FCS S30 Surveyor User manual

S30 Surveyor

®

S30 Surveyor User Manual

Fluid Conservation Systems, Inc

502 TechneCenter Drive, Suite B

Milford, Ohio 5150

Phone (800) 531-5 65

www.fluidconservation.com

2

TABLE OF CONTENTS

SECTION PAGE

1.0 INTRODUCTION 3

2.0 SYSTEM COMPONENTS 3

3.0 CONNECTIONS, CONTROLS & INDICATIONS 4 - 5

4.0 LEAK SOUND WAVES 6

5.0 TRANSDUCERS 6 - 7

6.0 LEAK DETECTION 7 - 10

7.0 LEAK PINPOINTING 10

8.0 BATTERY REPLACEMENT 11

9.0 WARRANTY 12

3

1.0 INTRODUCTION

The FCS S30 SURVEYOR is a precision leak detection/location

instrument incorporating several unique and advanced features,

including:

•Low Noise Design: To help the operator detect the minimum

signal level possible.

•Manual Volume Control: To provide great versatility.

•Analog Meter: To ensure consistent and accurate sound intensity

measurements.

•Adjustable Meter Control: To ensure accurate readings in a variety

of environments.

•Lightweight, compact, rugged and weather resistant to withstand

daily field use.

The S30 is designed as a survey instrument for use with the AX80

transducers.

