FCI OCTIS 10135748-101LF User guide

NUMBER GS-20-0454

TYPE APPLICATION SPECIFICATION

TITLE

PAGE

REVISION

OCTIS PLUG KIT ASSEMBLY –HYBRID, SIGNAL & POWER

1 of 30

D

AUTHORIZED BY

DATE

Stalin Alosius

2019-09-12

CLASSIFICATION

UNRESTRICTED

Copyright FCI

Form E-3334

Rev F

Form E-3334

Rev F

TABLE OF CONTENTS

Section Page no.

1. OCTIS PLUG KIT ASSEMBLY - USER INSTRUCTION……………………………………………………. 3

1.1. Hybrid - Signal & Power (Combo) connector interface (Crimped type).....................................3

1.2. Signal Metral HDXS connector interface Crimped type)..............................................................4

1.3. 2 position Power - Pwr Profile connector interface Crimped type)........................................... 5

1.4 2 position Power - Pwr Profile connector interface (Screw type)…………………………………6

1.5 3 position Power - Pwr Profile connector interface (Screw type)…………………………………7

2. OBJECTIVE...............................................................................................................................................8

3. SCOPE ......................................................................................................................................................8

4. GENERAL .................................................................................................................................................8

5. DRAWINGS AND APPLICABLE DOCUMENTS......................................................................................8

6. APPLICATION REQUIREMENTS ............................................................................................................8

7. RECOMMENDED WIRE SIZES AND INSULATIONS..............................................................................8

7.1. Wire insulation materials ...............................................................................................................8

7.2. Maximum insulation diameters and wire sizes............................................................................9

7.2.1 Signal Contact.................................................................................................................................9

7.2.2 Power Contact.................................................................................................................................9

7.2.3 Crimp on Wire (Power Contact)..................................................................................................10

8. ACCEPTABLE WIRE TERMINATION....................................................................................................11

8.1. Termination requirements, visual...............................................................................................11

8.1.1 Wire Location................................................................................................................................11

8.1.2 Wire Depth.....................................................................................................................................12

8.1.3 Strain Relief...................................................................................................................................13

8.1.4 IDC Terminal Damage ..................................................................................................................13

8.1.5 Wire Damage.................................................................................................................................13

8.2. Tool setup and destructive inspection techniques ...................................................................13

8.2.1 Wire Removal................................................................................................................................13

8.2.2 IDC Terminal Damage ..................................................................................................................13

8.2.3 Acceptable Metallic Contact........................................................................................................13

9. APPLICATION TOOLING.......................................................................................................................14

10.APPLICATION PROCEDURES..............................................................................................................15

10.1. Cable preparation for Power Profile Contact..............................................................................15

10.2. Cable preparation for Signal Contact..........................................................................................18

PDS: Rev :D STATUS:Released Printed: Sep 18, 2019

NUMBER GS-20-0454

TYPE APPLICATION SPECIFICATION

TITLE

PAGE

REVISION

OCTIS PLUG KIT ASSEMBLY –HYBRID, SIGNAL & POWER

2 of 30

D

AUTHORIZED BY

DATE

Stalin Alosius

2019-09-12

CLASSIFICATION

UNRESTRICTED

Copyright FCI

Form E-3334

Rev F

Form E-3334

Rev F

10.3. Cable IDC....................................................................................................................................19

10.3.1 Crimping Process-Method 1.....................................................................................................19

10.3.2 Crimping Process-Method 2.....................................................................................................23

10.4. OCTIS Assembly............................................................................................................ .............24

10.4.1 Assembling Hybrid-Signal & Power(Combo)Connector.......................................................24

10.4.2 Assembling Signal Metral HDXS Connector ..........................................................................29

10.4.3 Assembling Power-Profile connector(2 and 3 position power connector).........................29

10.5 OCTIS EMI cap assembly.....................................................................................................................30

11. REVISION RECORD...............................................................................................................................30

