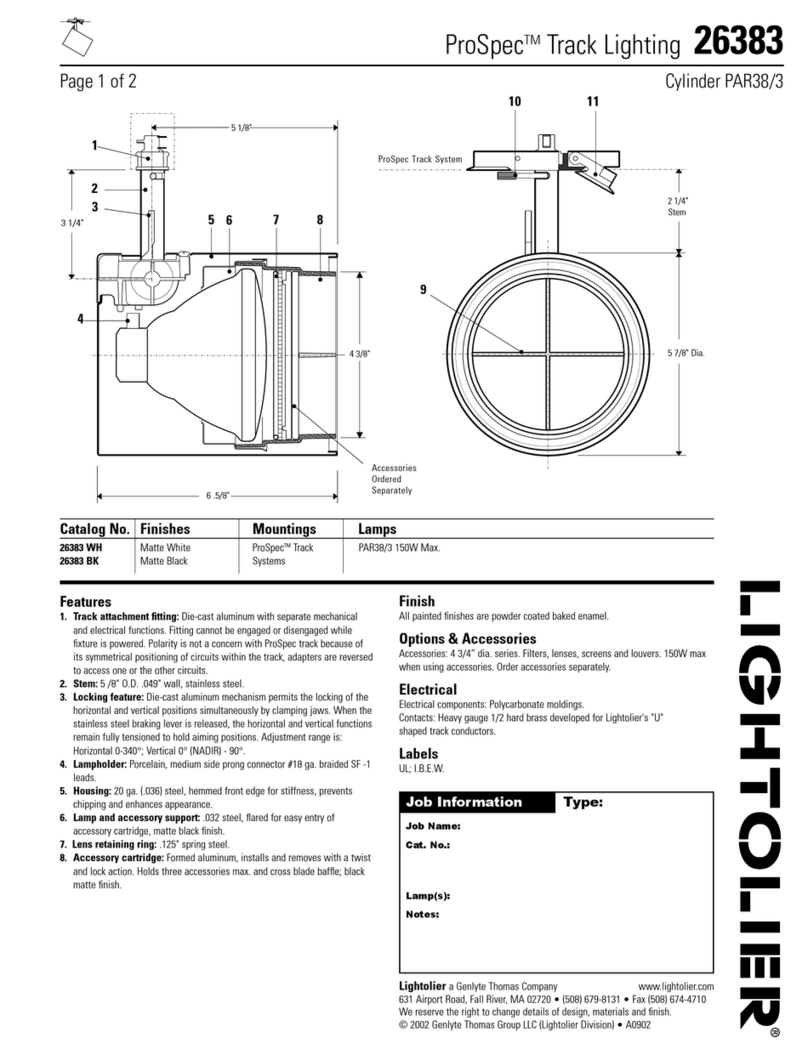

Lightolier Tangent FXG9P specification

DOMUS LINE

DOMUS LINE TOUCH ME FW installation manual

Beamz

Beamz Cobra 100H user manual

Westinghouse

Westinghouse W-207 owner's manual