2.0 SYSTEM COMPONENTS

2.1 TRANSDUCERS

2.1.1 AX-80 (standard) with replaceable 6’ cable or 10’ cable

2.2 S30 CONSOLE

2.3 HEADPHONES

2.4 GEOPHONE ADAPTOR PLATE (GROUND MICROPHONE)

2.5 PROBE ROD SET (3 PIECE)

2.6 BELT-MOUNTED CARRY CASE

2.7 PROTECTIVE STORAGE CASE

4

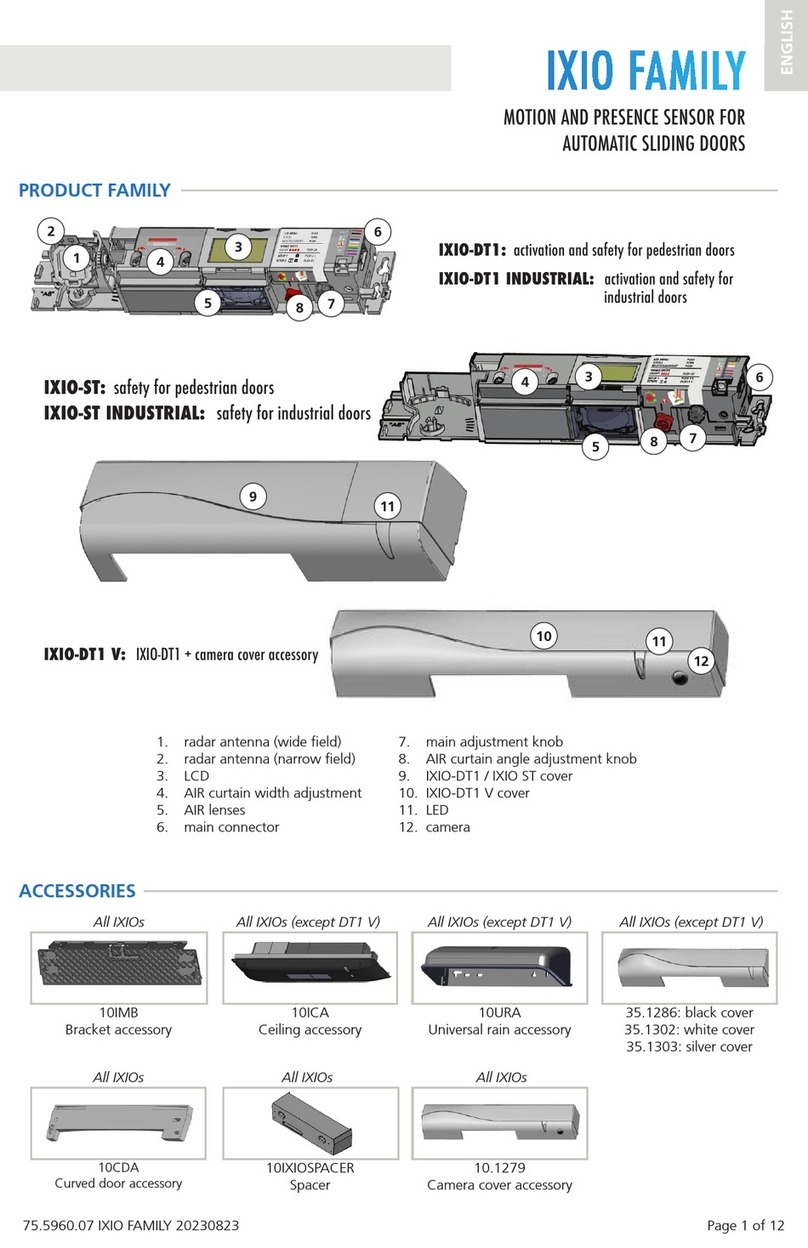

3.0 CONNECTIONS, CONTROLS AND INDICATIONS

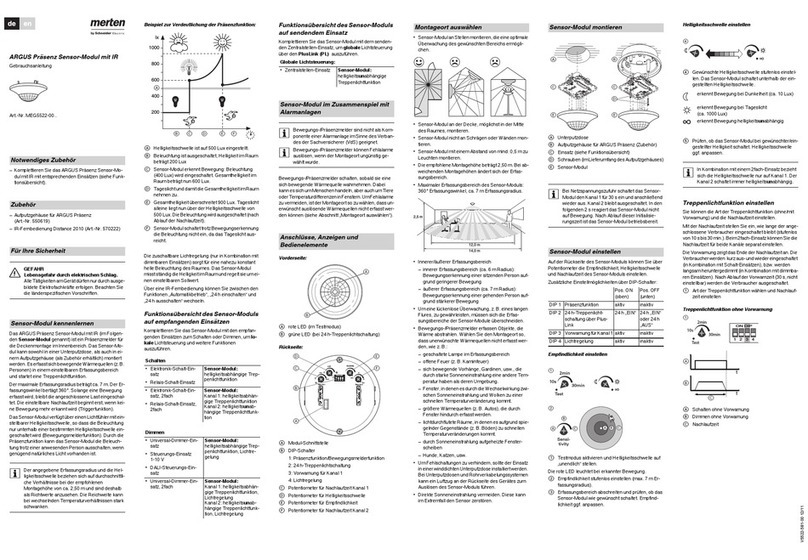

Rear Panel

Diagram I – Rear Panel

3.1 SENSOR CONNECTOR: Accepts the male LEMO plug from

the AX80 transducer.

3.2 TRANSDUCER (SENSOR) CABLE: The AX80 transducer is

provided with a rugged 10 ft. cable. This cable is mounted to

the transducer by means of a screw-on type connector. This

allows for replacement of the cable in case of damage to a

connector or the cable itself. Under typical day-to-day use, the

cable should remain attached to the transducer. The connector

assembly has been mounted to the transducer and packed with

a special purpose silicone grease to waterproof the sensor and

to prevent corrosion of the terminals.

Note:

WHENEVER

THE

CONNECTOR/CABLE

ASSEMBLY

IS

DISCONNECTED

FROM

THE

TRANSDUCER,

REPACK

THE

CONNECTOR

WITH

A

DAB

OF

G.E.

#661

SILICONE

GREASE.

DO

NOT

USE

ANY

OTHER

SUBSTANCE.

3.3 BACKLIGHT SWITCH: Controls the backlight mode of the unit.

To enable the meter backlight, press the switch into the “ON”

position. To turn the backlight off, select the “OFF” position.

3.4 HEADPHONE/CABLE JACK: Used to provide the audio output

to the operator. For survey, insert the headphone plug into the

jack to monitor the output.