PDS: Rev :D STATUS:Released Printed: Sep 18, 2019

NUMBER GS-20-0454

TYPE APPLICATION SPECIFICATION

TITLE

PAGE

REVISION

OCTIS PLUG KIT ASSEMBLY –HYBRID, SIGNAL & POWER

3 of 30

D

AUTHORIZED BY

DATE

Stalin Alosius

2019-09-12

CLASSIFICATION

UNRESTRICTED

Copyright FCI

Form E-3334

Rev F

Form E-3334

Rev F

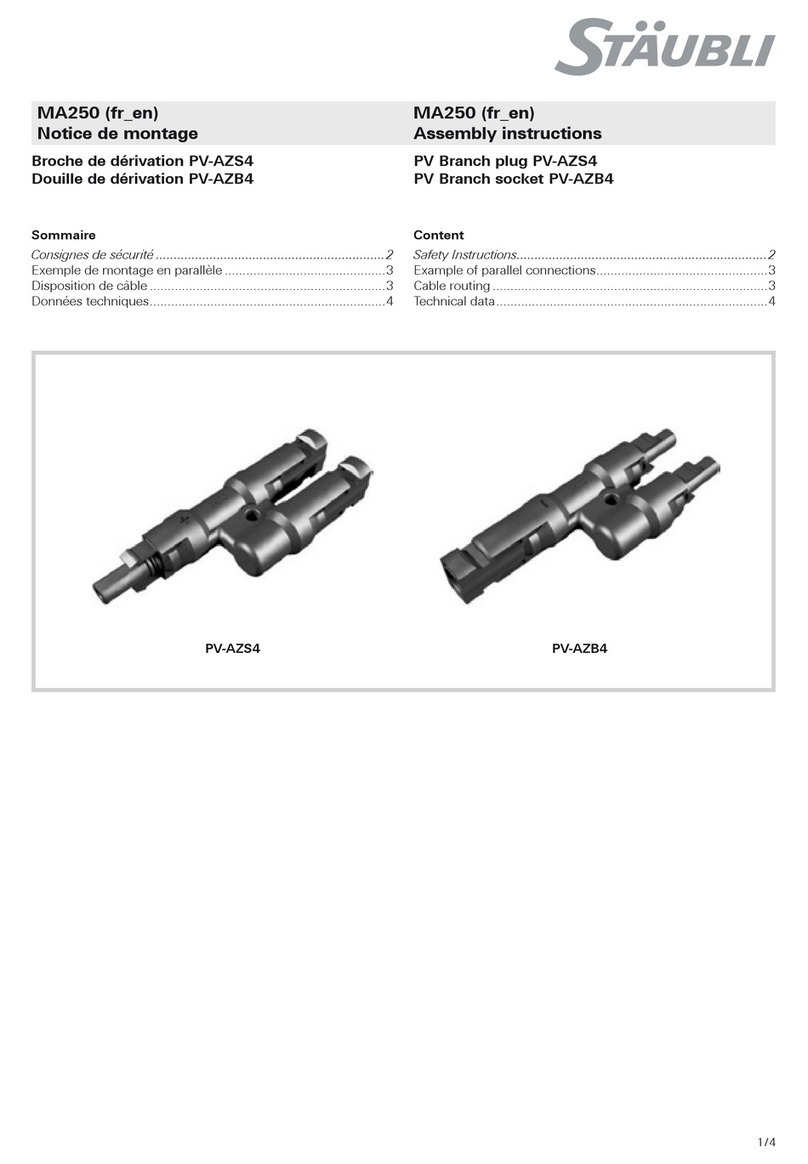

1. ASSEMBLING OF OCTIS KITS –USER INSTRUCTION

1.1. CRIMPED TYPE: Hybrid - Signal & Power (Combo) connector interface

Plug Kit Part Number 10135748-101LF

PDS: Rev :D STATUS:Released Printed: Sep 18, 2019

NUMBER GS-20-0454

TYPE APPLICATION SPECIFICATION

TITLE

PAGE

REVISION

OCTIS PLUG KIT ASSEMBLY –HYBRID, SIGNAL & POWER

4 of 30

D

AUTHORIZED BY

DATE

Stalin Alosius

2019-09-12

CLASSIFICATION

UNRESTRICTED

Copyright FCI

Form E-3334

Rev F

Form E-3334

Rev F

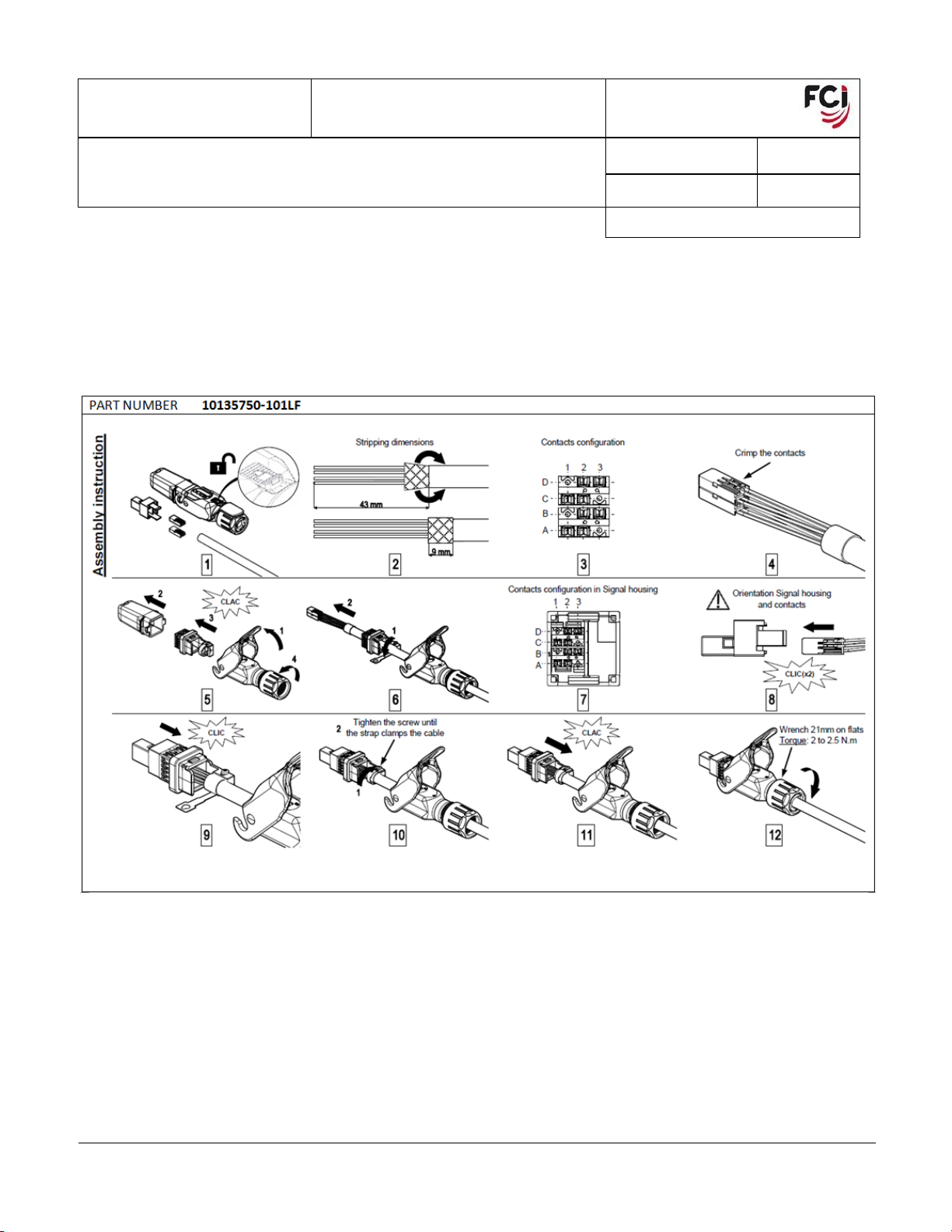

1.2. CRIMPED TYPE: Signal Metral HDXS connector interface

Plug kit Part Number 10135750-101LF

PDS: Rev :D STATUS:Released Printed: Sep 18, 2019

NUMBER GS-20-0454

TYPE APPLICATION SPECIFICATION

TITLE

PAGE

REVISION

OCTIS PLUG KIT ASSEMBLY –HYBRID, SIGNAL & POWER

5 of 30

D

AUTHORIZED BY

DATE

Stalin Alosius

2019-09-12

CLASSIFICATION

UNRESTRICTED

Copyright FCI

Form E-3334

Rev F

Form E-3334

Rev F

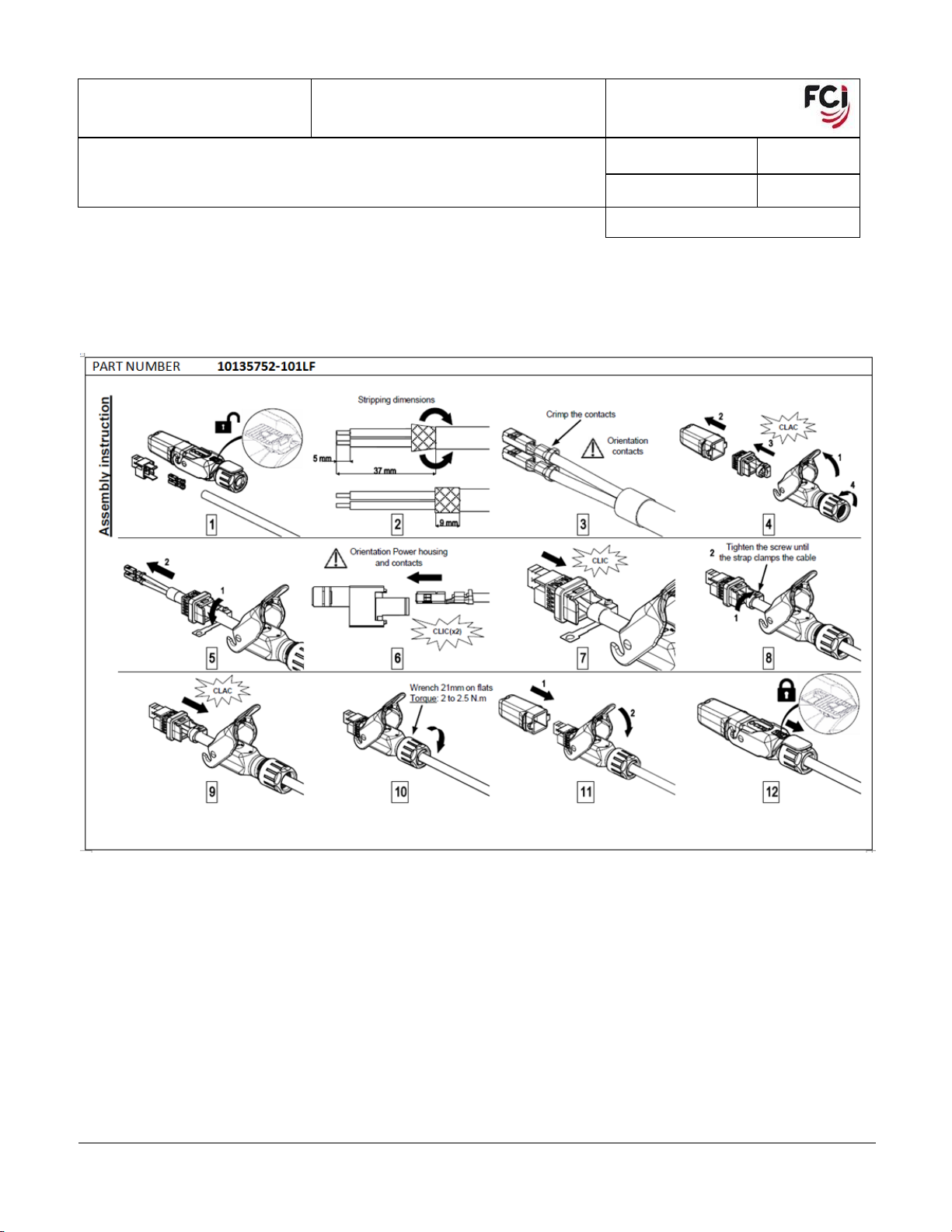

1.3. CRIMPED TYPE: Power - Pwr Profile connector interface

Plug Kit Part Number 10135752-101LF

PDS: Rev :D STATUS:Released Printed: Sep 18, 2019

NUMBER GS-20-0454

TYPE APPLICATION SPECIFICATION

TITLE

PAGE

REVISION

OCTIS PLUG KIT ASSEMBLY –HYBRID, SIGNAL & POWER

6 of 30

D

AUTHORIZED BY

DATE

Stalin Alosius

2019-09-12

CLASSIFICATION

UNRESTRICTED

Copyright FCI

Form E-3334

Rev F

Form E-3334

Rev F

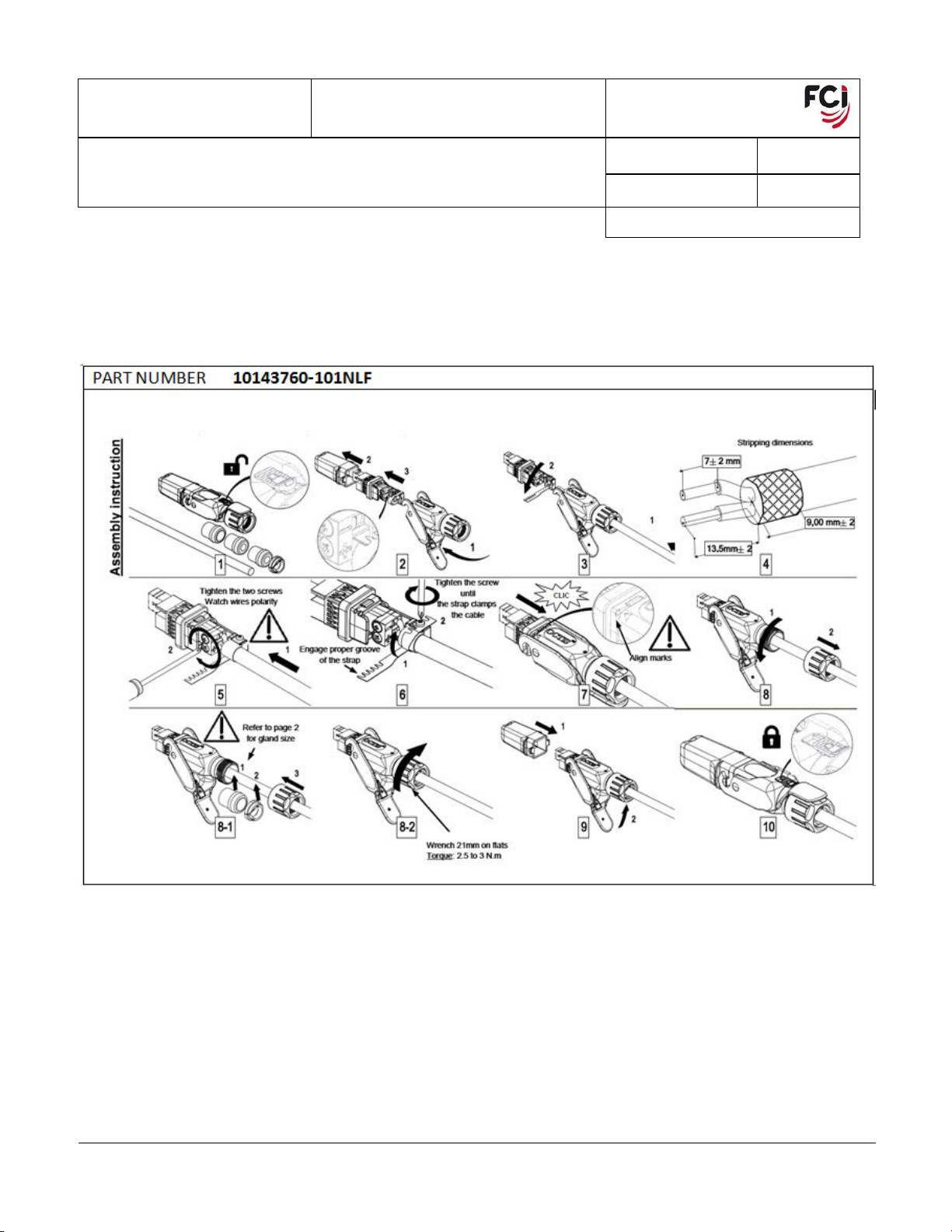

1.4. SCREW TYPE: 2 position Power - Pwr Profile connector interface

Plug Kit Part Number 10143760-101NLF

