FCS BMIC Manual

0

BMIC Operators Guide

Version 1

Warning: This manual contains important safety and operating information.

Please read, understand and follow the instructions in the manual.

1

Bmic

Operators Guide

Contents

Introduction & Equipment List

Page

3

Bmic Controls & Using the Bmic

4

LED indication

4

Care of the Bmic

4

Battery warning

5

Battery replacement

5

Charging the Bmic batteries

5

Operator Guidance

7

Technical Specification

8

Warranty

8

2

Bmic

The Bmic (pronounced “Bee mike“) is an easy-to-use, low cost, electronic listening stick and

ground microphone combined. It is ideal for general leak sound-ing operations and can be

fitted with either a tripod foot (for use as a ground microphone) or probe rods (for sounding at

fittings or in soft ground).

The control unit is a “trigger” operation and a volume/sensitivity rotary control. An LED

indicates operation and battery status. It can be used to confirm the position of

underground leaks audibly from ground level; sound pipe fittings; penetrate soft ground to

listen for leaks or carry out traditional acoustic surveys.

Equipment list

1 Bmic hand held control unit

2 Microphone unit with cable & Tripod Unit

3 2 probe rods

4 AC adapter

5 Headphones

6 Carry bag

7 Instruction manual

The Bmic equipment is shown below (note the AC adapter, carry bag and manual are

not shown).

2

3

5

1

3

Bmic Controls

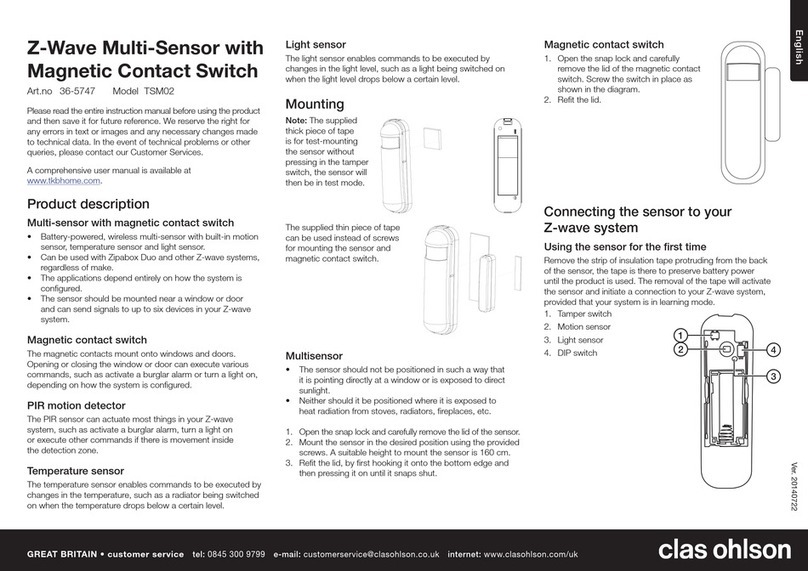

The picture below shows the location of the rotary control for volume and sensitivity, LED

and the trigger switch plus the Electrical connections for the headphones / battery charger

and microphone.

Headphones & Rotary volume/

Battery charger connection Sensitivity control

Microphone connection Trigger Switch LED

Using the Bmic

The Bmic is simple to operate. Select either the probe rods or the tripod unit and screw into

the microphone unit. (Use the tripod foot on hard ground and use the probe rods on soft

ground or when accessing water pipe fittings). Connect the headphones to the connector

and connect the microphone cable to the forward connector. Put on the headphones and

press the trigger button o n t o p o f the unit to listen for leaks. The volume/sensitivity

can be adjusted using the rotary control.

LED indication

The LED shows green when the unit is operating and red to indicate low battery power.

Care of the Bmic

The Bmic is rugged and showerproof (to IP65) but contains electronic circuitry and

should be handled with care. It should be kept clean and dry and when necessary cleaned

with a damp cloth.

4

The Bmic in use

Battery Warning

The Bmic contains a Nickel Metal Hydride battery which must not be used on any other

equipment if removed. Only batteries supplied by Halma Water Management must be used

as replacements. Do not short circuit or misuse these batteries as this may result in

explosion or fire.

Battery Replacement

Although the battery is rechargeable it may eventually need to be replaced. To do this

undo the four screws underneath the hand-held unit and separate the two halves of the

Bmic unit. Gently pull out the battery holder and replace the battery. When refitting the

battery and battery holder make sure no wires become trapped.

Charging the BMIC

Connect the charger lead to the headphone connector of the Bmic and connect the charger

power lead to the universal 110-240V AC supply. The Bmic can then be charged

overnight. An optional accessory is the vehicle cigarette lighter adapter that can also be

used to charge the battery.

5

Bmic Operator Guidance: Background information for effective acoustic leak

detection

All acoustic leak detection methods are based on the premise that normal water passage

through pipelines takes place noiselessly. When the water passage is disturbed a noise is

created. Causes can include partial pipe blockages, sudden changes in pipe diameter,

abrupt changes in pipe direction, pumps or meters installed in the pipeline, consumer

usage or pipeline damage. Pipeline damage can include holes, cracks or splits, complete

pipeline rupture, leaking joints or leak-ing valves.

Careful application of leak detection techniques will enable the operator to eliminate

detected noises generated by poor pipeline design or consumer usage and to identify

leakage due to pipe system damage.