5

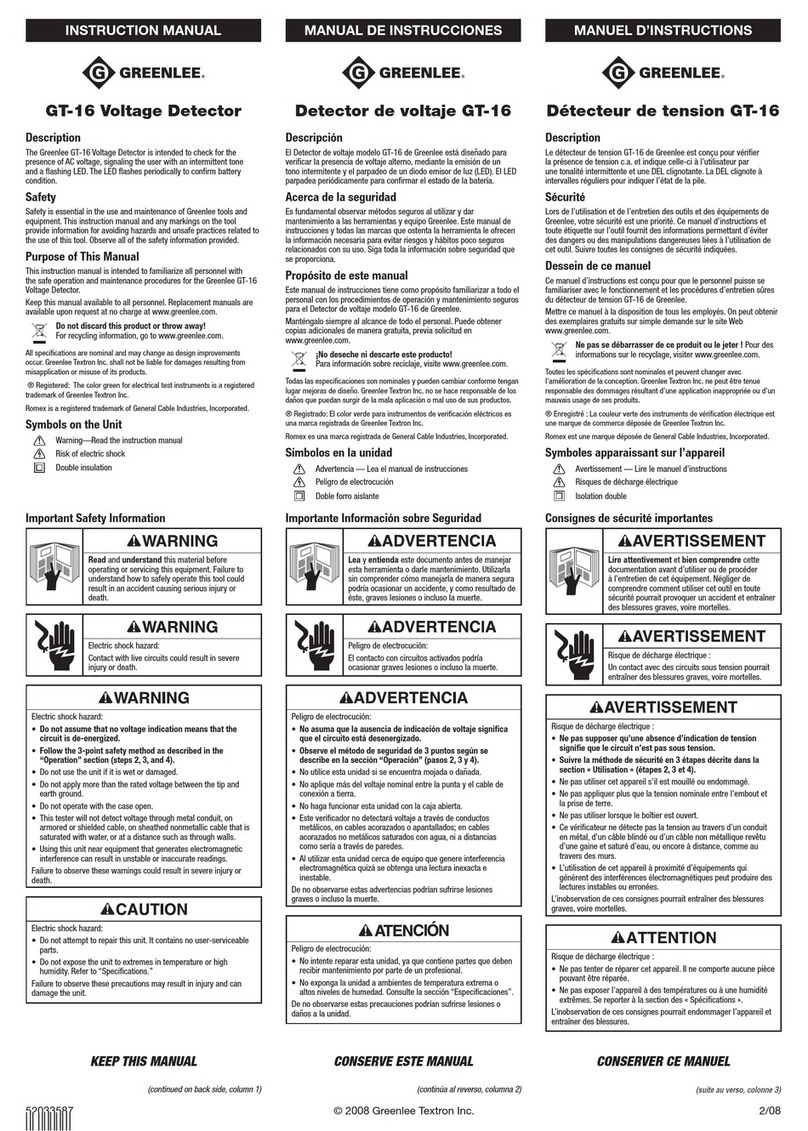

FRONT PANEL

Diagram II - Front Panel

3.5 ON/OFF BUTTON: Depressing and hold down on the ON/OFF

BUTTON to keep the S30 on and active. The red light will come

on to indicate that the S30 is operating. Release the ON/OFF

button and the S30 will turn off indicated by the on/off light going

out.

3.6 ANALOG METER: Indicates signal level. The meter reads

between 0 and 10 typically, depending on the intensity of the

leak signal input. The meter can provide valuable assistance to

the operator in determining the approximate location of a leak.

3.7 METER GAIN: Allows the operator to adjust the sensitivity of

the meter when the noise level is too high or too low for the

present setting. Turn the meter clockwise one click if the meter

is reading 0. Turn the meter counterclockwise one click if the

meter is reading above 10. Please note, though, that meter

readings can only be compared when the gain setting remains

the same.

3.8 VOLUME CONTROL: Rotating this inner knob allows the user

to control the volume level of the headphones (Each headphone

also has a control on the ear piece.) Turn the inner knob

clockwise to increase the volume and counterclockwise to

decrease the volume. Note that the meter reading is completely

independent of the volume control.

6

4.0 LEAK SOUND WAVES

The characteristic sound produced by a leak is a form of energy that

results from fluid escaping under pressure. This sound energy travels

as sound waves down the pipe in both directions from the leak site.

These waves are carried through the piping fluid and through the walls

of the pipe. Therefore, in order to detect leak sound, a device must be

able to detect the leak sound vibrations in the pipe wall or alternatively

on pipe fittings (valves, hydrants, etc.).