PDS: Rev :D STATUS:Released Printed: Sep 18, 2019

NUMBER GS-20-0454

TYPE APPLICATION SPECIFICATION

TITLE

PAGE

REVISION

OCTIS PLUG KIT ASSEMBLY –HYBRID, SIGNAL & POWER

7 of 30

D

AUTHORIZED BY

DATE

Stalin Alosius

2019-09-12

CLASSIFICATION

UNRESTRICTED

Copyright FCI

Form E-3334

Rev F

Form E-3334

Rev F

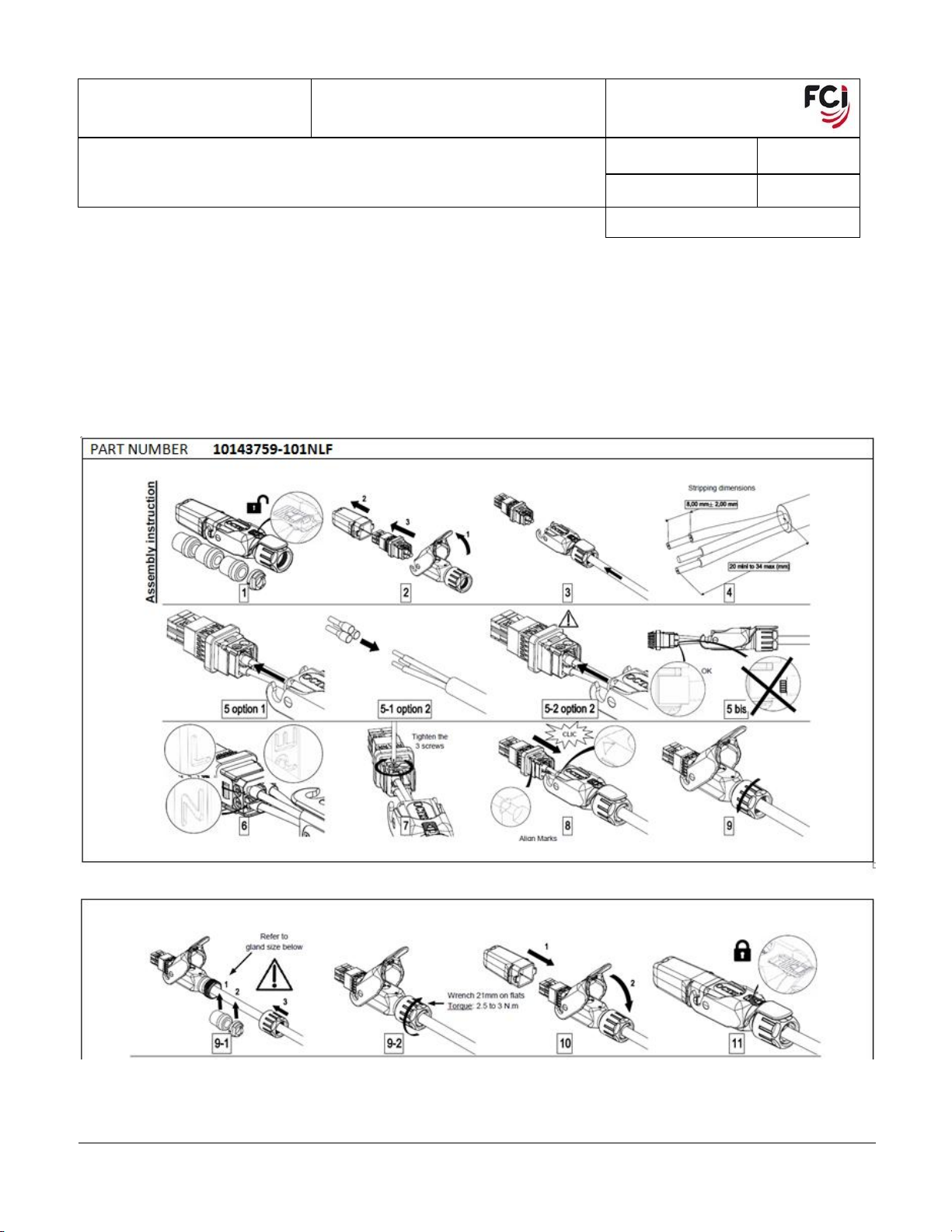

1.5. SCREW TYPE: 3 position Power - Pwr Profile connector interface

Plug Kit Part Number 10143759-101NLF

PDS: Rev :D STATUS:Released Printed: Sep 18, 2019

NUMBER GS-20-0454

TYPE APPLICATION SPECIFICATION

TITLE

PAGE

REVISION

OCTIS PLUG KIT ASSEMBLY –HYBRID, SIGNAL & POWER

8 of 30

D

AUTHORIZED BY

DATE

Stalin Alosius

2019-09-12

CLASSIFICATION

UNRESTRICTED

Copyright FCI

Form E-3334

Rev F

Form E-3334

Rev F

2. OBJECTIVE

This specification provides information and requirements for customer application of the OCTIS Metral

HDXS OCTIS Cable Connector & cable assembly. It is intended to provide general guidance for

application process development. It should be recognized that no single process will work under all

customer applications and that customers should develop processes to meet individual needs. However, if

the process varies greatly from the recommended one, FCI cannot guarantee acceptable results.

3. SCOPE

This specification provides information and requirements regarding application of Metral HDXS OCTIS

Cable Connector (FCI product number: 10135748-101LF, 10135750-101LF, 10135752-101LF, 10143759-

101NLF, 10143760-101NLF) into OCTIS cable assemblies.

4. GENERAL

This document is a general application guide. If there is a conflict between the product drawings and this

specification, the drawings take precedence.

5. DRAWINGS AND APPLICABLE DOCUMENTS

FCI product drawings and specifications are available by accessing the FCI website or contacting the FCI

Technical Service. In the event of a conflict between this specification and the product drawing, the