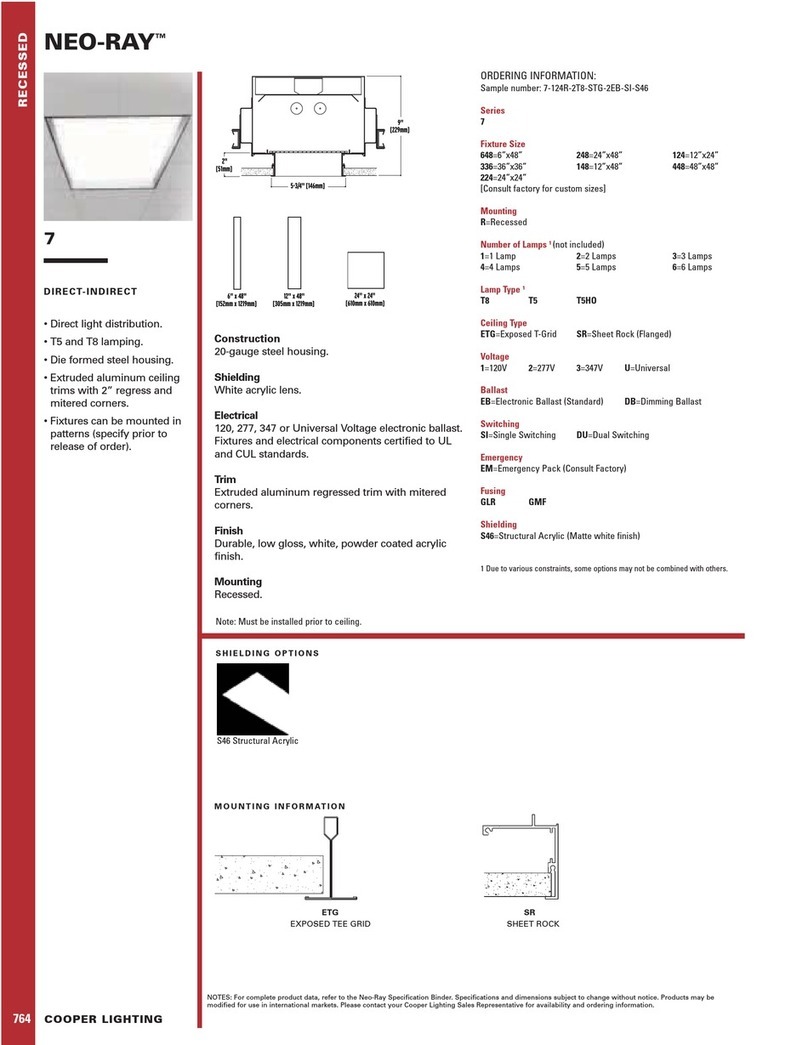

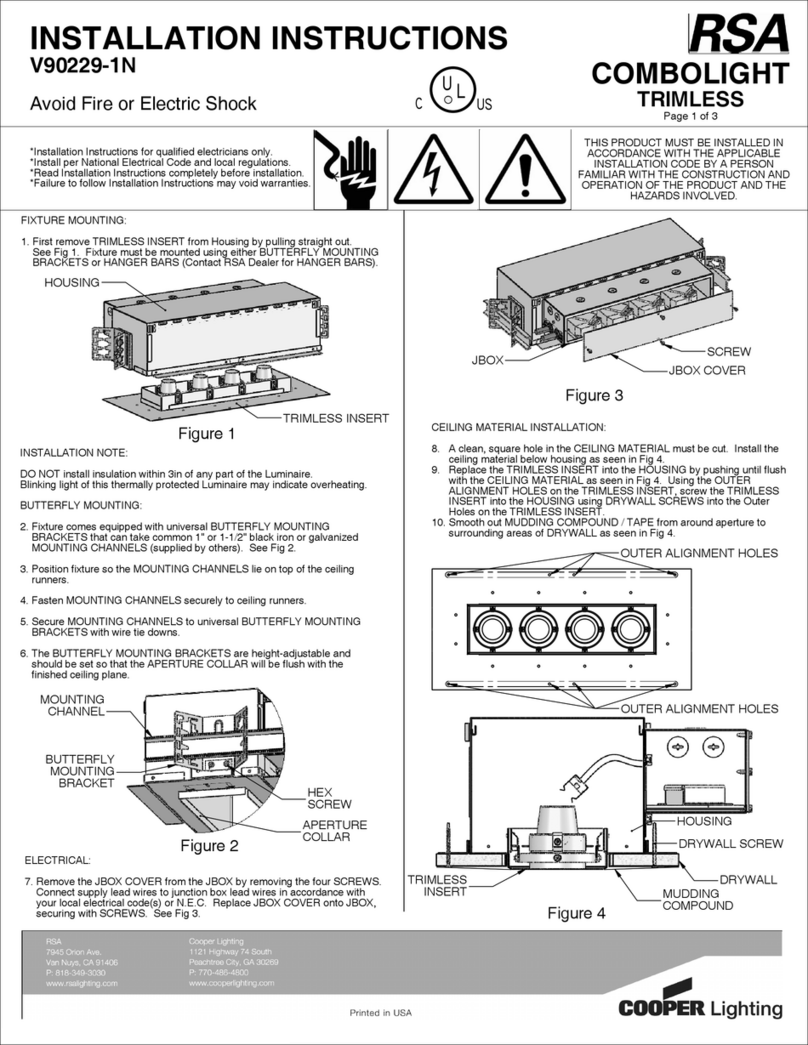

Cooper Lighting

Cooper Lighting Combolight Trimless V90229-1N installation instructions

Lightolier

Lightolier REFLECTOR TRIM instructions