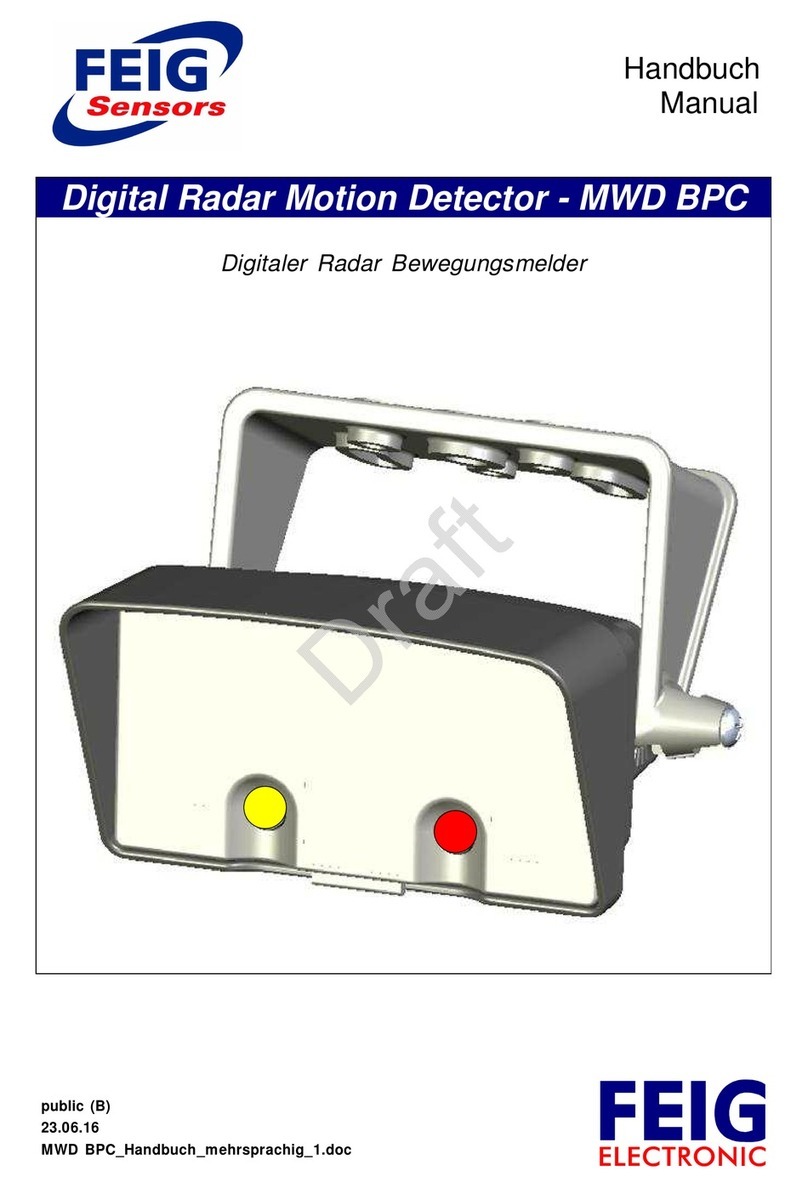

5.0 TRANSDUCER

Sound Pick-Up Transducers are the devices used to detect the leak

sound by generating an electrical signal in response to a mechanical

vibration. The standard transducer available for use with the S30 is:

AX-80 Transducer (accelerometer)

Leak

Sound Waves

7

Accelerometers are transducers designed to be placed in physical

contact with the pipe. The vibration that results from the sound waves

is sensed by a piezoelectric crystal in the accelerometer that generates

a small electrical signal proportional to the vibration. The amount of

signal in volts is determined by the intensity of the vibration as

measured in units of gravity, or "g's". Therefore, the sensitivity of an

accelerometer can be measured in Volts/g.

Because they use sensitive crystals to produce the electrical signal,

these accelerometers are susceptible to damage by mechanical shock.

They are rated for a shock of approximately 5000 g's; dropping the

accelerometer onto a hard surface from 3.5 feet results in a shock of

approximately 50,000 g's. HANDLE THE ACCELEROMETERS WITH

CARE, AS THEY ARE SENSITIVE PIECES OF EQUIPMENT.

6.0 LEAK DETECTION WITH THE S30

To utilize the S30 for detecting unknown leaks, a leak survey must be

conducted. A leak survey is the process of monitoring the distribution

system for the sound of leaks.

6.1 ACCESS POINTS AND SURVEY FREQUENCY

The typical access points that are used when conducting a leak

survey are: Main Line Valves, Fire Hydrant Valves, Fire

Hydrants and Service Connections. The number of access

points to be monitored will vary depending on how thorough a

survey you wish to conduct.

There are some rules of thumb that are helpful in determining

"how much is enough" with respect to leak surveys. These rules

are based on extensive field experience, but should still be used

only as guidelines. The predominant factor in determining the

distance between listening points is the type of pipe. For the

distances listed below, the most significant leaks in a system will

be monitored.

METALLIC (Iron, Steel, Copper) - sound on access points at

least every 500 ft.

ASBESTOS-CEMENT (Transite, etc.) - sound on access points

at least every 250 ft.

PLASTIC (PVC, Polyethylene) - sound all available access

points (i.e. services, gate valves, hydrants, etc.).

8

From the information listed above, it should be clear that leak

sound travels well in metallic pipe and not very well in plastic

pipe. Once leak sound is detected, treat the leak as a "known

leak" and listen at several access points to determine the

approximate location and where to place the transducers for

pinpointing with the correlator.