drawing takes precedence. Customers should refer to the latest revision level of FCI product drawings for

appropriate product details.

Product Specification GS-12-1334 (Combo), GS-12-1338 (Signal) , GS-12-1339 (Power)

Plug Kit Part Number, Hybrid - Signal & Power (Combo) connector for Octis 10135748-

101LF(Crimped type)

Plug Kit Part Number, Signal Metral HDXS connector for Octis 10135750-101LF(Crimped type)

Plug Kit Part Number, Power - Pwr Profile connector for Octis 10135752-101LF(Crimped type)

Plug Kit Part Number, 2 position Power - Pwr Profile connector for Octis 10135760-101LF (Screw

type)

Plug Kit Part Number, 3 position Power - Pwr Profile connector for Octis 10135759-101LF (Screw

type)

6. APPLICATION REQUIREMENTS

Materials, as cable and shrink sleeves must comply with the specifications mentioned in the product

specification

7. RECOMMENDED WIRE SIZES AND INSULATIONS

7.1 Wire Insulation Materials

Semi-rigid PVC, PVC, PE, PP is used.

PDS: Rev :D STATUS:Released Printed: Sep 18, 2019

NUMBER GS-20-0454

TYPE APPLICATION SPECIFICATION

TITLE

PAGE

REVISION

OCTIS PLUG KIT ASSEMBLY –HYBRID, SIGNAL & POWER

9 of 30

D

AUTHORIZED BY

DATE

Stalin Alosius

2019-09-12

CLASSIFICATION

UNRESTRICTED

Copyright FCI

Form E-3334

Rev F

Form E-3334

Rev F

7.2 Maximum Insulation Diameters and Wire Sizes

7.2.1 Signal Contact

Conductor Size

Insulation Diameter

mm

inch

26 gauge solid

0.74

0.0291

0.4mm solid

0.74

0.0291

24 gauge

1.00

0.0394

0.5mm solid

1.00

0.0394

Certain wire sizes other than those recommended above can be inserted in the contact IDC but

must be qualified individually. The specification of the cable using the stranded wire must have the

wire insulation type, wire insulation thickness, number of strands, size of strands and twist of

strands controlled.

7.2.2 Power Contact

Wire Size Range (mm²)

Insulation Diameter (mm)