The strength and clarity of noise generated by leaks will be affected by the water

pressure, the size and shape of the orifice allowing leakage, the type of ground material

around the pipeline, the type of ground cover over the pipe, the diameter, wall thick-

ness and material of the pipeline and the quantity of water leaking.

A small orifice or hole and high water pressure generally produce a higher frequency

noise. Often the noise level increases around valves, pipe elbows, T connections, pipe

ends etc. since the partial obstruction increases pressure and creates some further

disturbance in the water path.

Leak noise is transmitted along the pipeline both through the water and the pipe wall as

well as into the ground around the pipe. The noise travels much better through “hard”

materials so that the noise travels much further along metallic pipes than asbestos

cement pipes which themselves are better than plastic pipes. Ground material generally

provides a poorer travel path than the pipeline itself. Soft sandy ground provides a worse

travel path than well compacted ground with a hard paved surface covering.

The leak noise can change in strength and pitch as it travels along the pipe or through the

ground. The deeper the pipe is buried and the softer the ground the more the noise will be

dampened. The harder the pipe material, the higher the frequencies detected will be, and

the further from the leak the noise will be detected, this makes it harder to accurately find

the exact point of maximum noise.

Background noise can interfere with leak detection. Traffic and machinery noises can

travel for considerable distances through both air and ground material and often occur in

the same frequency bands as leak noise. Sometimes it is necessary to use leak detection

techniques at night when interfering noises are less.

It is very important to adopt a methodical approach when using any instrument for

acoustic leak detection.

It is necessary to practice good technique in order to distinguish between different sounds,

recognising background or interfering noises, so that they can be eliminated. It is also

essential that other (non-leakage) noise sources such as consumer draw-off or partially

closed valves are eliminated by logical site inspection practices prior to any excavation

taking place.

6

Hand probe

For normal soft ground surfaces the single pointed extension rod should be connected, do

not over tighten the screw thread. For direct contact with underground fittings via access

covers it may be necessary to use the second extension rod. To do assemble this remove

the single rod and connect the extension rod and re-fit the pointed rod again. If the rods have

been over tightened, spanner slots allow easy removal.

Surveying

The leak location can be narrowed down by listening at accessible contact points such as

meters, hydrants, valves and stop-taps, which provide points of good sound pick-up

particularly if the pipe is metallic. Use the hand-probe/extension rod to listen at these

points.

If there are no accessible contact points or if the pipe is of non-metallic material use the

microphone foot for listening, placing the foot over the pipe route in the area of the

suspected leak. Move along the pipe route listening at each accessible pipe-fitting or at

regular positions on the ground until you have identified the area of maximum noise level.

Note: When you are listening on pipe-fittings the location of the point of maximum noise will

probably not indicate the leak position, only the fitting closest to the leak. The noise level will

also appear stronger where there is less thickness of ground or other material for it to pass

through. The leak noise will follow the path of least resistance.

Pinpointing the leak position

Pinpointing the leak position involves a process of comparing a number of leak noises.

Select the most suitable sensor device; the microphone foot for hard ground surfaces or the

hand probe for soft ground.

Press the trigger to operate the Bmic and adjust the headphone volume control to a

comfortable listening level. Once you have listened to the noise through the headphones,

release the trigger to switch off the amplifier and move the microphone foot or hand probe to

the next test position.

Repeat the sequence to listen to each of the test locations moving along the pipe route in

the direction where signal strength is increasing. If the leak noise level falls you have

passed the leak and should go back and reduce the distance that you move between

measurements. The loudest leak noise will then indicate the location of the leak bearing in

mind the ground conditions already mentioned.

7

Technical Specification

Bmic hand held unit/sensor housing

Piezoelectric high sensitivity sensor mounted in PC-ABS (polycarbonate) housing

Single headphone/charger input socket with automatic sensing of device connected

Connectors

Amphenol military specification connectors for microphone and headphone/charger

connections

Charging

Universal 110-240V AC charger with 12V DC output

4-pin Amphenol connectors to control unit

Charge time: Overnight charge.

Microphone housing

High sensitivity piezo-electric sensor mounted in rubber housing with integral strain relief

Low noise 0.75m cable (detachable)

4-pin Amphenol connection to control unit

Weight: 400g

Hand probe attachment

2 stainless steel extension rods (each 400mm long) Weight: 150g

Headphones

Lightweight high quality headphones

Impedance: 16 Ohms

4-pin Amphenol connector to control unit

LED

Green = normal operation

Red = low battery power

Optional accessories

High specification aviation quality headphones

Car cigarette lighter adapter with 12V DC output

Acoustically shielded ground microphone foot, for use in all weather conditions

Warranty

All equipment is warrantied by HWM to be free from defects in materials and workmanship for

a period of one year (unless otherwise stated) from the date of shipment to the original

customer. This warranty is only valid if the equipment has been installed and used in the

correct manner as described in this manual.

Repair or replacement (at HWM’s option) will be made without charge provided the above

conditions have been met.

If any problems occur, notify Halma Water Management or its authorised representative

giving full details of the problem, and the model and serial number of the equipment. You will

receive technical advice and/or shipping instructions depending upon the nature of the

problem.

Table of contents

Other FCS Security Sensor manuals