6.2 TRANSDUCER CONTACTING METHODS

The S30 provides two different methods of contacting these

access points.

1. Magnet - to attach the transducer to iron or steel

access points (e.g., valve operating nut).

2. Extendable Probe Rod - The rod can be made up for

17", 33" or 49" length to reach valves or curb stops

below which may be buried or under water. Simply

attach the magnet to the Wave Guide, followed by the

rods to make up the desired length. See diagram

below.

9

SOUNDING FOR LEAK NOISE

Once the transducer is properly positioned on the access point,

turn the S30 on. Use the VOLUME CONTROL to set the S30 to

a comfortable level for your ears. At this time the operator must

determine two things:

1. Do you hear leak sound?

2. What is the intensity of that leak sound?

If leak sound is monitored, note the location and relative signal

level for reference.

When this has been completed the operator advances to the

next access point. The operator uses the intensity of the leak

sounds to determine the approximate location of the leak. The

stronger or greater the leak sound intensity, the closer to the

leak.

10

7.0 LEAK PINPOINTING WITH THE S30

The S30 can also be used as a leak pinpointing device. Leak sounds

being emitted from a pressurized pipe can transfer through the ground

and be detected on the surface above the leak. This technique is

called "Surface Sounding" or "Ground Miking". The success of this

method varies from leak site to leak site. The variables that dictate

your effectiveness are: Depth of Pipe, Size of Leak, System Pressure,

Soil Conditions, Surface Material, Traffic and Wind.

In order to effectively utilize this method, the operator must already

know that there is a leak in the vicinity and he must know where the

water main is located.

7.1 SET-UP: To properly use the S30 for pinpointing, the ground

microphone plate should be attached to the bottom of the

transducer magnet. See diagram below.

7.2 PINPOINTING: Place the transducer assembly on the ground

above the water main. Press the “ON/OFF” BUTTON to activate

the S30. Determine whether or not you hear the leak at this

location. Use your ears and the meter to determine the intensity

of the sound and make a notation of it. Move the transducer

assembly about 3' and repeat the process. Continue this

process every few feet until you have discovered the loudest

Sound Waves

11

point on the surface. Mark the location. If possible confirm this

location by using a leak correlator or by repeated soundings.

Sounding for leaks requires patience and acquired listening

skills. The operator using the S30 must be prepared to practice

with the instrument and to learn by experience.

8.0 BATTERY REPLACEMENT

To replace the batteries, remove the two screws from the back plate.

To access the batteries slide the top Black cover on the S30 back away

from the removed screws. The batteries are immediately accessible

and removable, replace batteries and replace black cover and screws.

For optimum battery life, use high-quality alkaline batteries (2 9-Volt

type). Do not use rechargeable batteries as their lower cell voltage will

impair the operation of the unit.

12

9.0 WARRANTY

The S30 SURVEYOR, AX-80 Transducer and Interconnect Cables are

warranted on parts and labor for 12 months from date of shipment to

customer. Headphones are warranted separately under the

manufacturer's own warranty. If your FCS product should prove

defective in material or workmanship within the prescribed period, FCS

will repair or replace the product, at its sole discretion, without charge,

upon presentation of satisfactory proof of purchase. This warranty

applies only for normal, reasonable use of the equipment and does not

cover damage which occurs in shipment, or failure which results from

alteration, accident, misuse, abuse, neglect or improper maintenance.

This warranty is void if the serial number has been altered or removed

from a serialized product; if the product is modified in any manner

which FCS concludes, after inspection, affects the reliability of the

product; if the product has been repaired or serviced by anyone other

than an AUTHORIZED FCS Service Technician; if the product is

damaged due to improper installation, maintenance or operation in

accordance with the instructions which accompany the product.

THIS IS NOT A SERVICE CONTRACT. THIS WARRANTY DOES

NOT INCLUDE MAINTENANCE, CLEANING, PERIODIC CHECK-UP

OR CHARGES INCURRED FOR REMOVAL OR REINSTALLATION

OF PRODUCT.

Table of contents

Other FCS Security Sensor manuals

Popular Security Sensor manuals by other brands

IMS

IMS 171707 Operator instructions

Schulz

Schulz TES013 instruction manual

Greenlee

Greenlee GT-16 instruction manual

Fire Sentry

Fire Sentry FSXP Installation guide and operating manual

Newton Security

Newton Security T-DAR T1000 Installation and operation manual

Karat

Karat AC Installation and operation manual