Min

Max

Min

Max

1.00

2.50

2.00

3.00

PDS: Rev :D STATUS:Released Printed: Sep 18, 2019

NUMBER GS-20-0454

TYPE APPLICATION SPECIFICATION

TITLE

PAGE

REVISION

OCTIS PLUG KIT ASSEMBLY –HYBRID, SIGNAL & POWER

10 of 30

D

AUTHORIZED BY

DATE

Stalin Alosius

2019-09-12

CLASSIFICATION

UNRESTRICTED

Copyright FCI

Form E-3334

Rev F

Form E-3334

Rev F

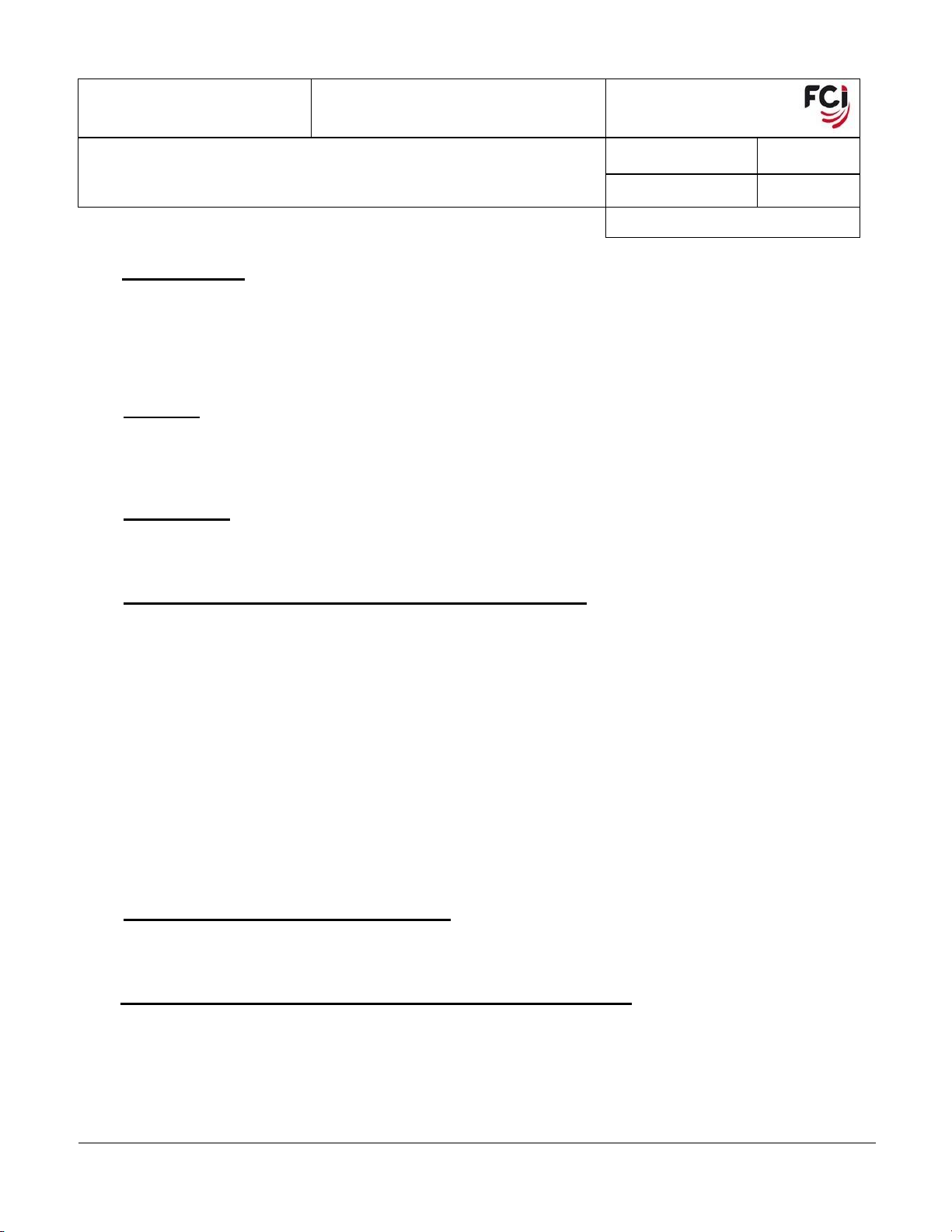

7.2.3 CRIMP ON WIRE (POWER CONTACT)

PDS: Rev :D STATUS:Released Printed: Sep 18, 2019

NUMBER GS-20-0454

TYPE APPLICATION SPECIFICATION

TITLE

PAGE

REVISION

OCTIS PLUG KIT ASSEMBLY –HYBRID, SIGNAL & POWER

11 of 30

D

AUTHORIZED BY

DATE

Stalin Alosius

2019-09-12

CLASSIFICATION

UNRESTRICTED

Copyright FCI

Form E-3334

Rev F

Form E-3334

Rev F

8 ACCEPTABLE WIRE TERMINATION

Caution: The wire strain relief of each contact must be closed by the wire insertion punch even if no wire is

inserted into the contact. If the strain relieves are not closed, a short can occur between contacts on both

shielded and unshielded connectors or between the contact and metal shields on shielded connectors.

The automatic wire terminators will set all the unused contacts unless the machine cycle is interrupted.

When using hand tools, the operator must index the connector subassembly to all unused positions and

activate the hand tool.

8.1 Termination Requirements, Visual

Requirements for an acceptable termination as well as non-destructive visual inspection methods

to ensure satisfactory terminations without removing wires.

8.1.1 Wire location

The copper conductor shall extend at least 0.75mm beyond the IDC dimples. This

requirement shall be considered to meet if the wire insulation extends at least 1.00mm

beyond the IDC dimples. At a maximum the insulation may extend to surface “D” (See fig

4).

PDS: Rev :D STATUS:Released Printed: Sep 18, 2019

NUMBER GS-20-0454

TYPE APPLICATION SPECIFICATION

TITLE

PAGE

REVISION

OCTIS PLUG KIT ASSEMBLY –HYBRID, SIGNAL & POWER

12 of 30

D

AUTHORIZED BY

DATE

Stalin Alosius

2019-09-12

CLASSIFICATION

UNRESTRICTED

Copyright FCI

Form E-3334

Rev F

Form E-3334

Rev F

Figure 4: Wire Insertion Visual Requirements

8.1.2 Wire Depth

The wire shall be inserted into the IDC dimples so that the wire depth is greater than or

equal to dimension “ab” as measured from the connector insulator to the top of the wire

insulation in region “A” (views A and C of fig 4). A dial indicator (as depicted on fig 5) can

be used to measure the depth required. The dimension “ab” is based on the diameter of

the wire being used.

Conductor Size

Insulation Diameter

(mm)

Dimension “ab”

(mm)

26 gauge wire

0.74

0.42+/-0.12

24 gauge wire

1.00

0.36+/-0.12

The measurement should be done when the insertion equipment is set up. If the

measurement is less than specified, reduce the depth of insertion until it meet. Contact

your FCI representative if the wire you selected cannot meet all requirements.

A standard depth gage is available for the measurement of “ab” as listed below. We have

observed that with some wire insulation types, the insulation gradually lifts off the wire after

insertion. For this reason, the measurement of wire depth “ab” should be made as soon

after insertion as possible to avoid incorrect low readings.

Figure 5: Wire Depth Gage

PDS: Rev :D STATUS:Released Printed: Sep 18, 2019

NUMBER GS-20-0454

TYPE APPLICATION SPECIFICATION

TITLE

PAGE

REVISION

OCTIS PLUG KIT ASSEMBLY –HYBRID, SIGNAL & POWER

13 of 30

D

AUTHORIZED BY

DATE

Stalin Alosius

2019-09-12

CLASSIFICATION

UNRESTRICTED

Copyright FCI

Form E-3334

Rev F

Form E-3334

Rev F

8.1.3 Strain Relief

For 26 gage wire, all strain relief tabs must be crimped firmly against the wire such that

retention of the wire will not be dislodged with a 9.8N (2.2LB.) minimum pull.

For 24 gage wire, all strain relief tabs must be crimped firmly against the wire such that the

wire will not be dislodged with a 19.6N (4.4LB.) minimum pull.

The wire shall be pulled at 90 degrees to the axis of the terminated wire, in a direction

opposite to the insertion direction. It should be considered a major defect if either of the

contact strain relief tabs have not been crimped over the wire.

8.1.4 IDC Terminal Damage

There should be no distortion of the metal terminal other than the intended forming of the

strain relief except that the insertion punch may cut into the ace of the IDC dimple a

maximum of 0.1 millimeter (0.004 inched) during wire insertion.

8.1.5 Wire Damage

There shall be no breaks in the wire insulation to expose the center conductor below

surface “E” In fig 4, view C. Marks and dents in the insulation caused by the insertion

equipment that do not expose the conductor in this area are permitted.

8.2 Tool Set up and Destructive Inspection Techniques

Techniques to verify proper tool set-up and for further inspection of suspected visual failures

require wire removal. Wire removal shall be done in accordance with the following instructions.

8.2.1 Wire Removal

Open the wire strain relieves of the contact and peel the wire away from the strain relief

and out of the IDC dimples, being careful not to damage the contact.

8.2.2 IDC Terminal Damage

Examine the IDC dimples. There shall be no visible damage other than that caused by the

intended forming of the strain relief and the normal widening of the IDC gap by the wire

except that the insertion punch must cut into the face of the IDC dimple a maximum of 0.10

millimeters (0.004 inches) during wire insertion.

8.2.3 Acceptable Metallic Contact

The removed wire shall show evidence of metallic contact with all four IDC dimples.