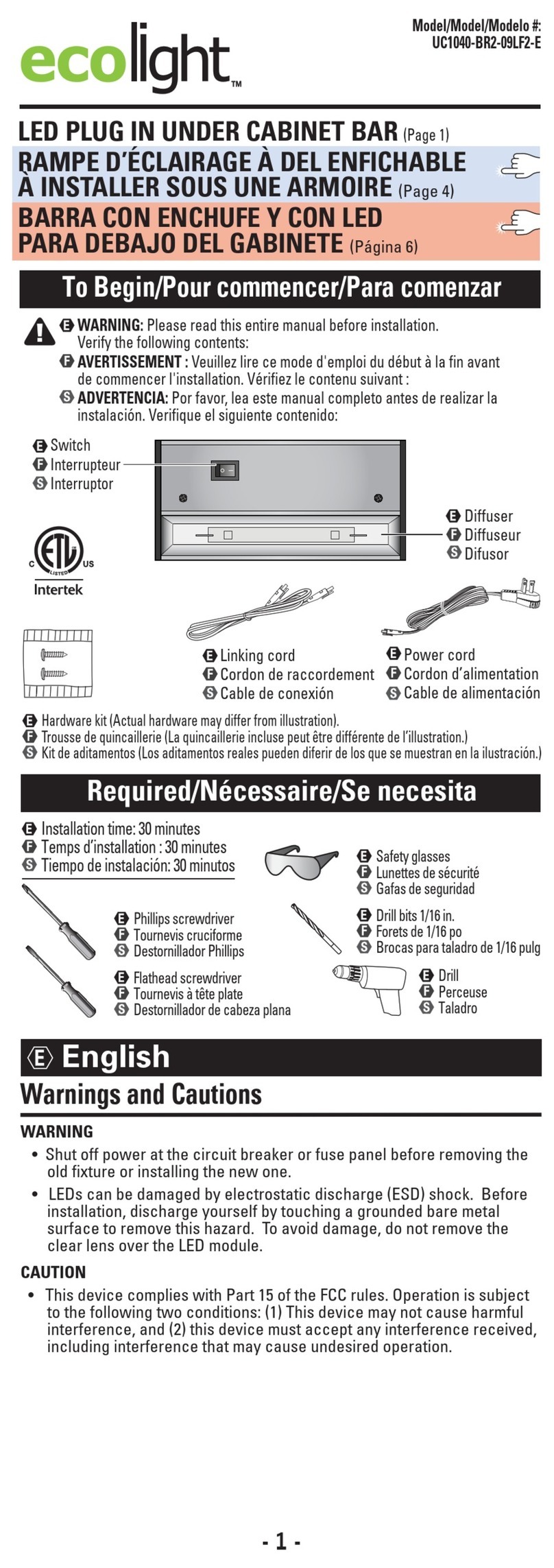

ecolight

ecolight UC1040-BR2-09LF2-E quick start guide

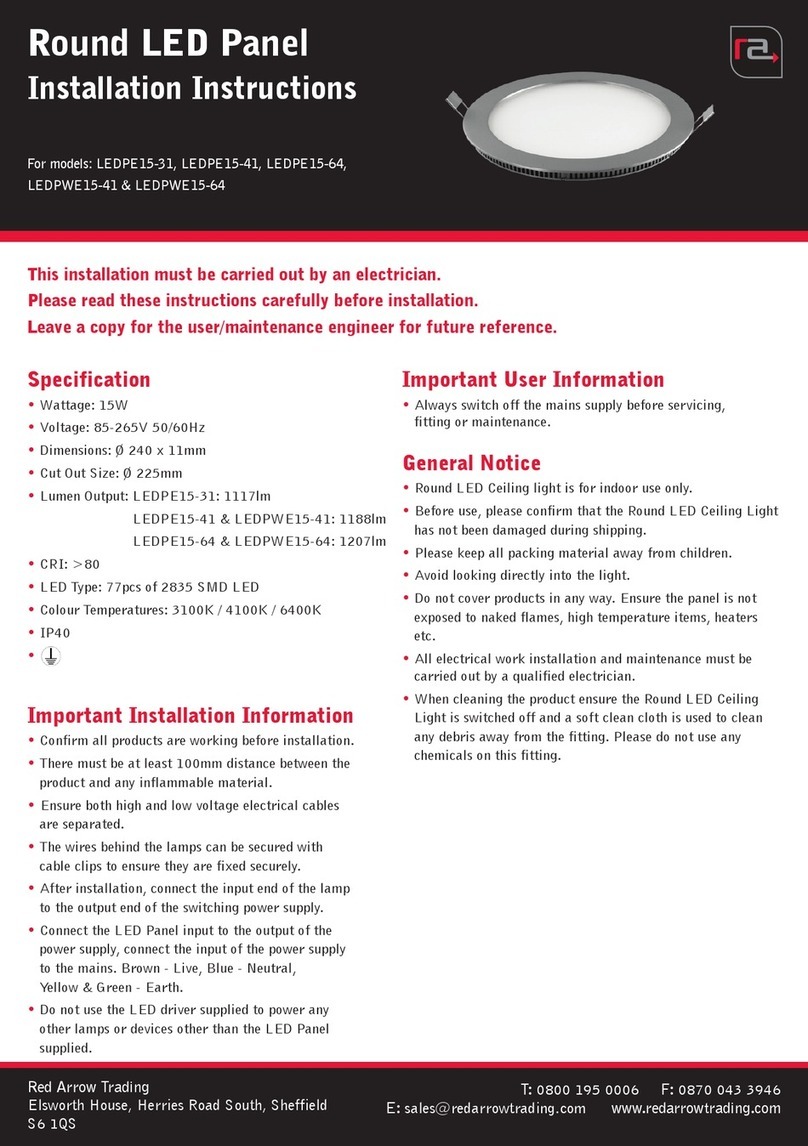

Red Arrow

Red Arrow LEDPE15-31 installation instructions