PDS: Rev :D STATUS:Released Printed: Sep 18, 2019

NUMBER GS-20-0454

TYPE APPLICATION SPECIFICATION

TITLE

PAGE

REVISION

OCTIS PLUG KIT ASSEMBLY –HYBRID, SIGNAL & POWER

14 of 30

D

AUTHORIZED BY

DATE

Stalin Alosius

2019-09-12

CLASSIFICATION

UNRESTRICTED

Copyright FCI

Form E-3334

Rev F

Form E-3334

Rev F

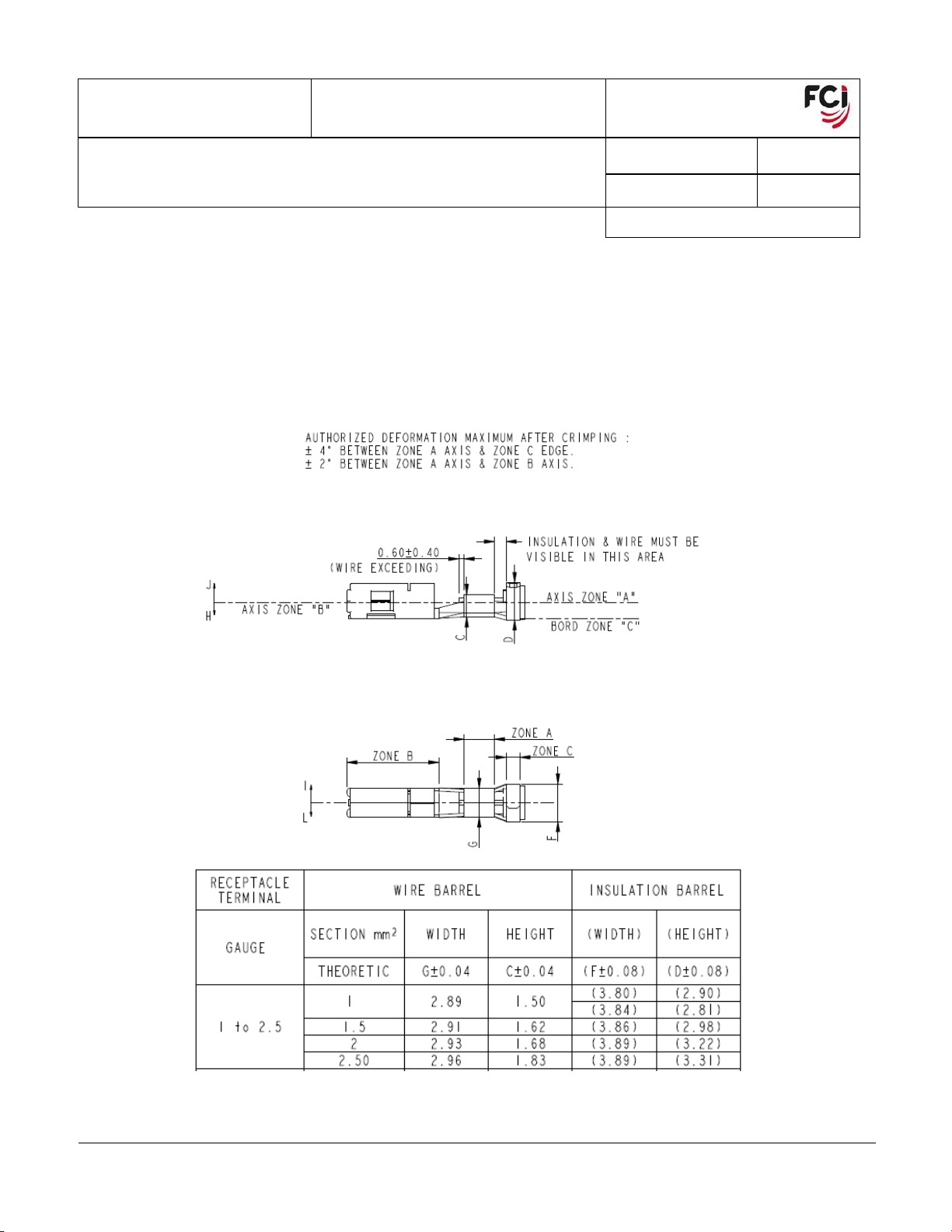

9 APPLICATION TOOLING

Product number

Tool description

10137182-001

Semi automatic IDC Cable Terminator (Fig 6)

10135856-001

IDC table top pistol for Metral HDXS Octis Cable Connector

(Fig 7)

10135701-001

Octis Power Profile Crimping Tool (Fig 8)

10141086-001

Octis Signal Crimping Tool (Fig 9)

Cable stripper

General available cable stripper

Figure 6: 10137182-001 Figure 7: 10135856-001

Figure 8: 10135701-001 Figure 9: 10141086-001

PDS: Rev :D STATUS:Released Printed: Sep 18, 2019

NUMBER GS-20-0454

TYPE APPLICATION SPECIFICATION

TITLE

PAGE

REVISION

OCTIS PLUG KIT ASSEMBLY –HYBRID, SIGNAL & POWER

15 of 30

D

AUTHORIZED BY

DATE

Stalin Alosius

2019-09-12

CLASSIFICATION

UNRESTRICTED

Copyright FCI

Form E-3334

Rev F

Form E-3334

Rev F

10 APPLICATION PROCEDURE

10.1 Cable Preparation for Power Profile Contact

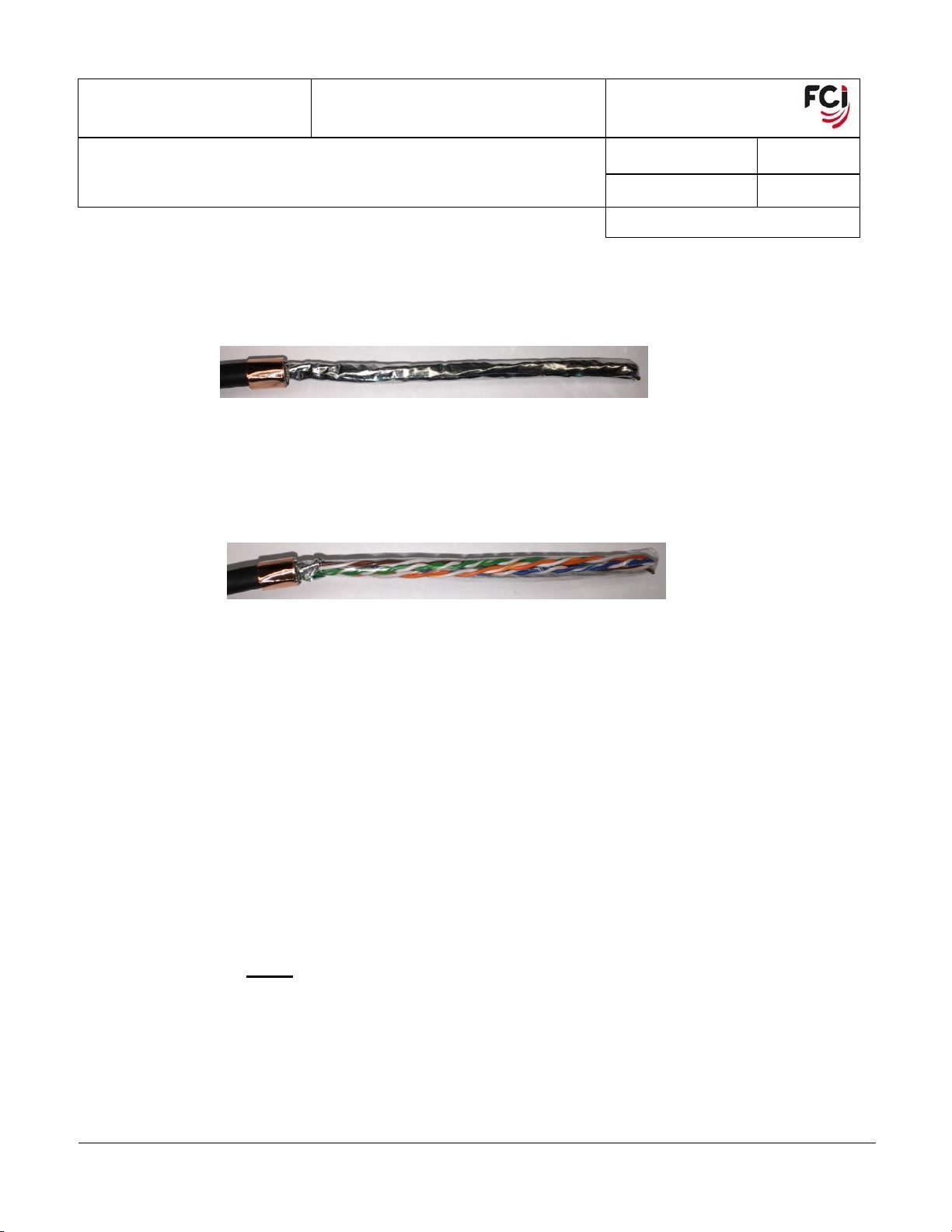

Step 1

Strip the outer jacket. (Fig 9)

Do not cut any wire on braid

Figure 9

Step 2

Unweave and fold back the braid (Fig 10)

The braid should be equally distributed

No Bundles

Figure 10

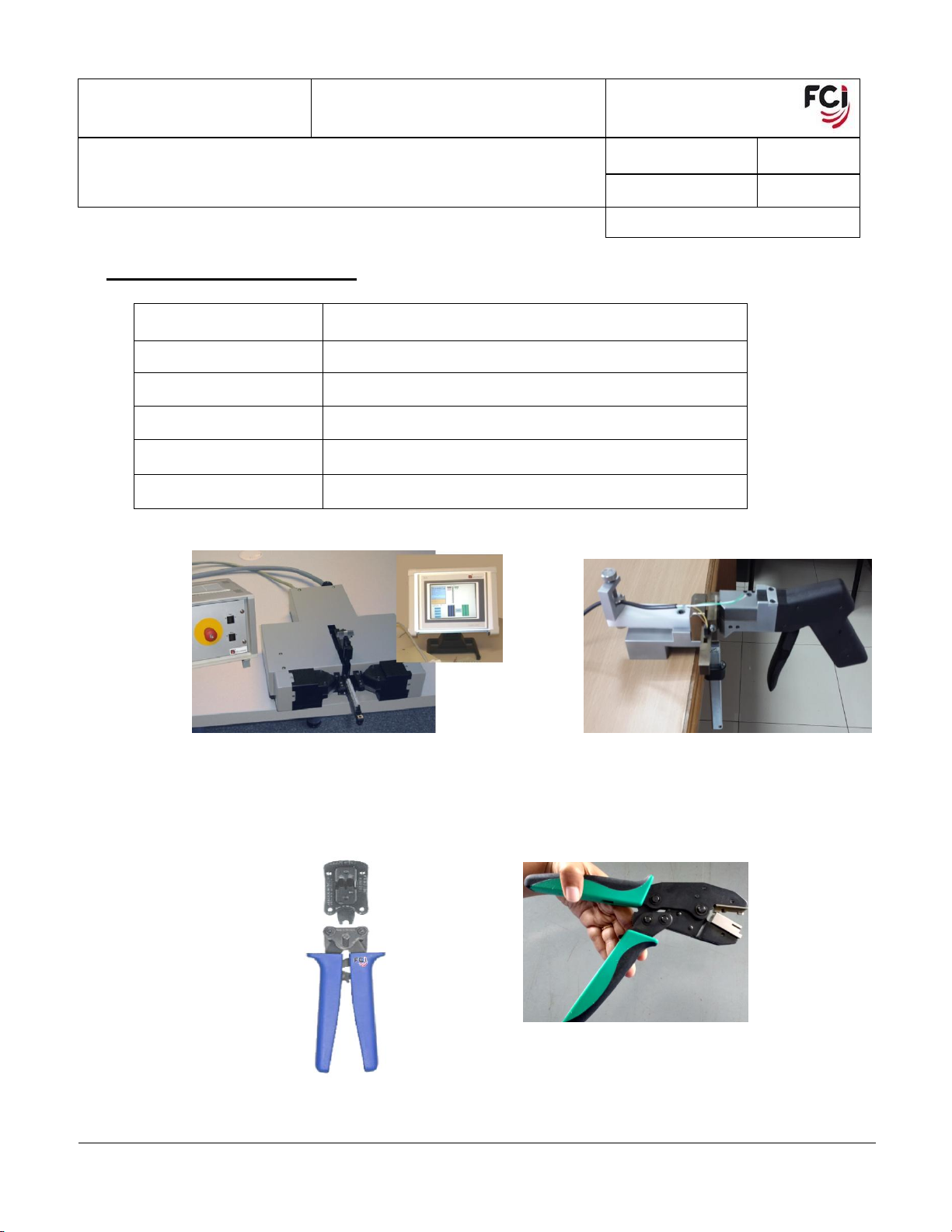

Step 3

Cut the braid to 9mm (Fig 11)

Figure 11

PDS: Rev :D STATUS:Released Printed: Sep 18, 2019

NUMBER GS-20-0454

TYPE APPLICATION SPECIFICATION

TITLE

PAGE

REVISION

OCTIS PLUG KIT ASSEMBLY –HYBRID, SIGNAL & POWER

16 of 30

D

AUTHORIZED BY

DATE

Stalin Alosius

2019-09-12

CLASSIFICATION

UNRESTRICTED

Copyright FCI

Form E-3334

Rev F

Form E-3334

Rev F

Step 4

Attach copper tape (1.5 turn) (Fig 12)

Figure 12

Step 5

Remove the foil (Fig 13)

When cutting away the foil, make sure that no wires of the braid are being damaged

Figure 13

Step 6

Remove the two fillers (Fig 14)

When cutting away the fillers, make sure that no wires of the braid or the individual wire

insulation are being damaged

Figure 14

PDS: Rev :D STATUS:Released Printed: Sep 18, 2019

NUMBER GS-20-0454

TYPE APPLICATION SPECIFICATION

TITLE

PAGE

REVISION

OCTIS PLUG KIT ASSEMBLY –HYBRID, SIGNAL & POWER

17 of 30

D

AUTHORIZED BY

DATE

Stalin Alosius

2019-09-12

CLASSIFICATION

UNRESTRICTED

Copyright FCI

Form E-3334

Rev F

Form E-3334

Rev F

Step 7

Remove the individual wire insulation (Fig 15)

Make sure that the wires are not damaged

Figure 15

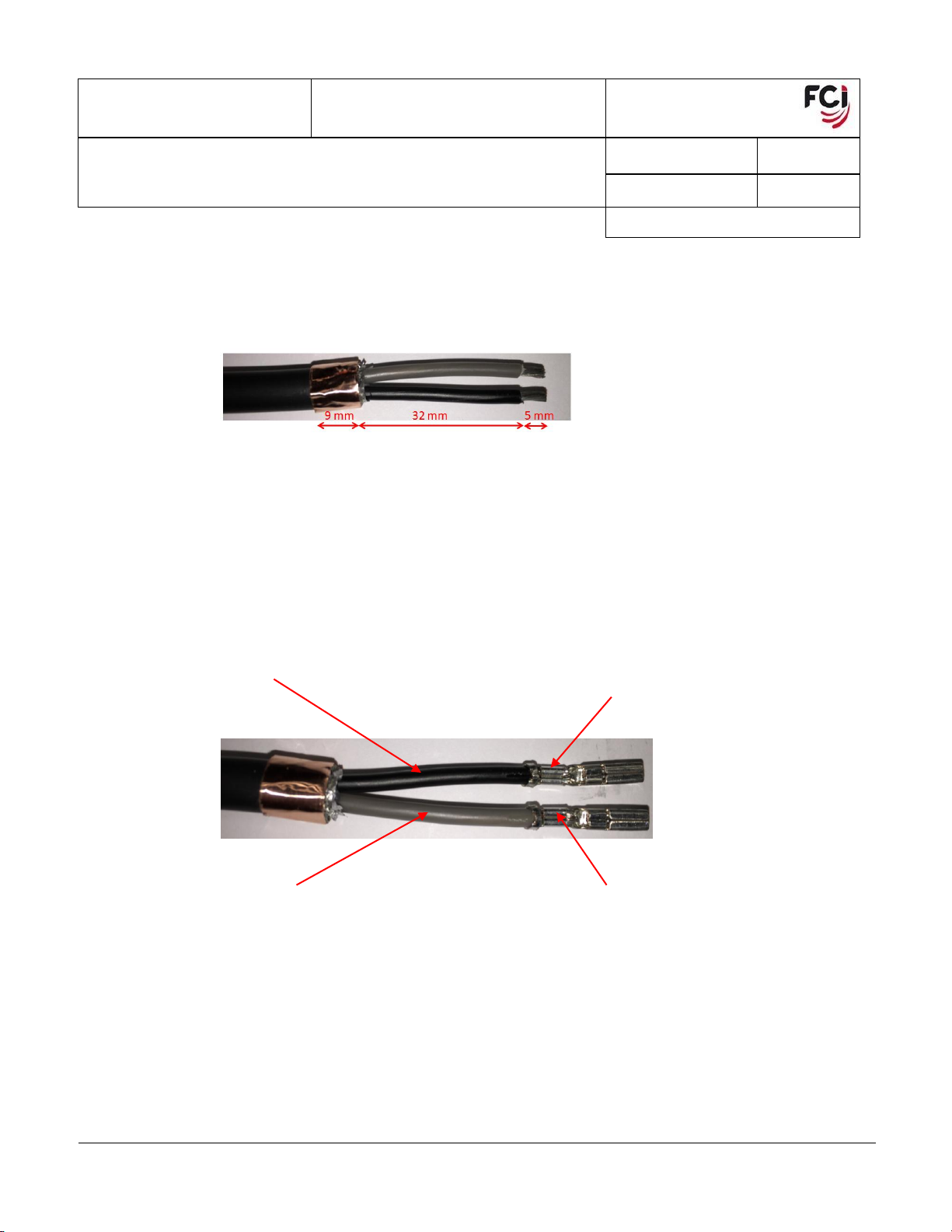

Step 8

Crimp the contacts (Fig 16) (By using 10135701-001, Octis Power Profile Crimping Tool)

Make sure the cables are positioned side by side, as flat as possible (no twisting allowed)

Figure 16

Black wire on top

Crimp position on top,

no rotation allowed

Crimp position on top,

no rotation allowed

Grey wire on bottom

PDS: Rev :D STATUS:Released Printed: Sep 18, 2019

NUMBER GS-20-0454

TYPE APPLICATION SPECIFICATION

TITLE

PAGE

REVISION

OCTIS PLUG KIT ASSEMBLY –HYBRID, SIGNAL & POWER

18 of 30

D

AUTHORIZED BY

DATE

Stalin Alosius

2019-09-12

CLASSIFICATION

UNRESTRICTED

Copyright FCI

Form E-3334

Rev F

Form E-3334

Rev F

10.2 Cable Preparation for Signal Contact

Step 1

Strip the outer jacket. (Fig 17)

Do not cut any wire of the braid

Figure 17

Step 2

Unweave the braid

Step 3

Fold back the braid

The braid should be equally distributed

No Bundles

Step 4

Cut the braid to 9mm (Fig 18)

Figure 18

PDS: Rev :D STATUS:Released Printed: Sep 18, 2019

NUMBER GS-20-0454

TYPE APPLICATION SPECIFICATION

TITLE

PAGE

REVISION

OCTIS PLUG KIT ASSEMBLY –HYBRID, SIGNAL & POWER

19 of 30

D

AUTHORIZED BY

DATE

Stalin Alosius

2019-09-12

CLASSIFICATION

UNRESTRICTED

Copyright FCI

Form E-3334

Rev F

Form E-3334

Rev F

Step 5

Attach the copper tape (1.5 turn) (Fig 19)

Figure 19

Step 6

Remove the foil (Fig 20)

When cutting away the foil, make sure that no wires of the braid are being damaged

Figure 20

Step 7

Remove the plastic foil

When cutting away the foil, make sure that no wires of the braid are being damaged

10.3 Cable IDC

General Tooling Setup:

For application tooling see Chapter 9.

Read the manual before setting up.

10.3.1 Crimping Process –Method 1 (by using 10135856-001, IDC table top pistol for Metral

HDXS Octis Cable Connector)

Step 1

First place the connector housing into the nest or positioning body. (Fig 22)

PDS: Rev :D STATUS:Released Printed: Sep 18, 2019

NUMBER GS-20-0454

TYPE APPLICATION SPECIFICATION

TITLE

PAGE

REVISION

OCTIS PLUG KIT ASSEMBLY –HYBRID, SIGNAL & POWER

20 of 30

D

AUTHORIZED BY

DATE

Stalin Alosius

2019-09-12

CLASSIFICATION

UNRESTRICTED

Copyright FCI

Form E-3334

Rev F

Form E-3334

Rev F

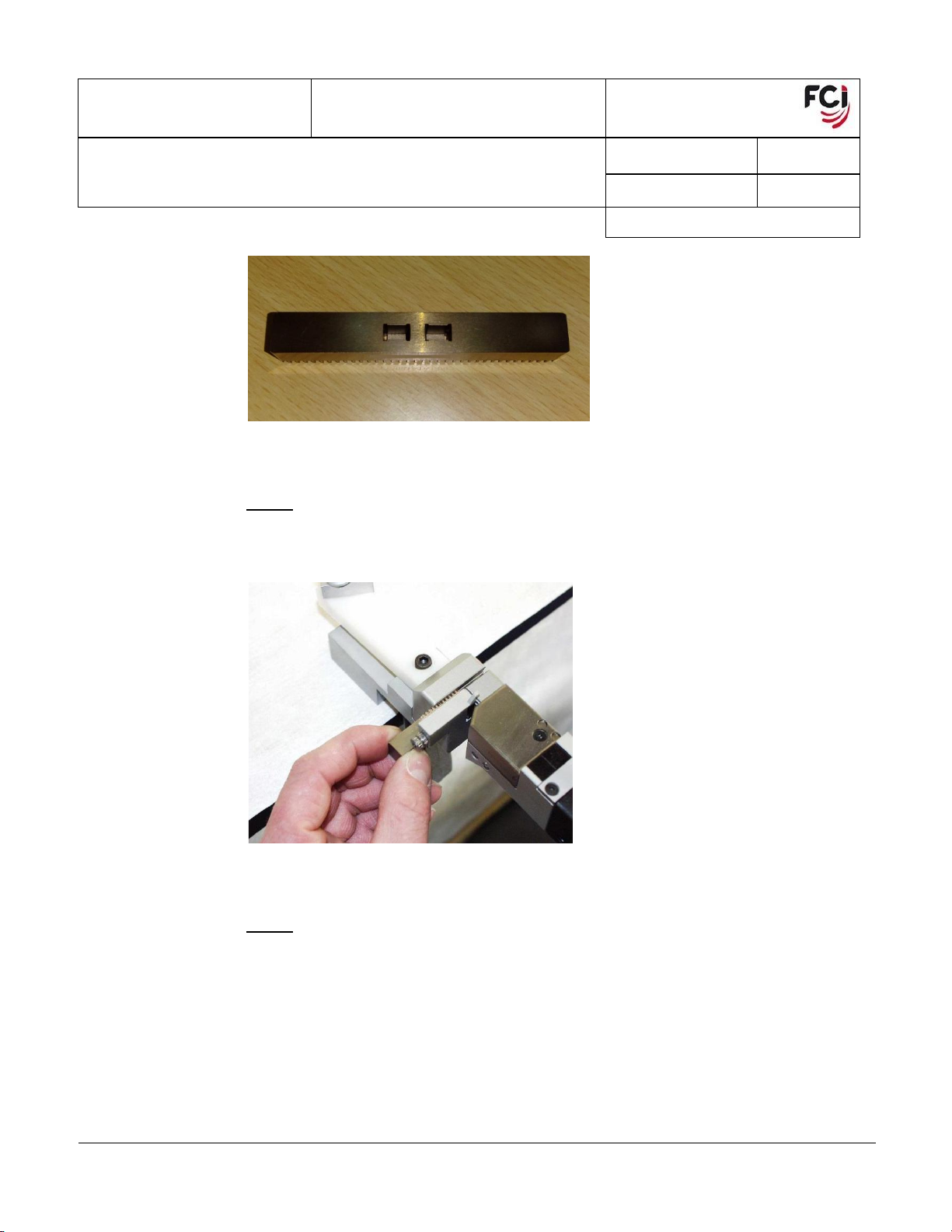

Figure 22

Step 2

Place the nest or positioning body into the insertion head. Move the nest by hand until the

first insertion position is reached. (Fig 23)

Figure 23

Step 3

Fix the cable by means of a cable clamp. This will ensure a correct positioning of the cable

and guarantees a correct length of the individual wires for easy cover mounting. (Fig 24)

PDS: Rev :D STATUS:Released Printed: Sep 18, 2019

This manual suits for next models

4

Table of contents